Chapter 18: Revisions in the Depot System

After starting in 1941 with a depot system that could not meet all its constantly increasing needs, Ordnance faced four major problems during the war: (1) finding storage space for general supplies far in excess of original forecasts; (2) meshing motor transport facilities into the Ordnance supply system; (3) adjusting to reallocation of depot space by Army Service Forces; and (4) shifting emphasis from support of troops in training in the United States to the support of overseas theaters.

Storage of General Supplies

As noted in the preceding chapter, Ordnance did not build many warehouses in 1939-1940 for storage of general supplies, or “combat equipment” as such matériel was beginning to be called. Its main effort had been directed toward ammunition storage. But with the rising tide of war production, actual and planned, in 1940, Ordnance was allotted $7,244,000 for warehouse construction in fiscal year 1941. This appropriation was divided three ways: $2 million was to be used to add 500,000 square feet at Ogden Ordnance Depot and the rest was to be divided very nearly evenly between two unnamed depots, one in the southeast to provide 650,000 square feet and one in the central area to provide 661,000 square feet.1

The existing depot at Anniston, Alabama, was selected as the site for new storage space in the southeast because its location was ideal to serve the maneuver area of the south, and adjacent land was available for purchase if needed for expansion. After the site was approved, construction proceeded rapidly. By March 1942, seventeen warehouses with a combined floor area of 772,200 square feet had reached completion.2 For the depot in the central area, Ordnance planners decided to enlarge Rock Island Ordnance Depot, traditionally a great center for general supply storage. One enormous warehouse, 1,423 by 545 feet, with a total of 767,888 square feet, reached completion in June 1942, and was the first of its size and type in War Department history. Planned to house tanks, it was one story high, covered eighteen acres, and could receive under its roof a freight train of sixty cars.3 The forty new warehouses begun at Ogden in the fall of 1940 were at first filled with inert ammunition components and empty practice bombs; this matériel, was removed to open storage when the first

stock of general supplies arrived in March 1942.4 Months before the new facilities at Ogden, Anniston, and Rock Island were ready, it became evident that space for combat equipment would again have to be increased because of accelerated production to meet rising mobilization objectives. In the summer of 1941 a new problem arose—the amount of lend-lease matériel that was accumulating in the United States because there were not enough ships to move it out.

In July 1941 the Ordnance Department, after a careful study of requirements, recommended that twelve million additional square feet of permanent-type warehouses for general supplies be built at the new ammunition depots; later it urged that seventeen million more square feet be provided to take care of the fiscal year 1943 program. Ordnance pointed out that the ammunition depots under construction were equally well suited for general supplies from the standpoint of transportation and strategic location. Many of them were in the high altitude region considered ideal for long-term storage. They had adequate power, water, and other facilities for expansion, and plenty of acreage.5

This pre-Pearl Harbor attempt at expansion was unsuccessful. At a meeting in September 1941 the War Department Budget Advisory Committee appeared uninterested in the Ordnance presentation. That fall, the War Department began to build general depots in Michigan, Illinois, Ohio, and Indiana—the area in which about 75 percent of the munitions would be produced—to regulate the flow of lend-lease supplies to ports; G-4 contemplated placing much of the new production of weapons and tanks, along with supplies of other technical services, in these depots. There were eventually eleven of them, called Defense Aid originally but soon renamed War Aid.6

After Pearl Harbor, the General Staff allotted to Ordnance about $39 million for new storage space for general supplies at Letterkenny, Anniston, Red River, Umatilla, Sierra, and Ogden; this sum was to provide a total of 2,747,000 square feet of warehouse space and 5,000,000 square feet of shed space.7 But the bulk of the space allotted to Ordnance was at the eight Defense Aid depots, a total of eight million square feet of covered space and sixteen million square feet of open storage. There was also in contemplation the utilization of commercial warehouses and the end of permanent-type construction.8

The War Munitions Program of

February 1942 set extremely high production goals for tanks, artillery, and other equipment.9 Preliminary estimates by Colonel Steese, chief of a new office established within Field Service on 2 February to consolidate all depot construction activities and planning, indicated that a total of about 119 million square feet of space would be necessary if Ordnance had to store all matériel to be produced in 1942 and the first three months of 1943. Not all of it would have to be stored, of course, for some of it would immediately go to troops or to allied nations. The best guess was that Ordnance would have to

store about 50 percent of the total production for U.S. troops and about 40 percent of War Aid production. On this basis, about 25,900,000 square feet of storage space would be needed; the Ordnance plan divided it into 13,400,000 for warehouses and 12,500,000 for sheds.

In their presentation to higher authority, Ordnance planners pointed out that postwar needs should also be taken into account, because building materials and labor would become scarce as the war went on, and funds for postwar construction would be hard to get. They also argued that sheds with walls were far better than open storage for artillery, tanks, and other combat vehicles equipped with delicate fire control instruments and radios. Granted that most of the supplies would be manufactured in the Ohio, Michigan, and Illinois area, they did not recommend that region for postwar storage because its climate would make excessive maintenance necessary. The Ordnance solution was to locate the new general supply space at twelve ammunition depots, balancing warehouse and shed space with that already authorized at Sierra, Letterkenny, Umatilla, and Ogden, and building both types in approximately equal amounts at Tooele, Sioux, Pueblo, Wingate, Navajo, Blue Grass, Seneca, and Black Hills.10

After a survey showed that 74 percent of the expected carload deliveries would be for tanks and combat vehicles that could not be stored in the open, the General Staff reversed its earlier decision to place Ordnance matériel at War Aid depots and approved the building of warehouses and sheds at the ammunition depots. Except for permanent buildings already authorized, all construction was to be temporary,11 meaning mobilization or theater-of-operations type. Warehouses of the latter type were built of some flimsy material, such as plywood, and were not much better than tents. They were not suitable for housing certain types of Ordnance matériel, as the Chief of Engineers pointed out to the War Department. Nevertheless, General Somervell laid down the principle in March 1942 that, because the first consideration was economy in money, time, and critical materials, warehouses were to be of light frame construction, with fire walls only where necessary, with roofing specifications not to exceed a 10-year limit, and without excessive roof spans; sheds were to be of open-type light frame construction, without concrete floors. On 1 June 1942 the War and Navy Departments and the War Production Board set up rigid rules for wartime construction. It was to be “of the simplest type, just sufficient to meet the minimum requirements.” Thus any additional construction at existing Ordnance depots, with the exception of igloos, had to be theater of operations type whenever possible. There was one loophole: masonry construction, such as concrete blocks, could be used if the material was not critical in the area concerned and if its cost would not run more than 15 percent

Open-type storage sheds (right) at Casad Ordnance Depot, New Haven, Ind., September 1943.

over the cost of the theater of operations construction.12

Not all the new combat equipment went into ammunition depots. Some of it was stored in Ordnance sections of the three Army general depots at Columbus, Ohio; New Cumberland, Pennsylvania; and Schenectady, New York. Some of it went into old-line repair arsenals such as Augusta, where Civil War caissons had to be moved out into the open to make room in the warehouses.13 But most of the general supplies went into warehouses and sheds built for the purpose at the new ammunition depots. At the time the fifty million additional square feet of combat equipment space was estimated, no great influx of new ammunition was expected. Of all the new ammunition to be produced, Ordnance assumed that about half would be stored and half would be expended in combat or in training.14 By December 1942, twelve of the ammunition depots that grew out of the expansion plans of 1940 and 1941—Anniston, Black Hills, Blue Grass, Letterkenny, Navajo, Pueblo, Red River, Seneca, Sierra, Sioux, Tooele, and Umatilla—each had, existing or authorized, between 900,000 and 2,500,000 square feet of combat equipment space. Anniston, Letterkenny, Pueblo, Red River, Seneca, Sierra, Sioux, and Tooele had more square feet in

combat equipment warehouses than they had in ammunition magazines and igloos.15

Early in 1942, when Ordnance storage officials planned the move of general supply stocks into ammunition depots, they were thinking in terms of reserve storage to back up distribution depots and space to store war reserves that would accumulate at the end of the war. Nobody knew at the time to what extent the great ammunition depots would be drawn into the distribution picture.16 Problems of distribution aside—and these would become acute in 1943 when the emphasis shifted from domestic supply to overseas supply—the disadvantages of isolation came to be keenly felt in the case of combat equipment. Ordnance supply experts felt later that general supply operations were more seriously hindered by isolated locations and the lack of skilled labor resources than were the ammunition supply operations at the same depot.17

Yet the fact that the Ordnance Department combined equipment storage with ammunition storage and secured the necessary land at low prices stretched the funds allotted for land so that the General Staff could use some of the money for other supply services and buy the site for at least one training camp.18 Moreover, the early construction of equipment warehouses helped to ease a critical storage situation both during the war, when the War Department could place in Ordnance warehouses and sheds large stocks of matériel of other agencies for which no adequate provision had been made, and immediately after the war, when rented commercial warehouses and railroad storage yards had to be given up. General Crain’s insistence on permanent construction, in the period before building materials became scarce, provided for the first time in Army history suitable storage for war reserves.19

The Acquisition of Quartermaster Facilities

When the Ordnance Department in midsummer of 1942 received from the Quartermaster Corps the responsibility for motor transport vehicles,20 the storage facilities that came with the new mission included six War Aid depots, eight motor bases, four motor supply depots, eleven motor supply sections at Quartermaster depots, and one motor reception park. At the time of transfer, a large proportion of the covered storage at War Aid depots was shed space, and a great deal of the total area, in some cases most of the total, was open storage.21 There were maintenance difficulties, because the buildings had been hastily constructed for limited service at a time when shortages forced the use of substitute building materials. As “holding and reconsignment points” or stopping places for supplies already consigned to a destination, these depots had not had the function of filling requisitions and therefore had

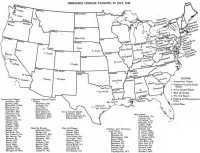

Ordnance Storage Facilities, 23 July 1944

little or no operating equipment, office space, lunchrooms, and so on; as reservoirs for bulk storage, they lacked bins and other facilities. But these disadvantages were offset by the location of the War Aid depots in the area in which about 75 percent of general supplies were manufactured; after extensive rewarehousing programs, they served Ordnance well. Rossford (formerly named Toledo) became the master depot for automotive parts and Lordstown the master depot for tools.22

The motor facilities that came with the Motor Transport Service were scattered throughout the country. The eight motor bases were at Atlanta, Georgia; Fort Crook, Nebraska; Fort Devens, Massachusetts; Holabird (near Baltimore), Maryland; Fort Lewis, Washington; San Antonio, Texas (called Normoyle); and Pomona and Stockton in California. The four motor supply depots were mostly in the central area: Little Rock, Arkansas; St. Louis, Missouri; Fort Wayne, near Detroit, Michigan; and Candler, at Atlanta, Georgia. There was one motor reception park, at Carteret, New Jersey, and there was space for motor supplies at eleven Quartermaster depots, more than half of them in the east.23

Space had been allotted to the Motor Transport Service on the basis of the 1942 procurement program, which consisted of approximately one million vehicles with corresponding parts, tires, and supplies. The plan for 1943 called for about the same number of vehicles but with an increase of approximately 67 percent in the volume of parts, and an 85 percent increase in tools and equipment. All this added up to a heavy load on storage facilities, beginning in the fall of 1942 when most of the matériel ordered under the 1942 program would be delivered. Against this load the Ordnance Department could count on using some space that had been intended for such material as gasoline drums, since responsibility for petroleum products remained with the Quartermaster Corps; also, some vehicles could be stored for short periods in railway transit yards. A few vehicles could be stored at factories, though Quartermaster policy had been to keep such storage at a minimum because of the bad psychological effect on labor.24

Ordnance storage specialists, with the aid of the experienced motor transport officers who were transferred along with their service and the reservists who continued to come into the Army from the automobile industry, worked throughout 1942 and into the summer of 1943 to mesh the Quartermaster motor bases and depots into the Ordnance distribution system. They consolidated the two Atlanta installations, the motor base and the motor supply depot, to form the Atlanta Ordnance Depot. In Texas they moved the Normoyle Ordnance activities to San Antonio Arsenal, forming the San Antonio Ordnance Center. At Pomona, California, they turned over the buildings and facilities of Pomona Ordnance Base to the Desert Training Center, which was run as a theater of operations with an Ordnance base. All the motor transport bases were designated depots, and two were renamed.

Fort Lewis in Washington became Mt. Rainier to distinguish it from other military activities at the Fort Lewis installation, and for the same reason Fort Devens in Massachusetts was renamed Whittemore, in honor of the late Brig. Gen. James M. Whittemore.25

Reallocation of Space by ASP

Ordnance reached the peak of its storage expansion in December 1942. At that time it had fifty-four depots in the United States, twenty sections in Quartermaster or other non-Ordnance installations, two depots in territorial areas, and storage facilities at ports of embarkation. At Ordnance depots general supplies were allocated nearly thirty-nine million square feet of warehouse space, more than eight million square feet of shed space, and about fifty-two million square feet of open storage. Some two million square feet were devoted to packing, shipping, receiving, and repairing. When Ordnance space at shipping terminals, general Army depots, and depots of the other technical services was added, the total figure for general supply storage exceeded one hundred million square feet. This made Ordnance the largest warehouse operator in the world, with more storage space at its command than all the commercial warehouses in the United States combined.

At this point, Army Service Forces began to question whether Ordnance really needed all this space. The answer was made clear by a survey showing that the depots were only about half full. Only 54.2 percent of Ordnance’s net usable warehouse space was occupied, 55.2 percent of the shed space, 31.2 of the open space, and 60.7 percent of the igloo and magazine space.26 ASF planners con- cluded that Ordnance had overbuilt in the early stages of the war, a conclusion that was reiterated in a postwar study by the General Staff. Conceding that it was natural enough for each service to allow itself some margin for reserve, ASF officials blamed lack of strict General Staff supervision in the early days of the war for inequitable distribution of space. In the spring of 1943 they decided to reallocate existing space on the basis of collective needs rather than add new space. They not only redistributed space among the technical services and Ground Forces but also coordinated requirements of the Army Air Forces, the Treasury Department, the Navy, and other Government agencies.27

In July 1943 Ordnance surrendered to the Medical Department the Louisville depot that had come in with the War Aid group. In the fall, two of the motor transport depots were released: Little Rock went to the Army Air Forces and Holabird to the Signal Corps. The functions of both could easily be absorbed by great Ordnance depots nearby—Red River in the case of Little Rock, which had carried a small stock of tires only; and Letterkenny in the case of Holabird. About the same time, the old World War I ammunition depot at Charleston, South Carolina, was turned over to the Transportation Corps. In January 1944, two more motor transport depots were released, Whittemore to the First Service Command, and Normoyle to the Army Air Forces. By then Ordnance had also released motor supply sections at Quartermaster depots in Richmond and

Alexandria in Virginia, Atlanta and Savannah in Georgia, and Mira Loma in California. During FY 1944 Ordnance lost about four million square feet in warehouse space, two million in shed space, and about half a million in open space. At the same time, the percentage of occupancy rose sharply in all cases, from 54.2 to 67.7 in warehouses, 55.2 to 64.5 in sheds, and 31.2 to 65.3 in open storage.28

After this period of contraction there were a few minor additions and some readjustments. Facilities once a part of Fort Wayne Ordnance Depot became Palmer Woods Ordnance Depot. In the spring of 1944 a one-story rented building at Vernon, California, became Los Angeles Ordnance Depot; and the Pennsylvania Ordnance Works, transferred from Industrial Service to Field Service, was renamed Susquehanna Ordnance Depot.29 In April 1945 space had to be provided at depots and plants to take care of the overflow of ammunition stopped on its way to Europe; but this was temporary in-transit storage lasting only from V—E Day to the time of reshipment to Japan.30

On the whole, the Ordnance storage space that remained after the contraction of 1943 and early 1944 carried the load throughout the war. By 1944 the emphasis had shifted to overseas supply and there was an increasing number of direct shipments that bypassed the depots. Better warehousing and depot management and, in some cases, better methods of stock control also aided in the supply of armies much larger than had been estimated in early planning.31

The Changing Pattern of Distribution

For ammunition storage, at the beginning of 1943 there were three types of depots—reservoir, area, and transshipment. Typical of the reservoirs were the big depots in the interior that stored slow-moving stocks—Black Hills, Blue Grass, Milan, Navajo, Ogden, Portage, Red River, Sierra, Sioux, and Wingate. Area depots were Pueblo, San Antonio, and Savanna; along with Anniston, Letter-kenny, Seneca, and Umatilla, they had the responsibility in certain areas of supplying posts, camps, stations, and air bases. San Jacinto was primarily a transshipment depot, a kind that handled ammunition shipments en route to ports and awaiting ship movements. Other transshipment depots were Charleston, Curtis Bay, Delaware, Nansemond, and Raritan on the East Coast, and Benicia on the West Coast. Some of the reservoir depots had had from the beginning the responsibility for “backing up” various area depots and ports. During 1943 and 1944, as the emphasis shifted to overseas supply, a number of depots of all three types were given “back-up” or “intermediate” duties, in order to regulate the flow to the overburdened ports. Some of the reservoir depots began to supply the service commands in their own areas. Generally the tendency was to reduce the number of depots that were exclusively reservoir or transshipment and to increase the area and intermediate missions. In 1944 there were some changes in terminology: reservoir became “reserve,” area became “distribution.”32 But on the whole there was no

major revision in the ammunition depot system. The most significant change in the pattern of ammunition supply from 1943 on was the trend to ship direct from plants to ports, training camps, the Navy, or other users. And, to avoid unnecessary movement of this heavy and dangerous matériel, better stock control methods were evolved.33

In planning for the distribution of the tremendous quantities of weapons, tanks, and other general supplies produced after Pearl Harbor, Field Service officials relied on the old-line general supply depots, backed up by reserve stocks stored in warehouses and sheds at the new ammunition depots. Seneca and Letterkenny were to back up Raritan, which handled the First, Second, and Third Service Commands and supplied the Atlantic bases; Anniston would back up Augusta, which served the Fourth Service Command, Red River would back up San Antonio; Ogden would back up Benicia, which served the Ninth Service Command and supplied the Pacific bases. Space at the great high altitude depots like Sierra, Pueblo, Sioux, and Black Hills would be used to store the reserves that were expected to accumulate after the war.34 This plan was feasible enough as long as general supplies consisted mainly of weapons and combat vehicles. But when the heavy load of motor vehicle responsibilities was added, involving an unprecedented spare parts problem, it became evident that the depot system would have to be revised.35

In December 1942 the storage experts of the Supply Branch of the Tank-Automotive Center in Detroit, which now had most of the responsibility for general supplies, drew up a plan for the distribution of parts, tools, and equipment. It contained the germ of the change in depot missions that took place in 1943. The planners proceeded on the premise that distribution depots ought to be kept to a minimum and ought to keep their stocks at the lowest possible level consistent with requisitioning demands. Keeping the number of such depots to a minimum would avoid undue dispersal of critical stocks and would permit the concentration of office and warehouse equipment, key personnel, and labor, all of which were becoming scarce. Getting rid of excess stocks would free more space for fast-moving items and would cut down on physical handling and paper work. The depots would be kept fluid. Current stocks over and above those needed to fill requisitions would be moved into Master Supply, or wholesale, depots, from which they could be withdrawn by the distribution depots as needed. Current stocks in excess of the capacity of the Master Supply depots would be shipped into Reserve Storage depots, on a bulk basis. Obsolescent items would be concentrated in one depot.36

In applying these principles, the planners brought into the active distribution pattern some of the large new ammunition depots and revised the missions of some of the motor transport and War Aid depots acquired from the Quartermaster Corps. For example, in the eastern area the distribution depots serving the First, Second, and Third Service Commands and the ports of Boston, New York, and Hampton Roads in the fall of 1942 were Schenectady, Raritan, and Holabird. In the future,

Letterkenny was to be the distribution depot for all parts, supplies, tools, and equipment, with one exception —tools and equipment for tanks and tractors were to come from Lordstown, the distributor for this kind of matériel to all service commands and ports of embarkation except those on the West Coast. The substitution of Letterkenny would free Raritan to be the requisitioning point for the eastern ports of embarkation for all parts and supplies except those of wheeled and semiwheeled vehicles, which would come from Toledo (soon to be renamed ‘Ross-ford), a kind of reservoir for automobile parts in the same sense that Lordstown was for tools and equipment.37

The Master Depot System

From this early planning stemmed the Master Depot concept that profoundly influenced the Ordnance depot system. By April of 1943 the pattern was clear. Parts, supplies, tools, and equipment flowed through four major types of depots: master, distribution, storage, and arsenal. There were only four master depots, but each stocked every item required for the maintenance of certain classes of matériel. Rock Island was responsible for tank, tractor, artillery, and small arms parts and supplies; Rossford for wheeled and half-track parts and supplies; Lordstown for tools and equipment, except for fire control instruments; and Frankford for parts, supplies, tools, and equipment for fire control instruments. Their stocks were available for immediate movement into combat theaters or into domestic activities, as the situation demanded. Supplies from master depots flowed through the distribution depots, the second major type.

In the category of distribution depots were several groups, the most important of which were the “retail” or domestic depots that supplied the service commands within their respective areas. In the eastern area, Letterkenny supplied everything needed; in the south, Atlanta furnished motor transport matériel and Anniston everything else; in the middle west and west, Ft. Wayne and St. Louis supplied motor transport matériel and Rock Island everything else; in the southwest, Red River carried the full line, as did Ogden for the West Coast. Second in importance in this category were the filler or export depots that supplied the ports of embarkation: Raritan serving Boston, New York, and Hampton Roads; Atlanta serving Charleston and New Orleans; Anniston serving Charleston; Red River serving New Orleans; Mt. Rainier serving Seattle; and Stockton and Benicia both serving San Francisco. Less important than the retail depots and the filler depots, but still in the category of requisition points, were the “special stock” depots that carried parts for major items that were in limited supply because they were substitute standard, obsolescent, or experimental. For this type of matériel St. Louis issued parts for wheeled and half-track vehicles and Rock Island parts for weapons, tanks, tractors, and fire control instruments; Ft. Crook issued tools and equipment for all major items, with some assistance from Lordstown.38

The storage depots, the third of the four major types, were the largest in number.

There were twenty-two in all. Five of them were Ordnance sections in ASF depots, five were 1940-41 war-reserve depots such as Black Hills and Sierra, nine were former motor transport or War Aid installations, and three were old-line Ordnance depots. Of the latter, in a reversal of roles, Augusta was now supporting Anniston, and San Antonio, Red River. Some of the storage depots were well located geographically to support filler, rather than domestic retail, depots. Known as “advance” depots, they temporarily held boxed or crated parts and tools until the Ports of Embarkation called for them on movement orders. Others had processing layouts to assemble certain classes of matériel into sets, and box and crate it. Assembly and processing were important functions also of the fourth type, the arsenal depots at Springfield, Watertown, and Watervliet, and also at Aberdeen and Erie Proving Grounds. At these Industrial Service installations, workers assembled the parts, supplies, tools, and equipment that accompanied the major items that went forth to the requisitioners.39

By the time the new depot system went into effect, on 1 July 1943, the trend from domestic to export business had already set in. Fifty-seven percent of all general supply tonnage was being shipped overseas. But the impact of this shift on the new depot system did not become plain to Ordnance planners until late in 1943 when the campaign in Italy was well under way and stockpiling had begun for the invasion of Europe. Then it became apparent that the weakness in the new system was the bottleneck that could be caused by an inadequate filler depot. Raritan, a comparatively small installation, was attempting to supply the eastern ports with stocks of weapons parts, general purpose vehicles, combat vehicle parts, and cleaning and preserving materials; and it was falling behind. Ordnance storage experts decided that it was better to depend for export less on the “country store” type of filler depot and more on the master depot specializing in certain lines. Two of the master depots had been shipping for export direct to ports for some time, Lords-town for tools and Rossford for automotive parts.40

With the emphasis increasing on master depots rather than distribution or filler depots, in the spring of 1944 General Campbell, acting on the advice of Mr. Lewis H. Brown, president of the Johns-Manville Corporation, and Mr. Keller, president of Chrysler, decided to use the master depot technique to speed the flow of tank and automotive supplies to troops overseas, concentrating at one depot all parts for a certain make of vehicle, such as Chevrolet, and at another all parts for a certain kind of vehicle, such as heavy duty trucks. The object was to achieve better control of stocks by concentrating like and interchangeable parts in one place and enabling depot employees to specialize more narrowly; to simplify requisitioning; and to give more flexibility in meeting overseas demands.41 As of August 1945 the principal master depots were Rock Island, Frankford, Palmer Woods (a new depot added in the spring of 1945), Ross-ford, St. Louis, Letterkenny, Terre Haute, Fort Wayne, Lincoln, and Atlanta. Depots with more limited master depot

responsibilities were Watervliet, Watertown, the Submarine Mine Depot at Fort Monroe, Anniston, Blue Grass, Aberdeen, Ogden, and the Ordnance section at Columbus General Depot.42

General Campbell believed that the master depot plan for automotive supplies “contributed greatly to the lessening of serious bottlenecks in the overseas supply problems.”43 But stocking by make of car, such as Dodge or Chevrolet, ran counter to the parts-identification system set up in 1944.44 Another obstacle to smooth functioning was the inability of the Ordnance Department after May 1945 to operate the master depots strictly as wholesalers shipping bulk quantities in unbroken cartons or boxes. ASF Manual M411 of 1 May 1945, Procedures for Processing Overseas Requisitions, required that if an item was anywhere in the depot system, any customer was entitled to it, regardless of the quantity desired. Consequently, retail depots were forced to requisition small lots from the master depots, which had to set up retail departments. Ordnance storage experts believed strongly that wholesale and retail operations could not be efficiently combined.45

Even under the master depot system, missions were not clearly defined. One depot usually had several functions; that is, it might be some combination of the master, distribution, filler, or storage type of installation, and the missions varied, not only as to type of depot but as to type of matériel. For example, by June of 1945 Anniston was a master depot for parts and supplies for scout cars and K and L groups (cleaning and preserving matériel and targets). It was also a distribution depot for the Fourth Service Command for tracked and wheeled vehicles, K and L matériel, supplies and equipment for automatic weapons of 20-MM. and above, and for field artillery; for the same matériel, excepting wheeled vehicles and K and L items, it was a filler depot to the Charleston Port of Embarkation.46

Instability in Depot Missions

Changes in missions were common in the last two years of the war. A case history, perhaps an extreme one, is the story of Letterkenny. One of the large ammunition depots of the 1940-41 group, it first came into the general supply distribution pattern in January 1943 as a reserve storage depot to back up Raritan. In the changeover to the master depot system that took place on 1 July 1943 it became the distribution depot for the First, Second, and Third Service Commands. When congestion became apparent at Raritan late in 1943, Letterkenny became a filler depot to assist Raritan for Dodge, Ford, and General Motors parts. In addition to these major changes, there were several minor changes in types of matériel handled and requisitioners supplied; in September 1943, for example, the Army Air Forces in the area became one of the depot customers. In the words of the depot historian, “The missions given to Letterkenny during the year speeded and picked up like a snowball rolling downhill. Heterogeneous carloads of matériel were rolling in to a depot with incompleted bins and

warehouses while back orders were accumulating for matériel that was not yet stored.”47

Early in 1944 the depot took over Raritan’s filler responsibilities and ceased being a domestic distribution depot except for targets and cleaning and preserving matériel. Six months later came another important change. In July 1944 Letterkenny became the master depot for parts and supplies for Chevrolets, the distribution depot for combat, wheeled, and semi-wheeled vehicles for the First, Second, and Third Service Commands, and the filler depot for eastern ports for wheeled vehicles, common hardware, parts common, and major items. Early in January 1945 storage planners at Detroit, seeking to relieve the overburdened Ft. Wayne installation, gave Letterkenny the master depot responsibility for heavy duty trucks, taking away certain parts supply functions.48

Criticism by higher authority that the Ordnance Department failed to achieve stability in depot missions appears to be justified; and there is evidence that instability placed heavy burdens on the depots.49 When mission changes were made, Ordnance tried to keep interdepot movements of matériel to a minimum, using them only when it was not possible to deplete stocks through attrition; but they were necessary at times and often required not only shifting stocks but extensive rewarehousing, moving bins and other storage equipment from one depot to another, and retraining workers.50

Some rearrangement of the depot system was doubtless inevitable to correct faults caused by the improvisation of the early expansion period. Some changes were adjustments to decisions of ASF, such as the loss in the summer of 1943 of some of the motor transport depots that had been inte- grated into the master depot system.51 An Ordnance study made in June 1945 ascribed the large number of mission changes in the second and third year of the war to the fact that planners had had to work by trial and error. With very little basis on which to forecast the quantity of matériel to be shipped, or the rate at which such shipments would be required by the theaters, they had found it almost impossible to forecast depot loads with any degree of accuracy.52 Also, there were defects in organization, notably an unfortunate division of responsibility for distribution between Detroit and Washing-ton.53

But it is permissible to speculate whether some of the changes in depot missions might not have been avoided by more careful planning. At the time the Master Depot system was evolved early in 1943, the congestion at Raritan might have been foreseen. And if the change-over to stocking master depots by make of car such as Chevrolet or Dodge was desirable it might better have been effected then rather than

in 1944, after the by-item system had gone into effect. Col. W. C. Gamrath, an experienced Ordnance supply officer, feelingly expressed one point of view on shifting patterns of distribution:

“The methods of distribution of ordnance supplies seemed to be a target of many `experts’ within the Ordnance Department, within Headquarters ASF, and from industries on the outside. There was a period during 1943 and 1944 when it seemed in vogue to change the methods. ... I have observed and studied a sufficient number of businesses to realize that there are several different methods under which materials similar to Ordnance supply may be successfully distributed. I am of the firm opinion that it would have been far better to select one of these approved methods and stick to it throughout the war than to go -through a constant state of change.”54

Though some alteration in the pattern of supply was contemplated to meet the emphasis on a one-front war in the Pacific, changes in 1945 were kept to a minimum. Looking to the postwar period, Field Service began comprehensive planning to achieve a stable program of supply. The program envisaged a network of permanent depots carefully selected on the basis of the facilities that were available, the workload that could be handled, the sources of labor that could be tapped, and the technical knowledge of the workers. To these permanent depots there would be gradually transferred the functions of the less desirable installations, which would be closed out. Generally speaking, the pattern of distribution after the war would be based on two factors. One was the correct location of depots, with distribution responsibilities assigned to depots situated in the area they served. The other was storage by commodity, with related types of matériel stored at specific depots.55

The Ordnance experience in World War II showed that the efficiency of a supply and distribution system depended on many factors, chief of which were the location of depots, the nature of depot facilities, and availability of civilian workers. In its final report, Logistics in World War II, ASF observed that, “As the war progressed, it became evident that the entire distribution system depended for its efficiency upon the location of the depots.” Unfortunately, no pattern of depot locations would serve all purposes equally well. Nearness to manufacturers was an advantage that had to be weighed against nearness to ports of embarkation. In terms of safe storage of ammunition, vast desert tracts were ideal, but in terms of labor supply they left much to be desired. At the start of the defense period the War Department permitted each technical service to develop its own system of distribution and storage with the result that there was no integrated plan for the army as a whole. As far as Ordnance was concerned the result was overexpansion of depots in the early years. But the choices of sites were generally good, and the excess capacity created in the 1940-42 period was readily redistributed by ASF in the 1943–44 period. The capability of individual depots as measured in terms of buildings, equipment, and labor supply was also of great importance to efficient operations. On this score, the lack of adequate provision in the early years for storing general supplies—as distinguished from ammunition—proved to be the biggest

shortcoming. But it was rather quickly remedied after Pearl Harbor, as was the other major problem of integrating with Ordnance depots the storage space acquired from the Motor Transport Service. Not so easily solved were the problems of supply terminology, stock control, and maintenance discussed in the following chapters.