Chapter 6: The Completion of BOLERO

The Flow of Troops and Cargo, January–May 1944

The U.S. build-up in the United Kingdom was accomplished largely in the twelve months preceding D Day, having received its major impetus from the TRIDENT Conference of May 1943. The BOLERO operation accelerated noticeably in the fall of 1943, achieved tremendous momentum in the early months of 1944, and crescendoed, in the manner of the Ravel composition for which it was named, to its climax in May. In the five months from January through May alone the number of American forces in the United Kingdom was doubled, rising from 774,000 in December 1943 to 1,527,000 in May 1944. In cargo shipments the record was similar; upwards of 2,000,000 long tons, or 40 percent of all U.S. tonnage discharged in U.K. ports in the two and one-half years from January 1942 to May 1944, were received in the five months preceding D Day. This performance was all the more remarkable in view of the serious restriction on both troop and cargo reception imposed by the limited British port and inland transportation facilities, which in the final stages actually threatened to prevent the consummation of the build-up.

At the QUADRANT Conference in August 1943 the Combined Chiefs of Staff had agreed to have 1,416,900 U.S. soldiers in Great Britain by 1 May 1944, and shipping was subsequently set up to permit this target to be achieved. In the fall of 1943 approximately 50,000 air force troops intended for the ETO were diverted to the Fifteenth Air Force in North Africa, and at the SEXTANT Conference held by Allied leaders at Cairo in November–December 1943 the Combined Chiefs, on the basis of shipping and unit availability, lowered the U.K. troop ceiling to 1,366,000, a reduction roughly equivalent to the diversions to North Africa. Either through misunderstanding or through ignorance of this reduction ETO officials responsible for the preparation of flow charts continued to plan for and request shipments considerably in excess of the SEXTANT schedules,1 basing their requisition on the first phase troop basis. OPD officials honored these requests at first. They even diverted some 20,000 troops from other theaters and activated additional units totaling 30,000 men, although inadequately trained, to meet the ETO’s D-Day requirements. In February, however, the OPD pointed out the growing

Table 5: Troop build-up in the United Kingdom: August 1943–May 1944

| Year and Month | Arrivals* | End of Month Strength | |||||

| Monthly | Cumulative from Jan 42 | Total | Ground Forces | Air Forces | Services of Supply | Hq ETO and Misc | |

| August 1943 | 41,681 | 424,098 | 278,742 | 39,934 | 152,548 | 79,898 | 6,362 |

| September 1943 | 81,116 | 505,214 | 361,794 | 62,583 | 168,999 | 120,148 | 10,064 |

| October 1943 | 105,557 | 610,771 | 466,562 | 116,665 | 200,287 | 148,446 | 1,164 |

| November 1943 | 173,860 | 784,631 | 637,521 | 197,677 | 247,052 | 191,208 | 1,584 |

| December 1943 | 133,716 | 918,347 | 773,753 | 265,325 | 286,264 | 220,192 | 1,972 |

| January 1944 | 166,405 | 1,084,752 | 937,308 | 343,972 | 317,227 | 273,294 | 2,815 |

| February 1944 | 136,684 | 1,221,436 | 1,084,057 | 442,474 | 338,317 | 299,710 | 3,556 |

| March 1944 | 124,412 | 1,345,848 | 1,199,077 | 488,379 | 375,152 | 325,577 | 9,969 |

| April 1944 | 216,699 | 1,562,547 | 1,422,276 | 599,425 | 410,562 | 391,994 | 20,295 |

| May 1944 | 108,463 | 1,671,010 | 1,526,965 | 620,504 | 426,504 | 459,511 | 20,131 |

* By ship. Excludes movements by air.

Source: Troop arrivals data obtained from ETO TC Monthly Progress Rpt, 30 Jun 44, ETO Adm 451 TC Rpts. Troop strength data obtained from Progress Rpts, Progress Div, SOS, 4 Oct 43, ETO Adm 345 Troops, and from Progress Rpts, Statistical Sec, SOS, ETO Adm 421–29. These ETO strength data were preliminary, unaudited figures for command purposes and, while differing slightly from the audited WD AG strengths, have been used throughout this volume because of the subdivision into air, ground, and service troops. This breakdown is unavailable in WD AG reports.

discrepancy to the theater and asked for additional information on the theater’s needs so that adequate preparations could be made for the shipment of units.2

The high rate of troop shipments created no particular difficulty in the winter months, except for the problem of providing adequate accommodations in the United Kingdom. Record shipments from November through April averaged almost 160,000 men per month, and reached a peak of 216,700 arrivals in the month of April. (Table 5) Shipping plans for May were a more serious matter since outloading for the cross-Channel operation was to begin that month and was bound to restrict movements into the United Kingdom by limiting port and inland transportation facilities. On 20 April the War Department informed the theater that, in compliance with its requests, it was making available and had set up shipping for 167,000 men in May, 140,000 in June, and 148,000 in July.3 The SEXTANT schedule had provided for the shipment of only 122,600 in May, 121,100 in June, and 142,800 in July. The lack of coordination in the troop flow planning was shortly revealed by the reply from the theater that it had planned accommodations for only 118,000. The War Department then offered to reduce the shipments for May and asked the theater which units it desired

backlogged to later months. The SEXTANT schedule, answered the theater immediately, did not provide adequate support for the operation as then planned. It argued that at least 151,000 of the 167,000 set up for May shipment were of vital importance to the operation, since they comprised many units already overdue. In the meantime the British War Office had made it known that British port and rail capacities in May, June, and July were capable of receiving only the numbers agreed on at SEXTANT, and stood firm on those ceilings.4

ETOUSA asked the War Department to submit the whole matter to the Combined Chiefs for decision, with the request that it raise the shipping goal to 151,300 in May, 152,000 in June and 152,000 in July.5 Since the problem was not one of shipping or availability of troops, and centered rather on the question of British port and rail capacity, the War Department instructed that these difficulties be taken up by SHAEF and the British Chiefs of Staff.6 Within a few days the whole matter was ironed out, and on 28 April ETOUSA informed OPD that the British had agreed to maximum shipments of 132,000 in May, 125,700 in June, and 122,000 in July, thus raising the SEXTANT schedule somewhat for May and June. The inability of the theater to receive the troops which the War Department had made available, and the imposition of these ceilings, had the net effect of creating a cumulative deferment of approximately 75,000 troops by August, and made it necessary for the theater to respecify its priorities for shipments of units.7

Establishment of these ceilings did not in the end have a serious effect on the build-up. As usual, there still were certain shortages in service units, and because of an urgent need for certain types of units the theater had again reluctantly called on the War Department in April to ship partially trained units.8 The U.S. force in the United Kingdom on the eve of D Day was therefore not as perfectly balanced a force as was desired, and the shipment of certain combat elements had been deferred. But in total numbers the BOLERO build-up had in fact exceeded the target of not only the SEXTANT but the earlier and higher QUADRANT build-up schedule. By 31 May twenty divisions had arrived in the United Kingdom, and the theater’s strength stood at 1,526,965 men, approximately 50,000 more than the 1,476,300 which SEXTANT schedule had called for on that date. The composition of this force was as follows:

| Type | Number |

| Total | 1,526,965 |

| Ground Forces | 620,504 |

| Air Forces | 426,819 |

| Services of Supply | 459,511 |

| Headquarters, ETO, and Others | 20,131 |

The cumulative arrivals in the United Kingdom over the past two and one-half years actually exceeded 1,750,000 men, some of whom had been withdrawn for

the North African operation. Of this total, 1,671,010, or about 95 percent, had been transported to the theater by ship, the remainder by air. Approximately 59 percent of the total troop movement to the United Kingdom was carried out by the usual convoys of slow-moving troop transports. But in contrast with the practice of World War I, considerable use was made of fast passenger liners converted to troopships, which could cross the Atlantic unescorted, protected only by their speed, submarine and plane detection devices, and light armament. The largest and fastest of these vessels were the British Cunard White Star luxury liners, the Queen Mary and Queen Elizabeth. The two Queens were capable of shuttling back and forth across the Atlantic with a remarkably short turnaround, each of them making three round trips per month and carrying 15,000 troops on each voyage. These two ships alone carried nearly 425,000 American troops to the United Kingdom, accounting for 24 percent of the entire build-up. Along with several other liners of large capacity, such as the Aquitania (a veteran of World War I), the Mauretania, the Ile de France, the Nieuw Amsterdam, and the Bergensfjord, they carried about 36 percent of the American troops going to the United Kingdom and played a significant and often dramatic role in the prologue to continental invasion.9

The limited port and transportation facilities in the United Kingdom were to have a much more serious impact on cargo shipment than on personnel movement, and in fact acted as an aggravating stricture which dominated the course of the supply build-up in the final months before D Day. British officials had given warning of this potential limiting factor as early as January 1943 at the Casablanca Conference. The entire problem was more fully aired in August 1943, by which time the BOLERO build-up had finally become a definite undertaking and was achieving considerable momentum. The reception and handling of cargo posed no particular problem at that time. Until early 1944, when the import program reached its peak, there was every assurance that British labor, with the help of an increasing number of U.S. port battalions, could discharge the tonnages scheduled for shipment to the United Kingdom.10 The period of greatest danger for the build-up would arrive just before the actual movement across the Channel, the period in which the reception and inland movement of BOLERO cargo would overlap the movement of men and supplies into the marshaling camps and ports. British officials pointed out that the resulting strain on port, railway, and highway facilities might well prove unbearable. Competition for the use of those facilities would be even further aggravated, they noted, by the necessity of withdrawing coastal shipping and refitting it for cross-Channel operations, since this would divert additional traffic to the railways. Moreover, the “sterilization” of berths in the southern ports for the assembly and loading of OVERLORD vessels would divert BOLERO shipping to the northern ports, creating

an additional burden on the railways because of the longer hauls involved.11

The increasing strain on inland transportation facilities was later illustrated in the handling of a single convoy in March 1944, even before the tempo of invasion preparations reached its height. This convoy included eighteen fully loaded U.S. Army cargo vessels and twenty-four part cargoes loaded on regular commercial ships. It contained about 1,500 wheeled vehicles, tanks, and self-propelled mountings, 2,000 cased vehicles, 200 aircraft and gliders, and about 50,000 tons of supplies. All this cargo had to be discharged within about eight days, the planned interval between convoys. The prompt clearance of this cargo from the ports involved the running of 75 special trains with 10,000 loaded cars and the movement by highway of large numbers of wheeled and cased vehicles and aircraft. The traffic in supplies procured locally from the British, and the traffic between U.S. depots, involved the dispatch of another 8,000 cars and the running of 27 trains. The movement of U.S. Army cargo thus necessitated running a minimum of 100 special freight trains with 18,000–20,000 loaded cars weekly, many of them using routes already overburdened with traffic.12

The question of port capacity was primarily one of labor shortages, although the availability of berths was also a consideration. In the spring months the port labor problem would inevitably be aggravated. The British estimated that all their military labor would have to be withdrawn on 1 April for operational purposes, and southern ports would require an augmented labor force for the outloading for OVERLORD. In September British officials made it clear that civil labor could be made available to handle a maximum of only seventy-five BOLERO ships per month, and it was agreed by General Ross and General Lord that U.S. port battalions would be provided to handle all ships in excess of that number. To bring in the approximately 150 ships per month desired in the early months of 1944, U.S. port labor might therefore have to handle up to one half of all BOLERO imports at the peak of the build-up.13

For these reasons the British felt it imperative that the BOLERO shipments be decelerated in the spring of 1944. They asserted that the reduction would have to start not later than with the March shipments from the United States if OVERLORD was to be launched on 1 May.14 At QUADRANT and again at SEXTANT they had succeeded in imposing a definite ceiling on the tonnages (actually expressed in numbers of ship sailings) which could be dispatched to the United Kingdom in the next several months.

In view of the inevitable limitation on the reception of BOLERO cargo in the months just preceding the invasion it was logical that an extraordinary effort be made to ship cargo to maximum capacity in the fall of 1943. Heavy shipping schedules were in fact set up for the fall and winter months, but the low priority of the European theater, which in turn was imposed by the unavailability of supplies and equipment in the United States prevented the complete fulfillment of the preshipment

program.15 This most pressing of the supply build-up problems—priorities—was finally settled in December 1943, when the European theater was assigned top priority for all needed items of equipment. Even so, the solution had no immediate effect in the theater. Not until February did the flood of cargo released under the new priorities begin, and even this was not reflected in the receipts at British ports until the following month. In March a record 467,824 long tons arrived in the United Kingdom for U.S. forces. Pre-shipped supplies now enjoyed the same priority as regular shipments, and in March the preshipment program was formally extended several months beyond the first phase troop basis, thus guaranteeing a continued ample availability of supplies and equipment.

But it was at precisely this moment that port and inland transportation limitations in the United Kingdom inexorably imposed themselves on the entire build-up program, threatening to nullify the favorable position which the theater had only recently attained in the matter of priorities and availability of cargo. A large backlog of cargo accumulated in the area of the New York Port of Embarkation, making it necessary for the service chiefs in the theater to establish priorities for movement in order to insure the shipment of cargo considered most essential for the coming operation.16 By 1 May, it was estimated, there would be a backlog of approximately 540,000 measurement tons at the New York Port and a shortage of sixty-one ships to move this cargo, even assuming that it could be received in the United Kingdom.17

This development was not entirely unforeseen. At SEXTANT it was noted that the availability of heavy construction equipment, weapons, and vehicles would increase very rapidly early in 1944, creating a difficult shipping problem for the ports of embarkation as well as the U.K. ports and forcing shipments in March and April beyond the established ceilings. The situation was discussed at that time with General Lee, who advised that, if necessary, arrangements could be made to exceed the ceilings, and it was therefore hoped that, somehow, the cargo would be accepted in the United Kingdom.18

Realities soon had to be faced. Initially a request was made that the ceilings be lifted, and for March the allocation of shipping was first raised from 109 to 120, and then to 140. In April, as a result, a record 496,384 long tons reached the United Kingdom. (Table 6) But these shipments in excess of the limits agreed to at SEXTANT were made possible mainly because the cross-Channel operation had by that time been postponed a month (to June), and the pressure on port and transportation facilities was temporarily relieved.19 Other remedies would have to be found in succeeding months.

A partial solution was found in the use of shipping to store supplies temporarily in U.K. waters until they were required either in the United Kingdom or on the Continent. The theater made a proposal

Table 6: Cargo Flow To The United Kingdom: November 1943-July 1944

| Year and Month | Monthly Shipments (Measurement Tons) | Received Measurement Tons Monthly | Received Measurement Tons Cumulative from Jan 42 | Received Long Tons Monthly | Received Long Tons Cumulative from Jan 42 |

| November 1943 | 848,054 | 790,754 | 6,935,640 | 322,757 | 2,838,095 |

| December 1943 | 910,482 | 1,008,150 | 7,943,790 | 378,078 | 3,216,173 |

| January 1944 | 982,738 | 886,359 | 8,830,149 | 281,588 | 3,497,761 |

| February 1944 | 1,170,235 | 815,948 | 9,646,097 | 233,722 | 3,731,483 |

| March 1944 | 1,370,183 | 1,443,248 | 11,089,345 | 467,824 | 4,199,307 |

| April 1944 | 1,637,690 | 1,478,651 | 12,567,996 | 496,384 | 4,695,691 |

| May 1944 | 2,003,987 | 1,482,294 | 14,050,290 | 601,615 | 5,297,306 |

| June 1944 | 1,815,145 | 1,609,569 | 15,585,161* | 635,866 | 5,933,172 |

| July 1944 | 1,912,878 | 2,092,771 | 17,047,606* | 541,223 | 6,474,395 |

*. Cumulative totals adjusted in source report with no indication of months in which corrections are applicable.

Source: Shipment data from [Richard M. Leighton] Problem of Troop and Cargo Flow in Preparing the European Invasion, 1943–1944, prep in Hist Sec, Control Div, ASF, 1945, MS, p. 154, OCMH. Receipt data from ETO TC Monthly Progress Rpts, Hq SOS, Statistics Br, OC of T, ETO Adm 451–2.

to this effect in January, asking that a system of “type loading”—more commonly known as “prestowage”—be instituted. Vessels would be loaded with specified blocks of supplies for use on the Continent, each ship carrying a spread load of selected items of supply somewhat analogous to a general depot. Deck space was to be utilized for cargo destined for the United Kingdom. After this deck-loaded cargo was unloaded, the ships were to be consigned to the Continent where they could be discharged as needed. The plan had obvious advantages: it would save four handlings in the United Kingdom and would prevent the congestion of port and transportation facilities there.20 As finally worked out, the prestowage plan provided for the dispatch of fifty-four ships loaded with subsistence, landing mats, clothing and equipage, and ordnance supplies, and eleven loads of ammunition, totaling approximately 500,000 measurement tons.

Shortly after the prestowage program was accepted, theater representatives offered a variant of it known as “commodity loading.” This called for the loading of an unspecified number of ships (commodity loaders) either solidly with a single type of supply or with closely affiliated types of supply. Most suitable for commodity loading were such items as rations, ammunition, vehicles, and engineer supplies. Commodity loaders were easily and economically loaded. It was intended that they be held in U.K. waters until called to

the Continent, where they could serve either as floating depots or for bulk discharge. Nearly 150 commodity loaders and 54 preloaded ships were dispatched to Britain in the months of May, June, and July 1944, providing the theater with something like mobile depots which could be moved forward on call to back up any particular area. Both practices were costly improvisations in that they immobilized badly needed shipping for long periods of time. Commodity loading had a further disadvantage. If the enemy sank a ship so loaded, a heavy loss of one particular type of supply resulted. For these reasons the system was discouraged by the New York Port.21

In any event these expedients did not offer the final solution to the problem of cargo reception in the United Kingdom. No preloaded or commodity-loaded ships were sent to the United Kingdom in April. Meanwhile a ceiling of 140 ships had been established for acceptance in the United Kingdom for that month, representing approximately 1,310,000 measurement tons. Shipments actually exceeded this figure by some 325,000 tons, with the result that many vessels arriving in the United Kingdom were forced to stand idly by for lack of berthing facilities. In May, as fully predicted long before, the situation became even worse, for the OVERLORD mounting machinery was set in motion. The rising tide of traffic from the many depots and camps to the ports of embarkation gradually restricted all importation through these ports and taxed to the full the inland transportation system. It was inevitable, therefore, that the flow of supplies into the United Kingdom would have to be constricted even more. Against vigorous opposition from the Army Services Forces, the theater announced that the discharge ceiling for May and June would be lowered from 140 ships to 120.22

Meanwhile, theater officials for their part resisted pressure in the United Kingdom to cut imports any further. Early in May British officials were told that BOLERO shipments could not tolerate additional reductions for June. The provision of certain items of equipment for combat units was already critically behind schedule, and it looked at that time as though the Third Army would have only 60 percent of its wheeled equipment.23 By the middle of the month, with the mounting process in full swing, the disparity between ship arrivals and port discharge capacity had become sufficiently serious to force a showdown on the entire problem. On 18 May SOS officials reported to the New York Port that British ports simply could not accommodate BOLERO cargoes at the rate at which they were arriving. Between 35 and 40 ships in excess of available berths were arriving in May, most of them with critically needed supplies. British officials stood firm in their insistence that BOLERO arrivals could be discharged only within the agreed-on monthly totals and that 120 ships was the absolute maximum that could be accepted in May.24 To meet the increasing outloading

requirements for OVERLORD it had already been necessary to allocate additional berths in the southern ports, which entailed handling a still greater portion of the incoming traffic in the northern ports and throwing an additional strain on the railways. Some British officials feared that the opportunity was being taken to clear U.S. ports irrespective of the congestion thus caused in those of the United Kingdom. Plans were even made to dump cargo in the streets and open spaces near the ports, where storage capacity was already taken up.25

Barely two weeks before D Day the impasse was finally resolved at the highest levels in the United Kingdom. On 20 May General Eisenhower appealed to the Prime Minister. Admitting that the import ceilings had been exceeded by nearly forty ships, he cited as the chief reason that it had been impossible to ship cargo in the desired quantities during the fall months of 1943 when the U.K. ports could have accepted it. These vessels contained large quantities of supplies and equipment vital to the success of operation OVERLORD. Eisenhower assured the Prime Minister that the matter was of grave importance, and stated that it was imperative that the ships be discharged.26 As he later reported to the War Department, “We have simply developed one of those bottlenecks (for no one is at fault for it) incident to big operations.”27 A few days later the Supreme Commander met with Mr. Churchill and Lord Frederick Leathers, the Minister of War Transport, and prevailed upon them to adopt the only obvious solution—a cut in the British import program. That program had been subject to repeated changes. Now the British agreed to delay the delivery of 500,000 tons of cargo to make berths available for the BOLERO vessels, with the understanding that the United States would provide assistance later in the year to make up this loss.28

This adjustment averted the worst effects of the port crisis. After June the port capacity of the United Kingdom would gradually be supplemented by and eventually superseded by that of the continental beaches and ports which would receive cargo directly from the United States. But for the next few months British port capacity would definitely be limited, and the Army Service Forces was urged to adhere closely to the theater’s loading requests and priority lists for the ships intended for both U.K. and continental discharge. General Lutes of the ASF, on the basis of his own observations of the congested ports in the United Kingdom, accordingly instructed the New York Port to accede to the theater’s wishes in these matters so that the delivery of vitally needed equipment would be expedited.29 By other special measures it was possible to maintain a tremendous flow of cargo to the United Kingdom in the final months preceding the invasion. The crisis over port capacities nevertheless had illustrated a very fundamental logistical paradox: the threat that the invasion forces might not be equipped in the presence of plenty. The

limiting factor of 1943—shortage of supplies in the United States—was now having its long-range effect on the ability to equip the OVERLORD forces, threatening an artificial shortage in the spring of 1944 because of a new limiting factor—the inability of the British ports to receive the cargo now becoming available.

In the final month of preparation 600,000 long tons of supplies arrived in the United Kingdom, and cargo continued to arrive in unprecedented volume for another two months. The May receipts had the following composition:30

| Type | Tons | |

| Total | 599,739 | |

| Quartermaster | 137,729 | |

| Ordnance, Total | 296,523 | |

| -- Ammunition | 101,523 | |

| -- Unassembled vehicles | 73,436 | |

| -- Assembled vehicles and tanks | 65,248 | |

| -- General | 56,316 | |

| Engineer | 55,984 | |

| Air Force | 26,880 | |

| Transportation | 22,518 | |

| Miscellaneous | 60,105 |

Of the May total, 567,268 long tons arrived on 141 regular BOLERO ships, and 32,471 tons as part cargoes on 95 other vessels. By 31 May a cumulative total of 5,297,306 long tons, or 14,050,290 measurement tons had been received in the United Kingdom.

Construction and Local Procurement, 1943–May 1944

For more than six months after the North African operation was launched, the limitations imposed by the War Department had circumscribed development of administrative facilities for U.S. forces in the United Kingdom. Except for the beginning made toward meeting the enlarged air force requirements, the Americans could offer little assistance in the construction program. Fortunately British officials had continued with portions of it, and in May 1943 the TRIDENT decisions injected new life into the program. In reviving the BOLERO build-up, these decisions inevitably had a corollary impact on U.K. plans for accommodating the BOLERO force. The Combined Chiefs of Staff had noted in their final report to the President and Prime Minister that “the expansion of logistical facilities in the United Kingdom will be undertaken immediately.”31

Within a few days of the Washington Conference General Lee and others of his staff, including his Chief Engineer, General Moore, met with the British Quartermaster General, Gen. Sir T.S. Riddell-Webster, and other British officers to initiate planning for the revived BOLERO. Six weeks later, on 12 July 1943, the Deputy Quartermaster General (Liaison) issued the fourth and last edition of the BOLERO Key Plan for the reception, accommodation and maintenance of U.S. forces in the United Kingdom. The fourth edition of the plan did not differ substantially from the earlier editions except to bring them up to date by reflecting the most recent build-up schedules. It used the round figure of 1,340,000 for the buildup expected by 30 April 1944, thus allowing a small margin of safety over the figure used at TRIDENT (1,300,300).32 Finally, in October the figure was raised to 1,446,100

in an amendment reflecting the new troop build-up schedule agreed to at the QUADRANT Conference in August.33

Since the scheduled U.S. troop build-up represented an increase over that used in earlier plans, the Fourth Edition also called for an enlarged accommodations plan, and therefore entailed a larger construction program. Within the U.S. Army in the United Kingdom the provision of all facilities, by construction or other means, was the responsibility of the chief engineer. The requirements of the various services were first coordinated and consolidated by the Installations Branch, G-4, SOS, which administered the entire accommodations plan. Once these requirements were determined, however, it was the responsibility of the Engineer Service to acquire the facilities. The Engineer Service, in turn, arranged for the construction of the needed facilities, or for the transfer of existing accommodations, with the Office of the British Quartermaster General (or Q Branch), its principal point of contact with that agency on policy matters being the Quartermaster Liaison Branch, Q(Liaison), which had been specifically set up under General Wootten for that purpose in 1942.

When adequate facilities did not exist or could not be transferred for American use, the U.S. base section engineer and the British command concerned selected a site where the accommodation could be constructed, and the Q Branch was then asked to requisition the property. Once a project was approved, the actual construction of the new facility might involve several British government departments. The Ministry of Works and Planning, which supervised the entire project and constructed the hospitals and many of the depots and camps, had to turn to the Ministry of Supply for materials and to the Ministry of Labor for workers. The Ministry of War Transport constructed railways, roads, hardstandings, and docks. The Ministry of Agriculture arranged for the clearance of land needed for the new installations.

Much of the real work was accomplished at lower levels. Within the Office of the Chief Engineer, SOS, it was the Construction and Quartering Division which was in actual charge of the accommodations program, and had direct contacts with the various British directorates under the Deputy Quartermaster General and Engineer-in-Chief, such as the Directorates of Quartering, Movement, Transportation, Fortifications and Works, and Engineer Stores. Once it was determined that the necessary labor and materials were available, details of the project were worked out between the U.S. base section engineer and the corresponding British command, and construction could then proceed. The procedure for arranging for new construction was a cumbersome one, particularly in the early stages, each project requiring the approval of several agencies in the War Office. The resulting delays often tried the patience of American authorities, for on the U.S. side construction was much more decentralized, the base section and district commanders having considerably more leeway to authorize expenditures for construction projects.34 On the other hand, British officials were exasperated by the

repeated modifications in the plans of the Americans.

Virtually all construction in the United Kingdom was carried out to meet established War Office standards on such matters as space scales, types of huts, methods of flooring in hospitals, layouts for buildings, and screening and blackout facilities. U.S. scales differed from the British, and some modifications were made to meet American requirements, but U.S. standards had to be relaxed somewhat to meet accommodations requirements in the fall of 1943 when U.S. troops began to arrive in great numbers.

U.S. War Department construction designs proved of little use, for they called for a much greater quantity of wood than was available in the United Kingdom. British resources and practice dictated a much more extensive use of tile, plasterboard, sheet steel, corrugated iron, and precast concrete, and most facilities therefore took the form of steel Nissen huts, curved asbestos or prefabricated concrete huts for housing, and various types of steel huts for covered storage and shops. U.S. troop labor was not accustomed to working with these materials and required additional training. The use of these materials also resulted in the construction of more durable structures than was customary in a theater of war.

British and U.S. construction methods also contrasted because of the difference in tools and equipment. In general, U.S. engineer units were equipped with heavier-duty machinery, best suited for work on large projects such as depot and airfield construction in which extensive earth-moving jobs and concrete construction were called for. Much of the work that British labor had to perform by hand was carried out with patrol graders, bulldozers, mobile cranes, paving and trenching machines, and posthole diggers where U.S. engineers were employed. By the time U.S. units so equipped arrived in England many of the larger construction projects had already been assigned to British labor, both civil and military, and U.S. engineers initially were dispersed over a number of minor jobs for which they were not best suited. Not until the large depots and airfields were authorized in 1943 were they utilized to best advantage.35

BOLERO construction policy from the beginning envisaged that all labor and materials would be provided by the British, with only incidental help from U.S. engineer units. But it was soon apparent that construction requirements would exceed British capacities. U.S. forces were therefore called on to provide a substantial contribution in materials and equipment as well as in military labor, and it became necessary to requisition items like lumber, cement, and pipe from U.S. depots.

The Fourth Key Plan, as amended in October 1943, estimated that the U.S. Army would require accommodations for 1,027,400 ground and service troops in the United Kingdom by 1 May 1944. In addition, the British War Office undertook a commitment to provide quarters for 33,000 U.S. air force personnel, the bulk of the air force requirements remaining the responsibility of the British Air Ministry. The War Office program therefore called for 1,060,400 spaces.36

This housing was acquired either by billeting, by the transfer of existing

accommodations, or by new construction. Billeting of troops in British homes was avoided as long as possible and remained on a voluntary basis until the end of 1943. Requisitioning was resorted to only when the build-up reached its peak in the winter and spring months. Although some incidents caused bad feelings between civilian householders and soldiers, most of the apprehensions and anxieties regarding the effect on Anglo-American relations proved unfounded.37 About 110,000 billets were provided for American troops, accounting for a small portion of the total personnel accommodations.

Approximately 60 percent of all troop quarters were acquired by requisition or transfer of existing facilities, the remaining 40 percent consisting of new construction. Most of the accommodations turned over by the British required additional work to bring them up to U.S. standards. Americans were notoriously wasteful in their use of water, for example, and additional facilities had to be constructed to provide an adequate supply. New accommodations took the form of tented expansions of existing camps, hutted camps, winter tented camps, and summer tented camps, and did not come into extensive use until late in 1943. Since U.S. troop labor for construction work was lacking earlier in the year, U.S. scales of accommodation were reduced to scales comparable with the British, and maximum use was made of existing facilities. Most familiar of the various camp structures was the Nissen hut, a utilitarian structure which was used for living quarters, administration buildings, hospitals, mess halls, bath houses, and a variety of other purposes. A typical 1,000-man Nissen hut camp contained 123 buildings and covered about 40 acres. Tented accommodations were built to U.S. designs and caused no great difficulty. A typical 1,000-man tented camp contained about 200 tents and covered 34 acres.

The BOLERO housing program met requirements with remarkable accuracy. Available accommodations totaled 1,206,349 at the end of May, at which time the ground and service force troop strength was approximately 1,100,000. Since only about 90 percent of theoretical capacity could be counted on because unit strengths did not exactly coincide with camp capacities, the available housing almost exactly met U.S. needs. At no time was there an actual shortage.

The Air Ministry had provided accommodations, in addition to those under the BOLERO program, for 442,170 U.S. air force troops, bringing the total to 1,648,519. Another substantial addition in the housing program over and above the BOLERO needs had been made in the spring of 1944, when it was decided to prepare for bivouac camp facilities for 171,250 extra troops that would have to be accommodated in the event of a delay in launching the OVERLORD operation. Tented facilities were built in the marshaling areas near the ports to accommodate another 200,000 troops during the mounting phases of the cross-Channel attack. The aggregate of all personnel accommodations provided U.S. troops in the United Kingdom just before D Day therefore totaled 2,021,387. The types and sources of these accommodations are summarized in the table on the following page.38

| Type | Total | Acquired or Requisitioned | Constructed by U.S. Army | Constructed by British |

| Total in United Kingdom | 2,021,387 | * | * | * |

| Total BOLERO Program | 1,206,349 | 729.107 | 348,503 | 128,739 |

| Hutted camps | 665,986 | 612,131 | 50,230 | 3,625 |

| Expansions to hutted camps | 56,985 | 0 | 12,930 | 44,055 |

| Expansions in winterized tents | 59,687 | 0 | 59,687 | 0 |

| Summer tented camps | 192,564 | 0 | 179,064 | 13,500 |

| Winterized tented camps | 30,470 | 0 | 30,470 | 0 |

| Accommodations at hospitals | 56,437 | 5,386 | 672 | 50,379 |

| Accommodations at depots | 32,630 | 0 | 15,450 | 17,180 |

| Billets | 111,590 | 111,590 | 0 | 0 |

| Total U.S. Air Forces | 442,170 | 37,024 | 404,606 | 0 |

| Existing facilities | 37,024 | 37,024 | 0 | 0 |

| Hutted camps | 348,436 | 0 | 348,436 | 0 |

| Tents | 56,170 | 0 | 56,170 | 0 |

| Total OVERLORD | 372,868 | † | † | † |

| Mounting accommodations | 201,618 | † | † | † |

| Bivouac Facilities | 171,250 | † | † | † |

* Not available because of lack of OVERLORD data.

† Not determined in source report.

Provision of hospital requirements did not proceed as smoothly. Hospital construction had lower priority than either depot or personnel needs. Its high building standards meant detailed supervision and greater demands for skilled labor and scarce materials. Furthermore, it was a considerably larger undertaking because existing facilities met only a small fraction of the total needs, and it was thus necessary to provide the great bulk of medical facilities through new construction. The various sources of hospital facilities have already been described. A small percentage of the eventual U.S. requirements was initially met by the transfer of certain permanent military hospitals and also several Emergency Medical Service hospitals. But the BOLERO planners had estimated that the great bulk of U.S. requirements would have to be met by the use of militia, conversion, and dual-purpose camps, and by the construction of regular station and general hospitals. In 1943 the acquisition of hospitals proceeded on the basis of the 90,000-bed requirements estimated in the Second Edition of the BOLERO plan. In order to give some stability to the hitherto uncertain construction plans, the chief surgeon announced in June 1943 that the

Typical medical installations: Interior of ward

Nissen hut hospital

goal would be to procure facilities with 90,000 to 95,000 fixed beds.39 This program remained fairly stable despite the fact that the Fourth Edition of the Key Plan, issued the following month, called for a larger troop build-up than before and stated a requirement for 103,690 beds.

Hospital capacities had already been altered in the Second Edition of July 1942, when station hospitals were increased in size from 750 to 834 beds, and general hospitals from 1,000 to 1,082 beds. The increased requirements were to be met largely through expansions of hospitals already planned. The first step in this expansion was taken in the summer of 1943 when the Surgeon General of the Army urged that a greater number of 1,000-bed hospital units be utilized in the United Kingdom. Such an increase of general hospitals required the expansion of the 834-bed station hospitals. Under new austerity quartering scales these station hospital plants were able to accommodate the staff personnel of a 1,000-bed general hospital with but little additional construction, and some of the station hospital units were eventually replaced or expanded to 1,000-bed units.40

In January 1944 plans were made to increase the patient capacity of all station and general hospitals by 30,000 beds. U.S. troop labor was to be used for the job of providing 27,750 beds in tented expansions, using standard war tents adjacent to existing hospital wards, and an additional 2,250 beds in three 750-bed, completely tented hospitals. The labor force was recruited chiefly from medical operating personnel not immediately needed in their assigned role, and the engineer service performed the necessary siting and technical assistance. Plans were also made for an additional 10,907 expansion beds to be set up in existing wards. By the beginning of June, after many changes, the hospital program called for 93,280 fixed beds and 40,907 tented expansion beds, or a total of 134,187.41 This was a maximum program, however, and was not expected to be completed for several months. The fixed bed portion of the program was to be met as follows:42

| Total | 93,280 |

| Existing Beds | 11,746 |

| Expansions | 5,597 |

| New Hospitals | 47,508 |

| 35 station | 29,106 |

| 17 general | 18,402 |

| Convertible | 28,429 |

| Militia barracks | 14,929 |

| Conversion camps | 7,500 |

| Dual-purpose | 6,000 |

The hospital construction program lagged from the beginning. As usual, the principal reason was the shortage of labor, particularly in the skilled categories required in this type of construction. Building a hospital was a considerably more complex undertaking than building a barracks or a warehouse. Special attention had to be given such matters as the installation of special electrical and plumbing fixtures, steam boilers, and hot-water generating systems. Innumerable complications attended the construction and operation of medical facilities. Mechanical dishwashers, for example, required additional construction because British-designed grease traps could not cope with the large amount of fats present in American

Aerial view of a Station Hospital (tented) in England

foods. This also created an additional problem at the sewage disposal plants, where grease fouled up the filtering beds. Even the type of flooring used in operating rooms took on such importance as to require high-level policy decision.

The majority of the newly constructed hospitals eventually consisted of 834- and 1,082-bed installations based on standard layouts designed by British experts and approved by American engineers and medical officers, although there were deviations to meet local conditions. While some were built of brick, most hospitals utilized Nissen huts, the standard 1,082-bed installations requiring about 160 buildings and 50 acres of land. Many were located on landed estates, miles from a railway and requiring completely new water and sewage disposal systems.43 By D Day 59,424 fixed beds of the original BOLERO program were in operation, and 24,786 of the tented expansions were completed, bringing the available facilities at that time to 74 hospitals (43 general and 31 station) with 84,210 beds.44 While

| Type | Unit | Total | Acquired or Requisitioned | Constructed by U.S. Army | Constructed by British |

| Covered storage and shop | sq.ft. | 19,905,070 | 13,415,735 | 2,567,351 | 3,921,984 |

| Opening and hardstanding | sq.ft. | 43,411,525 | 5,486,880 | 22,214,3071 | 15,710,338 |

| Roads and railways | miles | 269.80 | 0 | 86.04 | 183.76 |

| POL storage | tons | 173,325 | 4,005 | 163,965 | 5,355 |

| Vehicle storage | vehicles | 48,350 | 6,100 | 39,250 | 2,000 |

| Ammunition storage | tons | 448,100 | 148,000 | 177,000 | 123,100 |

the completed construction thus fell short of the target of the BOLERO Fourth Edition, the deficiency was not as serious as it first appears. Shortly after D Day the evacuated militia, dual-purpose, and conversion camps were turned to hospital use. General Hawley, the chief surgeon, was satisfied, as D Day approached, that the facilities would be adequate, and had particular praise for the quality of the physical plant. British construction had maintained a high standard, and the program had been carried out at considerably lower cost than would have been possible in the United States.45

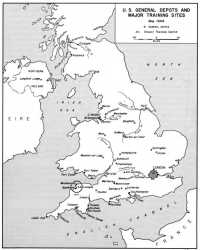

The depot program proved to be the best organized and best executed of all the BOLERO accommodation plans, despite the fears of 1942 that storage space would fall short of requirements. Its success was due in part to the fact that depot construction was accorded the highest priority and did not suffer as much from the shortage of labor and materials, and also to the fact that existing facilities provided more than two thirds of the required covered storage space. The Engineer Corps, either by acquisition or new construction, eventually provided almost 20,000,000 square feet of covered storage and shop space (of which only 6,500,000 square feet was new construction), 43,500,000 square feet of open storage and hardstandings, and additional facilities for the storage of 450,000 tons of ammunition, 175,000 tons of POL, and vehicle parks for nearly 50,000 vehicles. Not all of these facilities were in use on D Day. Their source is tabulated above.46 Insofar as possible, storage facilities, like other accommodations, were constructed according to standard layouts. A model general depot was planned and first built at Wem, near Shrewsbury in western England. It had 450,240 square feet of covered storage, 1,375,000 feet of open storage, and personnel accommodations for 1,250. Construction was begun in December 1942 and the depot was completed in June of the following year at a cost of $2,360,000. On this model five other depots, commonly known as “Wems,” were then built, one each at Boughton in Nottinghamshire, at Histon near Cambridge, at Honeybourne northeast of Cheltenham, at Lockerly near Salisbury, and at Moreton-on-Lugg northwest of Cheltenham. (Map 6) Those at Histon and Lockerly were built entirely by U.S. troops, and all took roughly six months to complete. The largest depot of all was constructed at Sudbury-Egginton, near Burton-upon-Trent, with more than 1,000,000 square feet of covered and 9,500,000 square feet of open space. It was built entirely by the British at a cost of approximately $6,600,000.47

Map 6: U.S. General depots and major training sites: May 1944

One of the biggest problems in depot construction was locating adequate footing for open storage of the generally heavier American equipment. Soil conditions were generally unfavorable in the United Kingdom, for the water table was very close to the surface. This created special problems in drainage and surfacing before adequate hardstandings were developed. Progress was generally good on the construction program, and the British ministries made every effort to make available the needed labor and materials. Even so, it was necessary to employ U.S. troop labor to complete the program, and American engineer units in the end accounted for more than half of the total man-hours expended on new construction. At the end of May 1944 the BOLERO storage program was almost 100 percent complete, the only deficit being in POL storage. At that time the ground and service force depot structure in the United Kingdom consisted of the following major installations in use:48

| Type | Number | |

| General depots | 18 | |

| Branch Depots: | ||

| QM Service Depots | 13 | |

| POL Depots | 14 | |

| Ordnance Service Depots | 17 | |

| Ammunition Depots | 9 | |

| Vehicle Parks | 12 | |

| Transportation Corps Depots | 2 | |

| Chemical Warfare Depots | 1 | |

| Engineer Depots | 1 | |

| Medical Depots | 4 | |

| Signal Depots | 3 |

Except for hospital facilities and a small number of personnel accommodations the BOLERO program included none of the air force requirements, for these were met almost wholly by other plans carried out by the Air Ministry and the Royal Air Force. On the U.S. side, however, the SOS was responsible for meeting the air force as well as ground and service force requirements, and this task was also delegated to the chief engineer. The only basic difference in carrying out the two programs was that in the case of air force projects the chief engineer, on behalf of the air force engineer, dealt with the Air Ministry rather than the War Office. The chief engineer of the air force prepared the statement of air force construction and quartering needs, transmitted them to the chief engineer of the SOS, who then requested the Air Ministry to provide the needed facilities, just as he also requested similar implementation of ground and service force needs under the BOLERO program.

In the Air Ministry the chief administrative officer corresponding to the Quartermaster General in the War Office was the Air Minister for Supply and Organization (AMSO). Like the War Office, the Air Ministry created a separate liaison agency as the chief point of contact with the U.S. chief engineer. It was known as the Assistant Directorate of Organization (U.S.), or ADO(US).

The procedure of implementing the entire air force construction and quartering program therefore paralleled very closely the procedure for the BOLERO program, and at lower echelons there was the same type of direct liaison, in this case between

the base section and Air Ministry field personnel. Once a project was approved in the Air Ministry, the actual job was carried out by the Director General of Works, a civilian heading a civilian engineering and clerical staff, who executed the project through contracts with civilian firms.

As with BOLERO, it was fully intended that the British should take care of all air force needs. But it became immediately apparent that British labor, material, and equipment resources would not be sufficient. As early as May 1942 agreement was reached that U.S. forces should assume responsibility for the construction of twenty heavy-bomber airfields. Eventually twenty-four aviation engineer battalions built fourteen bomber fields and also accomplished a vast amount of construction work on other facilities, such as headquarters installations and depots.

Another early agreement provided that Royal Air Force scales would prevail in the construction of U.S. installations. For all heavy-bomber airfields the Works Directorate of the Air Ministry prepared standard layouts that specified the number and size of runways, the number of personnel accommodations and repair shops, and the storage facilities to be provided for ammunition and gasoline. Heavy-bomber stations were built at an average cost of about $4,000,000. Each required more than 400,000 square feet of covered accommodations, and had runways equal to nearly 20 miles of concrete road 20 feet wide.49

Rigid adherence to blueprints produced difficulties. American B-17’s and B-24’s put excessive strain on the six-inch concrete runways of British fields, and all runways used by the U.S. air forces had to be capped with a new eight-inch concrete slab or resurfaced with other materials. So great was the deterioration on airfield runways that approximately 25 percent of the gross labor employed was eventually expended in maintenance. The ruling that U.S. air force personnel should be provided with accommodations on scales identical with those of the Royal Air Force also resulted in certain inequities favoring air force units over ground and service force personnel, for British air force accommodation scales were higher than those for ground units.

The air force construction program was a victim of substantially the same limitations as the BOLERO projects. An acute shortage of labor hampered the program at all times; materials were in critically short supply; and British contractors for the most part lacked the heavy construction equipment with which the American engineer battalions were favored. Nevertheless, the air force program enjoyed a high priority, and was completed substantially as planned in the spring of 1944 at the height of the bomber offensive against Germany. After many revisions, air force plans as finally stabilized in November 1943 called for 126 airfields, exactly the number occupied by U.S. air forces at the end of May 1944. In addition, 6 base air depots, 11 ordnance air depots, and 11 ammunition depots, and many other installations had been made available to USSTAF, with a total closed storage and shop space of more than 10,000,000 square feet. The 442,000 personnel accommodations have already been mentioned in connection with the BOLERO program. The cost of the air force construction program came to roughly $440,000,000.50

With the exception of the deficit in

U.S. Airfield construction in England

U.S. Airfield construction in England

medical facilities noted above, the mammoth construction program, begun two years before, was virtually complete on the eve of the invasion. It was accomplished despite innumerable handicaps, the principal limiting factor being the persistent deficiency of of both materials and manpower. American requirements were not the only demand on available resources, and had to be integrated with British needs. Administrative difficulties, among them the lack of parallelism in British and American methods of operation, and the different standards and scales also hampered the program, although these were successfully overcome. At times there was indecision as to whether to emphasize speed or quality. In the view of U.S. forces, British labor policies made for inefficiency. British civilian workmen had a limited mobility and adhered to traditional, and often time-consuming, construction practices. The quality of their work was usually high, however, and in fairness it must be noted that the cream of British labor was in the armed services. The physical condition of troop labor, army discipline, and the advantage of more modern heavy equipment, all resulted in a higher rate of production per man where service engineer units were employed.

A summation of the accomplishment provides some impressive statistics. At the end of May there had been made available to U.S. forces in the United Kingdom accommodations for 1,600,000 persons, 30,000,000 square feet of covered storage and shop space, 43,500,000 square feet of open storage space, hospitals with a capacity of 84,000 beds, 126 airfields, and many other facilities such as shops for the assembly of locomotives and freight cars, tire, tank, and vehicle repair shops, and chemical impregnating plants. The estimated value of these installations, either transferred to or built for American use, was nearly one billion dollars. Of this total, nearly two thirds represented expenditure for new construction, the breakdown of which is shown below:51

| Total | $664,000,000 | ||

| BOLERO | 200,000,000 | ||

| Personnel accommodations | $59,200,000 | ||

| Hospitals | 57,200,000 | ||

| Depots and shops | 50,800,000 | ||

| Miscellaneous | 32,800,000 | ||

| Air Forces | 440,000,000 | ||

| OVERLORD mounting installations | 24,000,000 |

All facilities turned over to the U.S. forces or specifically built for them remained the property of the British and were acquired by the Americans on a rental basis.

At the peak of construction activity approximately 56,000 civilians and 51,000 troops (both British and American) were employed, the larger portion of the civilian labor being employed on air force projects. The total labor expenditure is estimated to have exceeded 400,000,000 man-hours. The breakdown of this effort is tabulated on the following page.52

Provision of the greater part of the personnel quarters, hospitals, depots, and airfields by no means represented the total British contribution to the logistical support of the American forces in the United

| Type | Total man-hours | British | U.S. Troops |

| Total | 403,708,000 | 252,518,000 | 151,190,000 |

| Housing | 48,000,000 | 21,800,000 | 26,200,000 |

| Hospitals | 54,340,000 | 48,600,000 | 5,740,000 |

| Depots | 34,500,000 | 16,300,000 | 18,200,000 |

| Special Accommodations | 6,000,000 | 4,000,000 | 2,000,000 |

| Air Forces (to May 1945) | 260,868,000 | 161,818,000 | 99,050,000 |

Kingdom. While details cannot be given here, it is apropos to give some indication of the quantity of supplies and services, as well as accommodations, which U.S. forces procured from British sources under reverse lend-lease.

Plans written before the U.S. entry into the war contemplated that American forces in the United Kingdom, so far as practicable, would draw their logistical support from sources outside the British Isles. A General Purchasing Board was established in Britain in 1942 on the assumption that its main function would be to plan for later procurement on the Continent. The provision of accommodations in the United Kingdom was of course a vast program of local procurement in itself. But in addition it was found that the British possessed certain commodities in excess of their needs, and that there even was surplus manufacturing and processing capacity which could be employed. An even more compelling reason for procuring supplies locally was the shortage of shipping. Both facts made it natural and inevitable that U.S. forces should draw on local resources wherever practicable. In the summer of 1942 the theater commander asserted that conservation of shipping space would be the basic consideration in determining the desirability of procuring supplies locally. The basis for such “reciprocal aid” already existed in a Master Agreement of February 1942 pledging the two nations to provide each other with such supplies and services to the extent of their capability for the prosecution of the war.

Following the practice of World War I, the theater commander in May 1942 designated a General Purchasing Agent and established a General Purchasing Board, consisting of representatives of the service chiefs, the Eighth Air Force, the Army Exchange Service, and other agencies. Together, the General Purchasing Agent and General Purchasing Board acted as a central agency to negotiate agreements with British officials, to formulate purchasing policies and procedure, and to coordinate and supervise the purchase of supplies by the various supply services and other agencies. Until the General Purchasing Agent stepped in and temporarily stopped almost all local purchases, there was a great deal of haphazard buying early in 1942 to fill immediate needs. Once the system of local procurement was regularized, a vast program of purchasing was begun in virtually every class of supply.

U.S. troops arriving in the United Kingdom early in 1942 lacked supplies of all kinds and relied heavily on British sources for even such basic maintenance as rations. The British ration, containing more tea, bread, potatoes, and mutton, and less sugar, beef, coffee, fruits, and vegetables than Americans were accustomed to, was unpopular, and efforts were immediately made to add the desired items. Even after U.S. stocks were sufficient for

the issue of a full American ration, however, large quantities of meats, fruits, condiments, cheese, candy, dairy products, and vegetables (including the lowly Brussels sprout, whose popularity was short lived) were procured locally to supplement the canned goods, the boneless beef, the dried eggs, and that much-derided product in the U.S. Army ration which gave the theater its nickname—“Spamland.” Fresh vegetables were obtained in part through NAAFI, the quasi-official British organization which operated the canteens and post exchanges for the Royal Navy, Army, and Air Force. The British Government, through the Ministry of Food, had greatly intensified its agricultural production. In 1942, using British seed, fertilizer, and equipment, American troops aided in this program by planting 7,000 acres in and around camp areas, raising mostly corn, beans, peas, onions, and potatoes. In 1943 this acreage was doubled.

For more than a year and a half American units received all their bread through British Army and civilian bakeries, at first using wheat flour shipped from the United States. The British had for a long time been using “National Wheatmeal Flour,” a blend of English and Canadian wheat with a small percentage of barley and oats, accepted as a wartime measure. In September 1942, fearing the adverse effect on civilian morale if American troops continued to eat white bread in wartime Britain, the Minister of Food requested that the American forces also adopt National Wheatmeal Flour, which they did. The bread was not entirely satisfactory in texture or taste, but experimentation in baking produced a loaf more in accord with American tastes. Not until the fall of 1943 did American units begin to meet even a portion of their own requirements. Initially they lacked equipment; then they discovered the superiority of British Army mobile bakeries and decided to adopt them for general use in the theater. By May 1944 the U.S. Quartermaster Corps in the United Kingdom had acquired fifty-two bakery sets from the British and was operating thirty-eight of them, producing about 500,000 pounds of bread daily, or about 60 percent of American requirements. The remainder continued to be furnished by British civilian bakeries and by the Royal Army Service Corps.53

In the first half year of the reciprocal aid program, from June to December 1942, U.S. forces procured the equivalent of 1,120,000 measurement tons of supplies and equipment from the British, with a corresponding saving in shipping. By far the largest portion of these supplies—almost 600,000 tons—consisted of quartermaster items, including subsistence, clothing, coal, and other supplies.54 By mutual agreement woolen clothing was procured for U.S. troops in the United Kingdom while similar items were shipped from the United States to British units in the Middle East. Among the other major items provided were 1,450,000 square yards of portable airfield runways, 15,000 bombs, 70,000 rounds of artillery ammunition and several million rounds of small arms ammunition, 250,000 antitank mines, 500,000 hand grenades, 1,000 parachutes, several hundred thousand camouflage nets, plus hundreds of other items of all

classes.55 The transfer of British equipment in some cases aided materially in equipping U.S. units in time for the TORCH operation. By the end of the year supplies procured in this way had accounted for at least a third of all tonnages received by U.S. troops in the United Kingdom.

Local procurement was plagued with many complications, not the least of which was the difficulty with the “common language.” In literally thousands of items of supply and equipment the American and British terminology and nomenclature differed. Not only did the American serviceman have to learn to drive on the left side of the road and figure out the intricacies of pounds, shillings, and pence, but he had to learn to ask for petrol when he wanted gas, to refer to lorries instead of trucks, and lifts rather than elevators. To the Britisher a hot-water boiler was a calorifier, a garbage can was a dustbin, shoe tacks were tingles, burlap was hessian, cheese cloth was butter muslin, and a summer undershirt was a tropical vest. The British stenographer was puzzled to find that to her American employer the last letter in the English alphabet was “z” and not “zed,” and she insisted on the British spelling of such words as “programme” and “tyres” in correspondence which she prepared in the various U.S. Army offices. Wherever Americans came into contact with Britishers, particularly in the depots and in the local procurement program, where they dealt with or actually handled supplies of both countries it was inevitable that they should at times conclude that their languages were only nominally the same.

The reciprocal aid program also brought with it a vexing problem of bookkeeping and accounting. War Department regulations initially prescribed a system of receipted vouchers for all supplies, with American and British officers agreeing on prices and, in lieu of such agreement, American officers fixing their own valuation. This proved completely impracticable and was largely ignored. British officials frequently could not furnish cost figures on delivery, and there were not enough U.S. officers qualified to make price evaluations. The result was that, where such evaluations were insisted on, prices were often pulled out of the air. In October 1942 the attempt to keep a monetary record of reciprocal aid transfers was abandoned and the War Department authorized U.S. officers in the United Kingdom to maintain only a quantitative record. For several months U.S. reports therefore indicated only the amounts of goods received, while British quarterly reports gave monetary values in round numbers.

In June 1943 the War Department once more attempted to establish a procedure of monetary evaluation of locally procured supplies, but by that time the quantity of goods supplied under reverse lend-lease had reached such huge proportions that neither the independent evaluation by U.S. authorities nor the provision of unit prices by the British was possible. The estimated monetary values of the British quarterly reports plus the U.S. records of quantities were therefore accepted by ETOUSA as the best possible temporary solution. Under other circumstances the valuation procedure followed by the British would not have been acceptable, but more serious differences did not arise at

the time in part because of the realization that supplies furnished the British through lend-lease would far exceed the British contributions via reverse lend-lease.56 In the heat of the build-up for invasion the important thing was to fill the largest possible portion of American needs by local procurement with the hope of effecting savings in shipping; the accounting of these purchases was a secondary consideration and could be postponed.

Reciprocal aid, like the build-up, reached its height in the months just preceding the invasion. In the first year the Air Force was one of the largest beneficiaries from local purchase, for the United Kingdom was an indispensable source of almost all types of equipment in the Eighth Air Force’s early history. From June 1942 through July 1943 the American air forces drew 49 percent of all their air force supplies and equipment from British sources, in addition to quartermaster, engineer, medical, and other types of supplies received indirectly from the British through the SOS.57 Air force supplies included huge quantities of replacement parts, hand tools, photographic and communications equipment, flying clothing, parachutes, and Spitfire fighter planes. By the spring of 1944, to cite only a few examples, the British had provided 1,100 planes plus several hundred gliders, 32,000 bombs, 7,000 sets of armor plate for heavy bombers, 5,000 rubber dinghies, 10,600 aircraft tires, 35,000 belly tanks for fighter craft, 9,600 pieces of protective body armor, 43,000 jettisonable gas tanks, 44,500,000 yards of Sommerfeld track, 50 mobile repair shops for the repair of bombers crash-landed in the United Kingdom, and unspecified quantities of heated winter flying clothing, radio equipment, and other items.58

The Quartermaster Corps obtained 63 percent of its requirements through 1944 by local purchase, a larger percentage of its total needs than any other service. The nature of its purchases has already been indicated. In addition to subsistence, these included camp, laundry, bakery, and shoe repair equipment, soap, office supplies, 15,000,000 5-gallon cans, 800,000 55-gallon drums, 83 mobile bakeries, toiletries, and large quantities of woolen socks, shoes, towels, blankets, and other items of clothing.59

Engineer supplies procured in Britain took the form of amphibious and bridging equipment, railway supplies, construction machinery, and storage tanks. The Engineer Corps was one of the largest users of locally procured supplies, acquiring 58 percent of its needs, exclusive of construction materials, in this manner.

Between June 1942 and June 1944 the services procured varying portions of their supplies in the United Kingdom, as indicated in the table below.

| Quartermaster Corps | 63% |

| Corps of Engineers | 58 |

| Medical Service | 49 |

| Chemical Warfare Service | 25 |

| Signal Corps | 22 |

| Air Forces | 21 |

| Ordnance Service | 4 |

| Transportation Corps | 3 |

Ordnance and Transportation Corps supplies did not bulk large in actual tonnage, but British manufacturers produced almost all the waterproofing materials needed to prepare vehicles for the

amphibious phase of the cross-Channel operation, and British plants assembled nearly 130,000 vehicles for U.S. forces through June 1944.60 Reciprocal aid to the Transportation Corps consisted chiefly of facilities, such as ports and rail lines, and services, such as labor employed in unloading cargo and transportation services on British railways and highways. In the first six months of 1944 alone British railways operated 9,225 special trains with over 950,000 cars to move U.S. troops and supplies.61

By the end of June 1944 an estimated 6,800,000 ship tons of supplies from British sources had been furnished American forces in the United Kingdom, accounting for approximately 31 percent of all supplies received by ETOUSA forces up to that time, exclusive of construction materials and gasoline. More than half of this tonnage—3,851,000 ship tons—was delivered to U.S. forces in the first six months of 1944, as is indicated in the summary below:

| Total | 6,799,433 |

| 1942 | 1,121,786 |

| 1943 | 1,826,701 |

| 1944, first 6 months | 3,850,946 |

The U.S. Army in Britain received without cash payment through reverse lend-lease, or “mutual aid” as the British preferred to call it, innumerable other services, such as shoe repair, laundering, and camp utilities. The goods transferred and services rendered to U.S. forces within the United Kingdom before 30 June 1944 had an estimated value of $1,028,787,000. In addition, the British performed world-wide shipping services to U.S. forces in the amount of $356,050,000,62 and, as summarized earlier, had expended approximately $664,000,000 on new construction. The amount of British labor employed on U.S. account fluctuated widely, but during the peak months in the winter of 1943–44 reached nearly 100,000 workers (over 90 percent civilian), including labor employed directly by the Americans and on construction projects for U.S. forces.63

In a special report to Congress on reverse lend-lease aid, President Roosevelt noted that “it would have taken 1,000 loaded ships to send from the United States the supplies provided to our forces by the United Kingdom.”64 In view of the acute shipping shortages during most of the build-up, these goods and services were an indispensable contribution toward the maintenance and equipment of U.S. forces preparing for the invasion of the Continent.

The SOS on the eve of OVERLORD

In the five months that preceded the invasion supply officials in both the United States and the theater were concerned not only with the over-all volume of supplies being shipped to the United Kingdom,

but also with shortages in specific items of equipment. Huge tonnages in themselves did not insure that all units would be adequately equipped. In January 1944 the Army Service Forces made a comprehensive survey of the status of the BOLERO build-up. The most striking revelation of its report was the unbalanced nature of the shipments of the past months. To cite the extreme cases, the Quartermaster Corps had already virtually completed its shipments for eighteen divisions and their supporting troops, while Signal Corps equipment had been shipped for only five.65 Some variation was to be expected, since under the preshipment program every effort had been made to fill the available shipping with whatever supplies and equipment were available at the time, and quartermaster supplies had been available in greater quantities than those of other services. Nevertheless, the ASF report demonstrated how misleading tonnage figures by themselves could be, for despite the heavy movement to the European theater there were many shortages, and some of them persisted even to D Day. One of the principal reasons was that many items were only now beginning to become available in sufficient quantity in the United States.

At the time of the survey forecasts indicated that the principal requirements would be met by the first of May. By March, however, theater port capacity and shipping space so restricted the shipment of the mounting tonnages of cargo at the New York Port that the theater had to institute a system of priorities to insure that the most badly needed items were delivered in time. Late in March General Lord and several of the ETOUSA service chiefs journeyed to Washington and reviewed with ASF officials the entire supply picture for the coming invasion, discussing such matters as supply levels, inter-theater priorities, emergency requisitions, commodity loading, and tonnage allocations. Their most immediate concern was with the critical shortages in specific items of supply and equipment. Investigating the status of every important item, they prepared a “critical item list” which included all supplies whose lack might jeopardize the success of the operation. The list established deadlines for the delivery of the necessary quantities, and production schedules, rail shipments, port receipts, and port loading of these items were thereafter followed day by day. Their status was reported to the theater by air courier, and when difficulties arose or were foreseen, the problem was immediately reviewed and remedial action was taken. Under a system of priorities established by the theater, ETOUSA thus maintained virtually complete control of the make-up of shipments to the United Kingdom in the months just before D Day.66

In the United States the New York Port was instructed to adhere closely to the theater priority lists for loading, and the ASF did everything possible to expedite delivery of critical supply items in the final weeks of preparation for OVERLORD. Despite these efforts, shortages of both major and minor items persisted beyond D Day. Among them were amphibious trucks, tank transporters, LVTs, mine-exploding devices, certain heavy transportation equipment, and various types of ammunition. Fortunately, none of these shortages

were serious enough to affect the initial stages of the operation.67