Chapter 5: Launching Defense Construction

During the fall of 1940 work flowed into the Construction Division with unprecedented speed. Beginning shortly after Labor Day, the flood of directives reached its crest in October. On 11

September orders arrived for 9 large camps and one general hospital. Three mornings later the stack of mail on General Hartman’s desk contained authorizations for 8 additional camps and 2 lesser ground force projects. On the 19th, when 9 more camps, 7 miscellaneous housing projects, 2 airfields, and a munitions plant were added to the rapidly growing list, one of Patterson’s assistants informed him: “Work is now arriving and amounts to a total which was not reached until nine months after war was declared in 1917.”1 The total continued to climb. By late October Hartman had on file more than 300 emergency directives for jobs ranging in size from a single structure costing a few thousand dollars to a 75-million-dollar smokeless powder plant. With these directives came orders for the inevitable extras—service clubs, guest houses, infirmaries, dental clinics, officers’ quarters, induction buildings, chapels, painting, and paved roads.2 To get this program under way was Hartman’s first objective.

In ordinary times launching construction was a complicated process consuming months and sometimes years. Plans and specifications were prepared beforehand and in full detail. Estimates were figured with scrupulous exactitude. Sites were thoroughly surveyed, and layouts were drawn with care. Land was acquired by negotiation with the owners, which often meant much patient bargaining, or by condemnation, which might drag slowly through the courts. In neither case could building commence until the Attorney General had cleared the title; a law of 1841 forbade it. Another source of delay was the Bacon-Davis Act of 1931, which assured most laborers and mechanics working for government contractors wages not less than those prevailing on similar jobs in the locality. The task of determining the prevailing rates fell to the Secretary of Labor, who normally took from four to six weeks to complete the process.3 It was customary to make a separate “predetermination” for each contract. “Thus,” as Hartman’s adviser on labor relations, Leslie E. Brigham, explained, “if one building was to be constructed the whole process of determining wages ... was gone through with. Then, if two weeks later

street involving exactly the same trades, the process was again repeated.”4 Underlying much of the slowness with which most peacetime projects started was the law requiring competitive bids. Not until plans were firm, sites available, and minimum wage rates fixed could the machinery for advertised lettings go into motion.

With the emergency of 1940 “time is of the essence” became the watchword and speed became the “paramount consideration.” But, before it could rally to these slogans, the Construction Division first had to free itself from the shackles of peacetime procedures. This it attempted to do and with considerable success. The Act of July 2, 1940, the negotiation statute, cut through the tangle of competitive red tape. An understanding between Brigham and officials in the Labor Department put an end to duplicate predeterminations; wage rates were henceforth determined for a given locality and applied to all jobs undertaken there during a 90-day period. Legislation urged by Colonel Valliant and enacted on 9 October 1940 permitted construction to begin before property titles had been proved valid.5 Removing these procedural obstacles helped clear the way for action. Still there remained the task of starting a billion-dollar program almost overnight. The sudden surge of directives transformed the central office into a hive of frantic activity. “Nowhere in these high-pressure days is the heat any hotter and the pressure any greater in Washington than in the Construction Division of the Quartermaster Corps,” wrote columnist Jerry Kluttz early in October.6 To members of the Hartman team the description seemed apt. It was hectic, one man recalled. Another likened the division to a madhouse. The still relatively puny force was nearly snowed under with work. Mail arrived by the truckload. One small section of the Engineering Branch soon had a backlog of 1,100 unanswered letters. Calls swamped the switchboard. The halls teemed with visitors, as contractors, materialmen, equipment dealers, and a good many others beat a path to the men with a billion dollars to spend. Only by unremitting effort was the division able to keep abreast of it all.7

In the Munitions Building space was at a premium. With scores of new employees already at work and more arriving daily, the division had to utilize every available inch. Even storerooms served as offices, and some areas were so jam-packed that people had to climb over desks in order to move about. Hartman, who had been battling for larger quarters since spring, attributed these cramped conditions to “a total lack of appreciation by the Space Procurement Officer of the War Department and General Gregory of the office space needed.”8 Gregory was at length won over. “It seemed to me,” he later said, “that

one of the things we had to fight every minute was getting more office space. ... Finally, after much clamoring and so forth, we got what was known as the Railroad Retirement Building.”9 The division moved to its new quarters early in October. But even then, Hartman complained, “there was just about half the space required. ... This necessitated sending part of the personnel outside of the building with consequent loss in efficiency.”10

Despite many vicissitudes, the division’s morale was good. Everyone worked long and hard. The chief himself set the pace, taking time out only when he could keep awake no longer. Key officers stayed at their jobs until eleven o’clock seven nights a week, and, although the War Department had approved no overtime pay, civilians stayed, too. Most of the younger men took it in stride. One 34-year-old captain reported that the effort was no strain. But to men in their 50’s and 60’s these were arduous days. Jacobson, who was 52, wondered at times how long he could last, and Lamphere, at 59, allowed that he was not “so full of vinegar” as in 1917. If there was plenty of hard work, there was also plenty of jollity.11 Even from the front office, where events flowed fastest, came sounds of laughter now and then. There Major Nurse maintained a daily log. “General Hartman was aware of this diary,” Nurse related, “in fact, he encouraged me in keeping it up. When things got especially tough and he felt in the mood for a laugh (God knows he needed it on occasion), he would come to my desk and glance through my remarks and sketches which were often of a humorous sort.”12 Hard pressed though they were, Hartman and his crew generally displayed good humor, enthusiasm, and a will to do.

September found preparations well advanced and all the branch chiefs pushing their phases of the operation. The fixed-price end of the program was under Violante’s firm control. Bennett in Administrative, White in Repairs and Utilities, Koke in Auditing and Accounting, and Value in Liaison had their departments well in hand. Jacobson in Procurement and Expediting was ordering such varied items as kitchen equipment, laundry machinery, fire engines, furniture, and stoves. Jones in Legal was reviewing contracts and devising ways to get things done and still keep within the law. Bayer in Funds and Estimating was putting out a new manual for Constructing Quartermasters. The free lance, Major Thomas, worked at many jobs, establishing a system of progress reporting, trying to set up audit machinery, running the school for Constructing Quartermasters, breaking in new employees, and more. Yet in these critical weeks of getting started, the burden of responsibility fell with special weight on certain individuals and branches, on Lamphere and Engineering, Valliant and Real Estate, the Construction Advisory Committee, Loving as chief negotiator, and, most heavily, on General Hartman.

Policies and Policymakers

Undertaking the first mobilization program in more than twenty years, Hartman proceeded with the lessons of history in mind. As in World War I, military construction was to be largely a civilian endeavor. Heavy reliance was placed on industry. Rejecting the theory that the Army itself might do the work, using purchase and hire, Hartman turned to contractors and architect-engineers. He asked manufacturers of construction materials to double and treble their output. He appealed to workers in the building trades for cooperation. He designed the Army-industry team for getting work done fast. Nevertheless, he was keenly aware of his responsibility for protecting the public interest. It was, he emphasized, the duty of every construction officer “to see that all money is wisely and honestly expended.”13 Once again dollars would be traded for days but somewhat less freely than in 1917.

Under emergency conditions, cost-plus-a-fixed-fee was, as Dresser put it, “the only way.”14 The CPFF contract was not merely a timesaver; it could, if skillfully administered, save money as well. “I have always been convinced,” said Hartman, “that this form of contract is an economical one, provided that proper safeguards are thrown around the cost accounting of the project and also that strenuous efforts are made to keep politics and political appointees out of the picture.”15 His solution to the political problem was the Construction Advisory Committee, which would choose contractors without fear or favor and on the basis of merit alone. His auditing system confirmed the promise he had made to Congress in 1939, that all expenditures would be subject to absolute check and control. The new fixed-fee contracts promised reimbursement only for such “actual expenditures in the performance of the work as may be approved or ratified by the Contracting Officer,” and one of the chief duties of Constructing Quartermasters was to make certain that the government received full value for money paid out.16 Nor did the effort to marry speed and economy end there, for Hartman tried by every means he knew to get the most for every fixed-fee dollar.

CPFF contracts made possible substantial savings on bonds, insurance, and taxes—expenses lump-sum contractors passed on to the government in the price of their bids. Because the Construction Advisory Committee was selecting contractors of outstanding ability and unquestioned integrity, performance bonds were unnecessary; and, since fixed-fee contractors would receive no reimbursement for labor and materials until they turned in vouchers, the requirement for payment bonds was superfluous. At Hartman’s prompting, Congress excepted fixed-fee contracts from the law that made bonding mandatory. Since it was government policy to self-insure against fire, and since fixed-fee contractors were, in fact, agents of the War Department, fire insurance was nugatory. Additional savings were made

indirectly paid in taxes. Fixed-fee contractors were exempt from certain federal levies, including transportation, communications, and manufacturers’ excise taxes. Moreover, Hartman resisted collection of state and local taxes from these contractors, maintaining that the burden would fall on the United States. Of twenty-two states imposing sales, use, and similar taxes, eighteen granted full or partial exemptions, while four continued to exact payment.17 Although savings on these items amounted to a considerable sum, they were negligible compared with savings possible on materials and labor.

As the Army, the Navy, and other federal agencies got defense construction under way and private industry began expanding for war production, the demand for building materials rose rapidly. Scarcities developed, deliveries slowed, and prices started to climb. Hartman took steps to combat shortages and high costs. First, he tailored requirements to fit supplies. When the lumber industry revealed that it had on hand huge quantities of 10-foot joists—a short, nonstandard length which had been stockpiled as culls—he ordered structural blueprints altered to take the shorter studs. In the Engineering Branch, Lamphere made similar changes, adjusting specifications to productive capacity whenever possible. As a second step, appeals for help were broadcast to industry. The response was gratifying. The Southern Pine Association formed a special war committee to cooperate with the Army. The Lehigh Portland Cement Company placed its nationwide organization at the division’s disposal to assist with procurement. Meanwhile, Hartman was banking heavily on a third expedient, centralized purchasing, to help stabilize lumber prices and keep his projects supplied. Colonel Jacobson waited only for the necessary funds before swinging into action.18

Even more troubling than the materials outlook was the specter of the silk-shirted construction worker of World War I. Nothing, as far as national policy was concerned, prevented contractors from going into the labor market and bidding as high as they wished, for the administration made no attempt to control wages on a nationwide basis until after Pearl Harbor. A spiral seemed inevitable unless Hartman himself could control wages. Practical considerations compelled him to make the attempt. Slim construction budgets made no provisions for wage boosts. Furthermore, lump sum contractors, trying to keep within a prearranged price, would be deprived of workers if fixed-fee contractors “snowballed” wages. Hartman sought to prevent unnecessary increases by placing a ceiling on wages. What he did was to declare the minimum Bacon-Davis rates set by the Department of Labor to be

the maximum. Fixed-fee contractors who paid higher rates without his approval in writing would do so at their own expense. He thus retained the final, even if he did not possess the initial, say on wage rates.19

There remained the question of premium pay. Most agreements between contractors and the building trades unions called for time and a half or double time for work in excess of so many hours a week and on Saturdays, Sundays, and holidays. Labor had insisted on these provisions in order to shorten the work week, and contractors normally scheduled construction to avoid paying the almost prohibitive rates. In addition, unions sometimes demanded bonus rates and special concessions for shift work. With time the vital factor in defense, many of Hartman’s projects would be working six or seven days a week on multiple shifts. If labor costs were not to be excessive, he had to find a way to escape the usual heavy penalties. Major Jones pointed the way to a solution, by calling attention to the fact that the law required only one premium payment, time and a half for work in excess of eight hours in any one day. With this in mind, Brigham devised a plan he thought fair both to labor and the War Department.20 “We feel,” he explained to an official of the Carpenters’ Brotherhood, “that due to the emergency ... the men should be willing to work on a basis of forty hours a week and eight hours a day for any one man, and at least two shifts a day on straight time. This would permit staggering the crews so as to permit work every day of the week with two shifts and completing the job in time for the troops to move in.”21 Loving instructed his field officers whenever possible to schedule work to eliminate premiums.22

Only within certain limits was Hartman free to chart his course, for he had to comply with directives of The Quartermaster General, the Chief of Staff, and the Assistant Secretary of War and to respect the overall policies of the President. These men viewed construction from somewhat different angles. To General Gregory it was but one of several duties. In construction matters he usually followed the lead of his superiors. General Marshall’s supervision of the program was, with rare exceptions, exercised through Generals Moore and Reybold. As a rule, the General Staff considered construction from the user’s standpoint rather than from the builder’s. Judge Patterson, as business head of the War Department, looked upon construction as a most important trust. He was anxious to do his job honestly and well and to avoid any taint of scandal. Roosevelt approached construction questions in a spirit compounded of New Deal liberalism, political realism, and grave concern for national security. Alongside the regular authorities there arose in mid-1940 a new group—advisers, coordinators, and inspectors, agencies and individuals—who were to have great impact upon the building program.

Capt. Leslie R. Groves (photograph taken in 1939)

With the principal new defense agency, NDAC, General Hartman had two chief points of contact. One was the Office of the Coordinator of Defense Purchases, headed by Donald M. Nelson, executive vice president of Sears, Roebuck & Company. Named to this post on 27 June 1940, Nelson had the duties of preventing government bureaus from competing among themselves, advising the President on questions of priorities and allocations, and expediting procurement all along the line.23 Afterward General Hartman commented, “My relations with Mr. Nelson were always very cordial and he was very complimentary.” With Harrison, the member of the commission’s staff who was most immediately concerned with construction, Hartman also dealt easily at first. Recalling their association, he wrote, “With reference to Mr. Harrison, he was a very plausible individual. ... I was early informed in my relationship with him that he was Phi Beta Kappa and held an important job in New York City. Furthermore, he represented himself as being a man anxious to do a good job in the program without regard to personal matters.”24 Hartman’s secretary, Mrs. Mary B. Pagan, referring to this early period, said of Harrison, “He was in our office almost every day.”25 While the commissioners themselves seldom worked directly with the Construction Division, they nevertheless helped to guide it. In June, shortly after the President asked NDAC to review important purchases, Hillman began urging adoption of principles to govern the letting of contracts. It was to be some time before the commissioners agreed what their policies should be.26

July marked the entrance on the construction stage of a man who was to play an increasingly prominent role in the direction of the program. He was Maj. Leslie R. Groves, who became Gregory’s personal assistant for construction on the 22nd. A 1918 West Point graduate whose career included study at the Engineer School, the Command and General Staff School, and the Army War College; service with troops in the States, Hawaii, and Nicaragua; tours with the Galveston District, the Missouri River Division, the Chief’s office, and the War Department General Staff, Groves had a reputation as a doer, a driver, and a

Michael J. Madigan

stickler for duty. His new job, as he described it, “was to inspect in the field, spending not over a day at a camp, and seeing just what The Quartermaster General would have seen if he had been there.”27 The General Staff had advised Gregory to pick a good officer to check on the progress of construction. Gregory asked for Groves. The two men had been on familiar terms for many years—Groves was the son of an Army chaplain who had been Gregory’s close friend—and they had a great affection for each other. To the officers of the Construction Division the appointment came as a shock—a slap in the face, many of them called it. Most of them regarded Groves as an agent for the Engineers, despite the fact that such a role would have been completely out of keeping with his character. Aware of his delicate position, the new inspector tried to word his reports so that no feelings would be hurt. But the hostility against him was too strong.28 “It was felt at the time,” said Thomas, “that this officer’s reports were prejudiced and unreasonable and given with the intent to discredit the. ... Quartermaster Corps in order to help the Engineer Corps to take over the Construction Division.”29

As far as construction was concerned, one of the most influential figures to emerge during this period was Michael J. Madigan, who became Judge Patterson’s special assistant on 23 September. Able jurist that he was, Patterson understood the laws that governed federal construction. In Col. John W. N. Schulz, his Director of Purchases and Contracts, he had, moreover, a faithful exponent of the Army regulations. Nevertheless, both Patterson and Stimson felt the need for an adviser who knew the score in the public works contracting game, someone, as they laughingly put it, who could keep them out of jail. Such a one was Madigan. Senior partner of Madigan-Hyland, engineers of New York City, he was a man of humble beginnings, a onetime water boy, who had become a millionaire by 1940. Having been associated with Robert Moses in the Triborough Bridge Authority and other municipal projects in New York, he was politically astute. He had little formal schooling but was endowed with great native intelligence. He was also somewhat intuitive, playing

hunches that frequently proved to be happy. Brought to Patterson’s attention by William H. Draper of Dillon, Read & Company and by James V. Forrestal, who had recently become Under Secretary of the Navy, Madigan welcomed the appointment. He viewed it, he later said, as an opportunity to serve the country which had given him the chance to succeed. Before leaving for Washington, he told his partner that their firm would have to forego its share of military contracts.30

Madigan’s reception was, on the whole, a warm one. Patterson gave him carte blanche to act on construction matters; Harrison expressed the hope that they might work closely together; and General Moore hastened to offer a helping hand. Sociable and informal, the New Yorker made friends easily. Before long he was calling the old-line Regular, Colonel Schulz, by his nickname, “Pop.” Madigan’s operating method was in a class by itself. He formed no organization and hired no staff. He preferred to look around, talk to people, visit projects, and then retire to his hotel room to mull over his findings and emerge with a full-blown plan to give to Patterson. Thus began what he later termed “the happiest years of my life.” There was one discordant note. Madigan and Hartman did not hit it off. Discovering, as he quickly did, that the estimates were far too low, Madigan leaped to the wrong conclusion—that Hartman was responsible. He put the Chief of Construction down as “a nice old gentleman who was used to being bawled out by colonels’ wives” when their furnaces broke down.31 Hartman viewed the newcomer with misgivings. He wrote:–

My relationship with Mr. Madigan was always on a most guarded basis. I early sized him up as an opportunist who was on the lookout for a profitable contract for his firm in New York City. His name never came to my attention through the Construction Advisory Committee. However, I was certain after having been informed of his relation with General Somervell when that officer was on duty with WPA and relief organizations in New York City that Mr. Madigan was out to feather his own nest. ... Frankly, I did not trust him.32

Meantime, on 6 September, NDAC wrapped up its statement of contracting principles. While recognizing speed as the prime consideration in placing defense contracts, the commission emphasized that quality and price should also have due weight. Those making awards should take into account not only the contractor’s experience and ability but his character and financial standing as well. Keeping in mind effects on the economy and general welfare, they should also try to distribute contracts widely, to prevent congestion of transportation and utilities systems, and to safeguard consumers and labor. Where necessary to achieve defense goals, NDAC approved using negotiation. In a supplementary statement, the commissioners set forth their ideas on labor more specifically. Suggesting that the program might

serve “to reduce unemployment and otherwise strengthen the human fiber of our Nation,” they viewed site selection as a vehicle for social good. Moreover, they insisted on limiting working hours to forty a week until unemployment disappeared. If, in emergencies, projects worked more than forty hours or on Saturdays, Sundays, and holidays, overtime and premium rates would be obligatory. Discrimination because of “age, sex, race, or color” would be taboo, the commissioners declared. Finally, workmen’s health and safety would be a grave concern and adequate workers’ housing would be a must. Sent by the President to Congress with a message of indorsement on 13 September, the statement henceforth stood as administration policy.33

To Hartman the statement was a mixed blessing. By affirming the need for negotiated awards, the commission underpinned his position. In the wake of the President’s message, Patterson relaxed restrictions on CPFF agreements to permit their use “in all cases where the accomplishment of the national defense program may be expedited or aided thereby.”34 Furthermore, the commission’s criteria for selecting contractors were almost identical to some Hartman had adopted earlier as a guide for the Construction Advisory Committee. Nevertheless, from the construction standpoint, several of the labor principles were impractical. Even before the statement became public, Secretary Stimson had informed the President that shortages of skilled mechanics would force suspension of the 40-hour rule. Whether the policy on premium wage rates would be applicable to construction remained to be seen.35

As the election campaign gathered momentum, the President renewed the pledge he had given in May, that there would be no “cancellation of the great social gains” made under the New Deal. At dedication ceremonies for the Chickamauga Dam on Labor Day, he declared, “We understand now what we did not understand in 1917 and 1918—that the building up of the Army and Navy ... ought not to result in a waste of our natural resources and at the same time ought not to break down the gains of labor or the maintenance of a living wage.” That same day he told a gathering at the opening of the Great Smoky Mountains National Park: “We need not swap the gain of better living for the gain of better defense. I propose that we retain the one and gain the other.”36 This theme recurred in the speeches he delivered during the remaining weeks of the campaign.37 In vain did the War and Navy Departments argue against a policy promising “all things to all men—adequate national defense, full employment, higher living standards, the recovery of business, and the consolidation of labor’s New Deal gains, in short, both guns and butter.”38

At the same time that he refused to sacrifice the New Deal on the altar of national security, the President extolled the progress of defense preparations. Branding as false his opponent’s allegation “that the rearming of America is slow,” he declared, “We are going full speed ahead.” One of the few military programs then well started and, as such, one of the prime targets visible to the opposition, the Army’s construction effort came in for a share of Republican criticism and Democratic praise. GOP standard-bearer Wendell L. Willkie charged that new camps would not be ready when troops moved in, and on 30 October Roosevelt countered:–

I cannot help but feel that the most inexcusable, most unpatriotic misstatement of fact about our Army—a misstatement calculated to worry mothers of the Nation—is the brazen charge that the men called to training will not be properly housed.

The plain fact is that construction on Army housing is far ahead of schedule to meet all needs, and that by January fifth, next, there will be complete and adequate housing in this Nation for nine hundred and thirty thousand soldiers.

And so I feel that, very simply and very honestly, I can give assurance to the mothers and fathers of America that each and every one of their boys in training will be well housed. ...,39

It fell to the Construction Division to redeem the President’s promise.

A few days after the passage of the Selective Service Act, Representative Edward T. Taylor told Hartman, “Whatever you do, you will be criticized.”40 As time went on, Taylor’s prediction seemed increasingly likely to come true. Besieged by numerous and ofttimes conflicting demands, Hartman could not satisfy everyone. But he could and did forge ahead, providing plans, acquiring land, and placing construction quickly under contract.

Engineering

The work of converting appropriations into finished construction began in the Engineering Branch. To this, his largest unit, General Hartman gave the task of establishing the common yardsticks or standards of design that would govern almost every feature of the program—buildings, roads, runways, docks, power plants, trackage, drainage, water supply and sewerage systems, plumbing, lighting, heating, fire protection, installed equipment, and the like. It was Lamphere’s duty, as chief of Engineering, first to consider the War Department’s policies, the users’ requirements, the money allotted, the time allowed, the condition of materials markets, the availability of labor, and the cost of maintenance and, then, with these factors in mind, to develop blueprints, specifications, bills of materials, estimates, and layouts for projects of virtually every type. These plans would go to jobs throughout the country. Although Constructing Quartermasters would have considerable leeway in adapting standards to local conditions, Hartman insisted that fundamental changes be cleared with Washington. He thus preserved the system of centralized design most construction men thought proper.41

Frank E. Lamphere

The new Engineering Branch was built upon the solid foundation of the peacetime organization. Consisting during the late 1930s of a few carefully selected officers and some four hundred civilians, the division’s technical staff ranked among the best in Washington. During August 1940 Lamphere reorganized this force along the lines of Colonel Gunby’s World War I outfit. (Chart 4) The main work of design and engineering he assigned to six sections—Civil, Mechanical, and Sanitary Engineering, Mobilization Structures, Programing, and Estimating. To maintain close liaison with his clients, he appointed nine technical advisers: a hospital specialist to work with the Medical Corps, an industrial expert to work with Ordnance, and so on. To expedite the flow of vital information to the field, he named six engineering coordinators, each responsible for one or more corps areas or departments. A majority of the top posts went to division veterans. Maj. Elsmere J. Walters, a construction officer since 1918, became Lamphere’s executive. Like Walters, four of the principal civilians, Steinle, Leisenring, Drischler, and Anderson, had been on the job since World War I. Two others, Gramm and Engle, had between them a total of thirty-nine years with the Quartermaster Corps. Though younger than their colleagues, Captains Dreyer and Lyon, both West Point graduates with advanced degrees from leading schools of technology, were seasoned professionals. Most of the advisers and coordinators also came from the permanent roster, as did key assistants throughout the organization.42 But, although they lent great strength to the emergency effort, the experienced men were too few to cope with the avalanche of work that crashed in on them.

Beginning in July 1940, Lamphere staged a vigorous drive for recruits. Among the first to join up was Richard H. Tatlow III, a junior partner of Harrington and Cortelyou, who became deputy chief. “A very smart, young, peppy fellow,” Lamphere said of him. Another early arrival was Arthur L. Sherman, a distinguished sanitary engineer and veteran of the Construction Division of the Army, who agreed to help with the hiring of professional firms. The list grew longer. Frederick H. Warren, a young West Point graduate and former Engineer officer, became chief of coordinators. Fred S. Poorman,

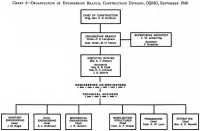

Chart 4: Organization of Engineering Branch. Construction Division, OQMG, September 1940

Source: Orgn Charts, Constr Div, OQMG, 1940, EHD Files.

an able highway engineer who had been with Lamphere on the Pennsylvania Turnpike project, took over the planning of transportation systems. Maj. Robert B. Field, who had retired in 1938 after more than twenty years as a construction officer, returned as Walters’ assistant. A Reservist who headed a nationwide building costs service, Maj. Everard H. Boeckh, came in as chief of the Estimating Section. And there were many, many more. In fact, some four hundred men responded to the call. Small wonder that Lamphere likened the growth of the Engineering Branch to an explosion.43

Just as private architects and engineers first consult their clients, so Lamphere started with War Department policies. Very early in the program, on 27 May 1940, General Marshall announced that G-4 would be the arbiter on construction matters. During the next few weeks, General Moore laid down principles to govern emergency work. Emphasizing the need for speed first, economy second, and serviceability last, he prescribed these rules: hold construction to the minimum; make maximum use of existing buildings; and erect no permanent structures where temporaries will suffice. At new stations hospitals would be temporary, but at old-line posts permanent barracks would serve as wards. Wherever possible, Regulars would double up to make room for Guardsmen and selectees. Additional housing would be of mobilization type, tent camps in the South and cantonments in the North. Both buildings and utilities would have a five-year life. Moore cut requirements to the bone. Family quarters, garages, swimming pools, painting, landscaping, and all such nonessential features were out for the duration—or so he said at the beginning. While recognizing that munitions plants, depots, and communications systems would have to be at least semi-permanent, Moore insisted that there be no embellishments.44 Describing to Congressman John Taber what the new Ordnance works would be like, General Wesson said on 25 July: “We will have simple but durable plants. We figure that this emergency is not here today and gone tomorrow, and that these facilities should be built on a basis that would make them available for the next twenty years.” Pointedly he added, “There are to be no high-fallutin’ gargoyles on these buildings.”45

Translating Moore’s broad policies into detailed plans and specifications was the Construction Division’s responsibility. Too vast and too complex for Lamphere’s group to tackle alone, the job was shared with private firms hired under negotiated contracts. Industrialists provided many of the basic designs for munitions plants. Nearly every project of any size, whether a plant, camp, airfield, or depot, had its own architect-engineer to fit standard plans and layouts to the site, design utilities and road nets, and supervise construction. Concerns specializing in particular fields of engineering occasionally acted as consultants. For example, two nationally known firms of sanitary engineers, Metcalf & Eddy of Boston and Greeley & Hansen

of Chicago, reviewed plans for sewerage and sewage disposal at fifty camps and airfields and advised architect-engineers how best to handle this important aspect of design. All this help notwithstanding, the Engineering Branch carried a heavy load, doing much of the planning itself and overseeing the rest.

When Lamphere took over in July, Major Walters was one jump ahead of the directives, which were starting to trickle in. Since March, when Hartman had begun his salvage operation, the mobilization drawings had come a long way. At the Fort Myer warehouse, a group of forty men, headed by Major Field, had redrawn most of the 700 series plans. Some technical difficulties had yet to be ironed out. One particularly thorny problem involved heating and steam distribution systems for mobilization hospitals, the largest of which would include some eighty buildings connected by 100-foot corridors. Paint shops in motor vehicle repair buildings posed another tough problem: the question here was how to minimize fire hazards in these large wooden structures. Serious complications sprang from the creation of the Armored Force, which needed wider roads and more water than older branches, and radically different layouts as well. By midsummer requests were coming in for extras—guest houses, service clubs, dental clinics, and field houses—which Moore had recently authorized or indicated he might authorize soon. Orders of this kind were comparatively easy to fill, since standard details could often be incorporated into the blueprints. A flock of orders for Air Corps structures—hangars, repair shops, parachute drying towers, bombsight storage buildings, and the like—were harder to execute, for they required much original design. Challenging though they sometimes were, these purely technical jobs were well within the staff’s capabilities. To the men in the crowded drafting rooms, the major stumbling block was the necessity of doing everything so fast.46 Meanwhile, their superiors grappled with problems of another sort.

During the fall of 1940, as it drew lessons from military operations abroad, the General Staff continually reorganized the Army. Construction suffered in the process. Looking back on the early months of defense preparations, Nurse reflected: “One of the principal delays in getting off to as early a start as we desired on cantonment construction was due to G-3 being unable to arrive at a definite table of organization. It was constantly being changed.”47 The size of the infantry company, the basic unit around which most of the camps were designed, was not firmly fixed until construction was under way. Original orders from G-4, issued in June, envisaged a company of 125 men, and Lamphere planned accordingly. He laid put cantonments in blocks consisting of two 63-man barracks plus a mess hall, a recreation building, and a supply room of appropriate size; he left space for a third barracks should the need for one arise. When, on 1 October, G-3 set the company’s war strength at 217, he had to redo the layouts to make room for a

fourth barracks and larger messing, recreation, and supply facilities. So late were decisions on the makeup of the new tank companies, and so scant the information as to what they would require, that he could complete no typical diagrams of armored division camps during 1940. These instances were by no means unique. October marked the publication of 35 new tables of organization and equipment; November, of 379; and December, of 30. Tables for units of thirteen types did not appear until January 1941.48

Once requirements were clear, planning of camps and cantonments proceeded fairly smoothly, for the Army was on familiar ground; the design of munitions plants was vastly more complicated. Structures had to accommodate complex processes and specialized machinery. Roads, railroads, utilities, shops, and laboratories had to be on a par with those at other large plants in heavy industry. Designs for storage magazines reflected the ever-present danger of explosion. Security against sabotage was always a consideration. Plans on hand at the beginning of the emergency were inadequate. On becoming assistant chief of the Industrial Service, Facilities, in June 1940, Lt. Col. Levin H. Campbell found that the Ordnance Department had very little in the way of factory layouts, equipment diagrams, and building specifications. The situation called into being a three-way partnership of using service, Quartermaster, and industry. The half dozen companies with experience in munitions manufacture served as design contractors. Engineers from other large industrial concerns, after a period of training at Army arsenals, also planned production units. Lamphere furnished blueprints for magazines, warehouses, shops, administration buildings, workers’ housing, transportation systems, and utilities. The using service and the Quartermaster Corps supervised the operation jointly. All plans were subject to review by the Construction Division, but, in order to expedite the work, Hartman told his field officers to start building first and get his O.K. later. Control by the using service was much more rigid. No plan could go to an Ordnance project until the Wilmington suboffice had approved it.49 “We are dealing with smokeless powder, with high explosives of all types,” Campbell explained. “We are all in fear and trembling” lest the plants “blow up on us due to poor workmanship or poor knowledge or lack of ‘know-how’.”50 Cumbrous though the system was, it produced results. By November Lamphere could start work on standard designs for industrial plants.51

Although they were then regarded as the least difficult, technically, of all defense projects, the new Air Corps installations produced many headaches. Under the regulations, General Arnold’s office could set functional requirements, make initial estimates, and recommend layouts. Actually, the airmen were

dabbling in design and had been for years. Col. Frank M. Kennedy, chief of Arnold’s Buildings and Grounds Division and himself a graduate engineer, insisted on furnishing plans to the Quartermaster Corps. The Construction Division tried to go along with Kennedy’s ideas but could not always do so. Some of his designs, according to Leisenring, had a safety factor of zero. Others, supposedly for temporary structures, incorporated many permanent features and carried estimates reflecting funds available rather than funds required: one drawing for an administration building came bearing a price tag of $13,260; Lamphere’s men figured the cost at $77,000. Referred to the General Staff, plans of this sort usually met a quick death at the hands of G-4. Efforts by the Air Corps to freeze specifications for runway pavements before service tests were run were blocked by Colonel Reybold. Although helpful at times, Kennedy’s incursions into design frequently cost the Engineering Branch a good deal of lost motion.52

Station hospitals proved to be a hornet’s nest. Part of the trouble stemmed from General Moore’s policy of using permanent barracks as wards, a policy adopted over General Hartman’s objections. Barracks, Hartman had pointed out, were seldom near permanent station hospitals, which housed laboratories, clinics, and operating rooms. Besides, conversion would cost far more than temporary construction. The Surgeon General, Maj. Gen. James C. Magee, also opposed the plan at first, but, pressed by Moore, he at length gave in. Announced on 7 June 1940, the policy drew immediate protests from the field. Nevertheless, G-4 held to the decision for nearly four months.53 Finally, on 20 September, Magee appealed to Moore’s successor in G-4, Colonel Reybold. Calling attention to “the patent impracticability of providing appropriate hospitalization in this way,” he asked that the policy be revoked.54 Reybold agreed, and on the 26th ordered the building of temporary hospitals at permanent Army posts. Much time and engineering effort had been wasted. Sudden jumps in requirements were a further vexation. As the troop distribution changed, many hospitals had to expand. One planned for Fort Custer grew from 350 to 750 beds; one for Fort Bragg, from 200 to 2,000. To make matters worse, in September the General Staff directed Hartman to redesign all hospitals so that they could later be enlarged by 20 percent.55

Difficulties notwithstanding, the Engineering Branch delivered the goods. By fall its catalogue of standard blueprints listed barracks for 25, 45, and 63

Mess Hall, 1,000-man capacity (700 series), Camp Grant, Illinois

men, mess halls with seating capacities of up to 1,000, hospitals ranging in size from 25 to 2,000 beds, dispensaries, guard houses, cold storage plants, fire stations, control towers, telephone exchanges, freight terminals, and numerous other structures. Specifications were available for everything from flagpoles to 500,000-gallon gasoline storage and distribution systems. Layouts for most types of ground and air stations were in the hands of Constructing Quartermasters. To be sure, a number of the plans left something to be desired. Thoroughness had necessarily been sacrificed to speed. In the rush to send drawings to the field, some details had gone unchecked. Lack of funds had occasionally dictated the choice of inferior materials; for example, the 55-pound roofing paper specified for the 700 series buildings was the lightest and cheapest on the market. There were, moreover, several gaps in the plans, one of the most notable being the absence of a layout for armored camps. But, by and large, planning was well and quickly done.

Once he had established engineering standards, Lamphere faced an exacting task in getting them accepted. Interest in the Quartermaster plans was widespread and intense. Producers and suppliers of building materials had a great deal at stake. According to the estimators’ rule of thumb, fifty cents of every construction dollar would go for materials. How orders totaling roughly half a billion would be apportioned among the materials industries depended on Quartermaster plans. The various construction trades would also be affected, carpenters benefiting if wood were specified, bricklayers, if masonry. Congress, too, was naturally attentive. In addition, a number of prominent persons were intent upon enhancing the beauty and amenities of the camps. Among them was Mrs. Roosevelt. All these groups

Hangar Construction, MacDill Field, Florida

watched developments closely. It was a rare engineering decision that failed to call forth comment from one or more of them.

Howls of protest greeted the announcement that the Army would build temporary frame housing. Manufacturers of excluded products promptly attacked the 700 series. The Clay Products Association of the Southwest warned against “spending Federal funds in a frenzy of excitement and haste, as was regrettably done during the World War,” in other words, against building camps of perishable wood, suggesting instead the “calm, wise, and business-like” procedure of “investing” in permanent buildings of brick and tile.56 Makers of concrete blocks, cement siding, structural steel, asbestos sheeting, and prefabricated buildings took up the cry for less restrictive designs. The bricklayers union demanded work for its members. Congressmen, at the urging of constituents, asked the War Department to reconsider. Advocates of sturdier construction appeared in some quarters of the Army. Lt. Gen. Hugh A. Drum of the Second Corps Area strongly recommended that more durable materials than wood be used in his command. Major Groves entered a plea for heavier roofing and higher grade screening. Dissatisfaction spread. Before long, Captain Dreyer was spending much of his time listening to people who visited Lamphere’s office to advocate changes in plans.57

As the program unfolded, suggestions multiplied. Senator Rufus C. Holman of

Oregon, protesting plans for a steel arch hangar, argued the advantages of timber trusses. Mrs. Roosevelt recommended that the streets of the camps be curved. Major Groves, after a visit to Fort Benning one hot summer day, when water consumption exceeded 180 gallons per man, wished to up water allowances and make provision for possible future increases in camp populations. Like many proposals Lamphere received, these were impractical. Because the new hangars were huge affairs, 275 feet across and 90 feet high, timber framing would cost much more than steel. Curved streets, however attractive, would be longer, and therefore more costly and less quickly traversed, than the straight, right-angled roads that had characterized military camps since Roman times.58 After studying Groves’ suggestion for more ample water supplies, Hartman reminded Gregory: “This office is constantly laboring under demand of higher authority to keep costs to a minimum. ... Though we invariably provide a quite liberal average to provide for any nominal increase, we could not well defend an expenditure of many thousands of dollars to provide a supply for an unanticipated increase of population.”59 Now and then a suggestion turned up that seemed worth trying. Manufacturers of steel siding and window sash who contended they could beat the price of competing wood products got a chance to prove it. But occasional changes of this kind did little to quiet the general uproar. In fact, lumber men raised a frightful clamor when steel men bid against them.60

To outsiders who challenged its building plans, the War Department presented a united front. Secretary Stimson answered advocates of permanent housing by explaining that camps had to be designed for economy and for speed of erection, and he gave two reasons why barracks of brick, tile, and concrete blocks were out of the question. First, durable materials would cost half again as much as wood; and, second, their use would add 10 to 15 percent to the time needed for construction. Judge Patterson told makers of prefabs that mobilization buildings would be cheaper to construct and to maintain than portables. Hartman offered additional reasons for rejecting durable materials and prefabs. Concrete would be too damp. Prefabs were not available in large quantities and would be difficult to transport. New plans and specifications would be necessary and it would take six weeks to prepare them. Refusals to make changes in the plans were softened by assurances that nearly every product would find a market in the program. General Gregory promised suppliers of brick, tile, and steel that their materials would be in brisk demand for depots, munitions plants, and Air Corps technical buildings.61 These arguments fell on deaf ears. The protests continued.

The commotion eventually caught the attention of NDAC. As a champion of the view that all should share the

benefits of the defense program, the commission could not ignore charges that the Army was excluding certain products. Concern lest orders be unduly concentrated led Harrison to hire one of the country’s leading architect-engineers, Holabird & Root of Chicago, to make a comprehensive review of the 700 series plans. On 18 September Holabird & Root submitted a report, praising the Quartermaster drawings but suggesting the possibility of alternate designs based on such materials as terra cotta, cinder blocks, concrete, and asbestos. They also recommended preserving the natural beauty of the sites. Major Nurse hastened to remind the field that typical layouts should follow contours of the land and that trees left standing would camouflage camps and improve their appearance. The commission had acted too late to effect further changes at jobs scheduled for completion in 1940 or early 1941. Time did not permit preparation of new designs for projects already under way. Hartman and Harrison agreed that, for the time being, construction had to proceed on the basis of existing plans.62

Painting interests benefited by the only major change made after 1 September. General Moore originally excluded paint from the cantonment plans in order to help reduce requests to Congress. His dictum provoked emphatic protests. Hartman advised Gregory that “temporary construction should be given protective painting as soon as erected in order to reduce maintenance costs.”63 Col. Stephen J. Chamberlin, chief of the Construction Section, G-4, held the same opinion.64 The Painting and Decorating Contractors of America and the Brotherhood of Painters, Decorators, and Paperhangers asked NDAC to intercede. In an appeal to Harrison, George S. Stuart of the contractors’ association maintained that no building was complete without paint. Paint, he wrote, made a building habitable, beautified it, made it sanitary, protected it from insects and termites, damp-proofed it, and, to some extent, rendered it resistant to fire. On a sentimental note, he added, “It will be a forlorn contrast for our boys to be brought from their painted and decorated homes and offices to Government buildings that are neither protected nor beautified with paint.”65 Harrison urged the Army to paint. And so did Mrs. Roosevelt. With no funds to pay for such a project, G-4 asked Hartman to see about painting the camps with WPA labor. But before the Army could take any action, the President intervened. On an inspection of Camp Meade, Maryland, he said he wanted the buildings painted. Assured of Roosevelt’s backing, the General Staff decided to let contractors do the job using skilled workmen. On 4 November Reybold instructed Hartman to include painting in all contracts for temporary buildings. This directive resulted in the largest order for exterior paint in the history of the paint industry,

945,062 gallons, and a deficit of $11 to $12 million for the Construction Division.66

The most serious challenge to Quartermaster designs came from within the War Department itself. In a situation where every day counted, Hartman had told Lamphere to complete standards quickly and rush them to the field. Such minor adjustments as were needed could be made locally. This arrangement, however expeditious, was unwelcome to the chiefs of the using services, and particularly to Arnold and Magee, who were reluctant to let their field representatives settle questions of layout and design. The Surgeon General forced the issue early in the program by insisting on numerous changes in standards for mobilization hospitals, plans his office had helped prepare and had once approved. Blueprints were ready for mailing to the field, when Lt. Col. John R. Hall, chief of the Surgeon’s Hospital Construction and Repair Division, demanded more toilets, storerooms, and offices. These changes took several weeks. Hall next served notice that he would furnish a layout for each station hospital. Since no two of his layouts proved to be alike, the Engineering Branch had the troublesome job of custom-designing heating systems. The Air Corps’ Colonel Kennedy followed Hall’s example. As delays developed (the Camp Custer hospital waited a month for plans from Washington), and as confusion mounted (the Orlando Air Base hospital went through three redesigns), Hartman appealed to G-4. The result was a “freeze order.” Declaring most changes unnecessary, the General Staff on 22 August decreed no further revision of the standards without G-4 approval. Typical plans and layouts were to go, without further ado, to be adapted in the field.67

Heavy responsibilities devolved on Constructing Quartermasters. Superintending development of detailed layouts, reviewing work of architect-engineers, and helping to plan utilities systems and design footings for typical structures were but some of their technical duties. Hartman directed his field officers to use initiative. When, in their judgment, changes in the standards would speed completion, save money, or improve the finished product, they were to act promptly, forwarding revised plans to Washington as soon as possible. At the same time, Hartman expected Constructing Quartermasters to resist local pressures for changes that might slow progress, increase costs, or lower construction quality. He reminded them that they were answerable only to him.68 Seasoned construction officers—Regulars like Colonel Thomas, who left Washington in September to head the Ogden and Vicinity office in Utah, Lt. Col. Lawrence L. Simpson, the veteran CQM at Fort Bragg, and Capt. Carl M. Sciple, the West Point careerist at Springfield Armory—understood their

assignment and knew how to carry it out. Inexperienced project officers had to learn by doing.

Real Estate

Recalling the role of the Real Estate Branch in the defense build-up, Colonel Valliant said, “No one could move until we got the land for them.”69 The size of the job was unprecedented. On 30 June 1940 the War Department owned about two million acres of land, the accumulation of a century and a half of gradual expansion. Needed at once were eight million more—fourteen times the area acquired in World War I. New Ordnance and Chemical Warfare plants required 263,000 acres; camps, firing ranges, hospitals, and depots, over two and one-half million; airfields and bombing ranges, five and one-third million. At scores of locations in some forty-two states the Army reached out for land.70 The Real Estate Branch was under enormous pressure for speed. Colonel Burns, concerned primarily with industrial preparedness, warned Valliant, “If you delay this munitions program, you will be crucified for it”;71 and Colonel Chamberlin, speaking for the General Staff, told him “that no matter how fast he worked, it would not be fast enough.”72

In the late spring of 1940 Colonel Valliant made plans for expediting a large-scale effort. His first big problem was personnel. Mirroring its peacetime mission, the Real Estate Branch numbered only two officers and seventeen civilians. The executive, Capt. Clinton J. Harrold, had ably assisted Valliant in the 200,000-acre program of 1939. Acquisition expert William F. Turton and leasing chief Edward T. Lindner, both veterans of the World War I Real Estate Service, directed experienced staffs. But a mere handful of specialists could not cope with the huge task ahead. In 1918 the Real Estate Service had needed 150 persons for a program far smaller than the one now contemplated. On 10 June 1940 Valliant explained to Colonel Chamberlin how he proposed to muster an adequate force. He envisioned a nationwide network of agents. Although the chief of Real Estate was the only man who could bind the War Department on land transactions, corps area quartermasters had for many years assisted in arranging leases and disposing of surplus property. Their duties would now include some purchasing negotiations. CQMs would also serve as agents. Meanwhile, Valliant planned to expand the Real Estate Branch as rapidly as he could. Men from the central office would handle the most complicated jobs. All agents would report directly to Washington, where Valliant and his top assistants would stand ready to speed to any site where trouble threatened.73

After two decades of meager budgets, the Real Estate Branch was suddenly glutted with funds. Within a 4-month period, Valliant received some $52,600,000 for land acquisition. During June

1940 Congress voted $8,239,824 for ground and air reservations. In July Ordnance turned over nearly $28,000,000 for plant sites. With passage of the National Guard and Selective Service Acts in August and September, $16,374,885 became available for land.74 Valliant found himself with an embarrassment of riches. “They just dumped the money in my lap,” he said later, “and I couldn’t get rid of it all immediately.”75 But impressive though the totals were, they gave little indication of program size, for most of the new acreage cost the army practically nothing.

More than 6 million acres, over three-quarters of all the land required, came from the public domain. Four bombing and gunnery ranges staked out on federal land were the largest in area of all defense projects: Choctawatchee in Florida covered 380,000 acres; Mojave Desert in California, 640,000; Wendover in Utah, 1.5 million; and Tonopah in Nevada, 3.5 million. Smaller but still quite extensive, 60,000 to 90,000 acres each, were several camp sites carved from national forests. Transfer of these public lands to the War Department lightened the burden on the Real Estate Branch appreciably. Purchasing such vast tracts would almost certainly have meant uprooting entire communities and dealing with hundreds of owners. As it was, the custodians, in most cases the Interior and Agriculture Departments, readily agreed to release the lands, insisting only that the Army minimize damage to improvements and take precautions against forest fires. The Quartermaster Corps had merely to arrange details of transfer and to settle mineral and grazing rights.76

Valliant leased four hundred thousand acres, mainly for maneuver areas, training grounds, landing fields, and temporary additions to existing posts. One National Guard camp, Bowie, was on a 90,000-acre site rented from the city of Brownwood, Texas, for one dollar per acre annually; and Camp Roberts, a replacement training center, occupied the 37,000-acre Nacimiento Ranch near Paso Robles, California, leased from its owners for $125,000 a year. These were exceptional cases. Most of the leaseholds were smaller—25,000 acres or less; and half of them contained fewer than 1,000 acres apiece. From Valliant’s viewpoint, leasing offered marked advantages. First, lessors were, on the whole, a willing group. Only once did he have to condemn in order to lease. Second, for a short-term program, it was more economical to lease than to buy. Rents paid during 1940 ranged from 7 to 15 percent of appraised values. Third, leasing avoided conflicts with local authorities over removal of properties from tax rolls. Fourth, it eliminated the problem of eventually disposing of surplus land. Finally, corps area quartermasters could do much of the work.77

But leasing was often impossible. During World War I Ordnance had built a number of plants on leased land. Subsequent forced sales of these valuable structures at junk prices had caused the

Comptroller General to prohibit permanent improvements on privately owned land. Because of this prohibition and because many desirable sites were available only through purchase, Valliant had to buy more than one and one-third million acres.78

Two courses were open to him: negotiate with the owners or take the land by condemnation. While the power to condemn was a potent weapon, he preferred not to use it. A hate-provoking action, condemnation was often also slow and costly. When the government filed a declaration of taking, the normal procedure in such cases, it turned control over to the court. Although title vested in the United States as soon as a declaration was filed and the amount of estimated compensation was deposited with the court, it was the judge who decided when the government could take possession. Under the Imminence of War Statute enacted during World War I, the government might in an emergency take possession immediately upon filing a petition in condemnation and giving a perimeter description of the land; but title did not pass to the United States until final settlement. Where dockets were crowded and other important cases were awaiting trial, condemnation hearings were frequently postponed. Moreover, in finding fair values, local juries tended to favor their neighbors’ claims; as recently as the spring of 1940, a Massachusetts jury had awarded $1,000,000 for land appraised at $300,000. Court charges and interest due owners added to the expense of condemnation. Hence, Valliant sought to reach voluntary agreements whenever titles were clear.79 By accepting the idea that the government would “pay somewhat more than the going price ... in view of the fact that the owners will be immediately dispossessed and, therefore, put to great inconvenience,” he avoided mass condemnations at all but a few sites.80

Whether he bargained with owners or took them to court, Valliant needed large numbers of surveyors, appraisers, and attorneys to assist him. Efforts to recruit such men were, for the most part, unavailing. The Civil Service Commission was unable to furnish lists of eligibles, and federal salary scales were too low to attract many real estate experts. By 1 November only nine civilians had joined the Washington staff, and several of them were clerks. Locating officers with real estate experience was even harder. During 1940 Valliant found but one, a Reservist who had worked for the Interstate Commerce Commission. Corps area and Constructing Quartermasters experienced similar difficulties. Valliant had to look elsewhere for help. The Soil Conservation and Forest Services, the Farm Credit Administration, the Home Owners’ Loan Corporation, and other federal agencies agreed to furnish personnel. Attorneys from the Department of Justice conducted many closings of direct purchase cases. These assistants rendered valuable service, but some of them were too accustomed to

the leisurely pace of peacetime activities to act with the speed demanded.81

Valliant turned in his predicament to private brokers. The Atlas Powder Company, operator For the shell-loading plant at Ravenna, Ohio, helped point the way. Early in August 1940, with the Ordnance Department’s approval, Atlas engaged the Bankers Guarantee Title & Trust Company of Akron to buy the Ravenna site. A 5-percent commission on the gross sale price was payable by the vendors. Later that month, after running into difficulties, Atlas assigned the Bankers Company contract to Colonel Valliant. Under his direction, the Akron firm produced quick results. Seeing in the brokerage arrangement a possible means of relieving his overburdened staff, Valliant consulted Turton, who advised him that a similar expedient had worked in World War I. During the next three months, with the help of Ordnance, NDAC, the Baltimore and Ohio Railroad, and local chambers of commerce, Valliant chose brokers for eight of his most urgent jobs—six Ordnance projects and two camps—involving a total of 1,692 tracts and 151,274 acres. He offered the brokers substantially the same terms Atlas had given the Akron concern: seven would receive commissions of 5 percent; the eighth, who undertook an unusually large and complicated job at Jefferson Proving Ground, Indiana, would get 6.5 percent. By hiring brokers Valliant obtained much-needed expert assistance. If his agreements with them resembled cost-plus-a-percentage contracts, recently prohibited by Congress, he was unaware of it.82

Knowing that advance publicity would encourage speculation and send real estate prices soaring, Valliant proceeded cautiously. Until his agents could enter an area, take a number of options, and stabilize land values, he fought shy of politicians and reporters. He did his traveling by day coach to lessen the chance of anyone’s learning who he was or where he was going. Hartman, Patterson, and Reybold helped throw a cloak of secrecy around new locations. Nevertheless, leaks occurred. One Ohio congressman announced the coming of the Ravenna plant at a public meeting. A series of untimely rumors was traceable to Chester Davis in NDAC. Local officials and business leaders in whom site boards had confided also passed the word along. During August and September 1940, leaks cost the Army an estimated $500,000. While Hartman and Valliant demanded greater secrecy, Stimson, in response to outside pressure, chose a very different course. Early in October he announced that sites would be made public at the time of their selection.83

News of the Army’s coming provoked intense excitement. Eight-column banner

headlines on page one of the Joliet Herald-News hailed the decision to locate two plants, Kankakee and Elwood, in northeastern Illinois. According to the paper, a boom was on the way. Farmers would be well paid for their land. Jobs would be plentiful and wages high. Within six months to a year, the Herald-News prophesied, the population of Will County would increase from 114,000 to 154,000, and 8,000 new homes would go up in Joliet alone. In community after community, optimism ran high. People on relief were jubilant at the prospect of working again. Chambers of commerce looked forward to a period of prosperity. But though many hoped to gain by the presence of military installations, other expected to lose. Taking thousands of cultivated acres would produce a major upheaval. In the rich agricultural areas of Ohio, Indiana, Illinois, and Missouri, 4,000 farm families would be uprooted. Whole villages faced extinction as the Army threatened to take the land on which they stood. Foreseeing much hardship, these people refused to give in without a fight.84

While townsfolk rejoiced at their good fortune, the countryside was in a ferment. Farmers held mass meetings, drafted petitions, and sought injunctions. Delegations went to Washington. Men wired their congressmen, and women wrote to Mrs. Roosevelt. The protests evoked a pathetic picture.85 “Some four hundred farm people will be thrown out in Iowa winter weather,” read one appeal to Vice President-elect Henry A. Wallace. “Stock, machinery, and household goods will have to be sacrificed. We are heart broken and desperate. Can’t you help us?”86 “Tragic, if not stunning,” an Illinois group described the blow.87 Many urged the Army to take waste lands instead of cultivated acreage. But the War Department argued military necessity. In answer to a plea that he spare an old homestead, Patterson wrote: “I agree with you that it is hardly a pleasant thing to give up a home that one’s family has occupied for nearly eighty years, but it is hardly a pleasant thing to have to build an ammunition plant. Ours, unfortunately, is a world in which such things are necessary.”88

At the first signs of unrest, Colonel Valliant hastened to the scene. Talking to the owners, he was understanding but firm. While he sympathized with the farmers and expressed sincere concern for them, he made it clear that individual interests must give way to the national interest.89 Complimenting the Real Estate chief on a speech to an angry gathering at Wilmington, Illinois, a judge of the State Court of Appeals said, “You handled it beautifully and left those

Site of Plum Brook Ordnance Works, Ohio

farmers in a much better frame of mind when they left the meeting than when they came.”90 Valliant made no extravagant promises, but with natural humanity, he frequently succeeded in calming the farmers down.

What proved more difficult was bringing them to terms. Arriving at the Army’s newly selected sites, Quartermaster agents were met by demands for high prices. Some claims, though large, were reasonable. Many sites, particularly those for munitions projects, included prize agricultural land. Indeed, the features that made for good industrial tracts—firm, level ground, ample water, and nearness to roads and railroads—also made for profitable farms. But many asking prices were clearly out of line; some were as much as thirty times appraised values. Perhaps the greatest stimulus to high prices was the Army’s insistence on immediate possession. One attorney reported sharp advances when farmers began “to realize the enormity of the task” of moving within thirty days.91 Rumors that speed was all-important and price was no object caused many owners to expect much more than they had ever before dreamed their properties were worth. Scalpers made a bad situation worse. Lashing out against the activities of “land option sharks,” a Quartermaster spokesman said, “When the owner whose land we take over attempts to move into the adjoining area, he finds the prices there have been skyrocketed and he is unable

to buy at a fair price.”92 At several places Valliant cut costs by redrawing site boundaries to avoid payment of severance damages and exclude expensive buildings and commercial properties. Generally, he told his agents to try to satisfy the owners but to remember that Uncle Sam was not Santa Claus.93

Reviewing options taken in the field, Valliant and Turton noted a startling development. Not only were valuations high, but sums had frequently been added to cover “disturbance damages.” A father was to get $2,000 for training his blind daughter to find her way around a new farm. A congregation was to receive $1,000 for the trouble of relocating its church; the preacher, $695 for lost salary. A dairyman had been promised extra compensation for driving his cows a few miles down the road—he said it disturbed their milk production. Though some claims were farfetched, others stemmed from genuine hardship.94 “In almost every instance,” one agent wrote, “we are purchasing somebody’s home, which means disruption of their family life, moving immediately from the premises, disposing of large quantities of livestock, farm machinery, feed, and other property, storing of household goods, renting of new quarters for living, etc. All of these inconveniences are considered by us.”95 Whether losses were real or fancied, there was no legal basis for such claims. The government was obliged to pay fair market value, no less and no more.

The source of the trouble was soon clear. Valliant learned that NDAC had asked the Attorney General for a ruling in favor of disturbance damages and had been refused. Correspondence on the subject between Chester Davis and professors at the University of Illinois came to light. Reports from the field told a fuller story. From agents in Ohio, Indiana, Illinois, Missouri, and Iowa came word that Davis’ top assistants, Arthur C. Ringland and John B. Hutson, had been out talking to the farmers. Lists of disturbance factors, compiled by NDAC, were passing from hand to hand. Indorsed by the Advisory Commission were claims for the following: rent for family quarters until new farms could be found; storage for equipment; housing for livestock; decreased milk production while herds adjusted to new surroundings; unused pasturage; unrealized benefits from fertilizing, plowing, and seeding; value of labor expended in moving; and losses of various types, including those sustained in forced sales of animals and machinery. Representatives of the Farm Bureau, the CIO Farmers Union, and the Farm Security Administration supported these demands. At some projects, agents refused to countenance disturbance damages, but at others, pressure was so extreme that they allowed such claims. Inclusion of disturbance items was increasing option prices as much as 40 percent.96

Valliant took what steps he could to force prices down. He returned options containing disturbance items, unsigned. Valuations up to $90 an acre he usually let go unchallenged, since time did not permit careful investigation of every parcel; but he checked larger claims against assessments. He used various means to bring the owners around. His agents tried persuasion and take-it-or-leave-it offers. His policy was to “give the farmers a break,” and whenever possible to let them graze cattle, cut timber, harvest crops, and salvage improvements after the government took possession. Nevertheless, some owners remained obdurate. At fourteen projects Valliant condemned all or part of the site. Among the larger tracts taken in this way were 1,678 acres for the Utah General Depot, 2,080 acres for the Denver Ordnance Plant, 16,246 acres for the Fort Dix target range, and 31,600 acres for expansion of Fort Jackson. A tense situation at the Ordnance project near Burlington, Iowa, received more delicate handling. Options on this site, taken by A. J. Cockrell, a local realtor working under a brokerage arrangement, showed an overall cost of $4 million, double the amount originally estimated. Farmers in the area, having just lost a furious fight to keep the Army out, were in an ugly mood. Warned that riots might occur if the government condemned, Valliant hired John J. Wagner of Cedar Rapids to make an independent appraisal.97 From Burlington, Wagner reported “that even a slight hint that our conclusions might be less than option prices would be ... dangerous.” He nevertheless agreed to see the job through. In reappraising the site, Wagner set prices at “the highest level of value which ... could, in any circumstances, be justified.”98 But Valliant feared that these prices would be unacceptable and established new ones averaging 18.5 percent above Wagner’s appraisals. Cockrell was able to renegotiate his options on this new basis, thereby cutting $650,000 to $700,000 from the cost of acquisition and possibly preventing unfortunate incidents.99

Disappointed and worried farmers took their troubles to NDAC’s Agricultural Division, bombarding Davis with complaints. Visits from delegations, longdistance calls, and numerous letters impelled the veteran farm leader to investigate. Since many of the early protests were from the Kankakee-Elwood area, he began there.100 By 17 October his assistant, Ringland, had completed a report. Criticizing Raymond E. Herman, the Chicago broker in charge of acquisition, Ringland wrote: “A number have complained that they were informed in a ruthless manner, ‘You might as well stop that plowing because the Government is going to take possession in thirty days.’ This caused a great deal of emotional distress and misunderstandings that still exist.” He went on to deplore Valliant’s use of city men and Herman’s dealings with tenants. Calling the tenant

“the forgotten man,” he explained:–

In all cases the broker has been dealing only with the owner, informing him that the tenant must look to the owner for the settlement of his rights. In the purchase price, however, it has been the general practice to be generous and to include ... an additional amount to compensate the tenant. But this leaves it to the owner to decide how much he will pass on to the tenant, and in some cases compensation for the tenant has been forgotten completely or is quite inadequate. ... Some tenants, knowing their rights, are ready to file suit to recover adequate damages from the owner. Such action would cloud the title and make for delay in the settlement of the project.

Ringland concluded by recommending, one, that the Army safeguard tenants’ interests, two, that it recognize disturbance factors, and, three, that federal appraisers replace private realtors.101

The first point was quickly settled. On 18 October Ringland, Hutson, and Turton agreed to a procedure that would protect the tenants. Before taking an option, Quartermaster agents would insist that owner and tenant come to an agreement. The tenant would be paid his share directly, not through the owner as before. But there was no accord on points two and three. On 23 October and again on the 25th, Davis brought these questions before the Advisory Commission. With his colleagues’ approval, he called a conference of representatives from various federal land agencies and laid his case before them. Upholding Davis’ views, the conferees advised the War Department in effect: dismiss the brokers, turn the projects over to us, and thus ensure that owners and tenants will receive sympathetic treatment and that purchase prices will include disturbance damages.102 On 5 November Patterson issued a statement. The Quartermaster General would try “to secure the good will of the community to the maximum extent possible, consistent with fair prices and the availability of the land at the time and in the location needed,” and “to cause the least hardship and inconvenience.” Patterson made no mention of brokers or disturbance damages. In fact, he did little more than set the War Department’s seal on Colonel Valliant’s policies.103