Section 2: Aid to China: The Theater Air Forces in CBI

Blank page

Chapter 6: Ways and Means

The CBI logistics problem has been touched upon more than once in dealing with B-29 operations. The principal difficulties arose from the great distance separating the theater from the United States, the prior claims of other areas of combat, and the lack of distribution facilities over the vast reaches of the theater itself. Until 1944 these difficulties imposed inescapable limitations on air activity in all parts of the theater, and even after that time prevented the build-up of adequate strength in China, where the barrier of the Himalayas had the effect of lengthening and exhausting the supply line. In Burma four principal factors contributed to the Allies’ final mustering of sufficient strength to drive the Japanese out. One of these was the progress of Allied military operations in the Pacific, which by 1945 brought heavy pressure upon the Japanese from several different directions at one time, and which, with the passage of each week, increased the supply problem for the Japanese in their most inaccessible theater – Burma. The second factor was the development in east and northeast India, as well as on the Burma fighting front, of strong Allied forces, given tremendous flexibility and striking power by Allied air supremacy. The third factor was the “miracle of production,” both in Britain and the United States, which brought into CBI on an unprecedented scale the supplies and equipment needed to press the advantages already established. And the fourth was the successful build-up within India, as well as in parts of Burma and China, of an extensive and well-coordinated service of air supply and maintenance.

The India Base

Beginning in 1942 India served as the base for all AAF operations against the enemy in Burma and for all aid, of whatever sort, forwarded

to China. Since the ports of Bombay and Karachi on the west were the only ones of any size free of enemy attack in 1942, American forces were compelled to depend upon them, and thus upon the extraordinarily inadequate trans-India transport facilities. Not until 1943 did Allied air superiority over the Bay of Bengal make it possible to use the full port facilities of Calcutta, which, though separated from the forward bases by cumbersome communications, at least had the advantage of being relatively close to the centers of military operations. Assam bases of northeastern India served as take-off points for planes flying the Hump into China, and as important supply and maintenance bases for tactical air operations in Burma. In the provinces of Bengal and Assam, therefore, the major installations of the CBI Air Service Command came to be situated.

The CBI Air Service Command came into existence on 20 August 1943 as the successor to X Air Force Service Command.1 The establishment of a separate air force in China the preceding March had been followed by activation of a separate XIV Air Force Service Command in May under Brig. Gen. Julian B. Haddon. That organization, however, never attained anything more than a tentative status, although General Haddon put forth every effort to save it from failure. The difficulty lay in the fact that heavy repair and overhaul still had to be done in India and in the fact that all supplies had to come into China by way of India. Furthermore, aircraft of the Air Transport Command, which carried supplies to General Chennault’s forces from the Assam valley, continued to be serviced by the X Air Force Service Command. The plan of a separate service command for the Fourteenth Air Force might have succeeded had the Fourteenth set up its own air depots and service groups on the Indian side of the Himalayas and been wholly responsible for their operation; but this would have led to a duplication of facilities impossible to justify with the prevailing shortages of personnel and equipment. Accordingly, it was decided to activate the China–Burma–India Air Service Command with responsibility for both China and India-Burma. Brig. Gen. Robert C. Oliver assumed command on the same day that Maj. Gen. George E. Stratemeyer took over the newly activated Headquarters, Army Air Forces, India-Burma Sector, China–Burma–India Theater.2 General Oliver became chief of staff for maintenance and supply on Stratemeyer’s staff; as commanding general of the Air Service Command he

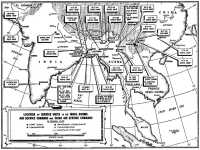

Location of Service Units in the India-Burma Air Service Command and China Air Service Command 31 March 1945

was responsible for the supply and maintenance of all American air forces in China, Burma, and India.

To allow for the maximum decentralization consistent with unified control, the new command established area commands in each of the main centers of service activity: China, Assam, and Calcutta. The 5308th Air Service Area Command (Provisional) was activated at Kunming on 30 October 1943 under Col. Reuben C. Hood;3 its provisional character was changed on 20 July 1944, when it was redesignated the China Air Service Area Command.4

The 5309th Air Service Area Command (Provisional), organized at Chabua on 19 November 1943 with Col. Daniel F. Callahan commanding,5 was redesignated the Northern Air Service Area Command on 20 July 1944.6 In the Calcutta area, the 28th, 47th, and 83rd Air Depot Groups, all operating within a few miles of each other and collectively known as the Bengal Air Depot, were provided with a supervising headquarters on 4 December 1943, designated the 5317th Air Depot Headquarters (Provisional).7 In addition, the headquarters of CBI Air Service Command, which moved to Hastings Mill near Calcutta in the spring of 1944,* exercised direct control over other installations in that area. In May, Maj. Gen. Thomas J. Hanley, Jr. replaced General Oliver.8

Besides the area commands, there were several air depot and service groups located at strategic points for the big build-up that reached its peak in April 1945. Of special interest among these was the Bangalore Air Depot, later redesignated the Southern India Air Depot, which was a supervising headquarters for the Hindustan Aircraft Factory. The factory, which was owned by the governments of India and Mysore, had been promoted in 1942 as a repair base for air force operations by American interests headed by Mr. W. D. Pawley. To facilitate negotiations, the Indian government acquired the rights of Mysore for the duration of the war and retained the services of the American promoters to operate the plant. Early arrangements to service AAF units on a job basis proved unsatisfactory, with complaints of both cost and inefficiency. Through a series of agreements with the Indian government, the first made in July 1942 and the last in September 1943, Tenth Air Force representatives acquired the right to direct the factory’s operations, the Pawley interests meanwhile having been

* At Hastings Mill, fifteen miles from the center of Calcutta, were also located the headquarters of Eastern Air Command, the India-China Wing, ATC, and the AAF India-Burma Sector, CBI.

bought out.9 Thereafter, the CBI Air Service Command ran the plant as managing agent; the 84th Air Depot Group which had been activated at Bangalore on 21 July 1943 and later the Bangalore Air Depot – manned by the 84th – was in charge of its operation.10

By the beginning of February 1944 the strength of the CBI Air Service Command reached 12,087 and in that month jumped to 17,442. In March an increase of another 5,000 was made. Then leveling off, the command showed only gradual increases until December when it reached 26,500, a thousand more than its strength in November. In April 1945, at the peak of the war in Burma, the India-Burma Air Service Command* had a complement of 35,148, a gain of 8,000 over March11 this increase, however, included engineer units assigned from the Tenth Air Force.12 The strength of the India-Burma Air Service Command in April 1945 was the largest of any command in both sectors or theaters throughout the entire war. In addition, at this time there were 7,530 air service troops in the China Air Service Command. In spite of the numbers be assigned to the CBI Air Service Command in 1944, there were el shortages in India, and greater ones in China. New tactical units were going into operation more rapidly than servicing organizations could be received and trained for places in the field, even though nine air service groups and one air depot group had been brought into the theater between January and August 1944. General Stratemeyer summarized the situation in mid-July when he asked Washington to advance shipping dates for needed service units.13 He pointed out that service groups, spread extremely thin, were extended to the point where they could not adequately provide for additional combat units. The 3rd Combat Cargo Group, for instance, was already in full operation, though inadequately supported, and since the 1st Combat Cargo Group was expected to be put into operation as soon as it arrived in the theater, more service groups were obviously needed. At the same time, General Stilwell sent a radiogram to Washington offering to waive unit and combined training of four special airdrome squadrons, two special service groups, and one air depot group, provided readiness dates could be advanced. He also asked that the 61st Air Service Group be sent be

* See below, p. 198, for the splitting of CBI Air Service Command into the India- Burma Air Service Command and the China Air Service Command, effective 12 December 1944.

fore its scheduled date of September.14 In August General Stratemeyer, seeking additional fighter squadrons for the 1st Air Commando Group, again pointed out the need for service troops, stating that the theater was short two standard service groups and three service squadrons provided for in the standard troop basis. This was in addition to the shortage of special service groups for the combat cargo groups.15 By the end of February 1945, however, the personnel needs of the India-Burma Air Service Command were almost satisfied: three standard and three special air service groups had arrived in the theater after October, and the 14th Air Depot Group was due at Ranaghat early in March. Only in certain categories of specialized training did critical shortages still exist.

Shortages of military personnel in India were in some measure overcome by the employment of civilians, most of whom were Indians. At the Hindustan Aircraft Factory several thousands were hired, and shortly after the establishment of the 3rd Air Depot in June 1942, civilians were employed at that station to work in the messes, perform guard duties, serve as clerks and typists, load and unload supplies, and assume other responsibilities for which they were qualified. As other installations were built, the policy of employing civilians was extended. They were used in all capacities for which the use of military personnel was not mandatory, Most of them were employed in so-called housekeeping duties, but many thousands were employed as technicians and skilled workmen; by simplifying the tasks and introducing production-line techniques, it became possible, under the supervision of American technicians, to use civilians without particular training in work that would have required great skill if done by single workmen. At the beginning of 1944 Over 10,000 civilians were employed by the command, exclusive of those at Hindustan Aircraft. By June 1944 over 20,000 were employed, at the end of the war in Burma over 37,000, and by the end of July 1945 there were more than 45,000. Most of these employees were at the Bengal Air Depot: some 8,390 civilians were employed there in June 1944, and this figure rose sharply in succeeding months until a peak was reached in July 1945 with 19,283 employed; of these, 15,236 were semiskilled or unskilled workers. Among air service groups, the 305th at Ondal employed the greatest number of civilians, 1,500 in May 1944 and almost 3,000 in April 1945. About 2,500 of these were semiskilled or unskilled.16

The cost of civilian employment was charged to reverse lend-lease,

except for clerical help during the early months, which was paid for directly by Army finance officers until August 1944 when it too was transferred to the reverse lend-lease account. Total wages ran to less than $500,000 a month during 1944, and in July 1945 costs ran to only $787,268.92 when employment stood at 45,408. Thus, the average wage in July was about $17.33 for each worker, the low figure sometimes being explained by the predominance of unskilled labor and the fact that some workers did not work the entire month; comparison with other months, however, indicates that that figure was little less than average for a full month’s work. Many skilled workers were paid considerably more than the average wage.17

The growing strength of the CBI Air Service Command was preparatory to expanding operations, which were reflected in the opening of the Calcutta port. Because air force units were the principal users of all supplies in CBI, the air service command was called upon for close coordination of plans with other responsible agencies, especially since the responsibility for the movement of gasoline, quartermaster supplies, and other common-user items belonged to the Army Service Forces. The arrival of troops and supplies at Indian ports had to be prepared for by making every effort to set up in advance the facilities that would be needed to handle their movement. Sometimes extra labor was required while at other times special machinery had to be constructed; and storage space on the docks always had to be arranged for until movements to interior depots could be accomplished. If rapid delivery were required, air transport, or an equally expeditious substitute, had to be provided, for which a Movements Control Section, set up in the fall of 1943 by the CBI Air Service Command, bore the chief responsibility.18

Typical of the problems falling to the Movements Control Section was speeding up transportation of critical Air Corps supplies within the theater. Previous dependence on air transport and slow freight trains had failed to meet the demands of operating units, either because of the prior claims of forward areas on aircraft or because of the inadequacies of normal rail service. For example, rail shipments from Calcutta to the 54th Air Service Group at Tezgaon had been requiring from 10 to 15 days, even though the distance was less than 300 miles by air. To step up deliveries, in 1944 an “express wagon service” was successfully tested on the Calcutta-Tezgaon run.19 In July the 54th Air Service Group stationed a four-man detachment with its

own trucks at Barrackpore to load a car each day and attach it to a parcel train. The loaded car moved by broad gauge to Goalundo Ghat, where another detachment of one officer and six enlisted men transferred the goods to a river steamer for movement down the Ganges to Narayanganj. At this point, another detachment shifted the cargo again, and movement was made by truck to Tezgaon. The route was much more direct than that used by regular freight, and despite the time consumed in shifting cargo, time in transit was reduced to approximately thirty-six hours, a saving of eight to thirteen days. The cargo carried on the express-wagon service fell in the category of third or fourth air priority; by the end of July only one air transport flight a day was needed to carry all other priority material from the Bengal Air Depot to the 54th Group.

Negotiations begun on 18 July among representatives of the Movements Control Section, the Army Service Forces, the British Deputy Director of Movements, and the Indian railways resulted in an announcement on 31 July of plans to begin a daily express-wagon service on 10 August for the Calcutta–Chabua and Chabua–Jorhat runs. Wagons at Sealdah yards, Calcutta, were closed for loading at 1730. Five hours later, they left Calcutta on a parcel-goods train. Going by way of Parbatipur, Amingaon, and Pandu (via ferry), the goods arrived at Mariani for Jorhat at night on the fourth day, and at Tinsukia for Chabua on the morning of the fifth day. Another express service was worked out for the Calcutta-Bangalore run, and on 10 August it was announced that tri-weekly service would start immediately. The schedule called for one railway car to leave Calcutta every Tuesday, Thursday, and Saturday. On the same days, a car left Bangalore for Calcutta. Although regular rail transportation continued to take eighteen days, the express cars got through in six; this was further reduced to four days in September when the express cars were attached to passenger trains instead of the parcel trains.20 Both of these express services resulted in a saving that in September, with over 853 tons carried by the new service, amounted to some 256 plane lifts, if measured by a 3⅓-ton net load per airplane. Over half of this was on the Calcutta-Chabua run.

No less representative of the way in which the CBI Air Service Command contributed to improvement of operating conditions was its successful effort to provide a better system of stock control. War reaches perhaps its dullest level in the bookkeeping which controls the

requisition and distribution of supplies, but when the system of control is at fault, planes which otherwise would fly are grounded. In the supplies delivered from the United States, the theater was by 1944 much more fortunate than it had been earlier, but the very size of the theater exposed it to the special risk of idle surpluses in one place and shortages in another. To guard against this danger, two main centers of stockage were established, one in Bengal and one in Assam.21 All units, according to their geographical location, made requisitions on one of these two centers. At the same time, specialized depots for certain technical supplies prevented the danger of over-centralization at the Bengal Air Depot, which served as the main center of stockage. The Central India Air Depot at Agra became the supply point for Curtiss aircraft; the Eastern India Air Depot at Panagarh specialized in aircraft combat materials; and the Delta Air Depot at Ranaghat handled tires and tubes, night-flying equipment, prefabricated hangars, shop and machine tools, aerial-delivery equipment, cordage, fabrics, leather, belly tanks, and wing assemblies. Moreover, local procurement under lend-lease agreements was used to the fullest in order to lighten the burden upon the requisitioning channels.22

To achieve maximum utilization of supplies under the new control system, frequent inventory reports were required. To distribute the work load at service command headquarters, the dates for regular reports from subordinate units were staggered throughout the month, and by the spring of 1945 electrical accounting machines had been installed for handling stock-balance and consumption reports. The reports which came in from seventeen air depot and air service groups in the India-Burma Theater, and from five groups in the China Theater, were processed by the machines so as to produce a complete inventory of all stock on hand in both theaters approximately eight days after receipt of reports. Some 163,532 different items bearing stock or part numbers were covered, which represented a consolidation of over 435,000 field stock-record cards.23 As before, use of local manufacture for a long list of items – among others, tires and tubes, supply-dropping parachutes, alcohol, lumber, oxygen, paint, cordage, turpentine, paper, wax, and ink – served to relieve the pressure on facilities for shipment from the United States.

In order to prevent excessive stocks of any one item from accumulating at one place, over-all responsibility at CBI Air Service Command Headquarters was divided between two main sections: the Aircraft

Section kept check on planes, engines, accessories, and hardware; the Equipment Section on other equipment. By a strict check of activity on both a 30-day and a 120-day basis, these sections established more accurate estimates on consumption rates and managed to put inactive stocks into useful channels or to relieve the pressure on storage facilities by shipping home some surplus inventories.

Bombs, Fuel, Aircraft

The supply of ammunition was at no time critical during the last two years of the war. Measured by the usual standard set up to test the size of an adequate reserve, that is, six times the normal expenditure, reserves were actually too high until full-scale operations in the Burma offensive altered the picture in November 1944. In March 1944, when reserve stocks were at their highest, 100,000,000 rounds of .50-caliber ammunition,* for instance, were on hand, with expenditures running to only 730,000 rounds for that month. During months of greatest expenditure, rounds on hand for all types of ammunition exceeded rounds expended by several times: nine times for .50-caliber ammunition in May 1945; thirty-nine times for 20-mm. in April 1945; and twenty times for 75-mm. in January 1945. In June 1945, with only 12 rounds of 75-mm. ammunition expended, 69,747 rounds were on hand. So plentiful were the reserves that excess quantities were sent to the Pacific Ocean Areas in the last few months of the war.24

As in other theaters, however, serious shortages were experienced in the supply of bombs.† Some supply officers in CBI showed a natural inclination to attribute their difficulties to failure of American production, but this has been vigorously denied by Donald Nelson, who claimed that after 1942 no American soldier at the front went without munitions because of a production failure.25 He attributed the difficulty to the shortcomings of intra-theater organization. The widely separated operational bases in CBI forced stockage of bombs at many different and distant points, and the cost of any attempt at redistribution tended to make bomb supplies expendable only at those bases which originally received them. As a result, some stocks remained inactive while operational demands at other points in the theater created

* The ammunition most used by the AAF in India, Burma, and China. Expenditures and losses of .50-caliber ran to 64,244,000 rounds during 1944 and 1945, as compared with 411,000 rounds of 20-mm. and 22,955 rounds of 75-mm. ammunition. Expenditure of other types was negligible.

† For the problem in ETO, see Vol. III, pp. 581-82.

critical shortages of the desired type of bomb. This situation was in part a penalty imposed by the great distances and the marked inadequacies of transportation in CBI, but the trouble must also be attributed to a failure at top planning levels to make adequate allowance for the unavoidable difficulties.

At no time in 1944, and not until June 1945, did adequate reserves exist for the 100-pound, 250-pound, and 500-pound general-purpose bombs.26 The greatest reserve stock of 100-pound GP bombs was in July 1944: 118,388 of them, with expenditures running to only 6,395. In succeeding months expenditures increased and reserves fell almost by the amounts expended, while resupply of this type bomb from the United States was negligible after July 1944. In May 1945 only 36,377 bombs of the 100-pound GP class remained to cushion an expenditure of over 11,000 a month, and the situation in respect to this type might have been worse had not enemy personnel become so important a target during the last ten months of the Burma war as to permit free use of plentiful stocks of 100- and 260-pound fragmentation bombs. Stocks of the 500-pound, as well as the 250- and 1,000-pound bombs, declined throughout the latter part of 1944, and the reserves of them were never adequate to support abnormal expenditures. The 1,000-pounders almost disappeared in 1945 at an average of 2,700 bombs a month. Replenishments were meager. Azon bombs, used in B-24’s by the 493rd Bombardment Squadron of the 7th Group and after April 1945 in P-38’s equipped with bombardier noses, were supplied in quantities equal to the need.27 The number of incendiary bombs was also sufficient, although authorized stock levels were not maintained except for the quick-opening clusters using the M50 and M69. Expenditures, however, never ran high, and reserves were always about twelve times the current expenditures.

Not until June 1944 did the CBI Air Service Command assume any responsibility for the handling of aviation gasoline and lubricants; before that time the Army Service Forces was charged with deliveries to the theater, British agencies attended to allocations, General Stratemeyer allocated fuel among AAF units, Army engineers had charge of pipeline construction, and ATC controlled storage in the Assam region.28 Complaints from using agencies were frequent, and the Fourteenth Air Force objected especially to the policy of having ATC in the dual position of distributor and consumer.29 A proposal to meet this objection and put the CBI Air Service Command in control of

Assam stocks met with opposition from ATC, which did not relish surrendering personnel to the service command in transferring the responsibility. The CBI Air Service Command, however, took over in Assam early in June.30

Improvement in the stockage and delivery of fuel to consuming units owed much to 6-inch and 4-inch pipelines from Chittagong to Tinsukia, and to the 6-inch pipelines running from Calcutta to Kharagpur and to Tinsukia, all of which had been completed before the service command assumed its new responsibility. From Tinsukia a 4-inch line reached Myitkyina in December 1944. Despite these facilities, it was still necessary, however, to rely at many places on tank cars, barges, and trucks.31 Tank wagons operated from the ports, and at transshipment points were drained into storage tanks, from which other tank wagons were filled. Barges operated up the Hooghly and Brahmaputra. Gasoline emptied from damaged drums augmented the supplies of bulk gasoline, which were generally sufficient for operations from Assam into China by the Air Transport Command. Drum gasoline was used in China.

During the last half of 1944 gasoline supplies were gradually improved for all operational units. By November supplies at Chabua, Dinjan, Mohanbari, Sookerating, Misamari, Tezpur, and Jorhat were, for the most part, adequate. Because of diversions, acute shortages existed at Jorhat and Sookerating in early December, but after the 20th of that month stocks on hand (that is, exclusive of the reserves that all fields maintained for emergency evacuation) never dropped below a day’s consumption rate at any of these several fields. Stocks were established at Myitkyina in mid-December, but so great was the consumption rate that stocks were never large: in June 1945 they declined to less than a day’s supply. In the preceding December and January Dergaon was also used as a gasoline supply field, and early in January Kurmitola-Tezgaon began operations as a supply field.32

Consumption in October 1944 had risen to about 400,000 imperial gallons a day for all fields. This rate was increased rapidly as the war in Burma reached a climax. In the first week of May 1945 consumption at all fields was over 700,000 imperial gallons a day. Then, as soon as the Burma war machine could be stopped and redirected toward aiding China, the rate again rose – this time – to the highest figures: on 25 July the consumption rate reached almost 900,000 imperial gallons (about 1,080,865 standard American gallons) a day. It was during this

In Burma

Rail bridge in Burma destroyed by the 7th Bombardment Group

Bomb damage at Myitkyina

Air supply

month that the Air Transport Command broke all records in carrying tonnage into China. Consumption during 1945 was greatest at the Kurmitola-Tezgaon station, where it reached over 262,000 imperial gallons in the first part of May. This reflected activity on the part of the Air Transport Command, of the combat cargo groups, and of tactical units operating in Burma.

At the beginning of 1944 AAF units in CBI had about 1,500 airplanes, of which approximately 900 were in commission. At the end of the year there were over 4,000 with 2,500 in commission. During the critical months of March, April, and May 1944, when the Allied forces gained air superiority in Burma, American aircraft strength in India, Burma, and China ranged between 1,700 and 2,500. In 1945 the number of aircraft varied as indicated by the following table:33

| 31 Jan. | 31 Mar. | 30 Apr. | 30 June | 31 July | 31 Aug. | |

| Fighters | 1,238 | 1,254 | 1,236 | 1,316 | 1,410 | 1,356 |

| Bombers (M) | 387 | 387 | 386 | 389 | 431 | 419 |

| Bombers (H) | 158 | 184 | 189 | 182 | 156 | 133 |

| Reconnaissance | 160 | 209 | 204 | 206 | 171 | 167 |

| Transports | 1,213 | 1,301 | 1,325 | 1,436 | 1,444 | 1,475 |

| Training and Liason | 536 | 540 | 538 | 513 | 487 | 485 |

| Gliders | 367 | 310 | 211 | 121 | 79 | 57 |

| TOTAL | 4,059 | 4,187 | 4,089 | 4,163 | 4,178 | 4,092 |

As these figures and those in table below emphasize, fighter and transport aircraft played the most important roles in CBI.*34 Among fighters, the old P-40 gave way to P-38’s, P-47’s, and especially to P-51’s.

There had been 44 P-38’s assigned to the theater at the beginning of 1944; in March of that year the first P-47’s, 100 of them, reached Karachi by water; and to the 60 P-51’s already in the

* Aircraft strength by types in CBI, December 1944–July 1945

| Dec. | Jan. | Feb. | Mar. | Apr. | May | June | July | |

| P-40 | 205 | 182 | 171 | 134 | 109 | 95 | 76 | 62 |

| P-38 | 92 | 109 | 140 | 205 | 190 | 225 | 280 | 231 |

| P-47 | 405 | 379 | 394 | 372 | 350 | 336 | 326 | 296 |

| P-51 | 417 | 492 | 510 | 482 | 527 | 518 | 556 | 753 |

| P-61 | 33 | 32 | 33 | 32 | 36 | 33 | 53 | 53 |

| B-24 | 163 | 157 | 170 | 180 | 185 | 180 | 171 | 147 |

| B-25 | 397 | 382 | 379 | 386 | 388 | 418 | 373 | 345 |

| C-46 | 350 | 408 | 431 | 472 | 466 | 592 | 614 | 611 |

| C-47 | 500 | 503 | 500 | 493 | 505 | 501 | 488 | 479 |

| C-54 | 23 | 43 | 52 | 74 | 99 | 100 | 107 | 132 |

| L-5 | 349 | 369 | 385 | 377 | 382 | 355 | 378 | 361 |

theater at the close of 1943, over 500 more in 1944 and 669 in 1945 were added to make this type the most numerous in both theaters. With the P-51 and P-47 capable of carrying fragmentation bombs and strafing, it was considered advisable to concentrate upon these types rather than to maintain an excessive number of bombers. In all, there were over forty types of aircraft assigned to the India-Burma and China Theaters in the last months of the war.* The following table shows the distribution of aircraft types among the principal commands of the theaters during 1945:

| C-46 | C-47 | C-54 | B-24 | B-25 | A-26 | P-38 | P-40 | P-47 | P-51 | L5 | ||

| AAF IBT | 31 January | 93 | 134 | 1 | 37 | 3 | 97 | 40 | 192 | |||

| 31 March | 99 | 138 | 1 | 40 | 3 | 2 | 110 | 35 | 204 | |||

| 31 July | 171 | 71 | 54 | 35 | 2 | 41 | 6 | |||||

| ATC | 31 January | 255 | 160 | 43 | 14 | 11 | 6 | |||||

| 31 March | 333 | 142 | 74 | 8 | 10 | 7 | ||||||

| 31 July | 330 | 167 | 132 | 1 | 33 | 10 | ||||||

| Tenth AF | 31 January | 5 | 149 | 60 | 106 | 47 | 3 | 140 | 97 | |||

| 31 March | 6 | 140 | 58 | 114 | 87 | 2 | 132 | 100 | ||||

| 31 July | 62 | 2 | 54 | 38 | 103 | 2 | 73 | 82 | 167 | |||

| Fourteenth AF | 31 January | 35 | 51 | 56 | 20 | 47 | 51 | 324 | 54 | |||

| 31 March | 38 | 73 | 61 | 30 | 32 | 55 | 317 | 41 | ||||

| 31 July | 21 | 76 | 51 | 72 | 22 | 19 | 13 | 59 | 228 | 125 |

The C-46 and C-47 bore the brunt of transport operations, but the C-54, first assigned to the theater late in 1944, was of growing importance through the last months of ATC’s operations, being used on the Trojan Run from Calcutta to Kunming. The Fourteenth and Tenth Air Forces used the C-47 mainly for supplying their units in the forward areas, and combat cargo and air commando groups also depended chiefly on the C-47, though they also had many C-46’s. Of the 600 C-46’s in the theater in July 1945, 330 were assigned to the Air Transport Command. The C-87 and C-109 were also used by ATC during 1944 and 1945, but their numbers never reached 100 for either type. Transport aircraft, like the C-46 and C-47, were needed in such numbers that any diversion of manpower from their maintenance would have seriously reduced the efficiency of the cargo-carrying units. Of the medium bombers in May 1945, 44 were assigned to units

* The glider CG-4 was introduced into the theater in large numbers during 1944 and was used in the second Wingate expedition in the spring. At the end of the year over 300 of this type aircraft remained in the theater, but their numbers were decreased in 1945. At the end of July there were but twenty-nine left.

under the theater headquarters, 82 to the Fourteenth Air Force, and 100 to the Tenth Air Force. The A-26’s, introduced into the theater in June 1945 to replace the B-25, were assigned to the Fourteenth and Tenth Air Forces for use in China.

Because of the jungle-type warfare expected by Allied commanders, it was anticipated that a great demand would develop for supply-dropping equipment. The CBI Air Service Command had the responsibility after August 1944 for procuring the parachute and its harness, leaving the procurement of the container to the Army Service Forces. In meeting this responsibility, the command made full use of Indian manufacturing facilities, and cut down on shipping requirements from the United States. Although the parachutes made in India were not as well packaged as the American-made ones, they were entirely satisfactory for their purpose. In August 1944 some 52,506 Indian-made parachutes were consumed in the India-Burma Theater, with 9,485 more in China, compared to 4,169 American-made parachutes consumed; in November of the same year over 78,000 Indian-made parachutes were used, as against 4,911 American-made. No American-made parachutes were used in China. By January 1945 the demand for supply-dropping parachutes decreased sharply, since a larger number of serviceable airstrips had been overrun in Burma, permitting transport-plane landings.35 At the end of the Burma campaign over a half million supply parachutes were on hand.

Many other items of supply could be mentioned in a longer account than the present one. For instance, Signal Corps supplies were a special problem, often failing to function properly in the CBI theaters: packing agencies in the United States did not provide protection against the damaging effects of moisture and fungus.36 Motor vehicles for air force use were also a problem, always being provided in numbers less than those authorized. When the Burma Road was opened in March 1945, the air forces suffered a sharp reduction even in their authorized number of vehicles.

Maintenance

Maintenance in CBI suffered from a variety of difficulties – among others, the extreme heat, the high humidity, the great distances – but especially from shortages of spare engines and parts. Though improvement of conditions came only slowly until the last year of the war, a change at that time marked a decisive turn for the better, as the following

table of engine supply (excluding the B-29’s R-3350) from August 1944 to the end of the war clearly shows.37

| Period Ending | Total Engines | Total Installed | Total Spares | Serviceables | Repairables |

| 31 August | 9773 | 5131 | 4463 | 2650 | 1993 |

| 30 September | 9439 | 5395 | 4044 | 1944 | 2100 |

| 31 October | 9838 | 5604 | 4234 | 2061 | 2173 |

| 30 November | 10794 | 6218 | 4547 | 2056 | 2614 |

| 31 December | 10765 | 6218 | 4547 | 2167 | 2380 |

| 31 January 1945 | 11100 | 6398 | 4702 | 2469 | 2233 |

| 28 February | 11732 | 6718 | 5014 | 2797 | 2217 |

| 31 March | 14271 | 6901 | 7370 | 4428 | 2942 |

| 30 April | 14261 | 6960 | 7301 | 4432 | 2869 |

| 31 May | 16506 | 7231 | 9275 | 5581 | 3694 |

| 30 June | 17090 | 7307 | 9783 | 5581 | 3802 |

| 31 July | 16330 | 7305 | 9025 | 5947 | 3078 |

| 20 August | 15956 | 7291 | 8665 | 5654 | 3011 |

At no time after March 1945 did the number of installed engines exceed the number of spares. Of still greater importance was the fact that about two-thirds of the spare engines were kept serviceable, which gave the tactical and transport units a type of support that allowed for more risks than could ordinarily have been taken in the early stages of the war. In some instances, stocks fell below the ninety-day consumption standard, but with maintenance as steady as it had become by 1945, operations were not affected.38

Experience had demonstrated that about 4 per cent of all types of aircraft in India-Burma and China could normally be expected to be out of commission for lack of spare parts (AOCP) because of the normal difficulties in distributing supplies over the long distances, but when the figure rose above 4 per cent, it was considered a matter of critical scarcity rather than a problem of distribution. By this standard, there were not enough spare parts until January 1945. The average for the nine months preceding this showed 5.3 per cent of the aircraft in India, Burma, and China out of commission for lack of parts; in April, May, and July 1944 this figure was over 6 per cent, but in September and October, it fell to 4 per cent. In the first three months of 1945 the figure stood at less than 4 per cent, and at no time during the remaining months of the war did it rise to 5 per cent, counting India-Burma and China together. For India-Burma alone, the AOCP rate varied from 2.8 to 3.2 per cent throughout 1945, but in China, it rose from 5 per cent to 9.3 per cent in 1945.39

If the supply of spare parts from the United States had much to do with the improvement of air service during the last year of the war, it is also true that the resources and ingenuity of air service command personnel in India, Burma, and China had much to do with the improvement, too. The Bangalore factory, once it was equipped, manufactured many of the required tools and instruments. One of the best examples of improvising equipment came at the end of the Burma war, when the 7th and 308th Bombardment Groups were placed under the operational control of the India-China Division of the Air Transport Command to haul gasoline into China. To convert B-24’s into gasoline-carrying aircraft, kits to install droppable bomb-bay tanks were made up under the supervision of the Southern India Air Depot. A standard piping manifold was designed to allow withdrawal of gasoline from the bomb-bay tanks through two outlets at the same time, and to facilitate emergency use of bomb-bay gasoline during flight through a connection with the engines. By means of the manifold, gasoline could also be drained from the auxiliary wing tanks into the bomb-bay. Maximum safety in flight was thus achieved, and rapid unloading with the maximum delivery of gasoline to China was made possible.40 Another example of conversion was the modification effected in the P-38 to make it serviceable for Azon bombing. “Droopsnoots,” or bombardier noses, were built into ten P-38’s during a period of fifty-one days in the spring of 1945. The standard M9 bombsight, the Azon Bomb Directional Control, and the automatic radio-bomb-release transmitting equipment were installed.41

The command’s basic maintenance problem, however, was meeting the normal requirements of operational units. Although production-line methods had been employed to some extent even in the earliest days of the command, efficiency had been hampered by inadequate planning, decentralized scheduling, improper supervision, inadequate training, and the lack of physical facilities for full-scale operations. Now, skillful employment of unskilled native labor, an in-service training program, and a plan for specialization by key installations in the theater all combined to solve the problem. Thus, the Bengal Air Depot specialized in the repair of engines, including the R-3350 for the B-29’s. Although the R-1830-43/65 and the R-1830-92 were repaired at both Agra and Bangalore during 1944, near the end of the war even these engines were scheduled for repair only at the Bengal depot. This brought all supply and training problems for engine repair into a single

area, and resulted in economy of effort. The Bengal Air Depot also came to do most of the repair on generators, starters, carburetors, turbosupercharges, magnetos, cooler assemblies, and gyro instruments. At Bangalore the air depot or factory overhauled the B-24, C-87, C-109, C-47, and in 1944 the B-25. It also repaired various accessories for these aircraft, manufactured tools, repaired gyro instruments until the Bengal Air Depot took over these functions, repaired other instruments, and overhauled the R-1830-43/65 engine for the B-24 until near the end of the war. In 1944 the R-2600 engine for use in the B-25 was also repaired there. The air depot at Panagarh specialized on major overhaul of the B-25, P-38, P-47, P-51, liaison aircraft, and, in June 1945, of the A-26; it also repaired accessories for these aircraft, tested aircraft assembled at the Bengal Air Depot, and at the end of the war was ready for overhaul of Curtiss propellers. The air depot at Agra specialized on the C-46 and its accessories, and in 1944 repaired the Pratt & Whitney R-1830-92 for use in the C-47. It also did overflow work on C-47 aircraft.

The achievement is indicated by the percentage of planes kept operational: for both India-Burma and China in January 1944, 58 per cent of the aircraft were in this category; in June, 69 per cent; in September, 52 per cent; in November, 57 per cent; in December, 62 per cent; in March 1945,70 per cent; in May, 72 per cent; and in July, 64 per cent. This covered all types, including gliders. At no time after June 1944 did the percentage of aircraft in commission in operational units fall below 73 per cent, and for the most part in 1944 and early 1945, it was around 78 per cent. In May 1945, when the India-Burma Air Service Command was no longer responsible for third echelon maintenance in the China Theater, the percentage reached 83 per cent. Aircraft in commission assigned to American units of the Eastern Air Command averaged more than 83.6 per cent for 1944 and 1945.42 And these figures should be read in the light of the very great increase in the number of planes assigned to CBI, one for which there was no parallel increase of service command strength.

The task of airfield construction was not a direct responsibility of the CBI Air Service Command; that job belonged to the engineers, working under planning operations of the air service command. The construction of B-29 bases has been recounted earlier,* and so it is necessary here to give notice only to the work of the engineers in support

* See above, pp.55-73.

of the advance into Burma. The Burma offensive had been launched with air support from bases developed in 1942 and 1943 in Bengal and Assam. After Myitkyina South airfield was captured in May 1944, it was converted into an all-weather field by the 879th Engineer Aviation Battalion. Although the siege of Myitkyina forestalled other airfield construction for some months, in September, after Myitkyina had fallen, a fair-weather field was built at Sahmaw. By November the Japanese were in retreat, and airfields sprang up in quick succession, all constructed by engineers assigned to the Tenth Air Force. Col. Manuel J. Asensio, Tenth Air Force engineer, worked under the theater air engineer, Brig. Gen. S. C. Godfrey. Fair-weather fields were built at Mawlu and Momauk in November; at Bhamo, Indaw West, and Katha in December; at Panghkam, Bahe, and Yanbo in January; at Mu-se and Kutkai in February; at Mong Mit, Lashio, Mong Long, and Hsipaw in March; and at Namsaw in April. All-weather fields were completed at Sahmaw and Myitkyina North in November; at Myitkyina East in December; at Namponmao in January; and at Bhamo in April.43 All of this construction was completed under actual combat conditions.

On duty with the American air forces in the India-Burma Theater were some fifteen engineer units. Some of these were assigned to road construction or maintenance, as the 823rd Engineer Battalion or the 1905th Engineer Battalion were on the Ledo Road; others were assigned to crash-fire protection, like the 2085th Engineer Fire-Fighting Platoon; and others were assigned to airfield construction, the 853rd, 879th, 930th, 1877th, and the 1888th Engineer Battalions.

The China Base

Supply and maintenance for the air forces in China were always tenuous and uncertain. In 1942 only a single base unit had been set up in Kunming.44 This, together with a Chinese factory, constituted the only air service available to Chennault’s forces at that time. Fourth echelon repair, when it was done, had to be accomplished at Indian bases under jurisdictional control of the Tenth Air Force. The establishment on 19 May 1943 of the XIV Air Force Service Command45 offered no real solution to the problem, as Chennault had predicted,46 and in August of that year its place was taken by the 5308th Air Service Area Command (Provisional), an organization which functioned as a part of the newly established CBI Air Service Command. This

set-up successfully removed controls from the Tenth Air Force, but, despite efforts to improve the services in China, the handicaps imposed by shortage of fuel and the local need for fourth echelon repair continued to affect China air operations.

Not until February 1944 did the China Theater obtain two full-fledged air service groups, the 12th at Kweilin, the 68th at Kunming. In April the 315th Air Service Group was set up at Hsinching, and in January 1945 the 14th Air Service Group was brought together in the Chanyi area. By December 1944, after a long struggle, CBI Air Service Command strength in China reached almost 5,000 enlisted men and officers. Together with the manpower from Chinese sources for supply and maintenance, this encouraged air force commanders in China to organize, for a second time, an independent air service command: on 12 December 1944 the CBI Air Service Command was divided into two parts, the China Air Service Command and the India-Burma Air Service Command.47 This move did not relieve the air forces in China of dependence upon fourth echelon repair in India nor upon the gasoline supplies coming through India, but it did provide a measure of self-reliance and flexibility never before attained.

With the war in Burma coming to an end, added service personnel were sent to China. In May 1945 some 8,445 enlisted men and officers engaged in service activities were in the China Theater, just short of the air service strength in India back in September 1943; in the same month, the China Theater received its first and only air depot group, the 301st. In July the 382nd Air Service Group (Special) was moved from its Indian bases into the Luliang area, and in September the 381st Air Service Group (Special) followed it to China.48 These movements were a part of the effort, beginning in the summer of 1945, to push forward into China the main strength of the AAF in CBI.* By that time the Ledo Road had been opened and the India-China airlift had reached totals which exceeded the expectations of Allied leaders in the earlier days of the war,† but all this had come too late to alter materially the record of air operations in China.

It was in Burma rather than in China that CBI forces scored their major victory-a victory that was peculiarly dependent upon the varied services rendered by the Allied air forces. This does not gainsay the role played by ground troops; it simply points out how Allied

* See below, pp. 267-72.

† See below, pp. 257-58.

commanders, without roads, railways, or other surface routes, were able to carry the battle to the enemy across the jungles. One Japanese officer, writing in his diary on 1 June 1944, showed, in an entry typical of enemy testimony, how his own machine-gun company had been reached:

Enemy aircraft are over continuously in all weather. We can do nothing but look at them. If we only had air power! Even one or two planes would be something. Superiority in the air is the decisive factor in victory. ... But only with economic and manpower resources, can one have superior air power.

Behind the air victory in Burma and behind the magnificent effort of American airmen in China, there lay the longest supply line in military history. The credit for putting aircraft, gasoline, bombs, and ammunition into the hands of operational commanders rested in no small way with the service personnel who, without much glory, worked in shops, supply rooms, and at desks.