Chapter 5: The Tunisian Campaign

As soon as the Allies concluded an armistice with the French, British units of the Eastern Task Force struck by air, sea, and land toward Tunis. With this port in Allied hands, the Axis hold on North Africa would be broken. On 12 November 1942, British commandos and paratroopers converged on Bone, 135 miles west of Tunis, but German units had begun flying into Tunisia from Sicily and the mainland of Italy three days earlier; by the twelfth they were arriving by sea.1 Before the month was out the British 78th Division with its Blade Force (which resembled a U.S. armored combat command and included an American armored battalion) drove to the outskirts of Djedeida, less than sixteen miles from Tunis. But five months would pass before the Allies reached Tunis. The rapid Axis buildup and a lack of air support (Allied planes were mired in the mud of fair-weather fields) brought the British offensive to a halt. By Christmas Day AFHQ had canceled immediate attack plans, for a much larger push was in prospect. The Allies were faced with building sufficient strength in Tunisia to crush the expanded German and Italian forces.

The British First Army, moving over the long land route east from Algiers, built up its strength in the hill country around Bedja. Elements of the American II Corps arrived from faraway Oran to take up positions east of Tebessa whence they could threaten central Tunisia; poorly equipped French forces were deployed along the Eastern Dorsal as a link between the British and the Americans. By mid-January II Corps elements had concentrated in the Tebessa-Kasserine region, and on the eighteenth the enemy began exerting pressure against the center of the Allied line, which the French held. These operations, continuing until early February, pulled additional American units into action but weakened Allied defensive positions along the Eastern Dorsal. The stage was being set for a swift, hard blow by enemy armored units, and the German-Italian Panzer Army had reached a strong defensive position (the Mareth Line) near the southeastern Tunisian border. Since it would be weeks before the British Eighth Army under General Sir Bernard L. Montgomery could mount an offensive against this position from the east, German panzer units from the north and south teamed up for an assault designed to overrun II Corps

and force the British First Army into a general withdrawal westward.

The main attack poured through Faid Pass on 14 February, sweeping elements of the U.S. 1st Armored Division before it and isolating American troops on solitary mountains: When the assault began, three U.S. divisions were in Tunisia, all rather fully committed along some one hundred miles of front. Before it ended eight days later, enemy tanks had swept through Kasserine Pass and struck some seventy miles deep into II Corps territory, coming dangerously close to a large Allied supply dump at Tebessa and a key road center at Thala. Allied armored reinforcements, along with increasing support from the XII Air Support Command (U.S.) and Montgomery’s buildup against the Mareth Line in southeastern Tunisia, combined to compel a German withdrawal, which began 23 February.

Two more phases of the campaign, both offensive, followed for II Corps in Tunisia. On 17 March the bulk of II Corps, aided by air strikes, pushed through Gafsa toward Maknassy and Gabes. This limited offensive was timed to draw off German reserves from the Mareth Line while Montgomery cracked through from the south. Montgomery’s offensive began on 20 March and during the next three weeks drove the enemy back into a small bridgehead around Tunis and Bizerte.

Squeezed out of the action by Eighth Army’s advance, II Corps moved north across the British First Army supply lines to take over British 5 Corps positions near Bedja. On 24 April the American force began the final phase of the Tunisian campaign, an attack through the hills near the north coast of Tunisia toward Bizerte. On its right, the British First Army, also driving eastward, pressed the attack on Tunis in conjunction with Eighth Army, pushing north from positions near Enfidaville. On 7 May American units first entered Bizerte. Tunis fell to the British, and by the thirteenth organized Axis resistance in Africa had ended.

Engineer support of air and ground operations in Tunisia had to take into account the terrain and the weather. In central Tunisia, where the main American effort took place, the terrain was quite different from the hilly area around Bizerte and Tunis in the north, where the British First Army began its buildup. From a wide, semi-arid plateau of sandstone and clay rose two ridgelines, the Eastern and Western Dorsals, which came together at a point south of Pont-du-Fahs. The Eastern Dorsal extended almost due south from Pont-du-Fahs for over 125 miles to Maknassy; the bolder Western Dorsal angled away to the southwest toward Feriana. Clay roads snaked through at a few points and two ribbons of asphalt macadam crossed to the sea, one through Sbeitla to Sfax, the other through Gafsa to Gabes. Except for bits of verdure, the landscape offered little color. Central Tunisia had no perennial streams and few trees except for a pine forest that hugged the hills from Bou Chebka through Kasserine Pass and north toward Thala.

Control of the passes through the two ridgelines was the key to hundreds of square miles of wadi-scarred tableland that lay between. Once through the passes, armor could range cross-country with comparative ease during dry weather. During the winter months rainfall

turned the flats into mud and made vehicular movement difficult on all but a few hard-topped roads.

By the time II Corps began to move into Tunisia early in January, the rainy season was more than a month old. Northern Tunisia and Algeria have an annual rainfall of about twenty-five to thirty inches, almost all between late November and early March. These rains were instrumental in keeping Allied planes on the ground and halting the first Allied drive on Bizerte and Tunis. The nearest hard-surfaced Allied airfield was a small one near Bone, in Algeria. Allied planes at hastily graded airstrips nearer the front soon became hopelessly mired in mud, whereas Axis planes, flying from hard-surfaced airfields only minutes from the battleground, ranged virtually unopposed over the front. Until drier fields could be found or all-weather ones built, Allied airpower could do little toward winning superiority or cutting the enemy’s air and sea supply routes from Sicily.2

Aviation Engineer Support

The North African invasion employed American aviation engineer units available in England or summarily assembled in the United States, and in the days after the successful landings they foundered amid a number of uncontrolled circumstances. The 809th, 814th, 815th, and 817th Engineer Aviation Battalions landed with the Center Task Force. From the United States came a battalion of the 21st Engineer Aviation Regiment, the prototype of its kind, and the 887th Engineer Airborne Company and the 888th Airborne Engineer Aviation Company. With the exception of the 21st Engineer Aviation Regiment, the units were hastily formed and sketchily trained. The 809th, though experienced in airfield construction in England, had to draw 150 enlisted men from the 832nd and 157 from the 825th in the United Kingdom to achieve its allotted strength. The 887th and the 888th were thrown together in the United States just weeks before the convoy sailed, and none of the units had any inkling of the conditions of forward airfield construction in a fluid campaign.

Charged first with resurfacing damaged runways near the larger cities within the landing zones, the American units were to support air operations including patrols over Allied lines of communications along the coast west of Algiers; east of that city, according to the invasion plan, British Airdrome Construction Groups were responsible for forward fields supporting the move toward Tunisia. Within this division of labor, the American aviation engineers were to construct six fields ringing the borders of Spanish Morocco on the possibility that the Axis might mount an offensive against the Allied bridgehead through the Iberian peninsula and into the Spanish dependency.

Aside from training deficiencies, the aviation engineers’ foremost problem was the fate of their equipment, especially that ‘coming from England. Loaded on different ships from the units, with some ships sailing in different

convoys, engineer paraphernalia from heavy machinery to hand tools often failed to arrive with the troops. The 815th’s equipment was lost at sea off Oran with a torpedoed vessel, and the ship transporting part of the 809th’s belongings returned to England with engine trouble two days after sailing with the invasion convoy. Heavy construction equipment was often diverted to other use or to other engineer units as it came ashore. Some of the 809th’s materiel arrived intact because members of the battalion traveled on the same ship and supervised its unloading, but the unit’s trucks, in a later convoy, arrived stripped of spare tires, all canvas supports, and the tools packed aboard them for embarkation. As late as January 1943, the 2nd Battalion of the 21st Engineer Aviation Regiment, working at Craw Field near Port-Lyautey, had to use secondhand French tools or improvised equipment. All the necessary equipment did not arrive until March 1943.3

The existing airfields in North Africa were ill-suited for the heavy invasion traffic. Of the French fields in the landing areas, only four had hard-surfaced runways: those at Port-Lyautey on the Moroccan coast north of Rabat; at Tafaraoui near Oran; at Maison Blanche, close to Algiers in the Eastern Task Force zone; and at Bone, fifty miles short of the Tunisian border. With its main strip and a crosswind leg, Tafaraoui became the focus for incoming American aircraft of all description belonging to Brig. Gen. James H. Doolittle’s Twelfth Air Force, and the resulting glut of planes on the field slowed operations to a crawl. When the seasonal rains commenced in late November, everything in the dispersal areas off the runways sank into mud “like liquid reinforced concrete of bottomless depth.”

In an attempt to give maneuvering room to some 285 mired planes, the Twelfth Air Force flew its B-26 mediums to Maison Blanche, where the 809th Engineer Aviation Battalion, leaving two detachments behind at Tafaraoui and other smaller dirt fields in the area, began work on 29 November on a second runway, taking up where the French builders of an intersecting runway to the main macadam strip had left off. The same insidious mud hampered operations; however, the engineers were able to lay gravel-clay taxiways and hardstands in a large dispersal area.

German air resistance to further Allied advances into Tunisia also brought a radical change to the arrangement that confined American aviation construction to the area west of Algiers. When General K. A. N. Anderson declared on 4 December that a lack of air cover had cost him the opportunity to move further against the Germans, American aviation engineers were already heading eastward in an attempt to bring Allied air power closer to the front lines.

British efforts to construct airfields behind their advancing lines suffered even more from inadequate heavy equipment than did the American efforts. Beginning on 20 November, detachments of a British airdrome construction unit attempted to build a fighter

field in Tunisia in the neighborhood of Souk el Arba, eighty miles west of Tunis, but the December rains defeated them. Their Sommerfeld mat, well-suited to English sod fields, sank out of sight in the Tunisian mud, and pierced steel plank was in short supply in the theater. They had better success with the sandy soil nearby at Souk el Khemis, but the British still had too few fields to support a concentrated aerial offensive against German strength in Tunisia.4

Early December marked the wholesale departure of American aviation engineers from northwest Africa for sites in eastern Algeria. On 2 December, acting on French advice that dry weather prevailed there, Brig. Gen. Donald A. Davison flew to Telergma, a village by a large bowl on a 3,500-foot-high plateau in the mountains southwest of Constantine. On the field guarded by French troops, Davison found a platoon of the 809th Engineer Aviation Battalion already working, having reached the prospective field by forced march from Maison Blanche. Another company of the battalion moved in by plane and truck, and, assisted by several hundred Algerians, the engineers scraped out a compacted earth runway that began handling B-26 traffic just ten days after Davison’s first visit. With this single runway, a well-drained strip of loam, caliche, and gravel, the 809th, the first American unit of its kind to work east of Algiers, began developing a complex of medium bomber fields in the Telergma area.5

Heavy bombers found a home farther south on the fringes of the Sahara at Biskra, a winter resort. Though Biskra and Telergma lay close to rail lines, the disruption in French train control and traffic forced most supply to the bases, especially Biskra, to go by air. Accordingly, the engineer unit chosen to develop the Biskra base was the 887th Airborne Engineer Aviation Company, its troops and light, air-transportable equipment carried to the site from Morocco, a thousand miles away, in fifty-six aircraft. Landing on 13 December, the company completed two new fields of compacted earth for B-17s and B-24s in four days to give the heavies a dry toehold within easy striking range of the enemy. Apparently vindicating the faith placed in the airborne aviation engineer concept by its developers in Washington, the 887th’s performance still could not redeem the failure of its sister company flown into Tebessa from Port-Lyautey to expand and improve advance fields at what became a main supply base in the drive into Tunisia. Here the 888th Airborne Engineer Aviation Company’s midget bulldozers could do little in the rough terrain, and the company took two long weeks to carve out a single runway, though it was supposed to recondition dirt fields lying as far away as Gafsa, across the Tunisian border. Eventually the 814th Engineer Aviation Battalion took over the job.6

The aviation engineers shared their problems of lost and inadequate equipment with other engineer units but

wrestled with problems of command structure peculiar to them. From the outset it was not clear whether the Corps of Engineers or the Army Air Forces (AAF) would control the aviation engineers. Field service regulations for 1942 did not fix responsibility for building airfields in the theater of operations, but in October 1942 AFHQ gave the job to the engineer, Twelfth Air Force, with the ruling that the aviation engineers were “an organic part of the air force.” Following the invasion, the Twelfth Air Force engineer, Col. John 0. Colonna, assumed operational control of all the American aviation engineers in North Africa. In the consolidation after the invasion, administrative control of the aviation engineers passed to individual commanders of service areas established at Casablanca, Oran, and Constantine, subordinate, in turn, to the new XII Air Force Service Command (AFSC), of which Colonel Colonna was also the engineer. Chafing under the division of control over the aviation engineers, Colonna saw to it that Twelfth Air Force issued orders for airfield construction directly to the constructing units without going through the service command. But the service command area commanders, in guarding their own prerogatives, frequently countermanded orders from Twelfth Air Force. The divided control created obvious and serious delays in construction projects for the aviation engineers.7

On 30 December 1942, Brig. Gen. Thomas B. Larkin, commanding the newly established Mediterranean Base Section, proposed that all requests for new airfield construction be submitted to base section commanders through AFHQ and be carried out by base section engineers, arguing that logistical agencies should control all construction, including that of airfields. Colonna strongly opposed this stand and recommended that the aviation engineers be removed from the administrative control of the service command and transferred into the Twelfth Air Force. While conceding that Services of Supply (SOS) control might be feasible in a static situation, Colonna was convinced that base section control would not work in a fluid situation like that in North Africa. He also opposed a proposal General Davison made to General Eisenhower on 13 February 1943 that all engineer troops, including aviation engineers, be placed under the chief engineer, AFHQ; Colonna pointed out that airfield construction was “intimately associated with shifting strategic and tactical situations” and should be “directly under the Air Force Commander.”8

Davison’s plan found no effective support. The activation on 18 February of the Northwest African Air Forces (NAAF) under the command of Maj. Gen. Carl W. Spaatz with Colonna as aviation engineer provided an opportunity to keep airfield construction under the control of the Air Forces. In addition, the fast-moving situation after the German breakthrough at Kasserine converted Davison to the principle of Air Forces control; early in March Davison joined Spaatz’s staff as aviation engineer, with Colonna as his deputy.

A growing concern in Washington lest the AAF should, in effect, detach

the aviation engineers from their organic connection with the Corps of Engineers and thus from their administrative subordination to Army Service Forces (ASF), the new name taken by the SOS on 12 March 1943, led to an ASF proposal in the spring of 1943 to abolish the aviation engineers and to reorganize all engineer construction under ASF. But the AAF was firm in opposing any such solution. Moreover, by April 1943 the AAF had become too important an element of the armed forces and its performance in North Africa too impressive a demonstration of its potential for successful opposition on a matter that it held vital to its functions in a theater of war. The hotly contested argument reached a firm solution only at the end of 1943.

In the closing two months of the campaign in North Africa, the aviation engineers improved and expanded the rear area construction and provided new fields, especially fighter fields, for swiftly changing tactical situations. For example, five fields the 814th Engineer Aviation Battalion built in the Sbeitla area were usable in seventy-two hours and complete in four days. By the end of March, with the arrival of 837th, 838th, and 845th Engineer Aviation Battalions and the 3rd Battalion of the 21st Engineer Aviation Regiment, the American construction force in the theater amounted to nearly 9,000 troops, three times the number in the British Airdrome Construction Groups active around the Souk el Arba—Souk el Khemis area. With ten American battalions and two separate companies available in North Africa, engineers established a first priority for fields behind the front, a secondary importance for the bomber fields in western Algeria and eastern Morocco. The new arrivals worked in the rear area but also were involved in transferring the large bomber base at Biskra, an untenable site in the heat and dust storms of the spring, to constantly expanding facilities at Telergma. The 814th carried most of the responsibility for forward airfield construction, though British engineers from Souk el Arba added their manpower to the projects, and in late April two platoons from the 21st Engineer Aviation Regiment scraped out a dry weather field at Djebel Abiod, on the coast north of Souk el Khemis and eighty miles west of Tunis.9

The arrival in Tunisia in the spring of heavy machinery necessary for airfield construction over and above the Table of Basic Allowance (TBA) of the aviation engineer battalions made possible such accomplishments. Another important factor was a Northwest African Air Forces order of 5 March setting forth new and realistic specifications for airfield construction. The new specifications called for the barest essentials—in the forward areas, one earth runway per field, with loop taxiways and dispersed hardstands. The directive also assumed that no buildings would be required, that bomb and gasoline dump areas would be served by existing roads, and that occupying troops would provide dugouts and trenches. Construction shortcuts and heavy machinery used on a scale unknown in any other Army found their first combined application to aerial warfare in the Tunisian campaign. Heavy bomber and fighter airfield construction could keep pace with the movement

of the ground forces in a rapidly developing campaign. In May General Spaatz stressed the contribution of the aviation engineers to the impressive performance of the AAF in North Africa. He termed the Air Forces and its aviation engineers a team able to “work smoothly and efficiently during the stress of battle.”10

The heavy equipment set the American engineers apart from the British Airdrome Construction Groups in their achievements; even with 3,000 British airdrome engineers in Tunisia, their efforts remained concentrated around their two main RAF bases at Souk el Khemis and Souk el Arba, the complex there consisting of around a dozen fields. This compared with the American construction of over a hundred fields throughout the theater.11

Their efficiency was all the more remarkable since the frustrating division of control over the aviation engineers continued until the end of the campaign in North Africa. The planning, the preparation of construction standards, and the issuance of work directives were in the hands of the engineer, NAAF, but the execution of all engineer work for the Air Forces and the administration of aviation engineers was the responsibility of the engineer of the North African Air Service Command (NAASC), an NAAF subordinate command that came into being along with NAAF in February 1943. The dual command hampered the procurement of heavy equipment and spare parts. Orders had to be processed through the service command staff, causing delay and confusion, and the divided control interfered with replacement and rotation of personnel and promotion of officers. At times “the aviation engineer officers and men considered themselves ... neglected and forgotten troops not belonging to any particular command.”12

The unsatisfactory command arrangements in North Africa were an object lesson to planners in England concerned with the employment of aviation engineers in the coming invasion of Europe. During the spring of 1943 the planners undertook studies aimed at resolving problems of administration, discipline, and supply, and in August 1943 Col. Rudolf E. Smyser, Jr., engineer of the Eighth Air Force, went to North Africa to study the command situation in the Mediterranean Theater of Operations (MTO). His observations confirmed his opinion that all engineer aviation units should be under the complete administrative as well as operational control of a single agency subordinate only to the Air Forces, a conclusion that played an important part in the later creation of the IX Engineer Command in England. General Davison convinced Lt. Gen. Carl W. Spaatz of the necessity of setting up a separate aviation engineer command, and the XII Air Force Engineer Command, MTO (Provisional)—changed 1 January 1944 to Army Air Forces Engineer Command, MTO (Provisional)—came into being.13

Colonel Smyser

Petroleum, Oil, and Lubricants Supply

Engineer construction for POL supply was of several types: pipelines from ship to shore, bulk storage tanks and connecting pipelines, and extensive lines with pumping units leading toward the front. In North Africa existing port facilities had to be improved, tank farms had to be built at convenient points, and many miles of pipeline had to be constructed. Initially, no centralized control for the distribution and use of POL projects existed in North Africa, for each task force of TORCH was responsible for its own POL supply. Confusion, duplication of effort, and waste resulted. Gradually, early chaos gave way to an integrated system of control and the establishment of a common Allied POL pool from which products could be released to the

British and American armed forces as well as to the French military and civilian agencies.14

The 2602nd Engineer Petroleum Distribution Company, which reached Oran on the D plus 3 convoy, immediately went to work to rehabilitate and operate existing French POL facilities at the port. Next, the company installed a seven-mile-long, four-inch victaulic pipeline from the Victor Hugo Storage Depot at Oran to airfields at La Senia and Tafaraoui. The same convoy also brought fifty miles of four-inch pipe that had reached England just in time to be loaded for TORCH. Delayed for weeks by heavy rains, the engineers eventually erected bolted steel tanks at the airfields for aviation gasoline; they also installed feeder lines and dispensing racks to service Air Forces trucks. The available storage at La Senia amounted to 462,000 gallons, at Tafaraoui 651,000 gallons. Another four-inch line, from Arzew to Perregaux, furnished a truck convoy connection with the airfields in the latter area. Such construction exemplified what was soon to be undertaken in other port areas in Algeria and Morocco.15

On 24 December 1942, a conference on petroleum supply, held at Algiers, determined the network of pipelines in Algeria and Tunisia. From the port of Philippeville a six-inch pipeline was to run to the heart of the airfield region in eastern Algeria, with bulk storage at

Ouled Rahmoun and lateral four-inch lines from there west to the Telergma fields and east to Tebessa. Eventually, the planners envisaged extending the Tebessa pipeline branch east to the port of Sousse and southeast to the port of Sfax. The ports of Bizerte, Tabarka, and Tunis would also be used.

Extensive pipeline construction got under way in earnest in February 1943, when two parallel four-inch lines were built from Philippeville to Ouled Rahmoun, one of them a V-80 line for motor gasoline.16 This project included plans for erecting bolted steel tanks for bulk storage at existing airfields and for building a tanker unloading line and a tank farm at Philippeville. Execution involved coordinating the activities of American engineers, French Army contractors, and local labor, and assembling extensive and complicated equipment as well as obtaining rights-of-way. The pipeline engineers had to supplement materials at Mediterranean Base Section (MBS) with additional stocks requisitioned from the Atlantic Base Section (ABS) and the Royal Engineers.17

By 18 February pipe extended more than twenty miles, with construction actually complete for only some three miles. Then the work virtually halted until more pipe and other materials arrived in the forward area. The fate of the project hung on transporting bulky and easily damaged materials from the base sections in spite of severely limited cargo space and enemy air and naval interference. To complete the system, additional materials had to be shipped by risky sea routes because of the bottlenecks in overland transportation.

The 2004th Engineer Petroleum Distribution Company completed the project in mid-April, and on the sixteenth the first American tanker discharged its 64,000-barrel cargo into storage tanks at Philippeville. Pumps took the aircraft fuel fifty-five miles through the pipeline to Ouled Rahmoun. In this construction job alone the engineers could claim a solid share in neutralizing the enemy’s air menace and hastening his final capitulation in North Africa.

On the same day that gasoline first flowed to Ouled Rahmoun, the 702nd Engineer Petroleum Distribution Company began work on a second important pipeline, closer to the front. This line ran southeast from the port of Bone in Algeria to Souk el Arba, Tunisia, with a branch line to Souk el Khemis. The whole system, involving ninety miles of four-inch pipe and nine pump stations, was completed in a month. During construction, petroleum engineers had the help of the 144th Native Labor Company, a working force of uncertain value, which furnished an average of 148 men a day.

Neither enemy action nor hostile natives impeded construction. The only necessary road work was that through mountains. Ample tools and supplies were on hand. Pipe had to be hauled an average of sixty-six miles, but the 702nd Engineer Company had a fleet of forty-five vehicles, including twenty-five 2½-ton trucks and ten pole trailers. The weather was cool, rainfall moderate. Enlisted men engaged in all phases

Gasoline storage at Port-Lyautey

of the operation, including such skilled engineering jobs as coupling, testing, tying-in and connecting, and working on pump stations. Natives did work requiring no special skill or training, such as clearing and grading for the main line to Souk el Arba, stringing pipes, and ditching and backfilling.

At the other extreme of the communication line, in French Morocco, the Army Transport Command and the North African Training Command at Marrakech in March 1943 estimated their combined need for gasoline to be 800,000 to 1,200,000 gallons per month. Rail tank cars to haul this amount were urgently needed elsewhere, and the obvious solution to the problem was a pipeline from Casablanca to Marrakech. Since materials were locally available to build this system, including terminal storage at Marrakech, the engineers laid a four-inch line 160 miles long. Four-inch lines from Casablanca and Fedala also supplied airfields at Mediouna, Sale, and Port-Lyautey, and another line connected Casablanca and Fedala. The 345th General Service Regiment, a unit that had no previous experience in building pipelines, did the work.18

Ground Support

Before the Kasserine breakthrough, the total combat engineer force with II Corps was three divisional battalions serving with the 1st and 34th Infantry Divisions and the 1st Armored Division, and, as corps troops, the 19th Engineer Combat Regiment. During the three weeks between the German withdrawal from Kasserine and II Corps’ attack on Gafsa, other engineer units joined II Corps: Company B of the 601st Engineer Camouflage Battalion, the 15th Engineer Combat Battalion (9th Infantry Division), the 175th Engineer General Service Regiment, the 518th Engineer Water Supply Company, and the 62nd Engineer Topographic Company. A few days after the II Corps’ attack on Gafsa started, the 20th Engineer Combat Regiment arrived from Casablanca, followed late in March by a platoon of the 470th Engineer Maintenance Company. Shortly before the Tunisian campaign ended, the 10th Engineer Combat Battalion (3rd Infantry Division) also joined II Corps.19

Since the Allied forces were on the offensive during most of the Tunisian campaign, the most important engineer function was to provide and maintain roads over which motorized ground troops could roll and to keep these roads clear of enemy mines. This function turned around in mid-February, when the Germans struck through the Faid and Kasserine Passes. At that time the engineers worked on roads leading to the rear, sowed mines in the path of the enemy, erected roadblocks, and fought as infantry. On the north, for example, the 109th Engineer Combat Battalion made possible the withdrawal of its parent 34th Infantry Division to Sbiba; on the south, the 19th Engineer Combat Regiment fought as infantry at Kasserine. (Map 4)

At daylight on 7 February the 109th Engineer Combat Battalion pulled into a bivouac near Maktar after a six-day trip through the mountains from Tlemcen, near Oran. A cold rain had changed intermittently to snow at night, and the lead trucks found the twisting clay roads into the bivouac area slippery with mud and clogged with broken-down French vehicles. German aircraft strafed the end of the convoy, still on the road at daybreak.

For a few days the battalion improved bivouac area roads and reconnoitered. The first task was to improve the road-net for troops holding the Pichon–Fondouk el Aouareb Pass area, a critical opening where many thought the impending German attack would come. Engineer reconnaissance found a 35-mile trail across semi-desert flats, rock-ribbed ridges, and sand dunes from Sbiba east to El Ala that could be made passable for six-by-six trucks in a week. By 14 February the companies of the 109th had spread out along the route. Men of Company C, responsible for the middle section of the road, discovered warm springs near their bivouac, and many had their first good bath in more than two weeks.

On the night of 16 February, Maj. Vernon L. Watkins, the battalion executive officer, carried alarming news over the rough route. German armor had cut the main road forward (Sbeitla–Hadjeb el Aioun) and, while the front could bend without serious loss, a break that allowed mobile enemy units into

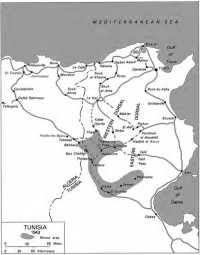

Map 4: Tunisia 1943

sensitive rear areas could be disastrous. The engineers were to convert the trail leading west to Sbiba into a road the 34th Infantry Division could use by noon the next day.

Promptly at noon on the seventeenth the last large fill necessary to make the rough trail passable was in place, and two hours later the first divisional vehicle passed over it. Traffic stretched half the length of the road when rain made the fresh grades treacherous. By dark congestion was mounting. At trouble spots all along the road small parties of engineers waited with tractors, half-tracks, and winch-trucks, and throughout the night they pulled and shoved vehicles. Finally, about daybreak, the division reached new defensive positions near Sbiba, where the tired, drenched engineers found many other pressing jobs waiting for them: digging gun emplacements, laying mines, erecting wire, building supply and access roads, and freeing stuck vehicles.20

At Kasserine, the 1,200 men of the 19th Engineer Combat Regiment formed the nucleus of a force defending a road leading northwest to Tebessa. The force included an infantry battalion, three artillery batteries, and a tank destroyer battalion—about 2,000 men. The 1st Battalion, 26th Infantry, defended the road leading north to Thala.

Since their arrival in Tunisia on 6 January, the 19th Engineers had worked almost exclusively on improving and maintaining corps supply roads into divisional areas. When the German attack began, one company was still in the Gafsa area with Task Force Raff, paratroopers with whom they had been operating for several weeks. Another company tunneled bombproof shelters for II Corps headquarters into a hillside near Bekkaria. The rest of the regiment, bivouacked near Bou Chebka, maintained II Corps roads leading out of Tebessa toward the front.

On 16 February, well before dawn, the 19th Engineers began a 3½-hour move into Kasserine Pass. Fog and rain slowed the column, but at 0530 the regiment reached an assembly point one mile west of the pass, where the regimental commander selected defensive positions. The men spent that day and the next digging in and laying mines across their front, interrupting work long enough on the seventeenth to cover the withdrawal of 1st Armored Division units. Fog and intermittent rains that had enveloped the battlefield for several days continued.

On the evening of 17 February, Lt. Edwin C. Dryden of the 19th Engineers received orders to supervise the installation of a minefield in front of an infantry battalion’s position. Along with two noncoms, he loaded a truck with mines and proceeded to Headquarters, Company C, 26th Infantry, arriving after midnight. At the infantry command post the engineers found no work detail ready to emplace the mines, nor anyone who knew where the mines were to go or what part they were to play in the defense. In the end, the engineer lieutenant, who had never seen the terrain in daylight, had to select the site and instruct a makeshift work party in laying and arming the mines. Work began after 0330. The light entrenching tools of the infantry proved useless in the rocky ground, and in order to finish by daylight the work

party had to leave the mines unburied, strung across the road from a hill on one side to an embankment on the other.

Enemy artillery fire started to fall on the American positions at Kasserine on 18 February. Engineers from Company A, 19th Engineers, had begun to grade a lateral road across the rear of the defenses, but the enemy took the bulldozer under fire and the grading had to be abandoned. That evening the II Corps commander, Maj. Gen. Lloyd R. Fredendall, instructed Col. Alexander N. Stark, Jr., commander of the 26th Infantry, to “Go to Kasserine right away and pull a Stonewall Jackson. Take over up there.” Colonel Stark assumed command of a provisional force (Task Force Stark) early on 19 February, about the time the first German probe entered the pass. This initial thrust turned back, and the rest of the morning passed while the enemy reinforced. During the early afternoon several more companies of American infantry and a few tanks arrived in Kasserine, some of them before the Germans renewed their attack in midafternoon.

About 1600 the enemy’s third attack of the day drove Company D, 19th Engineers, from its positions. A counterattack failed to dislodge the enemy troops, and the day ended with the engineer positions seriously weakened but still holding. A French 75-mm. battery was in position to support the engineers, but no heavier American 105s.

The Germans attacked again before dawn, falling mainly on the 26th Infantry. When the infantry positions collapsed, the engineers used reserves gathered for a counterattack to protect an exposed left flank, but the leverage exerted on the 19th Engineer’s exposed flank soon proved too great. German infantry, infiltrating behind well-directed artillery fire, took over the rest of the Company D positions and then drove back Company E. The regimental command post had to move, but the Germans brought the new position under machine-gun fire and the defenses quickly crumbled. Company F managed to keep control of its platoons until late afternoon, but the rest of the engineers made their way to the rear as best they could as platoons, squads, and individuals. When the regiment assembled again, it counted its losses in the three-day battle at 11 killed, 28 wounded, and 88 missing.

As the members of the provisional force, beaten and bloodied, found their way to the rear, few probably knew what they had accomplished. Field Marshal Erwin Rommel was operating on a tight time schedule, for Montgomery would soon fall on German positions in southern. Tunisia. The rebuff at Sbiba and the delay at Kasserine gave II Corps time to assemble the strength to stop the German-Italian Panzer Army a few miles north along the road to Thala.

Analyzing the preparation and conduct of the defense at Kasserine, Col. Anderson T. W. Moore, commanding the 19th Engineers, pointed out serious defects. Foxholes and gun emplacements had not been dug deep enough; few alternate positions had been prepared; barbed wire was delivered late and used little; and leadership and control left much to be desired. But the engineers had performed creditably for a partially trained unit. The 19th Engineers had not even completed rifle training before going overseas, and only one man in the regiment was known

to have been in combat before. Their experience at Kasserine underscored a lesson taught repeatedly in Tunisia: engineer units sent to meet German veterans in combat required hard, realistic training.21

One of the most persistent irritations for engineer officers was the use of their troops in other than engineer capacities. Standard doctrine permitted the use of engineers as fighting men under certain conditions, but in North Africa the procedure and the criteria for attaching engineer units to fighting units were hardly consistent or uniformly applied. Engineer units frequently undertook nonessential jobs simply because they were at hand. As a result, essential engineer tasks went undone. Furthermore, attachment sometimes tied up valuable pieces of engineer equipment where they were not needed. The II Corps engineer, Col. William A. Carter, Jr., carried on his arguments against using engineers without weighing the disadvantages in taking them away from support duties, especially in offensive operations. By the end of the campaign, only one of the four American divisions resorted to attaching engineer troops.22

After the Germans retired from Kasserine, many of the roads in the II Corps sector were virtually impassable. The clay surfaces, softened by frequent rains, had deteriorated rapidly under the heavy military traffic. The enemy had little or no hope of regaining this area and left behind scattered mines, cratered roads, and demolished bridges. Fortunately, there was little of value to destroy. New roads could be built easily across the central Tunisian plateau, and ruined bridges could be bypassed by fords or culverted fills, for there were not perennial rivers to cross. The rains had done more damage than the enemy.

Engineer road work on a considerable scale was necessary before II Corps could launch its attack through Gafsa. To move the 1st Infantry Division and the 1st Armored Division in this offensive, ninety-five miles of trail had to be made into two-way dirt roads. Grading these roads was no great problem. Using two D-7 bulldozers, two R-4 bulldozers, and two graders, Company C, 19th Engineers, with one platoon of Company B attached, in three days improved a rough fifteen-mile road to the last infantry outpost east of Thelepte and graded twenty-four miles of new road from there joining the Sbeitla–Gafsa road. Other units made similar progress. The main problem was keeping existing roads open in the heavy rains.

During the attack through Gafsa (17 March-10 April) corps engineers had 341 miles of other road to keep open, including a 140-mile bituminous macadam route from Ain Beida to Gafsa

and five dirt roads that required constant maintenance. As divisional combat engineers became involved in mine work, they had little time left for road maintenance, and that task fell to the corps engineers. At this time the 20th Engineer Combat Regiment made the long trip from French Morocco to aid the 19th Engineers. The 175th General Service Regiment was also sent into the II Corps area to help.23

Again, during II Corps’ attack on Bizerte in late April and early May, road work was vitally important, although once the rainy season was past, maintenance was less a factor. The corps roadnet consisted of about 100 miles of rough, water-bound macadam and about 260 miles of dirt roads, some little more than cart tracks. Offsetting the advantage of dry weather was the hilly terrain. Here, enemy mines and demolitions were more effective because the avenues of approach ran through the narrow valleys, and the bridges in these valleys could not be so easily bypassed. The attack in the north avoided the valleys when possible and generally followed the high ground. Some seventy-six miles of new roads were built from the main supply route to pack mule trails to reach infantry positions on the hills. Bypasses around demolished bridges accounted for some of this mileage.24

While no major, radical changes in engineer TBA resulted from experience in Tunisia, some additions appeared eminently desirable. For example, a definite need developed that each combat engineer battalion have at least one of the large D-7 bulldozers. More road graders and dump trucks would have proved useful in certain situations, but it was debatable whether this was a matter of changing the Table of Basic Allowances or of providing more Class IV equipment. One of the most needed Class IV items was the power shovel, for there was little point in providing a combat engineer regiment fifty-four dump trucks to haul road fill unless the means existed for providing crushed rock and for loading it on the trucks. Road maintenance took up a disproportionate share of the combat engineers’ time in Tunisia because mechanical means for loading fill were lacking. The only exception was a civilian-owned steam shovel the 19th Engineer Combat Regiment put into service. In the final days of the campaign the 20th Engineer Combat Regiment also made good use of a shovel—probably the same one. If so, only one shovel was available to the combat engineers in all Tunisia.25

Central and southern Tunisia had wet-weather wadis aplenty but no permanent streams. Except after very heavy rains, combat unit vehicles could cross wet-weather streams as soon as engineers bulldozed dry fords or built bypasses around demolished bridges. In northern Tunisia, on the other hand, there were permanent streams, and bridge building was an important engineer activity.

During this campaign the British Bailey bridge first proved its tactical value to Americans.

During the closing days of the campaign, the 9th Infantry Division employed a compromise plan that proved satisfactory. Under this plan the regimental combat teams (RCTs) had the support of one company of combat engineers each, with each company supporting its combat team in three echelons. In the vanguard, a small group of reconnaissance engineers accompanied forward infantry elements. Not far behind, a platoon of combat engineers cleared mines and prepared paths over which mules carried rations and ammunition to the front. The rest of the engineer company helped the artillery to displace forward; built roads, and cleared minefields. The 3rd Regimental Combat Team had only one platoon of combat engineers attached; being in reserve, this team moved less than the others. The rest of the engineer battalion remained under division control, to be used where most needed.26

Engineer combat battalion manpower increased from 634 to 745 in the years before 1942. In 1943 Army Ground Forces redesigned the American infantry division, reducing its organic engineer support to a battalion of 647 men, and cut the armored engineer battalion by 40 percent. North African experience argued for substracting the bridge company formerly assigned to engineer battalions, especially in armored divisions. Though highly enthusiastic about its Bailey bridge sets, the 16th Armored Engineer Battalion carried the equipment for three months in central Tunisia before putting it to hard use in the closing weeks of the campaign. The NATOUSA engineer also found that he rarely had enough reconnaissance forces either at corps level or below. The new organization gave each combat battalion a 22-man reconnaissance section equipped with three SCR-511 portable radios, binoculars, and compasses.27

Mine Clearing

As the Germans withdrew through the Kasserine Pass and Sbeitla to the Eastern Dorsal, clear skies enabled Allied planes to harry their retreat. On the ground American pressure bogged down, partly because at Kasserine American troops encountered ‘mines and demolitions on such a scale as to suggest a new weapon in warfare.” Behind a covering screen of thousands of mines, the enemy broke contact and withdrew unmolested by ground troops.28

The engineers were as ill prepared as the infantry for mine warfare, although they had responsibility for mine laying and mine clearing. One engineer combat company commander, who “had never seen a German mine, picture, or model before entering combat in Tunisia” had to rely on one noncom, who had attended a British mine school in the theater, to train company officers and key men only a few days before his unit encountered its first live minefield.29

Antitank mines were customarily placed in staggered rows, checkerboard fashion, spaced far enough apart to avoid sympathetic detonation. They were laid according to specific pattern for two reasons: an enemy tank or other vehicle missing mines in the first row would stand a good chance of coming to grief on the second, third, or fourth row; and, when necessary, friendly troops could more easily locate and lift mines laid in a pattern. This second consideration was important, for-armed mines played no favorites. Minefields had to be charted and marked with care.

During their retreat in Tunisia the Germans were hardly concerned with having to relocate mines, so they scattered them indiscriminately anywhere Allied troops and vehicles were likely to travel. Since Allied trucks and motorized equipment were confined mainly to roads or to occasional stretches off the road, the Germans mined shoulders, particularly where the roads narrowed; they also mined road junctions, likely turnouts, probable bivouac areas, and wadi crossings. The Germans used many tricks to deceive and slow down mine detection teams: they booby-trapped some mines and buried others two and three deep; around some they scattered bits of metal that Allied mine detector operators had to mark for investigation. One of the enemy’s most effective tricks was to bury mines too deep to be detected. In this way scores of trucks could pass safely over a road and then, when ruts became deep enough, a mine would explode. Such methods had a heavy psychological effect on attacking troops and delayed the advance more effectively than pattern mining could have. In such circumstances, even though only a few mines might have been laid in some areas, many miles of roadway had to be swept. All antitank mines had to be handled as if booby-trapped, even though only a small percentage actually were. And no matter how slowly or methodically mine clearance teams worked, they could never guarantee a clear route.30

The land mines that the engineers had to deal with fell into two categories, antitank (AT) and antipersonnel (AP). AT mines were generally pressure-activated—a man’s weight would not detonate them, but that of any military vehicle would. They contained several pounds of explosives which could demolish a jeep or immobilize a tank by breaking a track and damaging bogie-wheels. AP mines were smaller charges of explosives set for the unwary. Activated by sensitive push-pull, pressure, or pressure-release devices, they required much more delicate handling then AT mines. Varieties of these two types, and the subterfuges with which they could be employed, were endless.

The antitank Teller mine (“plate” in German) was the mine the Germans used most in Tunisia, although they also employed others of Italian, French, and Hungarian manufacture as well as captured British and American mines. Four different models of the Teller mine found in North Africa had the same general characteristics: disc-shaped,

German S-mine. The activated canister burst from the earth and fired over 300 steel pellets in all directions

about a foot in diameter, three to four inches thick with a zinc or steel jacket encasing eleven pounds of TNT, and a total weight of about twenty pounds. Teller mines had three igniter wells, one on top for a shear-pin type pressure igniter and others on the side and bottom for more sensitive and more varied booby-trap igniters. These extra wells, and the igniters to fit them, gave the mines a built-in antilifting feature that no American mines could match. American engineers had to assume that every Teller mine was booby-trapped.

The German antipersonnel “S” mine was a particularly clever innovation. Nicknamed “Bouncing Betty” by British troops, the mine’s activation detonated a small black powder charge, throwing a grapeshot canister out of the earth. Exploding at waist or chest level, the canister discharged a murderous hail of steel ball bearings in all directions.

The Germans made widespread use of booby traps with blocks of explosives rigged to houses, equipment, or even bodies—anything curious or unwary troops were likely to touch, move, or walk on. AFHQ engineer intelligence bulletins promptly circulated information on various types of reported booby traps, sometimes before they could be confirmed. For example, reports of a water bottle that exploded when the cork was withdrawn, a German whistle that exploded when blown, and a booby-trapped

Italian Bar Mines. The opened casing shows the simple pressure detonating device

cake of soap were published throughout the command; how many others—real and unreal—circulated by word of mouth can only be conjectured.31

In Tunisia a large part of the combat engineers’ time was given to laying, lifting, and clearing mines, often to the neglect of other work such as road maintenance. The 16th Armored Engineer Battalion, for example, spent virtually half its time on mine work, as did combat engineers with infantry divisions. To compensate, corps-level engineers had to push their road maintenance and minefield clearance work well forward into divisional areas. Although the engineers were better prepared to deal with mines than was the infantry, engineer training in the subject left much to be desired.32

While the engineers often had to use the slow and tedious method of probing With bayonets for mines, they generally relied on the magnetic mine detector (SCR-625) for speed on long stretches of roads, in bivouac areas, and on airfield sites. The detector was a 7½-pound instrument consisting of a set of earphones and a search plate

The SCR-625 mine detector in action on a Tunisian road

mounted on a wooden disc at the end of a six-foot handle. Dry cell batteries induced a magnetic field around the search plate and produced a low hum in the operator’s earphones. The soldier “swept” a wide arc before him with the instrument. In the presence of metal buried less than a foot deep, the hum in the operator’s ears continually increased in pitch until it became a near-shriek when the detector was directly above a mine. Engineers in the mine-clearing party marked the spot, and other engineers, following behind, unearthed and deactivated the mines. They dug out but did not deactivate mines unfamiliar or suspected of being booby-trapped. They sometimes placed a block of explosive beside these mines and relied on sympathetic detonation; more often they attached a length of wire and pulled the mines out of their holes from a safe distance.33

The SCR-625 was a valuable piece of equipment when it worked but had two serious shortcomings: it was not waterproof and was quite fragile. The instrument shorted out in wet weather and required such careful handling and delicate tuning that normally about 20 percent were broken or out of adjustment. In spite of these drawbacks, after Kasserine Pass the magnetic detector became one of the most sought-after pieces of equipment in the Army. The 16th Armored Engineer Battalion urged that the allocation be increased from eighteen to seventy-one. Experience in Tunisia prompted most engineer units to ask that one detector be provided per squad, with some provision for a battalion reserve.34

Experiments conducted in the Mediterranean theater as well as in the United States sought to find a faster way of detecting or eliminating mines, particularly under fire. The demand arose for larger magnetic detectors, mounted on vehicles, that could sweep long sections

of road rapidly. Engineers of I Armored Corps in French Morocco experimented with mechanical means, explosives, and fire to make gaps in pattern minefields. They found that tanks could push long sections of explosive-filled pipe across a minefield and that when detonated these “snakes” cleared a path wide enough for a tank to pass through. Bangalore torpedoes and nets made of primacord also tested well. But mine-clearing explosions alerted the enemy, and bulky devices occupied a great deal of shipping space. Nearby concussions also made more sensitive the unexploded mines which the snakes left alongside their path. Engineer units carried snakes in Tunisia but did not use them to blow gaps in minefields.35

Two mechanical means of detection and detonation offered some promise. The British Eighth Army developed the Scorpion—lengths of chain attached to a revolving axle suspended well in front of a tank. As the tank moved forward, the chain flailed the ground. The Scorpion exerted enough ground pressure to explode mines and could absorb at least the initial concussions; however, it also created clouds of dust and destroyed the chain flails quickly. The machine moved about one thousand yards into an active minefield before the blasts took so many links from the ends of the chains that they no longer struck the ground. The enemy could counteract the flails with wire entanglements, and the whirling chains often activated delayed-action mines that destroyed following vehicles. In the end, the only antimine innovation that American engineers employed in Tunisia was a “pilot vehicle” the 16th Armored Engineer Battalion and 1st Armored Division ordnance personnel developed, an M-3 tank with concrete-filled, spiked steel drums mounted in front. Its purpose was to find the forward edge of a minefield without needless searching. Used twice during the last days of the campaign, the vehicle revealed a serious defect—the mines demolished the roller. The first time the engineers employed the vehicle they replaced the roller under fire, but the second time they had to withdraw.36

American engineer officers in March and April 1943 studied British minefield clearing techniques and other mine warfare methods. ‘Training teams from the British Eighth Army, made up of men with two years of experience in mine warfare, provided valuable aid. Before the major attack during the third week of April, about forty American officers and more than a hundred noncoms attended a mine school that the British First Army conducted with instructors brought to Tunisia from the British Eighth Army. Other mine schools sprang up. Experienced engineers taught the less experienced, and they trained instructors from infantry, artillery, and other units. Fifth Army established a Mine Warfare School at Ain Fritissa that drew a few instructors from the British Eighth Army.

Scorpion tank crew loading bangalore torpedoes

One of the prime difficulties in conducting mine training was obtaining deactivated enemy mines. Although thousands of German and Italian mines were deactivated in the combat zone, they were scarce in the rear areas. There were exceptions. Some mines were sent to England for training purposes, and Lt. Gen. Mark W. Clark’s private plane ferried some from the front to the Fifth Army mine school. But most mine training had to be carried out without enemy mines. The main reason was the danger involved, which the theater command believed outweighed the advantages. Besides the normal hazards of handling unfamiliar varieties of live explosives, explosive sensitivity increased with age. In one incident on 30 March 1943, a 109th Engineer Combat Battalion truck loaded with 450 neutralized mines exploded, killing an entire twelve-man squad.37

German patterns of mining continued superior to American in most respects, as did the German system of charting and recording minefields. Where American units kept sketchy records or none at all in local unit files, German engineers carefully plotted each mine barrier and sent records to a central office in Germany.

The SCR-625’s noncollapsible handle forced the operator to stand upright, often in sight of an enemy covering the minefield with small-arms fire. Whatever reliability the detector promised for the future, it was useless in finding the German nonmetallic Schu mines, encased in wooden boxes, that appeared in small numbers in North Africa and would become more plentiful on the Continent. Out of their experience the engineers also demanded a new antitank mine that would do real damage to enemy armor; the German Teller, with twice the explosives of the American models, usually destroyed the hull and undercarriage of any tank striking it, while the American mine would only damage a track, leaving a salvageable vehicle.38

The magnetic mine detector, the bayonet, and a sharp, suspicious eye were the antimine measures that engineers relied upon most in Tunisia. From late February, when the Germans fell back to the Eastern Dorsal, until 13 April, American engineers found over 39,000 mines. In the area from Thala and Bekkaria through Kasserine to Sbeitla and along the road from Thelepte to Gafsa mine detection parties removed 10,750 enemy mines, and in the Gafsa area they found 8,700 more. Around E 1 Guettar they lifted 12,450 and found 7,300 more in the Maknassy-Sened area.39

Water Supply

Because reliable sources were scarce, the provision of water came next to road work and mine clearing in importance to combat engineers in Tunisia. Water supply involved three principal jobs: locating sources, testing and purifying, and distributing water to the troops. The engineers were concerned primarily with the first two; the arms and services usually provided their own trucks to haul water from engineer water points.

Each combat engineer battalion carried equipment to establish four water points and normally set up two forward and one or two back. As the divisions moved forward the rear water points leapfrogged over the forward ones. Combat engineer regiments provided similar service to corps units, as did general service regiments for units in areas to which they were assigned, although in rear areas much of the work was done by engineer units specifically organized and equipped for water supply. When II Corps’ offensive through Gafsa was impending, the 518th Engineer Water Supply Company moved forward to supplement the work combat engineers had done to establish water points, for the approaching end of the rainy season promised to make the job more difficult.40

The first step in activating a water point was to locate a stream, well, pond, or spring. In Tunisia most of the sources were wells, which were marked in the

central and southern parts of the country by clusters of trees. The next step was to test the water for potability, turbidity, and poison. An engineer technician carried a kit of test tubes and chemicals for this purpose. If he approved a particular source, a squad brought in a truck loaded with a motorized pump, a sand filter, a chlorinator, and a collapsible 3,000-gallon canvas tank which when erected stood about four feet high. Within about thirty minutes the squad had water pumping through the filters. The engineers used chemical disinfectants, principally chlorine gas or sodium hypochlorite. The purification equipment proved entirely adequate, even for water that was highly turbid and contaminated.41

During the Tunisian campaign the engineers continually put in and took out water points. Some sources had to be abandoned because pumps sucked them dry, others because the units they supplied had moved. During II Corps’ offensive through Gafsa between 17 March and 11 April, the 518th Engineer Water Supply Company had tanker trucks haul over three million gallons of water to forward distribution points called dry points. Trucks from the arms and services came to these dry points, as they would to any other water source, to fill five-gallon cans for their units. During the offensive the 518th also repaired a generator and a diesel well pump, which the Germans had damaged, to put the Gafsa and Station de Sened water systems back into operation.

In mountainous northern Tunisia during the final phase of the campaign, hauling water was less a problem since sources were more numerous. Combat engineers were able to operate several points in their own areas, while the 518th operated sources for corps troops and hospitals. The large number of enemy troops captured in the closing days of the campaign precipitated something of a water crisis, and all available tankers were needed again to haul water to prisoner of war enclosures. On its peak day during this period the 518th distributed 72,840 gallons of water.42

Camouflage

Engineer performance in camouflage was less successful than in water supply. Before the invasion AFHQ had specified that each army, corps% and major air force headquarters would have a qualified camouflage officer and that each unit down to the battalion and separate company level should name a unit camouflage officer. These officers became so burdened with additional duties during the campaign that unit camouflage suffered. To remedy this situation II Corps obtained Company B, 601st Engineer Camouflage Battalion, and for three weeks before the Gafsa attack had instruction teams teach corps units camouflage techniques. But, in the combat zone, more than teaching was essential, for camouflage was probably better understood than enforced.43

Camouflage was a command responsibility, and many commanders tried to enforce it. Covered windshields did not glint, and dusty, muddy vehicles blended with the terrain. Some units draped camouflage nets over their vehicles, some used the nets for bedding, and some did not use them at all. Units seldom attempted camouflaging vehicle tracks, for the barren North African landscape made it virtually impossible to conceal the army’s bulky motorized equipment, particularly when it was in motion. The best hope was to mask equipment identity. Toward the end of the campaign, as the Allies gained superiority in the air, camouflage discipline relaxed almost completely.44

Maps

The II Corps engineer was responsible for distributing maps to American units in Tunisia, with British First Army providing the maps according to stock levels set for the corps. The system worked well. Five men of the 62nd Engineer Topographic Company issued all maps, using a 2½-ton, 6-by-6 that the 470th Engineer Maintenance Company converted into a mobile map depot.

Old French maps provided the base for the maps II Corps used in Tunisia; the corps’ engineer topographic company overprinted more recent information. The maps often proved inaccurate on important points. Scales varied from the 1:10,000 town plan of Bizerte (useful during mine clearing and reconstruction work) to 1:200,000 road maps. Those most in use were 1:200,000 for southern Tunisia and 1:100,000 for northern Tunisia. These scales were satisfactory for regimental and higher headquarters but not for lower level units and artillery. Two days before the attack got under way in the north, British First Army furnished II Corps 1,000 copies of a 1:25,000 edition and a few days later 2,000 more copies containing revised intelligence data. This large-scale map proved valuable, as did a 1:50,000 operational series.45

Aerial photographs could have done much to correct and supplement the maps, but those available in Tunisia were wholly inadequate. Enlarged small-scale maps were poor substitutes for large-scale tactical maps. Good aerial photography was needed for intelligence and high altitude photomapping for map substitutions. The British First Army furnished some aerial photographs, but II Corps was never able to get enough. Wide-angle, high-altitude photomapping was not available at all.46

Command Reorganizations

With the Allies moving on an increasingly isolated but still dangerous enemy in Tunisia, the chief abiding difficulty in engineer supply in North Africa, apart from expected delays in shipments from the United States, was the tangled command structure that evolved in the area. In the attempts to resolve the awkward relationships between AFHQ and the ETOUSA headquarters in London, the War Department pushed for and General Eisenhower accepted the idea of a theater command in North Africa. A reorganization on 30 December 1942 centralized control of the Atlantic and Mediterranean Base Sections directly under AFHQ, relieving Western Task Force and II Corps of port and supply line operation. On 4 February 1943, taking advantage of the momentary lull in the Tunisian campaign, the War Department directed the establishment of the North African Theater of Operations, U.S. Army (NATOUSA), to consolidate and administer all American affairs in North Africa. General Eisenhower headed AFHQ and the new theater but acted on all theater administrative detail through his deputy commander, Brig. Gen. Everett S. Hughes. General Hughes, attempting to clarify his position for American forces, requested that he be designated commanding general of the Communications Zone, NATOUSA (COMZ, NATOUSA), since no American doctrine specified the office of deputy theater commander that Eisenhower had conferred upon him. Formally instituted on 9 February 1943, COMZ, NATOUSA, existed as a graft onto AFHQ, with senior American AFHQ officers doing triple duty as the staff for the COMZ command, for the NATOUSA headquarters, and for AFHQ.

Further complicating the structure after 14 February 1943 was the SOS, NATOUSA, command, established over arguments against maintaining a headquarters G-4, a communications zone command, and a separate services of supply organization in the same theater. Under the command of Brig. Gen. Thomas B. Larkin, former head of the Mediterranean Base Section, SOS, NATOUSA, was another level of command between the theater headquarters and the base sections; however, while the directive establishing his command assigned to Larkin all U.S. Army logistical functions except high-level planning and policy making, it failed to give him adequate control of the base sections. Already an anomaly under the current field service regulations, since American doctrine did not envisage a communications zone and a services of supply in the same theater, Larkin’s command entered into informal agreements with the base section commanders that placed overall control of supply, construction, maintenance, and transportation with SOS, NATOUSA. But COMZ, NATOUSA, did not confirm this arrangement; the agreements existed only as policy guidelines, which base section commanders could circumvent. Since SOS, NATO-USA, had to issue all directives to the base sections through COMZ, NATO-USA, General Larkin’s plans were altered or delayed in accord with other plans and priorities. Though the theater command tried to untangle the channels of command, the end of the Tunisian campaign found the lines of responsibility between COMZ, NATO-

USA, and SOS, NATOUSA, and between SOS, NATOUSA, and AFHQ’s G-4 still unclear. The AFHQ G-4, acting as planner for the inter-Allied staff and also in his NATOUSA capacity, frequently operated in the field of supply and dealt with the base sections directly where SOS authority should have prevailed. This command chain persisted for another year until the dissolution of COMZ, NATOUSA, and the consolidation of logistical operations under SOS, NATOUSA, on 20 February 1944. Within that chain, Brig. Gen. Donald A. Davison, as AFHQ engineer, also acted as chief engineer to the NATOUSA and the COMZ, NATO-USA, commands. As with other American staff officers similarly situated, he had to remember in which capacity he was acting in any given matter.

Other complications continued to plague the U.S. Army logistical system in North Africa. The chiefs of U.S. Army technical services remained at AFHQ/NATOUSA instead of transferring to SOS, NATOUSA, as might have been expected. This arrangement further circumscribed Larkin’s span of control and authority. Finally, SOS, NATOUSA, had to set up its headquarters at Oran, the principal American supply base in North Africa, although AFHQ/NATOUSA headquarters installations lay at Algiers, over 200 miles to the east. Communications over this distance often slowed logistical reaction time.

The establishment of SOS, NATO-USA, created a new set of personnel problems for the engineers. The Engineer Section of SOS, NATOUSA, informally came into being in February with six officers and seven enlisted men borrowed from the 1st Engineer Amphibian Brigade. Not until April did the section receive an allotment of five officers and fourteen enlisted men and return the borrowed personnel to the brigade. Initially, the principal function of the small SOS, NATOUSA, Engineer Section was to control and edit requisitions for engineer supplies that the base section engineers drew on the United States or the United Kingdom. In turn, the main tasks of the base section engineers during the Tunisian campaign were to construct and maintain supply routes and to operate engineer supply depots.47

Atlantic Base Section

All along the long line of communications from Casablanca east, preparations went forward with all possible speed for the decisive battles in Tunisia. Engineer supplies and equipment came into Atlantic Base Section (ABS) at Casablanca at the rate of 2,000 tons per convoy, and ABS issued large amounts of engineer supplies to units staging for Tunisia. The depot responsibilities taxed the ABS engineer supply personnel (built around the 451st Engineer Depot Company) to the limit, and local labor could not meet the emergency. In April the arrival of an engineer general service company eased the problem at the ABS engineer depot.

Unit demands for many items in excess of Table of Basic Allowances, together with a growing need for vastly more material for housing, hospitals, and sanitary facilities than originally planned, placed most items in ABS engineer dumps in the “critical” category. Construction supplies from the United States lagged far behind requisitions and procuring locally such items as cement, lumber, and electrical and plumbing equipment was difficult. A major drop in imports since the outbreak of war in Europe in 1939 had created a serious shortage of construction supplies of all types throughout French Morocco, and local merchants and manufacturers tended to hold back materials that might later bring higher prices; however, centralized purchasing for engineer supply items largely overcame the local procurement problem.

By mid-May, at the end of the Tunisian campaign, ABS engineers had virtually completed their own construction program and had issued tons of locally procured construction material. At the same time, less than half the construction supplies ABS engineers had requisitioned from the United States had reached Casablanca. Much of the missing materiel that began to arrive during succeeding weeks was no longer needed. By late June ABS engineer dumps contained 10 million board feet of unwanted lumber.48

Mediterranean Base Section

At Oran, the site of both Mediterranean Base Section (MBS) and SOS, NATOUSA, personnel problems were much the same as those at ABS. Four engineer supply depots were in the Oran area by late December 1942, but only the 450th Engineer Depot Company (less one platoon) was available to operate them. As early as December an engineer dump truck company and two companies of the 1st Engineer Amphibian Brigade had to be diverted to depot operations, and the depots also employed about 800 local laborers. In midwinter the understrength (1 officer and 80 enlisted men) 715th Engineer Depot Company joined the force. By March, when the 460th Engineer Depot Company reached Oran from the Zone of the Interior (ZI), the MBS engineer depots were employing approximately 1,500 local laborers. In April the 462nd Engineer Depot Company arrived from the ZI. Nevertheless, the MBS engineer constantly had to add nonsupply engineer detachments to the depot force. These detachments generally had no supply training and had to learn on the job to unload, handle, store, and account for engineer supplies.49

Shortages of equipment, especially vehicles, also plagued engineer supply operations within MBS. As of February 1943 the 450th Engineer Depot Company, the first such unit in the Oran area, was 30 percent short of its TBA vehicles, the 715th Engineer Depot Company 60 percent short, and other engineer units assigned to depot operations an average of 31.5 percent

short. The most serious need was dump trucks, and the MBS engineer constantly tried to obtain more of them. In late January 1943 he requested the highest shipping priority for dump trucks, pointing out that they represented a very small percentage of engineer tonnage.50 The Tunisian campaign ended, however, before the problem was solved.

During January 1943 MBS engineer depots shipped an average of 250 tons of engineer supplies per day eastward to support operations in Tunisia. The figure rose to 400 tons in February, 500 tons in March, and 900 tons in April; however, the end of the Tunisian campaign in mid-May brought that month’s average down to 450. While the MBS engineers were issuing supplies, they also had to handle increasingly large receipts. In February, for example, MBS engineer depots received an average of 600 tons of supplies and equipment per day, and at the end of the month engineer depot stocks approximated 35,000 tons. The receipt average for March was about 700 tons a day, for April approximately 1,400 tons, and for May 1,375 tons. At the end of May, MBS engineer depots held more than 100,000 tons of engineer supplies and equipment.51

Eastern Base Section

NATOUSA established the Eastern Base Section (EBS) on 13 February 1943 to support II Corps in Tunisia. The commander was Col. Arthur W. Pence, and the chief of the Engineer Section was Col. Donald B. Adams. The command organized and undertook planning at Oran, and on 23 February began moving eastward to Constantine, in Algeria, about 100 miles short of the Tunisian border. The organization of EBS nearly coincided with significant changes in tactical command within Allied forces in North Africa. On 7 March Lt. Gen. George S. Patton, Jr., took over command of II Corps from Maj. Gen. Lloyd R. Fredendall, and II Corps passed from the control of the British First Army to that of 18 Army Group, General Sir Harold R. L. G. Alexander commanding. The British First and Eighth Armies constituted the other major components of 18 Army Group.

The principal problems EBS engineers faced were receiving, storing, and issuing materiel; repairing and maintaining supply roads; building adequate depot facilities and shops; and rehabilitating ports at Philippeville and Bone, on the Mediterranean coast north from Constantine. The necessity of quick reaction to changes in the progress of the ground campaign differentiated EBS from ABS and MBS.

In March the principal EBS engineer depot lay at Tebessa, close to the Tunisian border, about 110 miles southeast of Constantine and within relatively easy supporting distance of II Corps. When II Corps suddenly moved to northern Tunisia in April, EBS engineers followed suit. They concentrated at a partially constructed EBS general depot at Mondovi, about twenty-five miles south of Bone, and rapidly set up advance engineer dumps at La Calle