Chapter 4: A Start in the Procurement of Equipment

In the hands of trained troops, power machinery, new types of emergency bridges, mine detectors, landing mats, and intricate devices for the compilation and reproduction of maps would become instruments for attaining the speed and efficiency required of engineer units in the new Army. Some of the most ingenious of these items were still in the development stage in 1940 when the United States began to build up its military strength. Assistant Secretary of War Robert P. Patterson, whose main function was to oversee the purchase of supplies for the Army, realized the potential of the equipment under development but insisted that suitable substitutes be bought immediately. The search for improvements must continue but not at the sacrifice of an accelerated procurement program, Patterson instructed Schley in August.1 Except for a few items, such as trucks, the Engineers had authority to buy all the equipment for engineer troops doing engineer work. Camouflage materials and searchlights were the only significant purchases made for other arms and services. For the accomplishment of its major tasks the Corps was ready in 1940 to order construction machinery and other equipment already selected as soon as money was forthcoming.

Peacetime Plans

For almost twenty years, during the interim between the two wars, the Corps of Engineers had planned for wartime procurement of equipment under the general rules laid down by the Office of the Assistant Secretary of War (OASW). The aim of such planning was the orderly placement of contracts during any future military expansion so as to avoid the competition for facilities and labor that had characterized military buying in World War I. Given the number of troops specified by the General Staff for a wartime Army, the services could presumably calculate the quantities of equipment needed. Industrial capacity could then be investigated and specific plants lined up. On the basis of recommendations received, OASW was to allocate plants or portions of plants to the various services.2

The services did not make elaborate plans for each item to be procured. Many articles that would be bought in wartime were commercial products and could be obtained without difficulty. For these items OASW required only that lists of prospective suppliers be maintained. For special military items and for commercial products which for one reason or another might prove scarce in wartime OASW encouraged the preparation of drawings and specifications,

Assistant secretary of war Robert P. Patterson. (Photograph taken 1944)

descriptions of the manufacturing process, schedules of production, and estimates of the requisite machine tools and manpower.3

The Corps of Engineers was not in a position to derive much benefit from the procurement planning program because accurate requirements were impossible to predict. It was simple enough to figure out how many bulldozers would have to be produced for direct issue to troop units, but it was quite another matter to estimate how many bulldozers, road graders, tons of cement, square feet of landing mat, or other such supplies, would be needed for special wartime construction projects. Estimates for a war in the Pacific would differ vastly from those for a war on the continent of Europe. Since the planners could not know where the war would be fought they had to make assumptions. The Operations and Training Section compiled lists of equipment and materials that would be needed in a given type of activity in a given climate and terrain. The Supply Section had little faith in such compilations and frankly admitted in 1939 that plans for operational supplies were incomplete. Since ultimate expenditures for such supplies accounted for approximately 60 percent of the dollar value of the Engineer procurement program, plans which did not state these requirements accurately were necessarily deficient in forecasting the amount of industrial capacity needed.4

The Engineers did not fit well into the planning program for another reason. Most of the items they were preparing to buy, including the whole array of construction machinery, were either standard or slightly modified commercial articles. OASW was naturally for the most part preoccupied with planning for the production of weapons and other matériel not manufactured in peacetime, an attitude clearly expressed shortly after war broke out in Europe. Anxious that procurement planning be accelerated, OASW considered limiting the allocation of facilities to special military equipment. The Engineers were quick to protest. Allocation of facilities and preparation of production schedules for construction machinery and numerous other standard commercial articles should be continued, the Supply Section maintained, since wartime requirements were certain to tax productive capacity, and since no reserve stocks had been authorized.

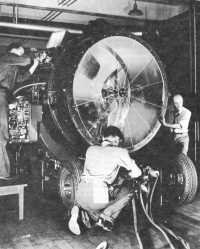

60-inch searchlight unit being tested by engineers in the General Electric plant, Schenectady, N.Y.

The Supply Section was also acutely conscious that many of the plants on which the Corps was dependent could be readily converted to the manufacture of munitions. If OASW were to stop allocating such plants, other services might successfully crowd the Engineers out. OASW did not press the matter.5

Ironically, the Supply Section was most successful in planning production for searchlights which were for the use of another service and which the development of radar made practically obsolete by 1943. The fear lest there be insufficient searchlights was understandable enough in the late thirties when to all but a handful of farsighted individuals the defense of the United States extended no farther than its borders. The Engineers could get money for searchlights when little could be had for anything else. With this one item, plans could be acted upon. The 60-inch searchlight unit consisted of a reflector with mirror, control station, power plant, and control and power cables. Sources of production were extremely limited. In the thirties the Sperry Gyroscope Company was the only plant tooled up for production of the light; the only producer of the parabolic metal mirror was Bart Laboratories of Belleville, New Jersey, a small plant owned and operated by the inventor of the process by which metal mirrors were made. In addition, the Engineer Board maintained a small experimental mirror laboratory at Fort Belvoir. In 1938 the Engineers received the first of three allotments of money to increase productive capacity for mirrors and lights. Under a program authorized by Congress to provide industry with some experience in the manufacture of special military items the Engineers granted an educational order to the General Electric Company which induced that plant to tool up for the manufacture of lights. Expansion of the Bart Laboratories, conversion of the Engineer Board’s laboratory to manufacturing, and finally, as demands for searchlights mounted in 1940, construction of a new mirror plant at Mariemont, Ohio, followed in quick succession.6

In June 1940 Kingman announced that procurement plans were complete for all but a fraction of those items which might present production problems.7 This meant at least that various facilities had been earmarked for wartime production. If the Engineers entertained any fears that these facilities would prove insufficient they did not say so. Indeed, lacking a firm base from which to estimate quantities of operational supplies, the Engineers could not produce any facts to bolster such a claim. Unfortunately, these uncertainties about requirements persisted throughout the period before Pearl Harbor. Of equally serious consequence was the fact that during this time the Engineers were afforded practically no opportunity to order the operational supplies that were to account for so much the greater part of their wartime purchases.

Two Million Extra

The Corps of Engineers was constrained to limit its purchases as a result of War Department policy. Uncertain itself as to if, or when, or where the United States might be committed to fight, the War Department concentrated upon readying an emergency defense force and providing industrial capacity for the production of weapons and ammunition. Accordingly the procurement program developed by the Engineers was limited to providing troop units with organizational equipment. Such a program was desperately needed. The bulk of ponton bridging on hand was obsolete. Troop units authorized construction machinery trained with hand tools.8

The Engineers received their first substantial allotment of money to buy modern equipment for troop units in February 1940, following the President’s declaration of a limited national emergency and his authorization to increase the size of the Regular Army from 210,000 to 227,000 men. The Engineers’ share of the February appropriation was $2,000,000, a small sum, not quite sufficient to equip completely all units in the Regular Army much less the National Guard. Small as it was the February appropriation signaled a fundamental change that was immediately recognized. The Supply Section shared in the general enthusiasm and understood the eagerness of unit commanders to receive new equipment, but cautioned restraint. The first of a series of bulletins designed “to furnish ... an insight into the inner workings of the Supply Section” and to “prevent dire accusations from the field of unwarranted delay and gross inefficiency,” pointed out that “we are not at war, and the supply of troop organizations still must follow our normal peacetime procedure. ... Many bright ideas of speeding up purchases have been proposed, but remember the laws must be observed.”9

The most fundamental of the laws which had to be observed was that requiring competition for government orders. Competition was assured by a system of bidding whereby a government agency advertised its intention to buy a given product and invited business firms to submit proposals as to quality, time of delivery, and price. The lowest bidder usually got the order, although the government could pass over a firm whose product did not meet specifications or who clearly would not be capable of delivering. This system of buying had many advantages in a normal peacetime market. Since all prospective sellers had an opportunity to bid, charges of favoritism were obviated. Since contracts were awarded to the lowest responsible bidder, the government presumably paid a price that was both economical and fair. But the system was not expected to work during an emergency. First, it was incompatible with the planned-for allocation of facilities. Second, it was too time-consuming. In case of a major rearmament the government would negotiate its contracts, as was the universal practice in private industry.

The time consumed by competitive bidding was of immediate concern to the Supply Section. Ten to thirty days were allowed for the submission of bids. Evaluation of bids and necessary paperwork followed. Anxious to get equipment into the hands of

the troops as soon as possible, the Supply Section tried to speed up this process somewhat. The Procurement Branch sent out invitations to bid as soon as money had been appropriated, not waiting as was customary for the actual receipt of funds.

By 1 March 1940 contracts valued at about a million dollars had been let for air compressors, power shovels, road graders, concrete mixers, bulldozers, assault boats, bridges, water purification units, and map reproduction trains. The Supply Section was most anxious to obtain all this equipment in time for the maneuvers scheduled for May but doubted this could be done. Bridges, boats, and water purification units—special military items—took a year or more to produce in quantity.10 “It takes months to buy even a standard type of gasoline shovel,” Godfrey lamented.11 Six months from ordering to delivery was about average for the amount and types of construction machinery the Engineers had placed under contract.

Engineer troops took little new equipment to the spring maneuvers. Their equipment, the Chief of Staff recalled, was “tragically short even for the few Engineer units in the Regular Army.”12 Summing up the situation at the end of June 1940 Kingman noted that funds allotted had enabled the Engineers to order equipment for the triangular divisions, IV Corps, and GHQ troops which represented most but not all elements in the 227,000-man Army. As Assistant Secretary of War Patterson presented the facts, in short, the twenty-four engineer units in the Regular Army in June 1940 were lacking some critical items and the National Guard’s nineteen engineer units had scarcely anything at all.13 Up to this point, both lack of money and lack of time had contributed to shortages. After the German advance through the Low Countries, it was time more often than money that threatened to run out.

Rearming in Earnest

When the Chief of Staff appeared before the House Appropriations Committee early in 1940 to defend the Army budget for the next fiscal year, the American people had recovered from the shock of the German attack on Poland. There had been little military action after the completion of the Polish campaign. This fact, generously reinforced with wishful thinking, had led to the popular concept of the phony war. Under these circumstances, many congressmen were unsympathetic toward the Army’s request for $853,000,000. The military, far less sanguine about the world situation, regarded the Army budget as the barest minimum of safety, but felt compelled to say nothing that could be construed as warmongering. On 9 April 1940, six weeks after General Marshall’s testimony on the appropriation bill, the Germans moved into Norway. On 10 May came the full-scale blitzkrieg in the west. Suddenly the budget that had seemed so large appeared modest indeed.14

The War Department had a plan—the Protective Mobilization Plan—that provided for the orderly expansion of the Army in case of a national emergency. The first increment was to bring the active Army to

750,000 men. The $853,000,000 budget which the Chief of Staff defended in February 1940 included money to stockpile critical items (defined as items not readily available from commercial sources) for the Initial Protective Force and to procure both critical and essential items available on relatively short notice for the currently authorized 227,000-man Regular Army and 235,000-man National Guard. On 19 April, ten days after the Germans attacked Norway, the Supply Division (G-4) of the War Department General Staff asked the services to prepare estimates to cover those critical items omitted from the budget which were needed by active units of the Army. This was the first of a number of estimates called for during the spring and summer of 1940 as the battle of France was being lost. By the end of June, Congress had appropriated nearly $3,000,000,000 to the Army, the goal now being to provide critical and essential items for a force of 610,000 and critical items for 1,200,000 men. The Munitions Program of 30 June raised the sights still higher. Under this program the Army proposed to provide a force of 1,200,000 with critical and essential items by 31 September 1941, to provide critical items for 500,000 more men by the following December, and to create productive capacity for the eventual arming of 4,000,000. In the fall, Congress appropriated additional money, bringing the total funds available to the Army to $7,000,000,000. The Corps of Engineers’ share of this amount was $70,000,000.15

Justifications for this sum had been prepared by the Requirements, Storage and Issue Branch, Supply Section, in great haste. The request for estimates made on 19 April had to be answered the following day. But the small staff of the Requirements Branch had had no difficulty in arriving at the answers to such requests. Computing requirements for organizational equipment, and this was all the Engineers were asked to do, was a matter of simple arithmetic. Quantities of items required for the initial equipment of troops were found by multiplying T/BA allowances for each type of troop unit by the number of units authorized. To this figure the Requirements Branch added a percentage to allow for replacement. From the resulting total it deducted quantities known to be on hand or previously financed and prepared a statement of requirements as called for.16

Since War Department policy prohibited the stockpiling of commercial products the Munitions Program did not include allowances for the purchase of any operational Class IV supplies for the Corps of Engineers. Although deploring this rule the Engineers did not apply immediately for its relaxation. They did call attention to deficiencies that were demonstrable under specific defense plans. In the spring of 1940 defense plans provided for the deployment of task forces to defend strategic points in the Western

Hemisphere.17 After a study of the requirements for an expeditionary force which if necessary was to be sent to Brazil, Kingman commented:

A review ... indicates that the magnitude of the engineer tasks involved needs to be appreciated and further emphasized. The theater of operations involved is one of very meager routes of communication and facilities for engineer operations.

…

The equipment needed for this force will involve much more than organizational equipment. Special attention will have to be paid to road building equipment, heavier than normally issued to troops, and including such plant as portable rock crushers. ... A considerable number of water purification units should be included. Portable sawmills will be needed to utilize local timber resources.

The tonnage of Class 4 operational supplies will be large. Such supplies as barbed wire, sandbags, cement, prepared timbers, structural steel, railroad rails, ... and many other supplies, must be taken in large quantities.18

When the General Staff revised its plans for defense in the light of the German victories, Kingman made a specific request. RAINBOW 4, as the new plan was called, contemplated the occupation of certain foreign possessions in the Western Hemisphere and provided for the defense of Hawaii and Alaska. Under the schedule of movements, troops would be deployed in three contingents, the first force to move on ten days’ notice, the second in thirty days, and the remainder in forty. The Engineers estimated they would need about $15,000,000 to ready themselves for the operations included in RAINBOW 4: $1,808,000 worth of equipment of the same type but in greater amounts than that automatically furnished troop units; $1,560,000 worth of special equipment such as heavy construction machinery and rock crushers; and $11,718,000 worth of construction materials. Only a small part of these supplies was on hand included in the current procurement program. Kingman notified G-4 in September 1940 that it would take at least 60 days to obtain the total quantities specified. G-4, persuaded by this justification, suggested that the request for funds be included in the next appropriation bill.

Early in December a representative of the War Plans Division, General Staff, persuaded the Engineers to withdraw the request for most of the funds. RAINBOW 4 had been changed to allow thirty days before movement of the first contingent. Strictly speaking, most supplies included in the $15,000,000 estimate might be gathered together within thirty days. But Lt. Col. John M. Silkman, the chief of the Supply Section, warned that “new equipment may not be available and ... used equipment might have to be commandeered or even confiscated depending upon the urgency of the situation under which the RAINBOW Plan became operative. The potentiality of such action as a source of confusion and delay in activities of first importance ... should not be overlooked nor underestimated.” The funds were not restored.19

On occasion the Engineers called attention to the great discrepancy between what was being bought under the Munitions Program and what would be required in wartime. The emergency had not developed according to the book with an M Day touching off a prearranged series of steps. Instead, as Kingman pointed out, “plans and requirements for supply, at least for the Engineers, have been made piecemeal with constantly changing objectives and authorizations dependent on expected appropriations.”20 The result was a relatively small procurement program which the Engineers believed could be executed without difficulty.

The launching of the Munitions Program resulted in a number of changes in the laws and policies which regulated government buying. The expansion of productive facilities was assured by a relaxation of the tax laws to allow amortization of expenditures for plant construction, and by government financing in the form of loans or outright ownership. Competitive bidding was no longer required. Advance payments on contracts could be made. In an attempt to insure the production of first things first the Army and Navy Munitions Board (ANMB) established a system of priority ratings for military orders. In general, speed of delivery consistent with an acceptable product replaced cost as the factor to be given primary consideration.21

A score of suggestions were added to these formal arrangements for expediting the Munitions Program. OASW directed that the time allowed for submission and evaluation of competitive bids be cut. In order to spread the work to as many suppliers as possible, restrictive specifications were to be avoided, awards split, the use of subcontractors encouraged, and inspections speeded up. The Advisory Commission to the Council of National Defense (NDAC), the civilian group charged with supervision of the over-all productive effort, gave further guidance to the program. The NDAC reminded the services of their responsibility for protecting the rights of consumers and of labor, cautioned against overconcentration of orders, and recommended that the financial condition of prospective suppliers be carefully investigated.22

That many of these rules and regulations were not particularly applicable to the Engineer procurement program points up once again its relatively small size as well as the commercial nature of the products being bought. While the Ordnance Department was sponsoring the construction of a multimillion dollar munitions industry, the only government-owned plant sponsored by the Corps of Engineers was the $450,000 searchlight mirror facility at Mariemont, Ohio. But some few contractors had to expand their facilities in order to fill Engineer orders and in these cases the Corps certified that they were eligible for relief under the tax amortization law. The Engineers were well acquainted with their prospective suppliers. They did not have to worry, as did those services whose volume of buying would tax productive capacity, about the fast talking gentlemen with offices in their hats who turned up in Washington offering to produce almost anything.23

With these facts in mind the Engineers decided to keep procurement centralized in the Procurement Branch of the Supply Section, OCE, although mobilization plans called for other administrative arrangements. In its civil works divisions and its district offices the Corps of Engineers possessed an extensive field organization which it believed would prove of great assistance in case the procurement load became unmanageable from Washington. In wartime the civil works program would shrink and personnel of the districts, experienced in the handling of government business, would become available to the procurement organization. In peacetime the Engineers maintained a procurement planning district in six of their district offices. Each manned by one officer and a clerk, the procurement planning districts had done much of the preparatory work in connection with the allocation of facilities. Mobilization plans stipulated the decentralization of purchasing to these six districts whose staffs would be expanded with personnel transferred from civil works and which would be supervised by Reserve officers especially trained for such duties. Even though procurement remained centralized in Washington the civil works districts and the procurement planning districts participated in the current program to some extent. The procurement planning districts sought out additional facilities and the civil works districts performed inspections required before acceptance of a product. In OCE the Procurement Branch handled the bulk of the workload.24

The Procurement Branch believed that most of the contracts to be let under the Munitions Program of 30 June 1940 could be advertised, but proposed to negotiate whenever possible and whenever to the government’s advantage.25 The decision to continue the use of competitive bidding wherever feasible was in perfect accord with the policies announced by OASW, which notified the services on 2 July that “the authority to purchase without advertising will be resorted to only in cases where that method of procurement is essential to expedite the accomplishment of the defense program.” When negotiation was resorted to, it should be preceded by solicitation of informal bids. Negotiated contracts amounting to $500,000 or more had to be submitted to the Assistant Secretary of War for approval; the supply services were to set up appropriate safeguards for controlling the award of contracts of lesser amounts.26 In order to speed up the placement of orders within the competitive bidding system the Procurement Branch reduced the time allowed between advertising and awards to a maximum of ten days.27

On 8 July, with $25,000,000 available from the regular appropriation, the Supply Section announced its intention to let contracts worth $17,002,266 within the next thirty days. All but one, an order for metallic parts for ponton bridges, would be advertised. By early September the Engineers

had obligated almost all of their $25,000,000, and another appropriation, for $42,000,000, was approved. Again the Procurement Branch moved quickly, obligating more than $19,500,000 by the middle of the month.

Of the approximately $44,000,000 obligated, more than $16,000,000 went into orders for searchlights in contracts negotiated with the two available suppliers, Sperry Gyroscope and General Electric. One other contract in the group let at this time, with the W. & L. E. Gurley Company for transits, was negotiated. A little over $2,000,000 in contracts for ponton bridge parts and road graders was advertised. Excluding contracts amounting to less than $100,000, the Engineers had obligated by the end of January 1941 over $23,500,000 through advertisement and over $30,500,000 through negotiation. Searchlights absorbed over 50 percent of the total spent under each type of contract. Of the major items contracted for during this period six were bought exclusively through competitive bidding, eleven by direct negotiation, and seven in part after bidding and in part through negotiation. In accordance with the instructions of the Assistant Secretary of War the Procurement Branch tried to retain as much competition as possible. Thus before the negotiation of a contract the branch sought informal bids from companies who could be expected to respond to advertisement.28

Even when contracts were advertised it was possible through a skillful wording of specifications to restrict the bids received to those manufacturers whose products were preferred, and the Supply Section did this on occasion. Carryall scrapers are a case in point. The Development Branch wrote specifications for scrapers so that only two manufacturers—R. G. LeTourneau, Inc., and La Plant-Choate Company—could meet them. When the Bucyrus-Erie Company, a newcomer to the scraper market, protested, the chief of the Development Branch noted the poor quality of some scrapers offered in the commercial market. Relaxation of the specifications in order to allow Bucyrus-Erie to bid would force the Procurement Branch into the undesirable position of accepting bids from a good many other, less competent, manufacturers.29

Writing restrictive specifications was a deviation from an announced policy to spread the work. “The majority of the items on the munitions program ... could be supplied expeditiously by one or two manufacturers,” Kingman informed the Assistant Secretary of War. “However, it is planned to distribute the load to 2 or 3 of the more prominent manufacturers, who are allocated to the Corps of Engineers and who have sufficient capacity to meet the war time requirements.”30 During the period July 1940 through February 1941, major contracts were placed with thirty suppliers out of a list of forty-eight potential ones. Of the forty-two separate companies represented in the list of potential suppliers, thirty were awarded contracts:31

| Item | Number of Potential Suppliers | Number of Suppliers Awarded Contracts Over $100,000 |

| Total | 48 | 30 |

| Earth auger | 2 | 1 |

| Air compressor | 6 | 2 |

| Road grader | 3 | 2 |

| Gasoline hammer | 1 | 1 |

| Power shovel | 7 | 3 |

| Trailer | 6 | 6 |

| Water purification unit | 3 | 1 |

| Magnifying lens prism stereoscope | 1 | 1 |

| Magnifying mirror stereoscope | 1 | 1 |

| Assault boat | 4 | 1 |

| Steel highway bridge | 3 | 1 |

| Ponton bridge | ||

| – Metal parts | 3 | 3 |

| – Wooden parts | 3 | 3 |

| Footbridge | 3 | 2 |

| Searchlight | 2 | 2 |

A number of the companies to whom the Procurement Branch took its business had been allocated to the Corps of Engineers under the procurement plans developed by OASW. A number had not. The system of allocations so painstakingly worked out during the thirties was quietly laid to rest during the creeping mobilization that preceded Pearl Harbor. As monies were received, all the services, the Engineers included, gradually acquired an interest in a facility through the placement of orders. Where one service could not utilize all the productive capacity available, another service was welcome. Yet there was a marked tendency to gravitate toward allocated facilities whose product and management were known. Patterson credited the procurement planning sponsored by him and his predecessors for much of the promptness with which the services let supply contracts. Procurement planning, together with the experience accumulated in the supervision of civil works and of development projects, goes far to explain not only the promptness with which the Engineers placed appropriated monies under contract but also the confidence they displayed in the abilities of their suppliers to produce on schedule.32

Contractors normally filled orders on the basis of first come, first served. Under the priority system established by the Army and Navy Munitions Board on 12 August 1940, contractors were to fill orders in any given month on the basis of preference ratings. Preference or priority ranged from A-1 to A-10 with an AA reserved for emergency use. The A-1 rating was to be applied to critical and essential items needed to complete the equipment of all active units of the Regular Army and National Guard; A-2 to critical and essential items to equip the 1,200,000-man protective mobilization force and maintain it for one year; A-5 to critical items and A-6 to essential items to equip 800,000 men and maintain them for four months. Under this setup most engineer articles were rated A-1 or A-2. At the end of October the Procurement Branch reported that no difficulties had been encountered in connection with priorities.

Indeed the Engineers had few difficulties of any sort. With the receipt of additional funds for searchlights for seacoast defenses and for the Navy, the Procurement Branch had a program of close to $76,500,000 and had put about 70 percent of it under contract by the end of December 1940.33 The

most critical items were on order and deliveries had equaled or exceeded scheduled production in nearly all cases. (Table 1) Three items—gasoline shovels, earth augers, and searchlights—were behind schedule. A strike had interfered with the production of shovels. Technical engineering problems had for a time dogged the production of searchlights. The essential fact was that troops in training had experienced no shortages of equipment. Troops were 98 percent equipped, General Schley estimated in January 1941.

Although the Engineer procurement program continued to be small, during the calendar year 1941 it became more complicated. After the passage of the Lend-Lease Act in March 1941 the Engineers began to purchase supplies for Great Britain and China. In January the first of several task forces moved out to one of the Atlantic bases that had been acquired from Great Britain. As the year wore on and more task forces occupied the defense perimeter the demand for power machinery and construction materials began to put a strain upon engineer supply. In January 1941 the War Department decided to ask immediately for funds to cover that part of the Munitions Program heretofore included in the budget for fiscal year 1942. The Engineers received $18,674,000 from the appropriation act passed in April. That same month the Engineers received their first allocation in the amount of $9,707,000 from lend-lease funds. By the end of the summer, appropriations for troop equipment had added $73,000,000 and lend-lease allotments $13,000,000 to Engineer funds.34

The Engineers saw nothing in this situation that called for the decentralization of procurement activities. So far the Supply Section in Washington had been more than equal to the job. It should prove capable of being so in the foreseeable future. Naturally some minor administrative changes had to be made. In April the Requirements Branch established a small organization to take care of the special problem of lend-lease. But while the Washington office handled the bulk of the work, the Procurement Branch called increasingly on the civil works districts to investigate delays in production, to look into questions about priorities, in short, to expedite.35

The Procurement Branch planned to award contracts under the April 1941 appropriation in much the same way it had handled previous programs, by a combination of advertising and negotiation. But when the month of June arrived with a substantial amount of money still to be obligated, advertising was temporarily abandoned. For the first time the Procurement Branch resorted to the use of letter contracts, which were informal instruments authorizing the contractor to go ahead, with the guarantee of his expenses for a certain amount of preliminary work. Letter contracts did not replace formal contracts but served as another short cut pending the execution of a formal contract which, even if negotiated, consumed valuable time. By such expedients the Procurement Branch succeeded in obligating practically all of the funds allocated to purchases for the

Table 1—Status of Major Items of Engineer Procurement Program: 31 December 1940

| Cumulative Deliveries as of 31 December 1940 | ||||

| Item | To Be Procured Fiscal Year 1941 | Under Contract | Scheduled | Actual |

| Construction Machinery | ||||

| Angledozer* | 547 | 547 | 289 | 289 |

| Auger, earth | 68 | 68 | 60 | 48 |

| Compressor, air | 890 | 890 | 296 | 312 |

| Grader, road | 93 | 93 | 75 | 79 |

| Hammer, paving breaker | 1,063 | 1,063 | 143 | 143 |

| Mixer, concrete | 78 | 78 | 78 | 78 |

| Shovel, gasoline, 3/s-cubic yard | 83 | 94 | 54 | 38 |

| Special equipment, engineer aviation battalion | 7 | 0 | 0 | 0 |

| Welding and cutting set | 131 | 131 | 131 | 131 |

| Boats | ||||

| Assault | 3,446 | 3,446 | 2,446 | 2,456 |

| Bridges | ||||

| Fixed steel, box girder, H-10 | 86 | 86 | 21 | 28 |

| Fixed steel, box girder, H-20 | 10 | 10 | 0 | 0 |

| Footbridge | 111 | 111 | 43 | 43 |

| Ponton, 10-ton | 81 | 81 | 40 | 48 |

| Ponton, 25-ton | 47 | 47 | 1 | 1 |

| Mapping Equipment | ||||

| Compass, lensatic | 113,194 | 50,000 | 0 | 0 |

| Reproduction equipment | ||||

| – Corps Area Headquarters | 4 | – | – | – |

| – Mobile reproduction train | 1 | 1 | 0 | 0 |

| – Motorized | 32 | 32 | – | – |

| Stereoscopes | ||||

| – Lens-prism | 142 | 142 | 1 | 1 |

| – Magnifying mirror | 2,450 | 2,450 | 0 | 0 |

| Utilities | ||||

| Water purification units | ||||

| – 900 gallon | 217 | 217 | 140 | 155 |

| – 5,000 gallon | 34 | 34 | 4 | 8 |

| Electric lighting equipment, 5 KVA | 15 | 15 | 15 | 15 |

| Searchlights | ||||

| 60-inch | 1,870 | 1,870 | 35 | 0 |

* Procured for the Engineers by the Ordnance Department at this time.

– Data not available.

Source: Sched of Prod Rates on Critical Items and Status of Engr Equip Required To Meet Time Objective, submitted with Ltr, Sup Sec OCE to Prod Br OUSW, 31 Jan 41, sub: Sched of Prod Rates. ... Special Collection Subsec of Hist Div WD Special Staff file, OUSW Plan Br 381, Time Objectives.

American Army before the close of the fiscal year.36

The branch failed, however, to make much headway with the program for the British. The Engineers could transfer a few items from depot stock. Beyond this they had put under contract by midsummer only $2,500,000 of the $9,000,000 worth of construction machinery, bridges, boats, and other equipment requisitioned by the United Kingdom. By the end of the fiscal year 1941 the Engineers had $23,000,000 in lend-lease funds, $13,000,000 of which was for construction materials and rolling stock for the Burma–Yunnan Railway. Between July and December 1941 they received an additional $56,000,000, most of which was for railroad building materials and rolling stock for lines in the Middle East. By December the Procurement Branch had obligated $53,000,000, or 67 percent of the total.37

The Beginning of Production Problems

As early as January 1941 the Engineers had expressed some uncertainty about the future rate of production. Kingman had called attention to “an apparent slowing trend” in the receipt of certain raw materials which the Supply Section feared might cause a reduction in the rates of delivery of end products. These materials could be readily identified by a look at the Army and Navy Munitions Board’s priority list, he wrote the Under Secretary of War, “but among other things, a shortage may be expected of steel and steel alloy products, aluminum sheets, certain qualities of plywood, and expanded rubber.”38 The Army and Navy Munitions Board had by this time overhauled the priorities system, which had become overcrowded in the A-1 category. Accordingly, a hierarchy ranging from A-1-a to A-1-j was created. Under the new ratings engineer items that formerly enjoyed an A-1 priority with planes and tanks dropped to A-1-i or A-1-j. Yet the Engineers could hardly protest; all the Army services were in the same position. The Air Corps and the Navy absorbed top priorities. What bothered the Engineers and indeed all the Army services more than the lowering of ratings was the fact that the rating system did not cover a sufficient number of items and raw materials. The civilian agencies in charge of production—first the NDAC and after January 1941 the Office of Production Management (OPM)—were anxious to preserve the normal flow of production to civilians. They sought to achieve this result by keeping raw materials and components which went into civilian products free of the priorities system. Accordingly, the ANMB limited the extension of ratings to those items or materials appearing on the Critical Items List which were in general “noncommercial in character or type, made in accordance with particular military or naval specifications.” Commercial steel and lumber were offered

as examples of materials to which preference ratings could not be extended.39 This order created situations such as the one described by the Buffalo District Engineer:

Efforts made to accomplish the contracts of the Rogers Brothers Corporation ... and the Hanson Clutch and Machinery Company ..., both manufacturing platform type trailers, have previously required that this office extend preference ratings to subcontractors. Preference ratings have been given to items which are normally considered commercial items, such as structural steel, tires, brakes, etc. ... Steel mills have insisted that preference ratings be extended to the purchase orders from these companies in order that the mills themselves may be authorized to give precedence to the contracts.

The new system failed to make sense to the Buffalo representative who pointed out that there was “comparatively little commercial demand for specialized articles, and because of this lack of demand, obtaining delivery of special items is seldom difficult, whereas industry as a whole demands commercial items (structural steel, rubber, etc.), and because of the great demand, precedence for materials used for defense contracts is necessary. This indicates that strict interpretation of the new priority rulings nullifies, to a large extent, the underlying ‘raison d’être’ of the priority system.”40 The Supply Section registered its alarm over the new policy to the ANMB in February and again in April, and asked that the restriction be lifted.41 The Army was wholeheartedly in favor of lifting the restriction. All the services had experienced similar difficulties and entered similar protests. Gradually the OPM retreated. As of 1 May the services could extend ratings to nearly all the standard nonferrous metals and to iron and steel. By the fall of 1941 OPM had agreed to allow extensions to all materials that were physically incorporated in the product. By this time, the priorities system itself had undergone yet another overhauling which lifted all military orders into the A-1-a to A-1-j categories and placed limitations on the amounts to be produced in each category.42 Although the new rating structure was a step forward it did not get at the root of the problem, which was a rapidly developing shortage of raw materials. The Under Secretary of War had to call upon OPM to intervene in order to obtain steel for searchlight trailers. The priority rating on optical glass had to be raised in order to obtain delivery of stereoscopes. Substitutes for aluminum had to be made whenever possible.43 “Until such time as by joint command decision the War and Navy Departments establish a military priority for ponton bridges on the same level of importance as that which has been established for aircraft,” the ANMB Priorities Committee informed the Supply Section, “it is believed realistic to face the fact that in all probability aluminum will no longer be available for the production of ponton bridges.”44 The Engineer Board duly wrote

specifications for steel pontons despite their excessive weight, and despite the fact that many signs pointed toward a steel shortage.45

In August 1941 the Engineers reported a slight slippage in total deliveries:

Of the 54 items in the expenditure program deliveries were scheduled on only 21 items and were received on 18. At the beginning of the month 10 items were behind schedule and 6 were ahead, while at the close of the month 12 were behind and only 3 ahead. ...

The matériel provided by the Fifth Supplemental Appropriation Act was scheduled to come into production in a large number of cases in July but in some instances no deliveries were received. With these new contracts the Engineers are beginning to run into priority trouble in that the suppliers are unable to get the raw material and parts required because of the higher priority of other services and suppliers. This is a situation which did not prevail a number of months ago when earlier contracts were filled without difficulty.

Yet the Engineers preferred to look for the silver lining. The program was “well along.” Troop units had nearly all of their authorized equipment on hand. Statistics therefore might be deceptive because “from a military viewpoint the picture is very bright in that the initial requirements have been obtained.”46 The argument was true as far as it went. The goals of the Munitions Program were being met. But the over-all picture was not bright because the Munitions Program had made practically no provision for emergency stocks. The $1,716,400 left the Corps from its $15,000,000 estimate for RAINBOW 4 had been obligated, largely upon the advice of the War Plans Division of the General Staff, for portable buildings, water purification units, portable evaporators, and machine gun emplacements. The slim margin on which the Engineers were operating became apparent as soon as emergency needs cropped up. In May 1941 Brigadier J. F. M. Whiteley came to the United States with an urgent plea for supplies for the beleaguered British in the Middle East. When the General Staff assigned top priority to filling requirements on the “Whiteley List” the Supply Section discovered that deliveries to the British would cause some delay in equipping United States troops.47

Other emergencies likewise called for emergency measures as Engineer troops left for Alaska, Newfoundland, and Iceland. Bulldozers and dump trucks had to be transferred from the 18th Engineer Regiment stationed at Vancouver Barracks, Washington, to the 32nd Engineer Company stationed at Fort Richardson, Alaska. On 29 August, the Operations and Training Section requisitioned five bulldozers and three carryall scrapers for delivery at the New York Port of Embarkation in twelve days. Stevedoring equipment, structural timber and connections, rope tackle, power distribution equipment, a water supply system, and miscellaneous construction materials were requisitioned on 29 June to be available for shipment between 29 July and 14 September. Money was no problem, since the Engineers received special funds for this purpose. Approximately $3,000,000 was transferred from the Construction Section to the Supply Section between 25 June and 10 September 1941 for the Iceland task force alone. But the confusion that Silkman had predicted if the Engineers were not allowed an emergency stockpile was fast becoming part of the daily routine. In order to get supplies

out on schedule the Supply Section was sending equipment direct from factory to port. When sailing schedules changed, equipment piled up at the dock. When factories could not make deliveries in time the Supply Section drew upon small stocks stored for training purposes. This practice so depleted depot stocks that by late August 1941 the War Department directed field army commanders to cut down on training requisitions. Largely because of the higher priorities accorded to the defense build-up in these areas close to the United States, to equipping troop units, and to lend-lease, OCE could not begin to consider urgent requests from the Philippines until the fall of 1941. Support from the States failing, the Engineers in the islands exploited local resources to the utmost in a feverish attempt to provide airfields and other facilities for their defense. What was gathered together proved far from sufficient for that formidable task. And when the actual defense of the Philippines began, Engineer supplies, like those of the rest of the Army, were pitifully meager.48

On 17 June Schley entered a new plea to purchase a small stockpile of special equipment—“a minimum,” in his words, “which should be procured and stored at once near a port of embarkation.” This time G-4 approved the request. In the supplemental appropriation bill passed in August the Engineers received a minimum, $2,800,000, for this purpose.49 Meanwhile Kingman lodged an additional plea with the General Staff:

Our ports of embarkation are set up with a view to securing a continuous flow, and are unable to provide storage for any considerable time pending overseas shipment. Since factories cannot deliver supplies on prearranged schedules, storage difficulties will arise if purchases are made for delivery direct from factories to ports. Moreover, delivery of many kinds of Engineer supplies cannot be secured on short notice. It is, therefore, necessary that a reasonable quantity of Engineer supplies be purchased well in advance for delivery at interior Engineer depots and then shipped direct in proper quantity and kind to ports of embarkation as required.

Specifically he requested a directive to cover engineer operations in the field for task forces and emergency projects.50

Agreeing that a stockpile containing “a reasonable quantity” of supplies was “desirable,” G-4 directed the preparation of an estimate based on two infantry divisions, one operating under arctic and the other under tropical weather conditions, and one corps operating under either tropical or temperate weather conditions. On this basis Kingman requested an immediate allotment of $5,250,000. Funds were not available, the General Staff replied on 10 October. Engineer needs must be met through the next supplemental appropriation bill where provision had been made (on 27 September) for the inclusion of funds to purchase balanced stocks of construction materials and equipment that would be needed in

Table 2—Status of Major Items of Engineer Procurement Program: 20 December 1941

| Current Program | Cumulative Deliveries as of 20 December 1941 | |||

| Item | Appropriated Fiscal Years 1941 & 1942 | Under Contract | Scheduled | Actual |

| Construction Machinery | ||||

| Angledozer | 547 | 547 | 547 | 547 |

| Auger, earth | 100 | 100 | 68 | 68 |

| Compressor, air | 890 | 890 | 890 | 890 |

| Grader, road | 119 | 119 | 119 | 119 |

| Hammer, paving breaker | 1,079 | 1,079 | 1,079 | 1,079 |

| Mixer, concrete | 117 | 117 | 117 | 117 |

| Saw, timber | 1,715 | 0 | 0 | 0 |

| Shovel, gasoline, ¾-cubic yard | 5 | S | 3 | 3 |

| Shovel, gasoline, ½-cubic yard | 191 | 191 | 81 | 81 |

| Shovel, gasoline, ⅜-cubic yard | 99 | 83 | 83 | 83 |

| Special equipment, engineer aviation battalion | 31 | 31 | 17 | 17 |

| Trailer, for medium tractor | 1,265 | 609 | 609 | 609 |

| Welding and cutting set | 182 | 182 | 182 | 182 |

| Boats | ||||

| Assault | 3,446 | 3,446 | 3,446 | 3,446 |

| Power, with trailer | 62 | 62 | 2 | 2 |

| Bridges | ||||

| Fixed steel, box girder, H-10 | 165 | 129 | 97 | 91 |

| Fixed steel, box girder, 11-20 | 62 | 62 | 10 | 10 |

| Crane, truck mounted | 100I | 77 | 62 | 51 |

| Footbridge | 174 | 174 | 164 | 127 |

| Ponton, 10-ton | 91 | 81 | 81 | 81 |

| Ponton, 25-ton | 95 | 76 | 62 | 48 |

| Trestle, steel | 8 | 8 | 8 | 8 |

| Mapping Equipment | ||||

| Camera, copying | 24 | 24 | 16 | 15 |

| Reproduction equipment | ||||

| – Corps Area Headquarters | 4 | 4 | 4 | 4 |

| – Lithographic, platoon | 3 | 2 | 2 | 2 |

| – Mobile reproduction train | 2 | 2 | 1 | 1 |

| – Motorized | 40 | 34 | 32 | 32 |

| Stereocomparagraph | 188 | 187 | 57 | 57 |

| Stereoscopes | ||||

| – Lens, prism | 142 | 142 | 142 | 142 |

| – Magnifying mirror | 3,975 | 3,679 | 2,243 | 1,431 |

| Theodolite | 287 | 22 | 22 | 22 |

| Utilities | ||||

| Water purification units | ||||

| – 900 gallon | 580 | 572 | 520 | 496 |

| – 5,000 gallon | 103 | 59 | 34 | 34 |

| Electric lighting equipment | ||||

| – 5 KVA | 352 | 352 | 183 | 166 |

| – 3 KVA | 1,025 | 1,025 | 621 | 571 |

| Searchlights | ||||

| 60-inch | 3,907 | 2,261 | 1,788 | 1,583 |

| 24-inch | 126 | 126 | 22 | 0 |

| 18-inch | 160 | 160 | 160 | 160 |

| Tilting trailer for | 8,698 | 4,000 | 3,485 | 1,840 |

Source: OUSW Stat Br, Wkly Stat Rpt 25, Sec. 3, CE, 20 Dec 41. QM-Eng-Med Wkly Stat Rpt 25 (C).

[Continuation of table merged onto previous page]

Iceland, Alaska, Newfoundland, Greenland, and the Philippines, and for the 1st Division Task Force in the event of its involvement in combat. The Engineers put in for approximately $15,000,000 in the estimates for the third supplemental bill, but the attack on Pearl Harbor occurred before its passage. The Engineers were caught without a single crawler tractor or square foot of landing mat in reserve.51

Yet the Engineers had more than met the War Department’s objective, stated in October, of initial equipment for 1,418,000 men by the end of December. With $49,000,000 still unobligated, the Procurement Branch had let contracts for practically all engineer items, both essential and critical, for a force of 1,725,000 and by the end of November had received deliveries of 87 percent of this equipment.52

The status of forty-three key items was similarly encouraging. (Table 2) No contract had yet been let for timber saws or for 18x18-inch duplicating equipment. On the other hand, contracts for steel trestle bridges, ½-yard gasoline shovels, and special aviation equipment would eventually provide

for a 3,200,000-man Army. Deliveries of twenty-nine articles were either completed or on schedule. Twelve were behind: portable water purification units, both 3 and 5 KVA electric lighting equipment, magnifying mirror stereoscopes, motorized copying cameras, H-10 portable steel bridges, 25-ton ponton bridges, footbridges, truck mounted cranes, 60-inch searchlights, 24-inch beach defense searchlights, and tilting trailers. All activated antiaircraft regiments, however, had their allowances of 60-inch searchlights and new deliveries were for replacements and warehouse stocks. Production of searchlight trailers, delayed for months, was at last catching up—for the last week of November, for example, 700 were delivered against a monthly schedule of 580.53 The new Chief of Engineers, Maj. Gen. Eugene Reybold, summed up the procurement situation with satisfaction. “All existing troop units have been furnished practically all items of Engineer organizational equipment. In addition, small amounts for maintenance incident to training are stocked in depots.”54