Chapter 15: The Impact of War

The United States entry into the war galvanized the rearmament effort. Referring, on 9 December 1941, to the gradual buildup during the preceding 18 months, President Roosevelt stated, “It is all only a beginning of what still has to be done.”1 Maximum strength in minimum time replaced earlier goals. Sights were much higher than before. Schedules were much tighter. Demand was heaped upon demand. Pressure was ever increasing. A construction program of gigantic size and staggering complexity paced the all-out drive to mobilize resources. During the first critical year of war, several thousand military projects estimated to cost more than $7 billion assumed acute urgency. As head of the newly unified construction command, General Reybold declared: “The job may be tough, but we can and will do it.”2 The sooner this promise was redeemed, the sooner would the war be won.

The All-Out Program

The Pearl Harbor disaster had an almost immediate impact upon the building program. A warm clear Sunday in most parts of the country, 7 December 1941 was a workday at most major projects. Construction crews, pressing to take advantage of the waning autumn weather, learned of the surprise attack when loudspeaker systems broadcast the news and when officers, many of whom customarily wore business suits, suddenly appeared in uniform to announce the outbreak of war. Word passed through union ranks that a nationwide walkout scheduled for Tuesday by the Welders Brotherhood had been called off. At the Ravenna Ordnance Plant, strikers returned to their jobs. As excited workmen left for home that evening, armed guards patrolled every project. Telegraphic orders from General Reybold had called for precautions against sabotage.3 In a few hours the whole outlook had changed. For some months the construction program had shown signs of tapering off. It was now certain that much more work would be coming.

The rush began the following morning. In a memorandum for Groves, General Campbell asked that all Ordnance plants “be completed and available for production at the earliest dates possible.”4 Telephoning Leavey from G-4, Colonel Chamberlin relayed instructions from Somervell to push camp construction “vigorously to completion.” At Styer’s

direction, Groves issued expediting orders to the field.5 Meanwhile, requests for additional projects deluged General Moore’s office. On Monday afternoon, shortly after Congress declared war against Japan, a group of construction officers appeared to testify before the Senate Appropriations Committee. The estimate under consideration, the third supplemental for 1942, had received a thorough going-over in the House two weeks earlier. The Representatives had pared several items and had closely questioned Somervell and Reybold about construction costs.6 Now, the Senators wasted no time trying to economize. Instead, they concentrated their efforts on providing all that was necessary and on getting “this bill passed at the earliest possible opportunity.”7 Recalling “the beating we took” before the House committee in November, Colonel Plank described what happened on the Monday after Pearl Harbor. “We were just given a blank check,” he said. “That’s how quickly the damn thing changed. And, of course, from then on, you didn’t have any troubles in terms of getting funds.”8

Face to face with the grim actuality of war, military leaders made hasty reappraisals of construction needs. Taking note of “the national situation,” General Campbell on 8 December outlined the “order of preference” for various types of Ordnance plants. TNT topped the list. Tanks, small arms ammunition, anhydrous ammonia, and oleum also ranked high.9 With Groves’ help, Campbell began at once to map plans for quickly increasing TNT capacity.10 Reacting to the news from Hawaii and the Philippines—to reports of aircraft destroyed on the ground at Hickam and Clark Fields—General Arnold on 9 December called for camouflage and revetments at stations within the air frontiers and for additional runways and auxiliary fields to permit wider dispersal of planes. For a time there was talk of “a fighter base every five miles.”11 Anticipating a “greatly increased volume of shipments overseas,” Somervell conferred on 10 December with Quartermaster, Ordnance, and lend-lease representatives. The result was a decision to build intermediate general depots to regulate the flow of supplies to ports on the Southeast, Gulf, and West Coasts and to construct special ammunition loading piers at all principal ports.12 Estimates could not be ready in time for inclusion in the bill then before the Senate. Requests for additional funds would go to Congress early in the new year.

The old dictum, “time is of the essence,” took on added meaning. On 9 December Patterson told Reybold that speed was all important and money was no object. Complete construction with “utmost dispatch,” he directed, and

expedite work “by every feasible means.” The Engineers had only to ask to receive necessary funds.13 On the 10th Colonel Hardin wired the field, authorizing division and district engineers to exceed budgets on “truly urgent and important” jobs.14 Two days later General Robins suspended regulations requiring bids on purchases of materials. Before the week was out, the administration had sanctioned continuous operations at war projects, and building trades officials had renewed their no-strike pledge.15 Calling on construction men to “place their full energies at the nation’s disposal,” the Engineering News-Record editorialized:– “Building for defense is a thing of the past. The construction industry’s new standard must be emblazoned ‘building for battle.’ There is a great difference. Time was short. Now there is no more time.”16

In the ten days that followed Pearl Harbor, forty-five construction directives appeared, twice the number released during the preceding 10-day period. A flurry of orders for enlarging projects under way—a $20-million expansion of the Twin Cities small arms ammunition plant, a $4-million annex to the Detroit Tank Arsenal, and an additional 500,000 square feet of floor space at the Pentagon, to cite a few examples—preceded authorizations for entire new installations, including two TNT plants, West Virginia and Longhorn, with a combined estimated cost of $46 million. Planning activity quickened as money flowed in for design of four division camps at preselected sites, two ammunition depots, a gun casting plant, and an internment camp for enemy aliens.17 Slowly the first dim outlines of the mammoth wartime program were beginning to emerge.

Passage of the first wartime appropriation bill loosed a flood of orders. Approved on 17 December 1941, the measure carried more than one and a quarter billion in construction funds—$827,820,000 for military posts and $388,000,000 for expediting production, plus smaller sums for seacoast defenses, maintenance, and war-related civil works. Directives came in rapid succession for 4 general hospitals, 3 division camps, 13 air bases, 10 ammunition docks, 6 regulating depots, 3 holding and reconsignment points, 3 staging areas, and more. Requests were soon in Robins’ hands for large new industrial projects: the Lake Ontario TNT plant; the Buckeye anhydrous ammonia plant; a chlorine plant at Edgewood arsenal; and the Wabash River Ordnance Works, the .first facility in the United States for production of the super-explosive RDX. Work piled higher. Although troop housing requirements were still in question—the course of the war and the rate of deployment overseas would be determining—General Marshall gave the Engineers a green light to proceed with construction of 6 more advance planned cantonments and 5 temporary tent camps

in early January. An emergency railroad bridge across the Potomac, a huge munitions depot at Chambersburg, Pennsylvania, and scores of other projects swelled the program’s size.18 Meanwhile, far greater increases were in prospect.

In his state of the union message to Congress on 6 January 1942, the President called for “all-out scale production” to “hasten the ultimate all-out victory.” Presenting a program for attaining “overwhelming superiority” over the Axis Powers, for building armaments “to the utmost limit of our national capacity,” he announced production goals of 60,000 planes, 45,000 tanks, and 20,000 antiaircraft guns for 1942; 125,000 planes, 75,000 tanks, and 35,000 antiaircraft guns for 1943; and similarly huge quantities of “a multitude of other implements of war.” Turning to military manpower, he envisioned a force capable of protecting the Western Hemisphere, conducting offensives on a global scale, and inflicting “total defeat” upon the enemy.19 In terms of construction alone, the effort required was stupendous. To administer the all-out program, the President on 16 January 1942 created the War Production Board (WPB). Unlike NDAC and its successors, OPM and SPAB, the new agency was to be a powerful one-man directorate with sweeping authority and broad responsibilities. Advised and assisted by board members, the WPB chairman would perform the following duties:– Exercise general direction over the war procurement and production program.

Determine the policies, plans, procedures, and methods of the several federal departments, establishments, and agencies in respect to war procurement and production, including purchasing, contracting, specifications, and construction; ... and issue such directives in respect thereto as he may deem necessary or appropriate.

Compliance with the chairman’s orders was mandatory, and his decisions were final.20 For the post of chairman or “production czar,” Roosevelt chose Donald M. Nelson, former executive director of SPAB. Named to the board were Vice President Wallace, Secretaries Stimson, Knox, and Jones, William S. Knudsen, Sidney Hillman, Leon Henderson, and Harry L. Hopkins. Among the first matters this group considered were the size and urgency of the construction program.21

As plans crystallized, the magnitude of the construction task became apparent. By mid-January General Marshall had decided that an army of 3,600,000 would have to be ready before the end of 1942. Ground and service forces would increase by 1,270,000 men. More than 750,000 men, including 50,000 pilots, would augment the air forces. Thirty-seven divisions and forty-five air groups would come into being.22 This expansion would go forward side by side with efforts to step up lend-lease aid, to stem enemy assaults, and to launch full-scale offensives. Camps to house additional units; training, transport, storage, and hospital facilities;

factories to out-produce the enemy and give the United Nations vast superiority in weapons; defense installations and strategic bases; power plants and harbor improvements; flood protection for war industries: the list of needed projects seemed almost interminable. According to WPB estimates, essential war construction would amount to $10 billion during 1942.23 The bulk would be military.

Heading the President’s “must” list, planes received first consideration. On 16 January Roosevelt sent to the Capitol what was, in Representative Cannon’s words, “the largest estimate for war equipment ever submitted to any committee or any Congress in the history of the world.”24 Included in the $12.5-billion request for aircraft and air ordnance was an item of $933 million for facilities to expedite production. The major part of this expansion, mainly additions to privately owned plants (capacity which could be used after the war to produce commercial planes), would be accomplished under Defense Plant Corporation contracts. To be built by the Corps of Engineers were plants for which there was no foreseeable civilian use—four huge bomber assembly plants at Marietta, Georgia, and at Cleveland, Chicago, and Oklahoma City; a score of modification centers for adapting standard-model planes for use in various theaters; and Ordnance and Chemical Warfare facilities for producing air force weapons and ammunition. Estimated to cost roughly $350 million, these projects were a substantial addition to the Engineer work load.25

After more than a month of intensive planning, calculations, and recalculations, a munitions plant program finally emerged on 17 January. At a meeting in General Harris’ office, plans firmed up for new Ordnance manufacturing facilities with a total estimated cost of $2.5 billion. Eight ammonium nitrate plants, 7 toluol, 6 small arms ammunition, 4 TNT, 2 smokeless powder, 2 tetryl, and one RDX would be built from the ground up. There would also be 10 new plants for loading shells, bombs, fuzes, and boosters, 3 for casting guns, one for producing gun tubes, one for making optical glass for gun sights, and one for assembling military power units. A large tank arsenal, two armor plate plants, a hull welding plant, and government-owned-and-built annexes to plants of railway equipment and other manufacturers would augment productive capacity. Most of the facilities constructed in 1940 and 1941 would undergo expansion. The Chemical Warfare Service proposed a less ambitious program, comprising one new arsenal, two new plants, and additions to existing capacity, and carrying a price tag of about $100 million. In succeeding months the program fluctuated with changing requirements. For example, the number of small arms ammunition plants dipped from six to five and the number of smokeless powder plants rose from two to three. Yet the basic plan, drawn in January, held up rather well. Superimposed upon a going billion-dollar plant program, the

overall industrial construction task to enormous size.26

To cope with the anticipated flood of equipment and supplies, the Army would need much more depot storage space. Excluding Air Corps depots, the Army had 85 million square feet of covered storage available or building in December 1941, roughly half the space required for the 3,600,000-man force contemplated for late 1942. Proposing “to keep ahead of the production program,” General Somervell announced plans in January for expanding existing depots and providing a dozen new ones, 7 for Ordnance ammunition, 3 for Quartermaster supplies, one for Engineer, and one for Medical. With the addition of 2 motor reception parks, the cost came to $280 million.27 As time marched on, this program grew. Ten holding and reconsignment points and 12 new supply depots, 6 Ordnance, 4 Engineer, and 2 Quartermaster, brought the total estimated cost to well over $400 million. Six air depots, ranging in cost from $2.3 to $23 million, pushed the total almost to the half-billion mark.28

Amid concern over the rapid growth of the building program, plans went forward for sheltering the expanding army. On 15 January 1942 housing was available for approximately 1,700,000 officers and men at posts throughout the country, and facilities for 500,000 more were under construction. From a welter of information—induction schedules, tentative troop strengths, and projected overseas movements, the General Staff computed additional requirements for 1942: accommodations over and above those already authorized for some 700,000 airmen and at least 425,000 ground troops. Proposals called for building dozens of new installations and expanding scores of old ones. Blueprints for advance planned cantonments and air stations were dusted off and readied for use. Meanwhile, to ease a critical shortage of canvas, General Gregory recommended converting all tent camps to hutments. Another big wave of mobilization construction was fast gathering force.29

Troubled by the prospect of “imposing again a tremendous burden of cantonment construction on the country,” Secretary Stimson looked for ways to economize.30 To find them was not easy. Long-range plans for sheltering additional troops incorporated the 800 series drawings for high-quality mobilization structures. Having expended so much effort and money on blueprints and layouts for advance planned cantonments, Somervell naturally hoped to build them. What other course was open? Because of the shortage of canvas, permanent tent camps were out of the question. Could existing stations be enlarged? Utilities systems would largely determine how far. Could plans for the cheap, light buildings designed for use in theaters of operations be adapted for use in the United States? Only with a great deal of work. A suggestion by Madigan raised questions of public relations and military discipline. Returning

Hutments, Fort Sill, Oklahoma, July 1942

aboard ship from a visit to Puerto Rico early in the war, Patterson’s adviser on construction had noted that Miami Beach was blacked out. Struck by the thought that the war would hurt resorts, he had come up with a scheme for leasing big luxury hotels. Under pressure from Stimson, Somervell at length found an acceptable solution. Five cantonments would be built according to plan. Beyond that, minimum standards would apply. The capacity of existing posts would be stretched to the limit. New housing would be theater of operations (TO) type. Whenever possible, the Army would lease or buy civilian properties, including resort hotels.31

Once the decision to pare requirements was firm, a command construction program for the ground forces took shape rapidly. First came orders to expand existing stations. Wherever land was available and water, sewer, and power systems could take the load, camp garrisons were to increase to 35,000 men. Next came directives for complete, new installations: twenty camps, six overseas discharge and replacement centers, and dozens upon dozens of lesser projects. Efforts began at once to acquire preselected sites, to pick additional ones, and to provide modified layouts and TO drawings. Late in January, when General Gregory won his case for converting tent camps to hutments, the burden grew even heavier. During the first four months of war, the estimated cost of all ground troop projects jumped $800

million.32 The total would continue to rise.

Construction plans for the four continental air forces and the several air training commands unfolded much more slowly. Clamorous demands for countless projects followed the outbreak of war. Requests for auxiliary fields alone numbered in the hundreds. On 17 January the Engineers learned informally that a $3-billion program was in the offing, though, as Colonel Plank observed, this figure was “obviously general and purely preliminary.”33 That same day General Arnold issued a call for “Spartan simplicity” and started “a complete overhauling of our plans and concepts.”34 Just what his plans would finally entail was not apparent for some months. During the first quarter of 1942 the Air Forces issued directives for roughly 200 command projects—tactical fields, pilot and technician schools, bombing and gunnery ranges, CAA airports, and miscellaneous stations. The number of projects doubled in the second quarter and doubled again in the third. Not until fall, when it passed the $1.5 billion mark, did the program begin leveling off.35

Available when Japan attacked were 75,000 hospital beds, 16,000 at general arid 59,000 at station hospitals. To care for the 3,600,000-man force would require fifteen more general hospitals and scores of new station hospitals with total capacity for about 100,000 patients. Surgeon General Magee wished to erect semi-permanent fireproof buildings of tile and concrete blocks, using plans prepared by the Quartermaster Corps in 1941. So did Robins, Groves, and other Engineer officers. Somervell went along with the idea for a time, but as pressure for saving labor and materials mounted, he withdrew permission for semi-permanent structures, first, at station hospitals arid, then, at. generals. Consequently, most medical facilities built after Pearl Harbor were of cantonment or TO type. Further savings resulted from take-overs of civilian hospitals and conversions of private schools and hotels. Nevertheless, the Army needed an initial $60 million in construction funds for general hospitals alone.36

The construction burden grew, as still more projects crystallized. A $50-million program of war-related civil works included flood protection for vital industries, channel improvements at key ports, and additions to important hydroelectric plants. Relocation centers for the west coast Japanese, though relatively modest in cost, introduced unusual complications. Special housing for the Women’s Army Auxiliary Corps (WAAC), emergency highway bridges across the Potomac, an airfield at West Point for cadet flight training—these and a host of other miscellaneous projects added

to the strain.37 Two secret undertakings begun in the summer of 1942 presented unheard-of difficulties. One was the Holston Ordnance Works, a huge industrial plant at Kingsport, Tennessee, designed around a new and untried process for making RDX. The other, by far the larger and more complex, was the Manhattan Project.

With the country at war, the Bureau of the Budget readily acceded to military requests and Congress acted swiftly to provide necessary funds. The supplemental appropriations voted soon after Pearl Harbor were dwarfed by subsequent money bills. In the spring of 1942 billions upon billions became available in lump sums titled “Expediting Production,” “Engineer Service, Army,” and “Seacoast Defenses,” unspecified parts of which were for military construction. The largest single direct appropriation in the history of construction came in late April, when Congress voted $5,275,000,000 for the Corps of Engineers. A direct appropriation of $2,438,000,000, approved on 2 July, was to be the last until late in the war. In a relatively short 7-month span, Congress had provided well over $10 billion in construction funds.38

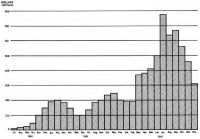

Rapidly, throughout the early months of war, construction directives multiplied. During February 1942 authorizations ran to $200 million a week; during March, to $500 million. The months that followed saw little slackening of the pace. There were many hundreds of jobs to be started, virtually all at once, and then forced through at top speed. To meet military goals for 1942, the value of work placed would have to average nearly $600 million per month.39 The challenge was unique in the annals of construction. Success or failure would depend largely upon the effectiveness of the newly consolidated construction forces under General Reybold’s command.

The War Construction Command

The weight of the mammoth war construction program fell on an organization in the throes of transition. The shift of building functions from one agency to another forced serious readjustments. Two systems had to be combined and two teams made to pull together. Policies and procedures had to be revised and channels of command realigned. Offices had to be relocated, units amalgamated, and personnel reassigned. Old ties had to be severed and new relationships formed. The upheaval was bound to cause turmoil and uncertainty. Likening every such change to “a major surgical operation,” Groves pointed out that “it usually takes several years to get an organization back on its feet.”40 In this case a speedy recovery was imperative, for the construction transfer

took effect only nine days after the Pearl Harbor attack.

Initial steps toward consolidation involved the two Washington headquarters. Early on the morning of Saturday, 13 December, movers started work. Day and night throughout the weekend, trucks rumbled back and forth between the New War Department and Railroad Retirement Buildings, transferring files and equipment. The merger took place the following Monday. General Robins, with Colonel Hardin and other members of his immediate staff, moved into Somervell’s old suite. Elsewhere in the Railroad Retirement Building, Engineer construction groups merged with branches of the former Quartermaster Construction Division. Reporting to Colonel Groves in Operations were the following sections: Fortifications, under Maj. Francis J. Wilson; River and Harbor, under Maj. Albert H. Burton; Flood Control, under Maj. Miles Reber; and Air Corps Projects, under Lt. Col. Ewart G. Plank. Reporting to Colonel Leavey in Engineering were Mr. McAlpine and his staff of navigation, flood control, and airport technologists. Minor elements of OCE, for example, labor relations and safety units, meshed into the old Quartermaster structure. The space occupied by the newcomers had housed the accounting, procurement, personnel, control, and public relations units, which joined General Reybold in the New War Building.41 Planned weeks in advance, the physical regrouping went off without a hitch.

In merging the top echelons of the two organizations, General Robins sought to preserve continuity and discourage contests for position. His immediate staff included men from both OCE and the former QM Construction Division. He named two executives, Colonels Hardin and Styer. As advisers he selected William H. Rose, a World War I Engineer general and retired Sears, Roebuck official who had recently returned to OCE as a civilian; Douglas I. McKay, whose background as Police Commissioner of New York City made him an ideal choice as consultant on protective security; and Mr. McAlpine. Initially, Robins retained all of Somervell’s branch chiefs. Changes in key personnel came about gradually, seemingly as a matter of course. Late in December 1941 Colonel Leavey left for duty in the British Isles to be replaced by Lt. Col. James H. Stratton, a graduate of West Point and Rensselaer Poly and lately district engineer at Caddoa, Colorado. Early in the new year Colonel Styer began devoting more and more of his time to helping Somervell with a plan for reorganizing the Army. One by one Styer’s duties devolved on Colonel Groves. It was Groves’ impression that Robins wished to replace him and that Somervell and Reybold kept him where he was.42 But friction, if it did exist, was below the surface. Topside, it appeared to observers, the transfer “just plain clicked.”43

At the operating level, problems were more numerous. Among members of the Quartermaster group, the transfer was decidedly unpopular. Many veterans of the long struggle to keep construction

General Hardin

in the Quartermaster Corps were bitter over the outcome. Many were uncertain of the future, fearful that the Engineers might not play fair with them. The military careerists wondered if they would be stigmatized as former Quartermaster officers. Civilians worried lest they be superseded by longtime Engineer employees. With the coming of Robins and his staff, the atmosphere of the division changed. Officers were more in evidence. Rules and procedures altered. A number of Quartermaster people had difficulty making the adjustment.

Concerned over this situation, Robins and his officers sought “to allay feelings of resentment and hurt among personnel coming from one proud organization to another.”44 They made special efforts to reassure members of the Quartermaster group and persuade them to stay with their jobs. Detailing his part in this endeavor, Hardin reported:–

I spent a great deal of personal time ... trying in some way to convince them, trying even to sell them, the idea of the Corps’ procedures and how badly we needed them. Maybe I did convince some to remain that might not otherwise have done so. ... It was, I am sure, a matter of great concern to all of us in the Chief’s office that we not lose any of these valuable people. We did our best to try to keep them within the Corps’ framework.45

But conciliation was slow work at best. It took time for members of the two organizations to learn to live together.

Involving several hundred offices throughout the country, consolidation of the field systems proceeded at a measured pace. The first step, taken on 16 December 1941, involved the quartermaster zones. At Boston, New York, Baltimore, Chicago, Omaha, and San Francisco, zone and district offices combined; and zone constructing quartermasters became assistants to various division engineers. At Atlanta, Columbus, and San Antonio, cities where the Engineers had no established organizations, zones changed into districts, with the former heads of zones as district engineers. The next move, absorption of the Quartermaster projects, 220 in all, was to be gradual. In a telegram to the field on 12 December, General Reybold pointed out the dangers of going too fast.46 Just before Christmas, division engineers received letters from General

Robins asking that they transfer no project until “the Division and District offices to which the transfer is to be made are fully prepared to take over the duties and responsibilities involved without delaying the progress of the work.” Warning against “blanket transfers,” Robins suggested that the limit for any district ought to be one major project a week. Several months would be necessary to complete the take over.47

In the field as in Washington, the shift caused some stress and strain. A few Quartermaster stalwarts, unwilling to cooperate with the Engineers, refused to discuss their work or delayed surrendering their authority. Many Quartermaster Regulars, unhappy over the transfer, debated whether to join the Corps of Engineers. One of the first to decide was Colonel Richards, former head of the Seventh Zone, who in late December asked to be relieved of construction duties in order to return to the Quartermaster Corps. Some twenty other Regulars, including such top men as Danielson, Burgheim, McFadden, and McIlwain, followed Richards’ example.48 Explaining his decision, General Danielson said: “The temptation to continue was quite strong. ... However, my service had been with the Quartermaster Corps and that was the determining factor in so far as I was personally concerned.”49 In an effort to counter this trend, Styer appealed to experienced construction officers who seemed to be on the fence. On 6 January 1942, he wrote to Colonel George:–

We had hoped that the qualified people who had been carrying on this work so successfully during the emergency construction program would like to transfer to the Corps of Engineers.

I do not know how much thought you have given to this matter, but I would like to see you make this step, and feel sure that the Chief of Engineers would like to count you among the officers of the Corps. ...

Identical letters went that same day to Dunstan, Hayden, Jabelonsky, Nurse, Thomas, and Vandervoort, all of whom eventually joined the Engineers.50 Giving the reasons for his action, Colonel Thomas said that although he was sorry to see the transfer come about, he wanted to stay in construction.51

As the dust began to settle, General Robins gave more authority to the field. He empowered division engineers to execute contracts in amounts up to $5 million and to approve virtually all plans and specifications and districts to make agreements involving up to $2 million and to furnish most designs. He also lodged direct responsibility for real estate, repairs and utilities, labor relations, and construction operations in the field. And he reaffirmed the channel of communications within the Corps—from Chief of Engineers, to division engineer, to district engineer, to area, and back by the same route.52 Boasting that “one phase” of construction was “going on as

usual,” General Reybold stated in March 1942:–

The Army Engineers still are operating on the principle of decentralization. We are still “giving a good man a job,” we are still “giving him the authority and the means,” and we are still letting him “go to it.” In time of peace this system was highly beneficial—in time of war it is more than beneficial—it is vital.53

Among the men on whom the Chief relied most heavily were the division and district engineers. As befitted their position, the division engineers were distinguished officers, proud of their profession, and steeped in the traditions of their Corps. All but one were West Point graduates, all had completed advanced courses at the Engineer School and the Command and General Staff School or the Army War College, and all had records of superior service in war and peace. With an average age of 55—two were 49, four were in their early 60’s—they were in order of rank and seniority: Brig. Gen. Max C. Tyler, Lower Mississippi Valley; Col. Warren T. Hannum, South Pacific; Col. Roger G. Powell, Great Lakes; Col. John N. Hodges, North Atlantic; Col. Richard Park, North Pacific; Col. C. Lacey Hall, Ohio River; Col. Frank S. Besson, Missouri River; Col. Malcolm Elliott, Upper Mississippi Valley; Col. Joseph D. Arthur, Jr., Caribbean; Col. John S. Bragdon, South Atlantic; and Col. Stanley L. Scott, Southwestern. The fifty-six district engineers were a more heterogeneous group. Twenty-two were non-West Pointers. Eight were retired Engineer colonels, who had returned to active duty in 1941. Five were former Quartermaster officers. Although one was over 70 and several were in their late 60’s, most of the district engineers were between 40 and 55. On the whole they were able men. Some were to attain high rank. Before the war ended, two would be major generals and nine, brigadiers. In the postwar period, Colonel Sturgis of the Vicksburg District would be Chief of Engineers.

Within the Construction Division, opinion differed as to how much authority should be vested in the field. Most Engineer officers shared the belief that in time of great emergency, a well-constituted organization could not be too decentralized. Floods, tornadoes, and other disasters had instilled the lesson that where minutes count, where lives may depend on speedy action, decisions must be made on the spot. Discussing the war construction program, Hardin said:–

It was too big for any strict control from the Washington office. Things were happening in the field at such a rapid rate that it was impossible for any group of men, no matter how competent they might be, whether they worked 24 hours a day or only 12, to influence the direction with too much detail. You could see what was happening and maybe guide the future. ... But if you held the reins on the people in the field who were so energetic and so enthusiastic about accomplishing results, ... you’d find them losing their initiative. ...54

Many who had served with the Quartermaster Corps questioned this thinking. From their viewpoint the Corps of Engineers appeared to have gone overboard on decentralization. This attitude

raised complications, some of which were quickly solved and some of which persisted.

Engineering, the largest of the Construction Division’s branches, adjusted most easily to the new pattern. When he succeeded Colonel Leavey in late December 1941, Colonel Stratton counted 1,400 persons on the Engineering roster, the great majority of them transfers from the Quartermaster Corps. “My immediate and first duty,” Stratton reported, “was to effect a decentralization.” Early in January he called in his section chiefs and gave them their instructions:– “Tell everyone we have a job for everyone in this branch, either here or in the field. ... I know many of the Quartermaster people particularly are worried. No one will be out in the street.”55 Gradually over the next four to five months, largely through transfers to district offices, he reduced the staff to about 500 persons.56 Stressing the importance of this move, he later said, “We would have bogged down hopelessly had we not effected decentralization of the engineering of the program.”57

Against stiff opposition, O’Brien modified the machinery for acquiring military real estate. With Patterson squarely behind him, the Real Estate chief had reason to expect that the Engineers would give him a relatively free hand. He intended to employ the same setup in the Engineer divisions as in the Quartermaster zones and to have the same personnel handle acquisition as before. But division engineers upset this plan by delegating responsibility to the districts, which had long procured land for civil projects. When O’Brien protested, Patterson backed him up.58 The division engineers held firm. General Tyler reminded Washington that the Lower Mississippi Valley Division had “been buying a great deal of real estate for a number of years and that we have maintained an excellent real estate organization in each of the three Districts.”59 Similarly, Colonel Hannum argued: “The present emergency requires that real estate operations shall be promptly and intimately coordinated with construction activities.” This, he asserted, could “be more readily accomplished by placing responsibility ... upon the District Engineer.”60 The division engineers appeared to be on solid ground; authority delegated to them by the Chief could be further delegated to the districts. For the time being, at least, the real estate function was decentralized—over-decentralized, O’Brien believed—to the district offices.

Of the Construction Division’s branches, only Operations continued to exert rigorous, centralized control. Direct contact with the projects, countless telephone calls, and frequent visits typified the methods of Groves and his lieutenants. Fully half of their action directives were oral. “Batting the right people on the head at the right time”

was one of their favored techniques.61 Clearly, this modus operandi did not square with decentralized control and formal channels. But Groves believed “it was simply not possible to accomplish the work on any other basis.”62 Maintaining close supervision over the jobs, frequently bypassing division and district engineers, he continued to run the show from Washington. Enlarged from 500 to 800 persons during the early months of the war, the Operations Branch functioned within the new framework much as it had within the old.63 Attempts to force it into the Engineer mold were largely unsuccessful.

Despite many trials and occasional frustrations, General Robins pressed steadily forward with the work of unification. By the last week in February he could report that activities, “both in the field and in the central office,” had been “combined, coordinated, and reorganized.”64 A short time later, General Reybold informed Congress that the merger had taken place “without disturbance either to construction progress or to the orderly procedure of our normal civil functions.”65 The Engineers were not alone in judging the operation a success. Particularly gratifying to them was a report from the House Military Affairs Committee that “the transfer of functions from one Corps to another was accomplished with a minimum of disturbance and without any disruption to the work whatever.”66

Hardly was the construction merger complete when a sweeping reorganization altered Engineer relationships with top echelons of the War Department. On 9 March 1942 the Army formed three overall commands—Army Ground Forces (AGF) under Lt. Gen. Lesley J. McNair; Army Air Forces (AAF) under General Arnold; and Services of Supply (SOS) under Somervell, who rose to three-star rank. The War Department General Staff and the Office of the Under Secretary contracted in size and limited their activities to high-level planning. Along with the other supply arms and services, the Corps of Engineers became an operating division of SOS.67 (Chart 16) During most of 1941 Reybold, as G-4, had exercised supervision over Somervell, then Chief of Construction. Now their positions were reversed. As before, the Chief of Engineers would report to the Secretary of War on civil matters, but on military programs he would report to Somervell.

The reorganization led to changes in the Construction Division. During March 1942 most members of the Construction and Real Estate Branch, G-4, transferred to Robins’ office. At the same time, Somervell began drawing personnel from the Engineers into SOS. Old titles were exchanged for new. General Styer became Chief of Staff, SOS, while Colonel Groves, at Somervell’s suggestion, became Deputy Chief of

Chart 16: Position of Corps of Engineers in War Department after 9 March 1942

Source: ENR, June 4, 1942, p. 79.

Construction, OCE. Col. Frederick S. Strong, Jr., who had headed the G-4 unit, succeeded Groves in Operations. When Mitchell went to join Somervell, Lt. Col. Clarence D. Barker reported from the Southwestern Division to head up Labor Relations. These shifts in the Construction Division lineup were to be the last for some time. Because Robins and Groves agreed that stability was essential, the central office organization in effect on 1 April 1942 (Chart 17) remained substantially unchanged until after the war construction program passed its peak.68

The organization in the field was more fluid. As military projects mushroomed and civil programs continued to decline, as the volume of work increased in some areas and decreased in others, and as unusual problems arose, General Reybold revised the map of the Engineer Department. He redrew boundaries and relocated headquarters. He created new districts and abolished old ones. He opened special offices, one at Wilmington, Delaware, to expedite approvals by the Ordnance sub-office, another at New Orleans, Louisiana, to facilitate purchases of lumber from Southern mills. In the spring of 1942, as construction activity increased along the eastern seaboard and in the region of the Rockies, he established three new Divisions—the New England, with headquarters at Boston, under Col. Beverly C. Dunn; the Middle Atlantic, with headquarters at Baltimore, under Col. Thomas F. Farrell; and the Mountain, with headquarters at Salt Lake City, under Col. Edward M. George. Designed by the Chief to further decentralization and improve administration, these changes won acceptance as a matter of course.69

Innovations which ran against established Corps principles were not well received. One highly controversial change was pushed through by O’Brien in the summer of 1942. At a mid-June gathering of division engineers, he announced that he was taking acquisition of real estate out of district hands. Citing examples of overly generous prices paid for land by district representatives, he asserted, “It has been impossible to rely upon appraisals submitted by the District Engineers’ offices.”70 A few days later, O’Brien issued instructions placing “all field real estate activities, civil and military,” under the exclusive jurisdiction of division engineers. District real estate sections were to shut down immediately.71 This order met stubborn resistance: protests flooded the Chief’s office; and compliance was slow. The attitude of the field was expressed by Col. William W. Wanamaker of the Denison District, who termed O’Brien’s approach “fundamentally wrong,” and by Colonel Hall of the Ohio River Division, who advised General Reybold that “a sudden change in procedure” was “impracticable.”72 At length, on 14 August, O’Brien issued a second order, instructing division engineers to take over district real estate sections and

Chart 17: Organization of Construction Division, OCE, April 1942

Source: OCE Orgn Charts, 20 March and 2 May 1942, EHD Files

organize them as division sub-offices, to be located in the same cities as the districts but, “if possible, in a space apart.”73 This time the divisions gave way. Describing the results, Sturgis wrote:–

Real estate sections in the Districts were abolished or a few retained only ... for the, by then, small number of civil projects. This worked out very poorly as District real estate sections long ago had learned the obstacles and the attitude of the American people—the hard way, if you please. They also knew well the local inhabitants and had a sense of fair play.

Strangers, unacquainted with local problems and local customs, O’Brien’s representatives antagonized owners in the Vicksburg area and “created angry attitudes” toward the War Department. “In sum,” Sturgis stated, “land acquisition for military projects ... should have been left with the Districts.”74 Rightly or wrongly, the issue was settled. For the duration of the war, district engineers had little or nothing to do with acquiring real estate.

A struggle with General Somervell overshadowed the intra-Corps conflict over real estate. Upon the reorganization of the Army in March 1942, the nine corps areas had come under Somervell’s command. Precisely what their role would be in SOS was not clear at first. Several months went by. The corps areas grappled with confusion, while Somervell’s headquarters studied the question.75 Finally, the answer came. On 22 July Somervell changed the name of the corps areas to service commands and clothed them with direct responsibility for “supply, personnel, administrative, and other service functions.” The service commands under Somervell’s authority would carry out all Engineer missions, except major new construction and related real estate activities. As a member of Somervell’s staff, the Chief of Engineers would furnish technical advice and direction. Division engineers would wear two hats, the customary one for new construction and a second for duties as directors of real estate, repairs, and utilities on the staffs of the service commanders. Thus, Somervell returned to the service commands functions he had taken from the corps areas in 1941:– post maintenance; the operation of utilities; and leasing and acquisition connected with command activities. According to him, the new setup was “indispensable to the proper conduct of this war.”76 General Reybold saw it differently. Work for which he was responsible was assigned to commands over which he had no direct authority—a violation of accepted organizational principles. In Reybold’s words, the system was “a mess.”77

Opponents were unable to block the plan. Protesting division engineers discovered that the Chief’s hands were tied. When Colonel Farrell called from Baltimore on 23 July, predicting trouble “if we’re in the chain of command through the Commanding General here,” Groves advised him: “That was all very pointedly discussed. You know who’s doing it. There is nothing that I know

of that we can do about it.”78 Wishing to keep all real estate activities under O’Brien’s firm control, Patterson did attempt to do something. On 31 July he wrote to Somervell:–

In connection with the Service Command reorganization, I am concerned that the purchasing and leasing of real estate is made a responsibility of the Service Commands, rather than of the Chief of Engineers.

As you know, the Real Estate Section of the Office of the Chief of Engineers, formerly with the Construction Division of the Quartermaster Corps, has been run most effectively since you went with the Construction Division in January 1941. The work of purchasing and leasing real estate is one that is likely to lead to scandals, and it will be much harder to control if it is scattered in the nine Service Commands.79

Patterson’s letter had no apparent effect. Somervell continued on his course.

On 10 August, professing “a bold disregard for anachronistic precedents,” he promulgated the basic organizational directive for the service commands. Nine division engineers reported to service commanders for additional duty as Directors of Real Estate, Repairs and Utilities. (Table 14) In their new capacity, these nine would operate outside Engineer channels. They would do their work as directors “under the complete jurisdiction of the Service Commander.” Any instructions they received from the Chief of Engineers would have to come through Somervell and the commanding generals. Their territorial jurisdiction would extend to the boundaries of the service commands, which differed widely from the boundaries of the Engineer divisions.80 Not only would the division engineer-directors serve two masters and perform two sets of duties, they would also have two geographic limits to observe.

With nine service commands, each comprising a cluster of states, and thirteen Engineer divisions, each conforming geographically to a major watershed, confusion was inevitable. Many post commanders had to deal with two division engineers, one for major new construction and another for leasing, routine purchases of real estate, maintenance, and repairs. As engineer of the Ohio River Division, Colonel Hall supervised new construction at Camp Forrest, Tennessee, which lay within the jurisdiction of the Fourth Service Command’s Director of Real Estate, Repairs and Utilities—the South Atlantic Division Engineer. At Camp Millard, Ohio, Hall wore his second hat. There he represented the Fifth Service Command, while the Great Lakes Division oversaw construction. Bitter complaints came from service commanders who found the setup troublesome.81 By the fall of 1942 there was general agreement that command and division boundaries ought to be coterminous.

Opinions differed as to which boundaries should obtain. Since the fall of 1941, Somervell’s thinking on the subject had not wavered. Then, he had unsuccessfully advocated redrawing division boundaries to coincide with those of the corps areas. As recently as June 1942 he had renewed this

Table 14: Division Engineer Service Command Assignments

| Divisions | Service Command |

| New England | I |

| North Atlantic | II |

| Middle Atlantic | III |

| South Atlantic | IV |

| Ohio River | V |

| Great Lakes | VI |

| Missouri River | VII |

| Southwestern | VIII |

| Mountain | IX |

Source: WD SOS, Services of Supply Organizational Manual, 1942.

recommendation, but Reybold had demurred. Now the question had come up again. The Engineers offered a proposal for dividing the Ninth Service Command into two parts to make a tenth and for moving the boundaries of the other commands. Although Somervell apparently considered this solution for a time, he at length decided to leave the commands as they were.82

Late in October 1942 General Reybold announced a plan for realigning the Engineer divisions. While bowing to Somervell’s demands, he endeavored to preserve the essential features of the permanent organization for civil works. The Chief’s plan was somewhat complex. Under it, there would be eleven Engineer divisions. (Map 3) Nine would have both military and civil functions. For war construction, real estate, and repairs and utilities, their boundaries would be identical with those of the service commands. For navigation and flood control work, their boundaries would follow major watersheds. The two divisions in the Mississippi Valley would have only civil projects and their borders would remain unchanged. Districts normally would have either civil or military missions, seldom both. District boundaries would be flexible, extending sometimes into two divisions; but no district engineer would report to more than one division headquarters. During November, after details were out of the way, districts received their assignments. The North Pacific, South Pacific, and Mountain Divisions combined to form the Pacific Division, with headquarters at Salt Lake City. General Hannum would head the new division. On 1 December 1942 the plan went into effect.83

Reshaped, consolidated, and decentralized, the organization for military construction attained a high level of efficiency during the year following Pearl Harbor. An amalgam of several and at times opposing elements, a product of different and at times discordant views, the organization nevertheless

Map 3: Boundaries of Engineer Divisions, December 1942

Source: Incl to Ltr, Reybold to Div Engrs, 27 Oct 42, EHD Files.

withstood the strains imposed upon it. Despite some initial creaks and groans, the new machinery in the end proved equal to the challenges of war.

The Big Push

Seeking early in 1942 to describe the construction task ahead, General Reybold said, “I must borrow a word from Hollywood: the job is colossal.”84 In this context, that tired, oft misused adjective seemed appropriate. The undertaking was truly gigantic, dwarfing those previous great endeavors, the building of the Panama Canal and the emergency construction programs of 1917–18 and 1940–41. In urgency, complexity, and difficulty, as in size, it surpassed anything of the sort the world had ever seen. The speed demanded, the sums of money involved, the number and variety of projects, the requirements for manpower, materials, and equipment, and the problems of management and organization were unparalleled. So formidable was the enterprise that some questioned whether it was possible.

The Chief of Engineers had few doubts on that score. He knew the Corps to be a great construction organization unequaled in experience, size, and capability. In the past, whenever a job had come up that no one else could do, the government had called upon the Engineers. There had been no failures and there would be none now.85 The 1930s had been a decade of peak activity in civil works. Recalling the Fort Peck and Bonneville Dams, the work along the lower Mississippi, and the projects at Pittsburgh, Johnstown, Muskingum, and scores of other places, General Reybold said: “We have had, so to speak, a tune-up bout for the championship fight that is now upon us.”86 Seasoned by more than a year of high-pressure defense preparations and strengthened by the transfer of the Quartermaster Construction Division, the Engineer Department, in the Chief’s opinion, was capable of shouldering an even heavier load than the one thrust upon it by the war.87

Reybold’s approach to war construction problems was consistent with this thinking. Convinced that the Corps knew how best to organize and to get results, he made no changes in basic policy following the outbreak of hostilities. Instead, he stuck to traditional principles and applied time-tested formulas. Holding with most of his fellow Engineers that decentralization was the art and heart of war, he placed his main reliance on the field, regarding the divisions as “our fundamental unit” and their decision-making power as “the negation of red tape.” Shortly after Pearl Harbor he announced that the era of fixed-fee contracts was over. He intended to use the Corps’ “old standby,” the fixed-price contract, in all but exceptional cases.88 Having what he

thought to be the right setup and the right procedures, Reybold did not immerse himself in construction matters. Adopting the attitude that the Chief of Engineers was “too big a man” to worry with details, he left the direction of the program largely to others. Construction, as he put it, was “pretty well delegated down.”89

Too great for one man, the burdens of leadership were shared by General Robins and Colonel Groves. One of the Engineers’ most respected senior officers, Robins had a reputation for sound judgment, cool-headedness, and tact. Friendly with top men in other branches, he moved easily in high circles of the War Department. Subordinates responded to his fatherly personality with loyalty and affection. Recalling their relationship, Hardin later said: “His calm forthright manner under all conditions and especially in periods of stress and criticism, his consideration of others, keen perception and ability to come to quick firm decisions made him an ideal superior to work for.”90 Colonel Groves, whose appointment as Robins’ deputy in the spring of 1942 confirmed the position he had occupied since shortly after the transfer, was noted more for forcefulness than for diplomacy. Critical and demanding, he was as unsparing of himself as he was of others. Each of these men assumed the role he was best equipped to play. Robins charted the overall course and dealt with persons outside the Corps, while Groves, acting under him with full authority, took charge of production.

Stepping up the pace was their first order of business. Soon after war was declared, a drive was under way to expedite all urgent projects. On orders from the Chief’s office, division and district engineers took the initiative. They relied heavily on overtime and continuous shifts, enlarged work crews, and offered premiums to contractors and material-men for early deliveries. They also diverted equipment and supplies from civil to military jobs, eliminated nonessential work, and employed virtually every known timesaving device.91 All this was merely the beginning. Discussing what had to be done, General Reybold pointed out:–

To increase the tempo of all work and to accelerate the completion dates of all projects requires an almost perfect balance and timing of and for land acquisition, preparation of plans and specifications, approval of locations, layouts, and designs, assemblage of field forces, procurement of material, coordination and direction.92

He thus emphasized the need for systematic planning and concerted effort.

In the first hectic weeks after Pearl Harbor, while consolidation was going forward and the huge war program was taking shape, Robins and Groves pressed for solutions to longstanding difficulties and tried to anticipate future troubles. They launched fresh attacks on old, familiar problems—delays traceable to using services, careless selection of sites, bottlenecks in design, and low priorities. After weighing probable requirements against resources, they ordered further savings of materials and equipment. Confronted with a shortage of

contractors for large and complicated jobs, they tested a scheme for stretching the capacity of experienced firms. By probing continually for weak spots in the system, for potential sources of delay, they hoped “to foresee problems before they arise and to have planned solutions and planned policies ready for promulgation at the proper time.”93

In the interests of speed and efficiency, General Robins urged the using services to fall into step with the Engineers. Emphasizing that close coordination at the local level would reduce confusion and minimize delay, he called on them to decentralize approvals. Response to this appeal was mixed. The Chief of Ordnance and The Surgeon General refused to relax their control over designs and layouts. General Arnold, on the other hand, was willing to make concessions. Early in 1942, he delegated authority for approving layouts to the field.94 At the same time, he relieved Colonel Kennedy as head of the Buildings and Grounds Division and replaced him temporarily with Col. Walter J. Reed. An Engineer officer, Col. James B. Newman, Jr., became Reed’s deputy and after a few months succeeded him. Relations with the Air Forces improved markedly. “As soon as we got Walter Reed in there, lots and lots of things smoothed out like that,” said Plank, snapping his fingers, “and then, when Jim Newman got a little tighter hold, many other little things smoothed out immediately. ... We were brothers working together—some friction, of course, but not significant.”95

Concerned by forecasts of crippling supply shortages and belated deliveries, Robins launched determined assaults on problems of requirements and procurement. To strip designs to bare essentials, curtail the use of critical materials, and keep shipments flowing to the projects were high on his list of objectives. A sustained Corps-wide effort to achieve these ends featured a whirlwind revision of structural plans directed by Colonel Stratton, the saving of huge quantities of critical materials through the work of Harry B. Zackrison, and the choice of the Construction Division as the principal lumber purchasing agent for the federal government. This effort was crucial to the success of the program as a whole. Its story constitutes an important chapter in the history of wartime construction.96

To improve methods of choosing sites was another of Robins’ aims. With the advent of war, engineering aspects of site selection took on increased importance. If contractors were to meet accelerated schedules, they must have sites which lent themselves to high-speed construction methods. No time and effort could be spared for extensive clearing, grading, and draining, and no scarce equipment could be diverted to such work. “I know of no better security in the fulfillment of the responsibility of the Engineer Department for expeditious and economical construction,” Robins wrote, “than to assist in initial selection of sites which facilitate rather than

hinder construction.”97 Supported by Somervell in G-4, he persuaded the General Staff to put Engineers in charge of site investigations for cantonments and general hospitals. Although corps area and medical officers would normally assist them, district engineers would conduct surveys and prepare reports. Subject to G-4 approval, selections would be up to the Chief of Engineers. Unable to gain a larger role in locating plants and airfields, Robins stressed the importance of Engineer membership on site boards and the need for a proper engineering evaluation of each proposed site. He insisted that all concerned maintain vigilance to prevent costly mistakes.98

Not the least of Robins’ worries was personnel. In January 1942 the Engineer construction establishment in Washington and the field included some 1,600 officers and 70,000 civilian employees. Even to maintain this strength was difficult enough in the face of demands for troop-age officers to serve with units, heavy selective service levies, and competition from industry and from other war agencies. To increase it vastly, as Robins had to do, was a Sisyphean labor. The Engineer reserve was practically exhausted, and most retired Regulars who were able to serve had returned to active duty in 1941. The usual sources of trained administrative personnel were running dry. Only by commissioning men from civil life, searching endlessly for undiscovered talent, refusing to let employees transfer to other government bureaus, opening more jobs to women, and occasionally winking at applicants’ qualifications was the Engineer Department able to build up to a peak strength of approximately 4,700 officers and 180,000 civilians by the mid-summer of 1942.99 The inexperience of many of these people was a disadvantage that could not be entirely overcome.

Directing part of his abundant energies into planning an accelerated plant construction program, Colonel Groves came to grips with several pressing problems. The first had to do with design and supervision. The few concerns qualified for highly complex munitions jobs were already heavily overloaded. Using untried firms would entail serious risks. As a way out of this dilemma, Groves suggested a “master design and procurement” contract, under which a single company would supply drawings, furnish consulting services, and purchase process equipment for a group of projects. In early 1942 the first such agreement, for three TNT plants, Lake Ontario, Longhorn, and West Virginia, went to DuPont.100 A second problem had to do with process machinery. By taking various expensive shortcuts, the Engineers could trim several months from plant completion schedules. The question was whether deliveries of machinery could keep pace with construction. “We are making use of the only known means of improving delivery,” Groves reported

on 2 January 1942, “applying for AA priority ratings on appropriate items and authorizing increased payments for overtime worked by vendors.”101 He soon contrived additional means, sending top government expediters to plants producing equipment and calling on experienced contractors, such as E. B. Badger & Sons and Stone & Webster, for assistance.102 While it was Groves who put these ideas across, much of the credit for them was due Creedon, whose ingenuity and expertise were major factors in the success of the munitions program.

Combating delays at current projects was also in Groves’ department. In the first weeks of the war—the program as a whole was then slightly ahead of schedule—scarcely more than a handful of major projects were behind. Immersed in the details of the transfer, in carrying the big Quartermaster organization over to the Engineers “practically singlehanded,” as Hardin put it, Groves relied on his principal assistants to push construction, Creedon at munitions plants, Daley at ground troops projects, Plank at airfields, and Davidson at ports and supply depots. From time to time, he dispatched specialists from the Chief’s office to trouble spots in the field: for example, he sent Zach to assist with a difficult layout at Camp Wood, Missouri, and Kirkpatrick to investigate problems with the sewage system at Camp Stewart, Georgia. The Pentagon, a center of public interest and a magnet for politicians, was one of the few projects to which Groves gave close personal attention in the early winter of 1941–42.103 This period of relative calm along the operations front did not last long.

As the avalanche of war directives descended on them, the Engineers began to fall behind. Each week saw a widening of the gap between the estimated cost of the program and the value of construction in place. During January 1942 new directives totaled $670 million and the value of work put in place was $210 million. During February, these figures were $800 million and $200 million, respectively. Meanwhile, the number of jobs behind schedule increased from 50 on 31 December to 76 on 28 February and the number not started rose, alarmingly, from 60 to 193.104 Unless the pace accelerated greatly, the program would bog down.

Flooded with orders, the Construction Division threatened to become a bottleneck. Reduced, as the Engineers decentralized, from 3,000 members in mid-December to 2,200 on 1 March, the staff was hard pressed to cope with the heavy new demands laid upon it. As one officer remarked, there were simply not enough people to “crank out” that much work. Moreover, the presence of two groups in the office, one accustomed to Engineer methods of operation and the other not, sometimes made for misunderstanding. Under the

Colonel Sturgis

circumstances, confusion and delay were inevitable. Papers choked the in-baskets. Decisions were slow. As of 24 January there were 18 major directives which had been in the office awaiting action for two weeks or move.105

The points of sharpest impact were in the field. Districts and divisions, though strengthened by participation in defense construction, were nevertheless unprepared for the tidal wave that hit them in early 1942. Colonel Sturgis’ troubles illustrated what the field was up against. Prior to 1941 the Vicksburg District had expended an average of $10 million a year for civil works. Totals for 1942 would probably reach $14 million for civil and $46 million for military projects, an increase of 500 percent. Yet since 1940, the district’s personnel strength had increased only 55 percent, from 320 employees to 500. Appeals to the Civil Service Commission, the Chief’s office, and other Engineer districts for qualified men had been of little avail. An advertising campaign was producing scant results. By February 1942 Sturgis was at his wits’ end to know where to turn. And Vicksburg, which had ranked fifth among the prewar districts according to volume of work, was better off than most. One effect of understaffing was the growing backlog of directives awaiting action by districts and divisions.106

A certain dualism characterized the newly consolidated organization—the Quartermaster Corps of Engineers, some jokingly called it. Many area engineers in charge of important projects had served as Constructing Quartermasters. Accustomed to being largely independent and to dealing direct with the Washington office, they tended to resent control by districts and divisions. Commenting on this situation, Groves said:–

There was a considerable amount of friction from time to time between outstanding Area Engineers ... and their District and Division Engineers. It must be remembered that in many instances these Area Engineers had had over a year’s experience in this type of construction ... and it was not surprising that they would know more of the details and even more of the general problems than a District Engineer who had not had the same experience.107

Most district engineers viewed the matter differently. In a speech to fellow

officers of the Lower Mississippi Valley Division, Colonel Sturgis caustically remarked:–

Sometimes I get quite embarrassed at the old time-worn methods under which we operated until the great metamorphosis took place. ... Under the old system, when I wanted to get instructions about a project, I went to the Division Engineer. Now, I get them from the Area Office. ... After all, it’s the Area that’s doing the job and all we’ve got is the responsibility.108

Division engineers were strongly in favor of time-worn methods and time-honored channels, and evidently Robins was too. But Groves, proceeding along “the path of speed and action” he had followed in the Quartermaster Corps, often short-circuited districts and divisions to exercise centralized control. Whether this state of affairs caused delays was debatable. In fact, as some conceded, it may have helped keep everyone on his toes. That it produced conflicts was beyond doubt.109

“The great problem,” as Groves saw it, “was to combine the Engineer and Quartermaster procedures and to see to it that this amalgamation not only was efficient in the end but that it was efficient at the very start.”110 His analysis was sound. But his solution to the problem ran against the Engineer grain. Reflecting the attitude of most Engineer Regulars, Hardin reminisced:–

I thought it was bad ... taking responsibility out of the hands of the decentralized organization and trying to run the show from a Washington office. I always agreed and I would say so today that there are times and there are conditions when direct contact from the Washington level to the job area may be necessary. But it is always a highly desirable thing at least to contact the responsible official in the field and tell him what you did and why you did it. Now General Groves might not always have done this. ... He was working under great stress and time didn’t permit him, maybe, to call these District Engineers and say, “I have contacted your area officer and told him so and so.”111

Commenting further, Hardin wrote:–

The belief that direct contact from a branch or division chief in OCE was a preferred and necessary procedure was very difficult to change and control, but the backlash from the District or Division Engineer when such procedures were employed was generally prompt and vigorous.112

On their visits to Washington, division engineers seemed to avoid Groves, but they seldom missed an opportunity to complain to his superiors. When these complaints were unavailing, some tried obstructive tactics. For example, General Tyler advised Sturgis not to answer telephone calls from Washington.113 Balancing the feeling against Groves within the Corps was Somervell’s strong faith in his ability and the Engineers’ awareness of that faith.

In January 1942 Somervell named to the top G-4 construction post a man after Groves’ own heart. Chosen to succeed Colonel Chamberlin as head of the Construction and Real Estate Branch was Col. Frederick S. Strong, Jr. A 1910 West Point graduate, Strong had been an Engineer officer until 1919, when he resigned from the Army to go into the

real estate and land development business. From 1927 to 1941, he was a member of the Booth Investment Company of Detroit, serving successively as vice president, president, general manager, and director. Recalled to active duty in 1941, he had served as Constructing Quartermaster of the most important zone, the Fourth, and later as district engineer at Atlanta. Commenting on Strong’s appointment to G-4, Groves observed:–

During his service in Atlanta as Zone CQM, Strong had been thoroughly indoctrinated with my viewpoint that no delay was excusable and that most delays were caused by slowness in decision, not only on the site, but in the higher echelons. Strong was a brilliant man. He stood Number One in his class and had lost none of his intellectual keenness. His criticism of other people’s work was always extremely sharp.

Wishing to keep this valuable officer on his own team, Groves opposed Strong’s assignment to the G-4 post; but Somervell, as usual, had his way.114

Strong soon made his presence felt. Visiting the Construction Division and traveling widely throughout the country, he questioned officers and key civilians as to their difficulties and complaints. Stepping up inspections by members of his staff, he obtained detailed reports on a number of major projects. Poring over the Engineer progress reports, he grasped an overall view of the program. His first move came on 12 February, when he turned over to Somervell a list of 14 important projects that were “substantially behind schedule” and also warned him that architect-engineering on the Pentagon was not keeping pace with construction. Somervell promptly wrote to Reybold, asking what steps he was taking to correct the deficiencies Strong had noted.115

Replying to Somervell on 25 February, Robins stressed extenuating circumstances. Unusually severe weather had hampered construction at many of the projects Strong cited; at Schenectady General Depot it had been too cold to lay bricks without protection, which was “not covered under the terms of the lump sum contract in force.” Owing to low priorities, several jobs had fallen behind while waiting for delivery of materials. Delays at several others were traceable to the Air Corps, the Public Roads Administration, or the Ordnance Department. In the case of Fort Sam Houston, shown as 31 days behind but actually on schedule, Strong had been misled by a typographical error in the progress report. With better weather, higher priorities, and additional overtime, most of the projects were now moving along in fine style. Design work on the Pentagon was picking up speed.116 Whatever reassurance Somervell might have gained from Robins’ memo was dispelled by the next bimonthly progress report. On 2 March, after seeing the latest report, he advised Reybold: “In general, the whole program is not moving along as rapidly as might be desired or as is consistent with the ‘All-Out Effort’ for War.” Gratuitously he added, “Present exigencies demand an extraordinary effort.”117

That same day Strong launched a

slashing attack against the Engineers. In a report to Somervell, which featured examples of “inordinate delay,” he said:–

It seems evident that the present tempo of the Construction Division derives from the conservative practices of the Engineer Department under its normal program and that the more flexible and dynamic operations required under present conditions are bogging down in a mass of administrative impedimenta. Some of the things I feel are wrong under present war conditions, when we must get the work done not a minute too late, are:–

Confusion and indecision in the Central Office, with a hodge-podge of control on some matters and attempted decentralization on others; hence, confusion in the various lower echelons as to the responsibility of each.

Too many echelons: Central Office, division, district, area, and even job offices.

Too many old officers and old civilians thinking in terms of peacetime Engineer Department procedure.

Lack of flexibility in employing certain engineering talent, in design, in use of materials, and general lack of ingenuity in solving problems and getting the work going.

Moreover, he complained, district engineers were “so enmeshed in administrative detail” that they had no time to keep abreast of what was going on at their projects. Strong predicted that unless the system promptly received a thorough overhauling, the program would fall further and further behind.118 Somervell passed the report on to Reybold with the comment that some of the delays seemed “inexcusable.”119

Before the Engineers could respond, changes overtook them. On assuming command of the Services of Supply, Somervell acted swiftly to insure aggressive leadership. To head his Control Division, he chose his longtime associate and fellow Engineer, Col. Clinton F. Robinson, widely known as “Somervell’s hatchet-man.” Robinson’s attention promptly focused on the construction program. Meanwhile, at Somervell’s insistence, Groves became Deputy Chief of Construction and Strong took over the Operations Branch.120 Soon after these appointments, a call went out for division and district engineers to meet in Washington.

Arriving for the conference, the field officers were in no mood to admit to serious shortcomings. Their general feeling was that the record spoke for itself. Between 7 December 1941 and the last day of February 1942, they had started construction at the unheard-of rate of $200,000,000 per week.121 While struggling under the crushing load of directives, combating shortages of various kinds, and battling winter weather, the Engineer Department had scored impressive gains. Momentum was increasing. Districts and divisions were gearing up as rapidly as possible. A great thrust forward would come when the weather broke. Continued harassment and interference from Washington would only hinder the work. As a group, the division and district engineers regarded Robins’ new deputy with antipathy. Some senior officers were heard to mutter the phrase “too big for his britches.”122

Among the items on the conference agenda were progress reports and

relations with contractors. The Quartermaster Corps had approached these matters one way; the Engineers, another. Somervell had prepared his progress reports with an eye to official and public reaction. The emphasis was on accomplishment. Progress was equated with expenditures, and wasteful projects often made a better showing than efficient ones. Other devices—for example, use of the term “beneficial occupancy”—tended to magnify what had been done. Engineer reports, prepared for budgetary purposes, were far more conservative. Despite its obvious advantages, the Somervell system had won few adherents among the Engineers, who generally regarded it as “full of gimmicks” and somewhat shady. Accustomed to having the final say in their relations with contractors, Engineer field officers were also highly critical of CQM-contractor relationships.123 Getting along with the contractors had been a primary requirement for the Quartermaster field. Discussing this “most heinous” of Quartermaster “sins,” Sturgis recalled:–

On taking over the Minden, Louisiana, Shell Loading Plant, I asked the CQM what was his most difficult problem and he quickly replied: “Obedience from the contractor. Make a decision he does not like and off he flies to Washington, not only to get your decision reversed but sometimes to get you fired.”. ... Responsibility without adequate authority over the contractor ... was by far the worst characteristic of CQM operations and was the cause of secondary failures.124

Needless to say, suggestions that the Engineers adopt these Quartermaster methods evoked little enthusiasm.