Appendix 2: The Haifa–Beirut–Tripoli Railway

By A. E. Field

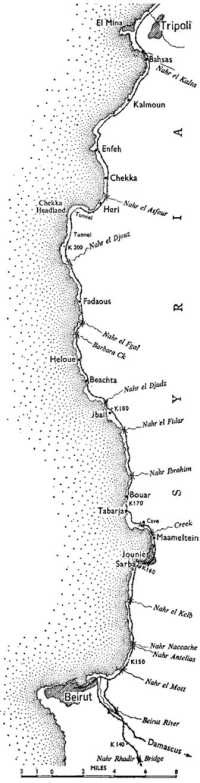

Syria does not lend itself easily to railway construction. Very little such work was undertaken between the two world wars. In 1940, however, the possibility of Allied occupation of the Lebanon, and the hope that Turkey would join the Allies, made it very desirable that there should be a direct link between the standard gauge line from the British bases in Egypt and Palestine then terminating at Haifa, and the northern Syrian system ending at Tripoli. Earlier the French administration had considered the linking of Haifa and Tripoli by a route along the coast, but the project had been shelved for fear that the port of Haifa would benefit at the expense of Beirut. In 1940 and 1941 Middle East Command had surveys made of various routes as far as the Lebanon border. From a map study the first route favoured was from Haifa round the north of the Sea of Galilee to Rayak where the proposed railway would join the Homs–Aleppo–Turkey standard gauge line. This was ruled out because it involved very heavy cutting in basalt. The next possibility considered was an extension of the line northwards from Haifa along the coast to the Litani River and thence inland to Metulla-Rayak, but the route could not be explored before the conquest of Syria in July 1941. It then became evident that much heavy bridge work would be necessary in the Litani gorges which would not be economically justifiable as a wartime project. Finally, after a quick appreciation made at the end of August 1941 of the country between Beirut and Tripoli by Colonel Simner1 and Lieut-Colonel K. A. Fraser of the Australian Railway Construction and Maintenance Group, a coast route from Haifa to Tripoli was chosen which, although it involved considerable tunnelling – including one tunnel of nearly a mile at Chekka headland – and several major bridges, had definite advantages over the alternative routes in that the rock cutting was not in basalt, a good all-weather road ran adjacent to the planned route and the provisional French plan was available. Moreover the route would serve Beirut and the Chekka cement works.

On 12th September 1941, No. 1 Section of 1st Railway Survey Company2 set up camp at Az Zib and commenced a location survey around Ras Naqoura and Ras Bayada. Five weeks later they handed over the task to the South African Survey Company, G.H.Q. Middle East having allotted the Haifa-Beirut section of the line to the South African Engineering Corps. No. 1 Section then moved north to Maameltein and began a survey from Jounie to Heloue. Meanwhile No. 2 Survey Section, which

had arrived at Heri, was concentrating on a topographical survey of the Chekka headland with a view to siting a line around it – a particularly difficult task. Colonel Simner decided to tunnel the headland and asked for a South African tunnelling company raised from miners of the Rand to carry out the work .3 The survey of the tunnel length was taken over by the South African survey section and No. 2 and No. 3 Australian Survey Sections then completed the survey of the rest of the line. The arrival of the South African survey section is described thus by a narrator:–

They arrived without a knife, fork or spoon – thought they were to stay at hotels. I didn’t even laugh, to my everlasting satisfaction; took them by the hand up to an AIF “Q” bloke I knew in Tripoli and persuaded him to cut the “bull” and imagine they were AIF, so got [them] tents, blankets, personal and cookhouse gear and arranged for rations.4

The plan for construction was developed as the survey and work progressed. The line was to be a first-class military railway of standard gauge. The ruling grade was fixed at 1 in 50 and minimum radius of curvature at 10 chains. Passing loops were constructed every five miles. Formation was 16 feet wide on banks and 15 feet in cuttings. To economise in bridging, road crossings were level with the rails. Where possible the line was located so as to avoid demolition of houses. Where this was unavoidable, houses were pulled down and compensation paid to the owners or, in a few instances, new buildings were erected by the construction companies.

The South Africans started work at the Haifa end in December 1941 and the Haifa-Beirut section was opened for traffic in the following August – 86 miles of standard gauge railway, the last five miles of which had been constructed by No. 1 Construction Company. This had involved the crossing of the Beirut-Damascus narrow gauge railway, the erection of a bridge over the Beirut River, of three 100-feet spans and the construction of the Beirut marshalling yards, for which about five miles of track was laid.

–:–

Early in 1942 the Australian construction companies, hitherto scattered over Egypt, Transjordan, Palestine and Syria, were concentrated on the route of the Beirut–Tripoli section, which was to be their task. They were allotted the following sections:–

No. 1 Construction Company – Nahr Rhadir to Maameltein Cave.

No. 1 Section, 1st Survey Company – Maameltein Cave to Kilo 166.7.5

No. 2 Construction Company – Kilo 166.7 to Fadaous.6

No. 3 Construction Company – Fadaous to El Mina (less the section embracing Chekka tunnel).

At the outset, the only tools available were picks, shovels and crowbars. Imagine the dismay of men recently arrived from the Sinai Desert, where

an 8-foot cutting in sand was a major job, when confronted with their first task in Syria – a quarter of a mile of hard rock excavation 30 feet deep, followed by a bank 80 feet high, then another rock excavation 35 feet deep; a bank of 46 feet and one more rock cutting of 35 feet, all within a mile. But plant gradually arrived: first a bulldozer that was worked night and day for six months, then compressors, drills, Decauville track and waggons until, by the end of September, the group was well equipped.

The group, with various attachments, was about 1,000 strong. Labour was drawn from two sources: the African Auxiliary Pioneer companies comprised of natives from Basutoland, Bechuanaland and Swaziland, of whom there were about 2,000, and local civilians. The latter, of various types and capacities, numbered at one stage up to 8,000, and included women, children and men of all ages. They were transported by motor lorries daily to and from their villages in the mountains. It was found economical at one stage to dismiss all those under 17 and over 70 years of age. The skilled workers of the civilian work-force were highly competent, particularly the stone-masons who displayed all the pride of craftsmen in their work. The unskilled civilians were of the usual Middle East standard, proficient in every known trick under the sun for receiving the maximum for a minimum of effort. The value of the South African natives was never very great. They had enlisted in an army, felt they should fight not work, and showed much more interest in military drill and parades. Cooks were observed instructing their helpers in the intricacies of rifle drill with ladles and brooms instead of rifles. Their fondness for drill

was used on one occasion in consolidating the track. A detachment of Basutos were marched at the double several times over a length of bank; the compression amounted to one inch in thirty after two passages.

From Dora, outside Beirut, the line followed the old tramway to the Nahr el Kelb. This stretch necessitated bridges at the Nahr el Mott (2 spans of 33 feet); at the Nahr Antelias (2 spans of 34 feet and one each of 27 and 20 feet) and a single 20-feet span bridge at the Nahr Naccache. These bridges were of similar construction. Foundations of the caisson type were put down to a depth of about 12 feet below water level on to clean sand. Piers were of concrete and the superstructure was launched from the shore by skids on to falsework and lowered to the piers. At the Nahr el Kelb a bridge was erected consisting of one 70-feet through-span and two 100-feet lattice-girder through-spans. Pier caissons and the southern abutment were sunk to a depth of 24 feet below water level and considerable water was encountered, necessitating the use of all available pumps. At 9 feet below water level a stratum of heavy loam was met, holding up the sinking of the caissons by extra skin friction. The caissons were allowed to fill with water and gelignite charges dropped into the caisson wells. This had the required effect and sinking proceeded to the prescribed depth.

Timber not being available for concrete formwork, it was decided to face the piers and abutments with masonry, laid in 10-inch courses in 4-feet lifts to act as formwork for the concrete core.7 No scaffolding was necessary, because the stone was laid from inside the piers. At the Kelb headland difficult rock excavation was necessary. The Beirut–Tripoli road had been cut out of the rocky promontory and the railway had to be routed farther inland where the rock excavation was 70 feet deep. Disposal of spoil from the cutting across the road – the main artery of the forces in the Lebanon – was slow on account of heavy traffic. The lack of motor-trucks with tipping bodies was a severe handicap which added considerably to the time taken on formation. Frequently spoil was left on the sides of cuttings and banks had to be built from borrow pits.

From the Nahr el Kelb the line traversed fairly easy country through orchards and banana plantations to Sarba headland, whence it again followed the tramway route to Maameltein. From this point to Bouar there was much heavy rock cutting. At Maameltein headland 35,000 cubic yards of limestone rock had to be excavated and removed by hand which took six months to complete with three shifts working. The spoil plus an additional 5,000 cubic yards was used in the formation of the railway and for road diversions. Maameltein Creek was bridged with two spans one of 60 feet, the other 36 feet. At Maameltein Cave a 44-feet deck span was provided over an opening in the rock below the surface level. The span which came complete from India was hoisted from the road level on to its bearings by a light steel derrick.

Formation through Tabarja and Bouar was in dark chocolate soil through banana plantations interspersed by many small water channels

and irrigation ditches. In many instances these ditches were carried under the line by syphons. Precast concrete pipes of from 30 to 80-cm diameter were used, and strengthened by a casing of a minimum of six inches of concrete.

For the bridge at the Nahr Ibrahim, two lattice through-spans, one of 100 feet and another 70 feet, had been fabricated in South Africa, but the smaller span had been sunk en route and the Middle East through-span substituted did not match the lattice work of the larger span. The northern abutment was founded on rock; the southern abutment, founded 13 feet below water level, and the pier, 20 feet below water level, were of the caisson type. A heavy flow of water was encountered in the pier and a diver and grab were requisitioned to clear the cutting edge and remove the spoil. Masonry was again used as formwork, but in this case was notable for the fine work of the masons. In addition to the usual white stone, some of a slate-blue colour was supplied to this job and the masons arranged the colours in a most artistic pattern.

The erection of the bridge over the Nahr el Djouz was of exceptional interest because it was the first time an attempt had been made in the field to launch a unit construction railway bridge by the cantilever method, using a launching nose. The bridge had 3 spans of 80 feet each. While the piers and abutments were being completed, trackwork adjacent to the abutments was laid. The first span was assembled together with the launching nose on three bogies on the track. When the piers were complete, the span and nose were hauled across until No. 1 span was in position above the opening provided for it. The dismantling of the 53-foot launching nose 70 feet in the air by the aid of a flying-fox was a difficult operation and to obviate a recurrence with the second span, the officer-in-charge obtained permission to launch No. 2 and No. 3 spans together, thus bringing the nose on to the northern abutment for easy dismantling. The two spans with the launching nose were assembled on bogies as before, the track laid on No. 1 span now in position and the long assembly hauled across to rest on temporary supports on No. 2 pier until lowered by gantries to rest on the piers and northern abutment. The experiment was a complete success and was the method used later on other bridges, notably that at the Nahr el Fidar, which required four 75-foot deck spans on high piers, the highest being 62 feet from foundation level. Here all four spans and launching nose were coupled together and hauled across in one operation. The assembly, launching, jacking down and dismantling of the nose took only 389 man-hours.

Another bridge of interest was the 80-foot deck span over the Nahr el Fgal, a wadi 69 feet deep. The high abutments with their extensive splayed-wing walls involved much stone facing and 2,000 tons of concrete. Major bridges were also erected at Barbara Creek, the Nahr el Djouz, the Nahr el Asf our and the Nahr el Kalta. At the more important bridges, provision had been made in piers for demolition chambers for use should the necessity arise.

Further heavy rock cutting was encountered north of Beachta, and north of Enfeh and along the Tripoli road from Kalmoun. Because of a general shortage of detonators and fuses, shots were larger than is usual in railway work and this caused damage to near-by houses, telephone wires and the slopes of the cuttings.

Because there was no room for expansion of the existing marshalling yards at Enfeh, a terminal yard for the new traffic was established at Bahsas. Here a marshalling yard, reversing triangle, coal stage, and water column were installed, also a 500-foot long platform and approach roads. The Bahsas yards were constructed on sand near the sea and from there to the junction with the Tripoli-Aleppo standard gauge railway, the line was located through orchards in sandy country. This enabled No. 3 Company speedily to complete the earthwork and platelaying at the Tripoli end with the result that the line from El Mina to Chekka, with four passing loops and a spur to the Chekka cement works, was opened to traffic on 22nd July 1942.

The 61st South African Tunnelling Company handed over the main Chekka tunnel plus a small one of 90 feet nearby to the Australians for platelaying at the end of September 1942 and then left for tunnelling operations at the Haifa end of the line. In the exceptionally short period of eight months they had driven the main tunnel 4,800 feet through rock at a level 100 feet lower than the 1,500-foot road tunnel on the main coast road. Working three shifts they had maintained air power, ventilation, water and electric light services along the whole length of the work without interruption – a praiseworthy achievement indeed.

Of the track laid by the construction companies, about two-thirds were 75-lb flat-bottomed American rails, the balance being bullhead English 85-lb rails. The former were laid on single steel tie plates fastened with dog-spikes. The bullhead track was supported on cast-iron chairs spiked to the sleepers and fastened with local timber keys, which if not driven home tight and kept so, went to alleviate the natives’ chronic shortage of firewood. Sleepers, spaced at 2 feet 5 inches, were of Indian hardwood and American pine. Local and Turkish pine was used in loops and station yards.

About 70,000 cubic yards of ballasting was obtained by local contract and the remainder in various ways. In some instances, stone was napped to size on the formation; in others it was transported to the site by donkeys, while long lines of gaily-dressed women carried ballast, some of it picked to size, in baskets to the formation. Later, when stone crushers were available, several were set up in a wadi about 10 feet from the line. Over the hoppers a platform was erected onto which motor-trucks carted stone from the beach. Labourers pushed boulders into the hoppers, a bulldozer pushed the ballast clear of the crushers towards the railway and a drag-line shovel loaded the ballast into waiting railway trucks.

The last gap in the rails was closed on 17th December 1942 near the heavy rock excavation at Maameltein headland. The ballasting of this section was quickly completed and three days later the railway was

officially opened by General Alexander, Commander-in-Chief Middle East. After inspecting a guard of honour of sappers of the group, General Alexander drove the last spike at the Nahr el Keib, selected for the opening ceremony because of its historic associations. Here is a band of hard rock with a vertical face on which are many commemorative inscriptions. The earliest celebrates the conquest of the country by Pharaoh Rameses II, Asarhaddon of Assyria, Nebuchadnezzar and the Greeks. Later ones include the French in 1860, Sultan Barquq, and the Australians in 1918. A carving had also been made in the rock commemorating the opening of the railway by General Alexander. The Commander-in-Chief and special guests boarded a full-sized passenger train drawn by a large Baldwin locomotive decorated with Australian and Lebanese flags and travelled the remaining length of the line to Bahsas, passing groups of sappers, Basutos and Swazis drawn up on their respective lengths.

Job 901 – the official designation of the Beirut–Tripoli connection – was done, which completed the London to Cairo railway link. Next day, 21st December, the line was put to use, when all concerned were thrilled to see a train-load of tanks travelling north, and at night to hear four wheat trains going south.

A total length of 176 miles had been finished in a year, six months ahead of the schedule laid down by the British War Office. This rapid railway construction through semi-mountainous country ranks among the more remarkable engineering feats of the war.

Principal Quantities

| Excavation, earth and sand | 630,000 | cu. yds. |

| Excavation, rock | 343,000 | cu. yds. |

| Pipe culverts | 11,050 | lin. ft. |

| Arch culverts, up to 6-ft. diameter | 135 | |

| Flat slab, reinforced concrete | 30 | openings |

| Sea and retaining walls | 4,500 | lin. ft. |

| Bridging, major | 1,833 | lin. ft. |

| Masonry in walls | 20,900 | sq. yds. |

| Concrete in bridges, culverts and walls | 39,990 | cu. yds. |

| Riveted shellwork in bridges | 950 | tons |

| Rivets | 56,700 | |

| Unit steel trestling (temporary) | 250 | tons |

| Track-work | 66.2 | miles |

| Ballast | 140,000 | cu. yds. |

| Explosives | 357,662 | lbs. |

| Detonators | 176,648 | |

| Cement | 12,103 | tons |