Chapter 18: Cutback and Continuation

From its peak in 1942, construction activity declined rapidly. As emphasis shifted from facilities to production, and as the spotlight swung from home front preparations to combat in war theaters, construction workers moved on to factories and fighting fronts, construction officers moved overseas, and contractors turned to such unfamiliar tasks as maintaining railroads, manufacturing landing mats, fabricating ship steel, and logging. Cranes and bulldozers went to troops and to lend-lease; vast quantities of lumber went for crates and boxes; and steel went into vessels, tanks, and guns. To be sure, construction continued until V-J Day and beyond, but in greatly decreased volume. The first major program to be undertaken in World War II, construction was also the first to be curtailed.

Curtailment

The resources of the United States, however vast, were not unlimited. The energies of her people, great though they might be, were not inexhaustible. During 1942 the nation spent nearly $17.8 billion for construction, maintenance, and improvements. This total accounted for approximately 11 percent of the gross national product.1 Was all this construction requisite for victory? Could the economy stand the strain? How could the effort be reduced and where? These questions, looming ever larger in the months following Pearl Harbor, were among the most vexed issues of the war. As procurement goals soared skyward in the early months of 1942, production authorities grew apprehensive. To continue recklessly heaping requirements on top of one another would invite disaster. Action was imperative to hold things within bounds. There was general agreement that construction offered an important source of savings in manpower and materials, but opinions differed sharply as to just where these savings should be made. Generals and admirals insisted that war-related projects get sole consideration and that other projects be lopped off. Illustrative of their attitude was a suggestion for a moratorium on school construction: would it not be better, the argument ran, to defer children’s education than to lengthen the war?2 WPB Chairman Donald Nelson expressed a different view, when he wrote:–

If they got complete authority over the disposition of the nation’s resources they would inevitably produce disorder, and eventually balk their own efforts by undercutting the economy in such a way that it could not meet their demands. Nor is this the whole story. In their drive to give military

requirements the precedence over all others they would be bound to take actions which would have serious effects on our democratic institutions.3

At the forefront of the drive to halt civilian projects was the Corps of Engineers. Hard pressed to meet military requirements, construction officers deplored the draining away of resources by “nonessential” jobs. Stating the Corps position, Colonel Groves declared: “The program as a whole is just too big for accomplishment. ... It is too big because of four things lacking, labor, materials, equipment, and management.” Projects having little or nothing to do with the war—“everything that every community wanted that they could tie into the war effort by any stretch of the imagination”—continued to proliferate. Road building was going strong; a $1.1-billion public highway program was taking more than 350,000 tons of steel at a time when the Engineers were economizing on steel “to the point where it hurts and hurts and hurts.” Another cause for concern was the growing demand for civilian war housing; if the trend continued, more than 500,000 family units and 600,000 dormitory accommodations would ultimately be provided. Many programs undertaken in the name of “civilian health and safety” should, in Groves’ opinion, be either cut down or cut out. He appealed for “greater effort ... to eliminate all work not indispensable to the war.” Meanwhile, General Robins went on record: “We do not mind doing what we have to do. We do not ask for heaven but just a little lessening of the burden.”4

From the Engineer viewpoint, efforts to ease the burden were too feeble and too late. The War Production Board, like its predecessor agencies, seemed unable or unwilling to choke off nonessential work. Priorities control was largely ineffective; jobs somehow managed to struggle along with little or no priority assistance. Not until March 1942 did production authorities try a fresh approach. On the 17th WPB Chairman Nelson decreed: “No new construction, except strictly military construction projects, shall be undertaken unless approved by the War Production Board as essential to the war effort or to public health or safety.”5 Accordingly, on 9 April, he issued a limitation order setting cost ceilings on jobs which could be started without WPB permission: $500 for residential projects; $1,000 for agricultural; and $5,000 for recreational, institutional, and industrial. He placed no restrictions on work for mining and oil producing industries. As materials became increasingly scarce, WPB lowered the ceilings for various classes of work.6 As a result of the limitation order, civilian construction declined steeply but, the Engineers believed, not steeply enough.

When the order came out, moves were under way to trim fat from war requirements. On 13 March Col. Joseph L. Philips and Cmdr. Horatio G. Sickel, joint heads of the ANMB Priorities Division, issued a call for action. Huge facilities programs were being launched “without sufficient thought as to the consequences,” they told the board’s

executive committee; and they warned that resources might not stretch to meet military demands for both new capacity and finished goods.7 Four days later Nelson received a similar warning. In a detailed analysis of the munitions and construction program, two of his assistants, Robert R. Nathan and Stacy May, set forth some sobering statistics. Outlays of $40 billion in 1942 and $60 billion in 1943 would be in line with the production goals set by the President in January 1942. Recently, however, the armed forces and others had raised requirements to $62 billion in 1942 and $110 billion in 1943. These new objectives seemed “wholly impossible.” Unless shooting for the stars gave way to realistic planning, the day would come when plants would suspend production for lack of raw materials and equipment would stand idle for want of parts. One area where cuts could and should be made was war construction. Echoing the concern of Philips and Sickel, Nathan and May urged their chief to act promptly.8

Responding to the danger signals flashed by his assistants, Nelson arranged for members of his staff to confer with Army and Navy representatives. A meeting held on 10 April 1942 resulted in the choice of Nathan, Philips, and Sickel as an informal committee to study ways of scaling down the program. Although the three men were in general agreement, their findings were not unanimous. In a majority report on 6 May, Nathan and Sickel recommended appointment of a powerful five-man board (with one Army, one Navy, and three WPB members) to screen construction projects and pass upon all plans and specifications. Until the board was functioning, they wanted a moratorium on most new construction. Allegedly on orders from the War Department, Colonel Philips filed a dissenting report in which he objected to any moratorium on war-related projects and to any review by outsiders of military plans and decisions.9

When Nelson approved the majority report, Patterson refused to go along. In a sharply worded protest to the WPB Chairman, the Under Secretary warned that the proposed board “could well be an important contributory cause for losing the war.” Calling the whole idea “inadmissible,” he contended: “If the War Production Board is to select items of equipment, it, in effect, governs the entire strategy of the war. Such a conception is little short of fantastic.” Patterson declined to submit engineering data for approval by WPB. “Only a moment’s reflection,” he wrote, “is required to understand that a month’s delay would be necessary to secure approval of plans and specifications for a job in the western part of the United States.” He further declined to appoint an Army board member. “The War Department,” he stated, “does not possess such a superman, as referred to in the report, who could be familiar with architecture and engineering, shop

production, raw materials, and other matters which would be necessary for him to make an intelligent decision.”10 Confronted with Patterson’s opposition, Nelson backed down.

In lieu of the board proposed by Nathan and Sickel, he created the Committee on Facilities and Construction, under the chairmanship of William H. Harrison, his director of production. To serve with Harrison, he named Rear Adm. Howard L. Vickery of the Maritime Commission; Admiral Moreell, together with two civilian Navy officials; and, for the Army, Generals Knudsen, Campbell, and Echols and Mr. Madigan.11 The committee’s task, as Patterson understood it, was “to review the present facilities program and to devise a workable scheme for passing on new facilities.”12 In his instructions to Harrison, Nelson cited a recent letter from the President, restating his January goals. “Other facilities necessary in our war effort,” Roosevelt had written, “but not essential to this program must be deferred until their construction can be undertaken without detriment to the program.”13 According to Nelson’s interpretation, the President’s meaning was “that no projects be undertaken which do not clearly contribute to the production of finished munitions by the middle of 1943.”14 How the preponderantly military Harrison committee would approach the problem was soon apparent.

On 20 May 1942, 9 days after the committee’s formation, Chairman Harrison unveiled the “Directive for Wartime Construction,” a policy statement afterward described as “one of the most important ... issued during the war.”15 Written by Harrison, and signed by Stimson, Knox, and Nelson, the directive laid down principles which would henceforth govern all construction coming under the Army, the Navy, and WPB. No project was to start unless one of these agencies certified that it was urgently necessary to the war effort. Even then the sponsor would have to show that he had made every possible economy in design and that sufficient labor, materials, equipment, power, transportation, and housing were available. Enforcement was left to the agencies themselves.16 Presenting the directive to General Reybold, Madigan emphasized “how fast we operate” and “what kind of service we can give the Corps of Engineers.”17 The speed was impressive and the service, beneficial. By the fall of 1942, Colonel Hardin could report that the directive had “done great things in providing the materials ... to carry on our necessary work, kept the program down, ... expedited construction, conserved materials, and reduced costs.”18

During the summer of 1942, under the guidance of the Harrison committee, the armed services restudied their

facilities and construction needs. The Army lowered its objectives considerably, deleting dozens of lines from the Ordnance plant construction program, suspending virtually all work on seacoast defenses, eliminating most family units from the civilian war housing program, and curtailing private plant expansions sponsored by the War Department. In addition, the Chief of Engineers deferred river and harbor improvements estimated to cost more than $50 million. All told, the War Department saving was about $1 billion. Cutbacks by the Navy, principally by the Bureau of Ships, matched those by the Army almost dollar for dollar.19

This record notwithstanding, the committee failed to win Nelson’s confidence. “Naturally,” Groves observed, “the more Harrison learned of the problems of the military, the more difficult it was for him not to support them; and, in the same way, the more he learned of the WPB recommendations, the more difficult it became not to slice them.”20 Compared with reductions in military programs, cuts sustained by WPB were modest. Deferred as a result of the Harrison review were WPB-sponsored projects estimated to cost approximately $400 million—about one-fifth of the Army-Navy total. Nevertheless, as the committee threw out power-generating facilities, transmission lines, and plants for producing coke, pig ingots, and semi-finished goods, Nelson came to regard it as a tool of the military. Harrison’s appointment as a brigadier general in July 1942 helped weaken Nelson’s faith in his impartiality. By late summer, the WPB Chairman had concluded that sterner measures would be necessary to force the military into line.21

Early in September Nelson stripped the power to assign priorities from the Army and Navy Munitions Board. Henceforth WPB would review requests for priority and a complete bill of materials would have to accompany every application.22 Anguished cries from military spokesmen greeted this move. Typical of the Engineer reaction was Colonel Sherrill’s outburst:–

The power to decide whether a priority rating is to be issued carries with it the decision whether the project will be constructed. ... This power will in some cases carry with it indirectly decisions on military strategy. It is conceivable that delay in starting and completing certain projects may decide the outcome of a battle or delay military plans due to lack of certain materials.

The Army and Navy are entrusted with the fate of the nation and the lives of its men. If the War Production Board fails, the war is not lost, but if the Army and Navy fail, the war is lost. Therefore, in the construction program why add to our difficult battle against time.23

In a memorandum for General Clay, Groves took the same stand. Objecting to “direct control of design and specifications by the War Production Board,” he pointed out: “The question of what agency shall make the determination of the need for munitions is involved to a degree.”24 Protests by the Engineers,

SOS, and ANMB had no effect. Nelson held to his decision.25

On 21 September he took another step toward curbing war construction. With the consent of the Army, the Navy, and the Maritime Commission, he abolished the Harrison committee and, in its place, set up the Facility Clearance Board. Clothed with authority to screen industrial projects estimated to cost $1 million or more, the new board was headed by Ferdinand Eberstadt, who had resigned as chairman of ANMB to become WPB Vice Chairman on Program Determination. Col. Gordon E. Textor, an Engineer officer on loan to WPB, would be acting chairman in Eberstadt’s absence. The membership, drawn originally from the armed services and the Maritime Commission, soon broadened to include additional representatives from WPB. In October Nelson extended the board’s authority to all classes of construction and lowered the monetary ceiling to $500,000.26 No longer would military men screen military projects. The system proposed by Nathan and Sickel in the spring of 1942 was an accomplished fact.

While Nelson was tightening his control over military construction, Patterson was preparing a counterassault. Late in August he asked the Chief of Engineers to find out how much civilian construction was under way throughout the country. Within a month Reybold had the answer—$3.1 billion worth: $1.4 billion by the federal government; $1 billion by states, counties, and municipalities; and $700 million by private enterprise. On 29 September Patterson made his move. Citing Reybold’s figures, he advised Nelson: “I am firmly of the opinion that a great part of this work can be deferred without impairment of the war effort and without injury to the health and safety of the community involved.”27 Replying for WPB, Eberstadt agreed that a great deal of unnecessary construction was in progress and that it ought to stop.28 The ax-wielding assignment would be carried out by a new body, the Facility Review Committee, representing WPB, the Army, the Navy, and the Maritime Commission. Engineer officers took a prominent part in the work of the committee. Col. Thomas F. Farrell served as chairman and Lt. Col. Richard H. Tatlow, as War Department member.29

Meantime, the long-simmering conflict over broad production goals was coming to a boil. By the fall of 1942 total military requirements for 1943 had climbed to $115 billion.30 Basing his opinion on WPB studies, Chairman Nelson said this objective was far too ambitious. Although military leaders conceded that he might be right, they refused to lower their sights. There was, they argued, no harm in trying. Nelson emphatically disagreed.

Setting up a production program which goes substantially beyond the limits of feasibility [he explained] does not merely mean that the economy will be subjected to a

greater strain than it can bear; it means also that military requirements and strategic plans themselves will be involved in a confused and incalculable production tangle, and that the very ends which the oversized program sought to achieve are likely to be defeated.31

Impelled by this logic, he decided to force a showdown.

At a conference on 6 October, Nathan presented the case for cutting back requirements. Questioning whether any economy could devote more than half of its productive capacity to war, he pointed out that the proposed program for 1943 “would absorb not less than 75 percent of the national product.” According to Nathan’s Planning Committee, “an outside and all-out and stimulating objective” for the coming year would be $75 billion for munitions and construction and $18 billion for other war expenditures.32 Raising the cry of civilian interference in military strategy, Somervell opposed a cut. In his opinion, WPB was unduly pessimistic; if materials were carefully allocated, there was no reason to believe that the $115-billion goal was unattainable. Nevertheless, it was Somervell who pointed the way to a solution. At the next meeting of WPB, on 13 October, he suggested that Nelson tell the Joint Chiefs of Staff the program was too big and leave it up to them to decide where to cut. Nelson agreed to this proposal. On the 19th he referred the problem to the Joint Chiefs and asked for a decision within one month.33

The next day he applied the brakes to construction. Declaring that decisive action could no longer be deferred, he pointed out that building work programed through 1943 would absorb between one-fifth and one-quarter of the war effort. Construction on so vast a scale would cut deeply into production of military and essential civilian goods. Even “most essential” synthetic rubber, high-octane gasoline, aluminum, steel, and aircraft programs would suffer. With most basic needs already taken care of, the time had clearly come for phasing out construction. Accordingly, he was making drastic cuts in the programs of the Tennessee Valley Authority, the Federal Works Agency, and the Interior Department. At the same time, he was asking the Secretaries of War, Navy, Commerce, and Agriculture and the Chairman of the Maritime Commission for lists of projects which could “be arrested or abandoned without seriously affecting the war effort.” In issuing this so-called “stop order,” Nelson made it plain that he meant business.34

Despite strenuous protests from cabinet officers, agency heads, congressmen, and other interested parties, Nelson made his order stick. By mid-December 1942 the Facility Review Committee had choked off projects estimated to cost $600 million. Three months later the total had risen to $1.3 billion. Slashes in programs of the Federal Works Agency, the War Production Board, the Tennessee Valley Authority, and the Interior Department and in the civil works construction of the Corps of Engineers accounted for most of this total. Although the record of the Facility Clearance Board was less impressive—projects

totaling only $76.2 million received its veto—the board, by its very existence, discouraged would-be sponsors of questionable projects. From $13.4 billion in 1942, expenditures for new construction in the United States dropped in 1943 to $7.7 billion. Projects unrelated to the war accounted for most, though by no means all, of this reduction.35

Late in November 1942 the Joint Chiefs of Staff announced a reduction in the munitions and construction goal for 1943—from $93 billion to $80 billion. Among the scaled-down items was construction for the Army, which was shaved 31 percent, from $3.2 billion to $2.2 billion. This curtailment, purportedly, effected “all possible economies.”36 Subsequent revisions of the army supply program cut construction objectives even further. From the end of 1942 until V-J Day, the total approved cost of the Army construction program increased by only $1.8 billion. By early 1943 the flow of new directives had slowed almost to a trickle.37

Topping Out

As construction moved overseas, as major efforts went toward securing worldwide supply lines and providing forward bases for global offensives, the buildup in the United States entered its final phase. On the first anniversary of Pearl Harbor, the war construction program amounted to approximately $10.3 billion and was 85 percent complete. A year later the figures were $10.8 billion and 98 percent. The monthly value of work placed declined steadily and so did total employment. New projects were fewer and generally smaller than before.38 The undertaking launched in 1940 by The Quartermaster General was drawing to a close. In his role as Chief of Construction, General Robins faced a twofold task—winding up the emergency program and adapting his organization to radically altered conditions.

The roster of key construction officers reflected the transition from home front preparations to offensive warfare. Overseas duty claimed most of the physically fit Regulars on Robins’ staff, among them Colonels Hardin and Strong. A secret mission of highest priority claimed Colonel Groves, and Colonel Lewis answered a summons from the Air Transport Command. To assist him in directing the still sizable program, Robins was fortunate in having Colonel Farrell and Colonel Antes, both of whom had worked closely with Groves. To take charge of Repairs and Utilities, he was able to obtain Col. Rudolph C. Kuldell, a 1912 West Point graduate who had resigned from the Corps in 1920 to engage in private business. To head up Rivers, Harbors, and Flood Control, he called on Col. George R. Goethals, son of the great general and a retired Engineer officer. Former civilian employees now in uniform helped fill the urgent need for officers. And, flouting the words of the old barracks ballad, “no promotion this side of the ocean,” a few young Regulars

remained at their desks. Touched by the dedication of these young officers, Reybold reflected: “They really sacrificed to stay with the job.”39

Within the districts and divisions, leadership was passing to the Engineer home guard. A study of the Pacific Division in December 1942 was revealing. Responsible for all construction west of the continental divide, General Hannum depended heavily on senior Regulars. Overseeing division suboffices at Salt Lake City and San Francisco were Col. Edward M. George, 62, and Col. John R. D. Matheson, 55, who kept going despite poor health. Holding other key positions in the organization were Colonels Richard Park, 60, Elmer G. Thomas, 62, Clay Anderson, 63, and Herbert J. Wild, 67. Backing up these men were a few troop-age Regulars awaiting orders overseas, several former Engineer officers recalled to active duty, and a score of Reservists. This pattern was repeated throughout the Engineer Department. Replacing Scott as head of the Southwestern Division was Col. Robert R. Neyland, Jr., a 1916 West Point graduate who had resigned from the Corps in 1936 to coach football at the University of Tennessee. Releasing younger men for combat were Col. Jarvis J. Bain, who stayed on beyond retirement at Memphis, and John H. Peil, a long-time employee of the Rock Island District, who was commissioned a lieutenant colonel. Many others rallied to the cry of “Essayons” (the motto of the Corps), among them Col. Rufus W. Putnam, namesake and descendant of a Revolutionary Chief Engineer, and Brig. Gen. Charles Keller, who at 75 was the oldest active officer in the U.S. Army.

Despite a high turnover in key personnel, the organization proved effective. In the first nine months of 1943 construction valued at $1.7 billion went into place and nearly 12,000 projects reached completion. Although most of the completed jobs were minor ones costing less than $500,000, approximately 900 were major undertakings, ranging in cost from $500,000 to more than $100 million. Headliners included Camp Shanks, New Jersey, a $4O-million staging area for the New York Port of Embarkation; the $60-million Pentagon Building with its extensive system of roads and parking lots; the Sunflower Ordnance Works, a $130-million TNT plant at Eudora, Kansas; and scores of other multimillion-dollar installations. Among the significant achievements of this period were the Cleveland Aircraft Assembly Plant, which included the largest all-timber building in the world, and a plant for centrifugal casting of gun barrels at Watertown Arsenal, the first of its kind. A noteworthy technical breakthrough was the successful paving of concrete runways in near-zero weather.40

For sheer physical difficulty, few engineering feats could match the building of the Mountain Home Air Base in southwestern Idaho. Scheduled originally for the spring of 1943, the start of this project was advanced to December 1942, when the crash of a B-17 demonstrated

Winter construction at Mountain Home Air Base, Idaho

the urgent need for an emergency landing field in the Boise area. Transferring a huge fleet of equipment from the recently completed bomber base at Pocatello and throwing onto the job a crack local highway contractor, J. A. Terteling & Sons, the Portland District Engineer, Col. Donald J. Leehey, set a target date of 15 March for the principal runways. Stratton rushed the latest information on winter construction to the area engineer, Maj. Oliver A. Lewis. Battling snow, sleet, and high winds, the contractor’s forces began dozing out the 10,000-foot airstrips. Thick blankets of straw and sand protected the subgrade. With the thermometer hovering around 10°, paving went forward. Heated aggregate, liberal use of calcium chloride, insulated tank trucks, tarpaulins, straw, and salamanders—Terteling used every known means to prevent damage by freezing. With these techniques, he finished the job on time. Awarding the Army and Navy “E” to the contractor, an officer of the Second Air Force questioned whether there was another bomber field in the world with runways so long and so sturdily built.41

The startup at the Holston Ordnance Works in the spring of 1943 symbolized a notable achievement. With two widely separated manufacturing areas (one for raw materials and one for explosives), dozens of major buildings (most of brick and reinforced concrete and some 8 stories tall), a vast transportation network (31 miles of railroads, 59 miles of roads, and 4 massive bridges), and outsized utilities systems (capacity for 2 million pounds of steam per hour and nearly 500 million gallons of water per day), the plant was a tremendous undertaking. Problems were many: a dearth of design information, an element of friction between the architect-engineer-manager and the principal subcontractor, the district engineer’s seeming reluctance to crack the whip, a weak priority rating, a scarcity of equipment, and a persistent shortage of labor. Both

Holston Ordnance Works, Tennessee

Creedon and his successor, Otto F. Sieder, kept the job under close scrutiny. So did Colonel Hall, the division engineer. With help from Washington and Columbus, the project straightened out. Progress, poor at first, steadily improved. Completed line by line in the spring of 1943, the plant was producing at full design capacity—170 tons of RDX daily—by July. In another five months, this capacity more than doubled. Depth charges and blockbuster bombs containing super-explosives from the Holston plant were crucially important in sweeping Hitler’s U-boats from the Atlantic and in pulverizing German war industries.42

General Robins took special pride in two record-breaking projects, the bomber modification centers at Tulsa and Oklahoma City. Comprising huge hangar-like fireproof structures of concrete and steel, these new plants bore $4-million price tags and carried “immediate” completion dates. When the directives reached him late in April 1943, the Tulsa District Engineer, Col. Francis J. Wilson, was battling floods along the Arkansas River. With rail traffic at a standstill, he flew in company officials and began negotiations. Within 24 hours, he had signed contracts for the architect-engineering—with two St. Louis firms, J. Gordon Turnbull and Sverdrup & Parcel, for the Tulsa plant, and with the Austin Company of Cleveland for the Oklahoma City job. Before the month was out, structural steel was on order and grading had begun. By late May the principal construction contractors were

Work in progress on Tulsa bomber modification center, Oklahoma

at work—the Corbetta Company of New York at Tulsa and the local firm of Charles M. Dunning at Oklahoma City. Describing the race for completion, General Robins wrote:–

Progress on both jobs proceeded at about the same rate, neither job getting more than a few days ahead of the other. ... The methods of attack used by the two contractors on the erection of the buildings, however, were quite different. The Corbetta Company chose to erect free-standing concrete columns and to start the roof steel almost immediately, while the Dunning Company chose to erect the concrete center portion first, letting the roof steel wait until that part of the work was complete.

By a narrow margin, Corbetta finished first. At sundown on the evening of 31 July, a squadron of heavy bombers landed at the airport adjoining the Tulsa plant. The following morning the first plane rolled along behind its tractor into the newly completed building. Commending both contractors, Robins pointed out that construction which normally would take a year had taken less than 100 days.43

While jobs like these were becoming increasingly rare, hosts of smaller ventures were getting under way. From 4,400 in December 1942, the total number of projects costing less than $500,000 rose to 11,400 in June 1943. Although much of this construction answered real needs, for example, WAAC housing and POW compounds, much of it stemmed from the desire of post commanders to embellish their installations. Moreover, many permanent improvements and not a few frills were masquerading as necessary maintenance. By the spring of 1943,

the situation was getting out of hand. In an Army-wide directive on 15 April, Secretary Stimson laid down the law:– “Spartan simplicity must be observed. Nothing will be done merely because it contributes to beauty, convenience, comfort, or prestige. Property should be kept in serviceable condition but not beyond that level.”44 Attempting to plug an oft-used loophole, Somervell defined maintenance as “work which is regular and recurring and which is continuous in the sense that it is not terminable on the completion of a specific project.”45 Largely as a result of this crackdown the number of new starts on minor projects dropped 66 percent during the latter half of 1943.

Statements by the Chief of Engineers mirrored the decline, of stateside construction. Speaking to officer candidates at Fort Belvoir in April 1943, General Reybold said:–

The mission of the Army’s Corps of Engineers is developing with the progress of our attack. We are finishing up the biggest job of emergency construction the United States has ever seen. Now we’re moving on to a job of construction overseas. ... We’ve got a date with a certain paperhanger; and an Engineer keeps his appointments.46

Addressing a meeting of the major construction trade associations in New York City early in June, he stated:–

The scene is shifting from areas of preparation here at home to the actual theaters of war, where there lies ahead a tremendous task for construction workers. Most of the construction activities and responsibilities are being transferred to foreign shores, and most of the work must be done with troop units whose skilled workers and officers are drawn in large numbers from the ranks of the construction industry.47

And in an article for the July issue of The Constructor, he explained:–

The volume of war construction at home this year will reach but about 30 percent of last year’s total of more than five billion dollars. Much of this year’s building is already in place. Outside of a number of prisoner-of-war internment camps and a few general hospitals and other relatively small projects, little war construction is in view for the remainder of the year.48

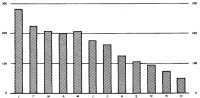

Construction budgets, employment figures, and monthly totals of work placed told a similar story. In June 1943, when he appeared before the House and Senate Appropriations Committees to defend the Engineer budget for the coming fiscal year, Reybold requested no new construction money. Instead he asked for authority to carry over $530 million from the previous fiscal year and to use it in winding up the program. The same act that granted this authority provided $580 million for maintaining the nearly completed military plant.49 The downward trend was depicted graphically in General Robins’ reports. During the calendar year 1943, both the monthly value of work placed and the total field employment fell approximately 80 percent. (Charts 20 and 21)

Changes in OCE attended this shrinkage. During the first five months of 1943, the strength of the Construction Division

Chart 20: Dollar value of work placed during 1943 (in millions by month)

Source: Constr PR, 31 Dec 43, p. 5.

Chart 21—Field employment during 1943 (in thousands by month)

Source: Constr PR, 31 December 1943, p. 10.

dropped from 1,712 to 1,010. Early in April, Robins discontinued the Operations Branch and set up the following branches in its place: Fortifications, under Colonel Burton; Materials and Equipment, under Colonel Sherrill; Military Construction, under Colonel Person; Munitions Plants, under Mr. Sieder; Rivers and Harbors, under Colonel Goethals; and Safety, under Mr. Blanchard. A month later, when Burton took over as district engineer at Philadelphia, Fortifications merged with Military Construction. A more sweeping change occurred late in May when Robins lifted the Engineering Branch out of the Construction Division and set it up as an independent division, responsible for research and development as well as for construction engineering.50 Behind these adjustments lay the narrowing scope of the building program. The next reorganization would take place in a somewhat different context.

In the spring of 1943, General Reybold launched a nationwide campaign to enlist construction workers for overseas service with Engineer units. Accompanied much of the way by President Oscar B. Coblentz and Managing Director Herbert E. Foreman of the AGC, he visited New York, Boston, Chicago, Dallas, Los Angeles, San Francisco, Portland, and Salt Lake City to address the following appeal to “the men who want to help engineer the forthcoming victory—the men who want to help get this war over as soon as possible”:–

Airdromes must be built all over the world, streams bridged to bear the advancing arms and armies of Democracy, roads constructed, water facilities provided, storage and repair depots raised, and harbors deepened, minefields and entanglements cleared for the advance of our troops, obstacles set up in the path of the enemy—a thousand jobs that call for the type of specialists who have been employed in the construction industry.51

With the thousands of “tough, trained construction men” and skilled equipment operators who responded to this call, the Corps was able to increase the work power of every Engineer battalion.52 Meantime, Reybold’s journey had another, unlooked for, result. Discovering on visits to division and district offices that service commanders were encroaching on his jurisdiction, the Chief took prompt action.

In a monitory message to division engineers, he stressed loyalty to the Corps. As construction diminished and work in the field offices slackened, district engineers were taking on more jobs for the service commands. Lines of demarcation between engineer divisions and directorates of Real Estate, Repairs and Utilities were becoming less distinct. Still rankling over a recent loss of authority (the power to assign post engineers now belonged to service commanders) and highly suspicious of Somervell’s intentions (the recent change in name from Services of Supply to Army Service Forces—what did that portend?), Reybold issued a ukase against “entangling agreements” and “informal arrangements cutting across command channels.” Faced with a choice of demobilizing or joining forces with the

service commands, the Engineer Department would demobilize.53

Late in July, at a conference in Chicago marking the first anniversary of the service commands, Reybold reached an impasse with “Somervell and his tribe.”54 In a curtain-raising speech which set the tone of the meeting, General Robinson inveighed against the attitude of “some technical services” that “they cannot discharge the responsibility for their functions without direct supervision of all their so-called personnel in the field.” Service commanders were more specific. Referring to the recent ban against “informal arrangements,” one of them complained: “We had a very fine system. ... On instructions of the Chief of Engineers, this was discontinued.” Confronted by his critics, Reybold refused to budge. When one commander asked him point-blank, “Should division engineers and their activities be placed directly under the jurisdiction of service commanders?” his answer was a categorical “no”; he reminded his questioner that the Engineer field had “many things to do aside from the military.” Noting this disagreement, Somervell declared:–

General Eisenhower and General MacArthur and a good many other people have been given complete responsibility for all activities that transpire within the territorial limits of their command; and that being the case, there is no justifiable reason why the same principle should not apply in the service commands.

It is to be remembered that in each one of these service commands there is far more activity now than there was in the whole War Department before the war. So why the service command should not be a little War Department, self-contained, carrying out all the functions in those service commands that we in turn are responsible for ... is still pretty difficult to answer in the negative.

The threat was clear. If Somervell’s plan went through, the Corps of Engineers and the other technical services would cease to exist.55

Immediately upon his return to Washington, General Reybold set about erecting roadblocks. By early August his staff had completed a detailed analysis of the conference minutes and had prepared an elaborate defense of the Engineer position. A 40-page communique was soon in the hands of every key official in the Corps.56 Before the end of the month, Reybold had adopted a plan to transfer procurement of supplies and equipment for Engineer troops from regional purchasing offices to the “river and harbor divisions.” This move would not only strengthen the Engineer Department but would also place Engineer procurement beyond Somervell’s control, since civil works was entirely outside his jurisdiction.57 To penetrate the secrecy imposed by Somervell on ASF planners required some undercover work. But Reybold and his fellow service chiefs kept abreast of what was going on.

Amid rumors that General Marshall would be “kicked upstairs” to take command in Europe and that General Somervell would become Chief of Staff, the service chiefs leaked the reorganization scheme to Congress. Remarks

inserted in the Record on 22 September by Representative Paul W. Shafer produced a furious to-do. Condemning “those in Government today who would play politics with the War Department,” the Michigan Republican revealed: “I have seen a blueprint of a plan which would presumably streamline the War Department, but in reality its intent is to convert that great department into a New Deal political organization.”58 Under sensational headlines, details of the impending “domestic coup d’état” appeared in the press. According to a front-page article in the Washington Times-Herald, the plan, cooked up by a White House “cabal,” was designed to give Somervell “personal control” of the Army’s production funds and to build him up as a “running mate for Mr. Roosevelt on a fourth term ticket to offset the possible Republican nomination of General Douglas MacArthur.” General Marshall, an implacable foe of politics in the Army, had to be gotten out of Washington. Explaining the mechanics of the scheme, the article continued:–

The coup d’état is to be accomplished by abolishing all production activities by the seven highly skilled technical supply services and transferring their $22,000,000,000 purchasing power to the Army Service Forces, which Somervell now heads. All these technical services are now grouped under Somervell, but he has no control over their expenditures, contract negotiations, or production schedules.59

Recognizing the value of corps traditions and loyalties, satisfied that production was going well under the existing system, and unwilling to stir up “a hornet’s nest right in the middle of a war,” Secretary Stimson vetoed the plan to abolish the technical services.60 Commenting on the affair, General Gregory later said of Somervell: “If he hadn’t been so much of a slicker, he could have succeeded General Marshall. You know you can kind of out-slicker yourself if you go too far with that kind of stuff.”61

Having survived the attempted takeover, the Engineer Department had to cut expenses. Neither the transfer of military purchases to division offices nor a modest increase in civil works approved by Congress in mid-1943 could offset the sharp decline in military construction. From 7.4 percent in January 1943 administrative field overhead rose alarmingly to 14 percent by the end of the year. Recommending that General Robins abolish some districts and confine others to civil works, Colonel Antes cited the example of the Wright Field office, an organization with 579 employees and only 3 projects. After consulting division engineers, Robins adopted a plan for gradually eliminating such temporary wartime districts as Wright Field and for reducing to approximately twenty the number of permanent districts directing military construction. Put into effect during 1944, this plan enabled the Engineers to cut

the size of their administrative force by almost 50 percent.62

As the field organization shrank, more responsibility shifted to temporary officers. To be sure, only top Engineer professionals were division engineers. Exemplifying the type of man selected for these posts was Brig. Gen. Roscoe C. Crawford, a former commandant of the Engineer School. Crawford took over the Missouri River Division early in 1944, after Pick departed for the China-Burma-India Theater. In this period, however, the majority of district engineers were of a different breed. By 1944 Reservists, most of them long-time employees of the Corps, headed three-fifths of the districts. According to Reybold, there was one difficulty with these uniformed civilians: many had been under officers so long that they were hesitant about making decisions. Nevertheless, the Chief observed, most rose to the occasion and did “a bang up job.”63 As insurance against failures in the districts, he relied on a small group of troubleshooting Regulars, former Quartermaster officers who were experts in contract construction but lacked experience with troops and Engineer veterans who were unequal to the rigors of service overseas.

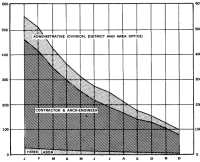

In the Washington headquarters, construction was further de-emphasized. On 1 December 1943, General Reybold streamlined his organization to insure maximum support for the fighting forces. Moved up to the newly created post of Deputy Chief, General Robins focused his attention on the more than half a million Engineer troops serving around the world. Reporting directly to him were the two Assistant Chiefs of Engineers—for War Planning and for Military Supply. The position of Chief of Construction disappeared from the charts, and the Construction Division split into three independent divisions:– Military Construction, under Colonel Kuldell; Civil Works, under Colonel Goethals; and Real Estate, under Colonel O’Brien.64 (Chart 22) Although they came under Robins’ supervision, these divisions required but little of his time. For the duration, their work would be of secondary concern.

Writing to a Los Angeles businessman early in 1944, Colonel Antes stated:–

As long as the war continues, a certain amount of routine war construction is anticipated. ... However, the trend is definitely downward, the dollar value of new work authorized during December 1943 having been only 12 percent of that authorized during January 1943. This downward trend will be accelerated as the military program proceeds; and, barring serious military reverses, the prospects are that new war construction in 1944 will show a steady decline from even the present levels.65

This forecast proved accurate.

Late Programs

As the United States entered its third year of war, homefront preparations were virtually complete and in the

Chart 22: Organization of Military Construction, Civil Works, and Real Estate Divisions, OCE, December 1943

Source: OCE Orgn Charts, 15 Dec 43, EHD Files

theaters crucial offensives were at hand. Since July 1940, the Quartermaster Corps and the Corps of Engineers had constructed an $11-billion military plant in this country, providing more than 1,800 command installations (training centers, airbases, supply depots, staging areas, ports of embarkation, general hospitals, harbor defenses, and POW camps) and 2,200 industrial facilities (manufacturing plants, proving grounds, shops, and laboratories).66 From the great base in the United States, American armies were advancing toward a decisive test of strength with the Axis forces. With the coming invasion of Europe in mind, General Reybold spoke for the Engineer Department:–

Home front problems become small . . As our men go forth to the toughest and bitterest task in our history, ... our dominating, driving determination is to back the fighting front, to speed the hour of triumph, to reduce the awful toll of war—and to preserve and strengthen the liberties and freedoms for which American men at this moment are dying.67

Mindful that unnecessary home front projects were still afoot, General Robins imposed restraint by centralizing approvals in Washington. On 2 December 1943 he withdrew the division engineers’ authority to approve minor jobs. Following Robins’ lead, Somervell soon established even stricter controls: all projects costing more than $1,000 needed certification by the Chief of Engineers and clearance from the Commanding General, ASF; all those costing $10,000 or more had to have the Chief of Staff’s approval.68 When field commanders protested that requests bogged down in the seemingly endless channels of the War Department, Somervell told them: “I have attempted to interpose all the red tape possible—and that is a lot.” He went on to explain:–

I cannot stand up before the country and before Congress and justify the expenditure of millions of dollars for construction work which is desirable but which does not have anything to do with winning the war; and so I have adopted what is admittedly a very cumbersome, fabian policy of delay in the hope that eventually you will get tired of asking for new construction and quit. ... There will be no question of delay if the matter is really necessary. Where it is a question of putting a fur lining in the swimming pool, we are certainly going to take a long time before we do it.69

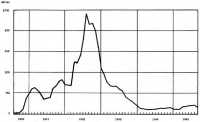

The policy succeeded. During the last 20 months of the war, excluding secret projects, expenditures for construction came to only $843 million, a sum not appreciably greater than the value of work placed in the single month of July 1942.

By early 1944 construction activity had sunk to about the level recorded for October 1940, a level not substantially exceeded during the remaining months of war. (Chart 23) At the beginning of 1944 Colonel Kuldell carried on his books unfinished construction amounting to $143 million. (Table 20} Of 2,108 uncompleted jobs, only 142 would cost $50,000 or more.70 During the first quarter of 1944, construction authorizations averaged $26 million per month.

Chart 23: Value of Work Places on War Construction Program, Continental United States, June 1940–August 1945

Source: ASF, Statistical Review: World War II, p. 12.

Table 20: Unfinished Construction, January 1944

| Type of Facility | Amount of Work Remaining |

| Total. | $143,039,000 |

| Air Force | 71,719,000 |

| Ground Force | 17,436,000 |

| Industrial | 26,271,000 |

| Storage & Shipping | 16,468,000 |

| Miscellaneous | 11,145,000 |

Source: Constr PR, 31 Dec 43, p. 5.

Most of the new projects were extensions to runways, conversions of barracks for the Women’s Army Corps, minor alterations at munitions plants, and additional warehousing and open storage. By far the largest project undertaken in this period was a $10.2-million inter-transit air depot at Alameda, California—a vast complex of railroads, sidings, warehouses, wharves, and deep-water docks—which was to serve as a principal supply point for the final offensives against Japan. Also worthy of mention were 1,400 flexible gunnery training devices, known as Poorman trainers, to be installed at 48 airfields. Invented by Maj. Fred S. Poorman of the Engineering Division, OCE, these trainers increased gunnery accuracy from 30 to 75 percent.71

No less marked than the shrinkage in construction was the altered character of O’Brien’s real estate operations. As the induction rate slowed and overseas deployment accelerated, the demand for troop housing diminished. As the possibility of enemy attacks became increasingly remote, defensive installations seemed less needful. As food shortages threatened the home front, more land had to go under cultivation. Late in 1943, Under Secretary Patterson told Reybold: “The acquisition phase of the War Department’s land program has now been accomplished.” Patterson asked the Engineers to “scrutinize present utilization of our military installations to determine which properties, if any, may be excess or surplus to present needs, and, where indicated, return such properties to private ownership or occupation.”72 By early 1944 the Real Estate Division was disposing of surplus holdings. Roughly 165,000 acres of idle agricultural land owned by the War Department were going under lease to farmers. Dozens of tactical airfields, antiaircraft artillery sites, harbor defenses, and other protective installations—including even Fort Brady, Michigan, which guarded the vital locks at Sault Sainte Marie—were changing hands. Several military reservations, the largest of which was a 17,000-acre tract near Toccoa, Georgia, were up for sale or transfer. Many of the hotels leased in 1942 had already reverted to their owners; and the Corps had auctioned off the

Stevens Hotel in Chicago for $5.3 million, only $300,000 less than the purchase price—a small markdown, considering that the Air Forces had occupied the building for more than a year. Except those serving as hospitals, the remaining hotels were soon to be let go.73

Cancellation of the hotel leases evoked angry protests from owners. Military tenants had left once proud properties in sad condition. Plaster had been damaged, woodwork marred, windows cracked, and mirrors shattered. Repeated scrubbings with GI soap had ruined hardwood floors. Looters had smashed in doors and plundered storerooms. Evidence of hard usage and of vandalism was widespread. Dissatisfied with restoration settlements offered them by the Engineers, owners appealed to the Truman Committee. At hearings in Miami during January 1944, witnesses aired their grievances against the Corps. After pressing claims for additional damages, they charged that the original leases were grossly unfair and had been obtained by intimidation and deception.74 Published in March 1944, the committee report contained the first serious criticism of the Corps’ wartime activities. “The manner in which the hotel acquisition program was carried out,” the report concluded, “resulted in many injustices which the War Department has shown little inclination to correct.”75 This judgment did not go unchallenged. Expressing “substantial disagreement” with the committee’s findings, the president of the National Association of Building Owners and Managers went on record: “Not only has the work of the Real Estate Branch been conducted efficiently and with dispatch, under the pressure of insistent war needs, ... but this has been done in a spirit of fairness and consideration for those whom this program has necessarily inconvenienced.”76

Scarcely had the Miami hearings ended before demands arose for a full-scale inquiry into another matter. Early in February the Philadelphia Inquirer headlined the news: “Congressmen Seek Probe of Pentagon Cost.” Calling the building “Somervell’s Folly,” and alluding to “fabulous spending, waste, and skullduggery,” members of the House Ways and Means and Appropriations Committees rallied behind Congressman Engel, who was winding up a five-month personal investigation of “the city with the roof on top.”77 In a speech before the House on 29 February 1944, Engel fixed the total outlay for the project at roughly $86 million, $51 million more than originally appropriated, and he taxed responsible officials with “an utter disregard ... for the wishes of Congress.” In a second speech one week later, he replied to a recent War Department statement that the Pentagon would pay for itself in 8 to 14 years by marshaling figures to show that in 50 years operating deficits would run the cost to the taxpayers to nearly $250 million.78 Among the military, Engel’s allegations produced some consternation. Breaking faith with Congress was an unpardonable offense.

Forewarned of Engel’s attack, the Engineers made defensive preparations. Colonel Renshaw, the former project engineer, returned from the Philadelphia District. Mr. Hadden, long a member of General Groves’ cabinet, went to work on the case. From his secret headquarters on the fifth floor of the New War Building, Groves helped mastermind the strategy. Meanwhile, Somervell armed friendly congressmen with facts and figures. When Mr. Engel took the floor, the defense was ready.79 Placing the cost of the Pentagon at $63 million, a War Department spokesman announced:–

The cost of a battleship doesn’t include harbor installations. Engel has included highways that were planned in 1934, when no one had dreamed of a Pentagon. He’s included sewage and drainage systems used by other buildings. The original estimate did not include a fifth floor, built as a war necessity, or 40,000 caissons, necessary because the building site was changed from high to low ground after the original plans were drawn.

The Pentagon, built faster than any building in the world, has helped us toward victory by providing operating efficiency. Costs of building were increased by the exigencies of war.80

Congress seemed willing to let it go at that. Light applause from the Republican side of the House was the only congressional response to Engel’s counterblast. Public interest flickered briefly and died.81 In an article entitled “Engel and the Monster,” Newsweek on 20 March reported that the Pentagon probe was over.82

By early 1944, most construction-minded congressmen had less interest in the past than in the future. Plans for postwar public works were under scrutiny on Capitol Hill, and special committees of the House and Senate were considering various blueprints for long-term national development. The Corps of Engineers was compiling a backlog of potential river, harbor, and flood control projects. In Colonel Goethal’s office, the work of building a “reserve shelf” of useful undertakings was making rapid headway. Looking forward to the time when the Corps could again build “for the benefit of mankind,” General Reybold reported in March 1944:–

For additional navigation improvements, advance planning has been done on projects that constitute a potential billion dollar program, and the program could be quickly expanded to two billion dollars. The potential flood control program involves an expenditure of over two and a half billion dollars. This work, like many other things, must now await victory over the Axis. But we are making progress toward that goal—substantial progress.83

Obscured by visions of peaceful endeavors, war construction continued. Totaling approximately $100 million, directives issued in the spring of 1944 covered 650 new projects, almost all of them minor. Called from Atlanta shortly after D-day to replace Kuldell as Chief of Military Construction, Brig. Gen. John S. Bragdon assumed direction of a program amounting to only

$160 million. Barely more than 100 major jobs were under way at the time; noteworthy among them were a large climatic hangar at Eglin Field, Florida, designed to test aircraft under extreme temperatures; a research center for biological warfare at Camp Detrick, Maryland; two huge postal concentration centers to handle the flood of mail moving through the New York and San Francisco ports; and three sizable industrial plants—one for making phosgene, at Monsanto, Tennessee, one for manufacturing stick powder, at the Badger Ordnance Works in Wisconsin, and one for forging 155-mm, shells, at Fontana, California.84 Although the volume of construction would remain small, Bragdon’s was to be a challenging assignment.

A shortage of heavy ammunition provided the first and greatest test of his leadership. Believing that the war in Europe would be mobile and that the jungles of the Pacific area would restrict the use of big guns, military planners had slashed shell requirements in November 1942 and again in February 1943. By late 1943 the output of ammunition was more than meeting the demands of theater commanders. As stocks accumulated, the Chief of Ordnance took steps to reduce production and by the end of the year had shut down a score of plants, dismantling some, placing some in standby status, and converting some to other use. Early in 1944, the situation changed.

It became evident [Somervell reported] that heavy artillery was destined to play a far larger role than had been anticipated. Effective use of the 155-mm, gun in the North African campaign and in the Pacific against the Japanese increased the demands for this weapon from theater commanders. Experience on the Italian front during the winter of 1943–44 showed that expenditures of heavy artillery ammunition had been underestimated.

In an effort to meet this emergency, General Campbell stepped up production, cut training allocations, stripped his depots bare, and borrowed from the Navy. But these measures proved inadequate. After the Normandy landings, shortages of large artillery and mortar shells threatened to blunt the Allied drive across France. Clearly, additional capacity was necessary.85

By mid-1944 the Engineers had a crash program on their hands. At a briefing for the new chief of Military Construction on 21 July, Sieder gave a rundown of the projects: seven facilities for forging and machining shells; sizable additions to the Badger, Radford, and Sunflower powder works; enlargement of the Alabama and Kankakee TNT plants; and expansion of two dozen shell, bomb, and bag loaders. To cost roughly $100 million, this work carried an end-of-the-year completion date. During the next several months, the size of the program more than doubled, as Bragdon got orders to build more shell casing factories, to reactivate standby plants, and to add or convert lines at project after project. How much of this capacity would be available before Germany surrendered? How much would be needful in the war against Japan? Dubious about launching so large an effort so late in the European war, Somervell ruled that most of the

munitions jobs would stop dead when American armies crossed the Rhine. Until then, Bragdon and Sieder were to go all-out.86

Cutting corners saved time. Disregarding policy, Bragdon awarded fixed-fee contracts for four-fifths of the projects and at ten of the largest jobs permitted architect-engineer-managers to do all work with their own forces. Despite objections from finance officers, Sieder commenced construction before funds were available from Ordnance. Pleading necessity, he called attention to a recent directive for reactivating a partially dismantled TNT plant. The project involved replacement of machinery and equipment, restoration of buildings, and renovation of corroded piping. “The cost of this work,” said Sieder, “obviously could not be determined until after detailed investigations were made in the field. Meanwhile, however, it was perfectly advisable to purchase materials and start work on the rehabilitation.” Had he waited for a detailed estimate and a formal allotment of Ordnance funds, several weeks would have been lost.87 If such methods raised eyebrows, they also produced results. By October work was under way at nearly three dozen projects and several new lines were already producing.88

By 1944 shortages of labor were the chief impediment to construction progress. The materials pinch had eased by then and manpower had become the number one home front problem. As appeals for help came in from the field, Robins went to work. He enlisted aid in rounding up mechanics from the Building Trades Department of the AFL; he established trailer camps at remote locations to provide worker housing; and he paid transportation costs from points of recruitment to project sites. Meanwhile, a step proposed by Sieder and acceded to by Ordnance—the cancellation of automatic sprinkler systems—eliminated requirements for several thousand critically scarce pipefitters. When the situation continued serious, General Robins asked Somervell to place the plant program on the urgency list. Robins pointed out that the list included all items the plants manufactured but, illogically, not the plants themselves. Although Somervell refused to go all the way, he did consent to list the five most troublesome projects—Gopher, Badger, Indiana, Cornhusker, and Susquehanna. Believing that the other jobs could probably get along all right, Robins let the matter rest.89

In the midst of their drive to expand industrial capacity, the Engineers received another big assignment—to provide more bases for B-29s. Reaching quantity production during 1944, the long-range “Superfortress” was destined for a decisive role in the war against Japan. Beginning in October 1944, the directives accumulated: for

longer, stronger landing strips at 19 Army airfields; for 25 large hangars at 18 locations; and for taxiways, hardstands, and similar facilities capable of bearing 120,000-pound gross loads. Estimated to cost in the neighborhood of $25 million, the program was well under way by early winter. The toughest problems encountered in construction were technical ones, having to do with pavement design. Nevertheless, the B-29 projects increased the strain both on tight labor markets and on the Engineer organization.90

Another program, which took shape around the turn of the year, increased the strain still further. As the number of casualties mounted, the President expressed concern over the welfare of the sick and wounded who would soon be returning to the United States. Early in December 1944 he reminded Stimson that these men deserved “the ultimate” in institutional care. Late in January 1945 the Chief of Engineers began a $54-million program of hospital construction:– expansion of 48 general hospitals to provide 43,500 more beds and conversion of 12 station hospitals to accommodate 49,800 convalescent patients. The plans included physiotherapy clinics, libraries, chapels, guesthouses, swimming pools, gymnasiums, bowling alleys, and virtually all types of outdoor recreational facilities. By Washington’s Birthday, General Bragdon could report that 48 of the new projects were under construction and that the remaining ones would start within 10 days. He promised that all the new facilities would be ready for use on or before 30 June.91

Meanwhile, the number of munitions projects had climbed to more than 100 and the total price of the industrial program was close to $400 million. During the fall of 1944, American forces in Europe experienced increasingly desperate shortages of heavy ammunition. After repeated cabled appeals for more large-caliber shells, General Eisenhower dispatched a mission late in November to present his needs to the War Department. Eisenhower’s calls for help caused grave concern in Washington. A personal inspection of the European Theater early in January convinced Somervell that there were “not enough ‘A’s’ in all the alphabets in the United States” to write the priority Ike should have.92 Shortly after Somervell’s return, the Engineers received hurry-up orders for additional plant expansions having a total estimated cost of $164 million.93

So acute was the manpower shortage when these directives hit that some military planners toyed with proposals for a work-or-fight law. Reviewing the situation early in 1945, Maj. William A. Mowery of Colonel Barker’s staff wrote:–

Manpower ... in construction is tight and it will get tighter. ... All concerned in our construction program must keep in mind that, in contrast to the early days of the construction program, we can no longer round up large numbers of

workmen overnight. It is now a long, tedious process of recruitment. ... Construction contractors never before encountered such problems and many of them haven’t the slightest idea what to do about them.

The Corps had to take the initiative.94 General Robins appealed again, this time successfully, to have the entire program placed on the urgency list.95 At the same time, he issued orders requiring closer cooperation with the War Manpower Commission and the U.S. Employment Service. His orders to the field read:–

In the past, many construction contractors have relied entirely upon their own resources and, in the case of union contractors, upon the labor organizations to supply their manpower needs. This practice has resulted in a disregard of the War Manpower Commission and other agencies charged with the responsibility for proper utilization of available manpower. Not infrequently, these agencies are called upon only after other methods have proven inadequate and after the projects involved have fallen behind schedule. Such haphazard methods can no longer suffice, particularly in view of the increasingly acute nationwide labor shortage and the more stringent manpower controls which are being established for all war industry.96

To deal with a critical shortage of common labor, he obtained authority to employ 1,500 furloughed soldiers and 2,000 German POW’s. Although most projects could have used more men, few experienced delays. On 1 March all but one were on schedule.97

The spring and summer of 1945 witnessed rapid changes in the construction mission. With the Rhine crossings in March and the opening of the drive across Germany, the munitions program underwent sharp curtailment. Work continued on a few large plants needed for the war in the Pacific. With the German surrender on 8 May, the Army began to call for redeployment training centers at 12 large camps; for disciplinary barracks on either coast; and for a large redistribution station in Texas. A plan of Somervell’s—for prettying up separation centers “to give the enlisted men a final good impression of the Army”98—went into operation late in June. Meanwhile, preparations for the scheduled invasion of Japan in November 1945—expansion of West Coast depots, improvements to Pacific ports, and construction of a huge base for the Air Transport Command at Fairfield-Suisun, California—proceeded rapidly. The dramatic events of early August cut these preparations short.

The war was over. But the engineering story behind the final victory was not yet fully told.