Chapter 19: Airfields for Very Heavy Bombers

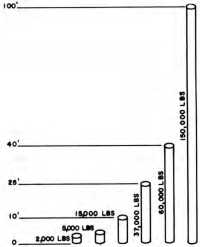

On 15 June 1944 a large flight of Superfortresses took off from fields in China to carry out a devastating raid on southwestern Kyushu. That same day two Marine divisions invaded Saipan in the Marianas, some 1,500 air miles south of Tokyo. With these operations the United States inaugurated a new strategy in the war against Japan—a strategy based on bombing by B-29s of Nippon’s industrial cities. Planes of a revolutionary type, the B-29s had a gross weight of 140,000 pounds when fully loaded, and an effective range of 3,250 miles. Their appearance in the skies above Japan climaxed years of effort by aircraft designers and manufacturers, by air force training centers, and, last but not least, by airfield engineers.1 The importance of construction engineering in the development of air power was emphatically confirmed in a statement by General Arnold: “Air bases are a determining factor in the success of air operations. The two-legged stool of men and planes would topple over without this equally important third leg.”2 Designing bases for very long-range bombers was among the most difficult technical missions accomplished by the Corps of Engineers in World War II.

The Technological Barrier

Experience with the first long-range bomber, the XB-19, suggested the magnitude of the engineering problem. Built at Santa Monica, California, by the Douglas Aircraft Company in the spring of 1941, the big ship had a maximum gross weight of 160,000 pounds, the equivalent of two railroad boxcars loaded to capacity. When it emerged from the Douglas hangar at Clover Field on 6 May, the newly assembled plane broke through the apron to a depth of about one foot. Towed with considerable difficulty to one of the airport’s asphalt runways, it caused noticeable damage as it taxied over the surface. Not until 27 June, when a recently laid concrete strip was ready for use, did the XB-19 take off on its maiden flight to March Field.3 On hand to observe the landing were members of Colonel Kelton’s Los Angeles District staff. Reporting the plane’s arrival, Kelton wrote to General Schley:–

No marking or imprint was evident at the point of landing, but as the ship lost speed a faint depression and hairline cracks appeared, increasing in severity as the speed was further

reduced. At the point where the ship turned to cross the oil-earth landing mat onto the apron, the depressions were at least one inch in depth and the cracks quite large.

Pointing out that the plane was lightly loaded and conditions were ideal—the weather was dry and the ground water level, low—Kelton warned that worse breaks were likely to occur. After heavy rains, “extreme damage” could result from landings by fully loaded B-19s.4

A technological barrier had been reached. Super-bombers required super-airports for which there were few engineering guidelines. The huge four-engine planes, with their exceptionally heavy loads, great landing speeds, pounding vibrations, and violent propeller blasts called for revolutionary methods of design. Runways would have to be longer and wider, pavements stronger, and grades gentler than before. Drainage would be more complex and dust control more needful. Theory would have to extend far beyond the limits of experience. Research would have to be energetically prosecuted. Discussing the challenge that had faced the Engineers, a spokesman for the Air Forces said in 1945:–

Only a short time ago the experienced airport engineer found no particular problem in the design of a runway pavement. His specialized knowledge was supported by the experience of hundreds of able highway engineers and by years of accumulation of data resulting from traffic tests and scientific research. Today the problem is vastly different. Loads applied to pavements on military airfields have no precedent in either airport or highway engineering.5

And although pavement design was the central problem, many peripheral problems, some of them highly critical, also needed solutions.

While Kelton and his officers kept track of the XB-19 and noted its effect on pavements in the Los Angeles area, the Chief of the Air Corps was insisting on runways of the heaviest construction. In June 1941 General Brett demanded that all new military airstrips be of portland cement concrete with beam strength characteristics. Mentioning the rapidly increasing weight of bombers and forecasting “continuous operations both day and night under a forced training program,” he submitted his runway specifications to General Schley: adequate bearing capacity under very heavy loads; high skid resistance; good visibility for night landings; and easy maintenance. In Brett’s opinion, only the best rigid pavements would be satisfactory. Opposing the view that concrete takes too long and costs too much, he counseled a more imaginative approach. First-rate rigid pavements would hold up even on weak subgrades, he argued; cutting down on grading and compaction would save time. Cost was a secondary concern. From the Air Corps standpoint, concrete runways were “well worth the expense.”6

The Engineers considered these standards visionary and wholly unacceptable. Attributing Brett’s proposals to Colonel Kennedy and his Buildings and Grounds Division, Plank afterward stated: “They wanted to introduce artificial concepts into engineering such as ‘no runway will be built except out of concrete with portland cement.’ But

there are other ways to build runways, and we, the Engineers, would not go for that kind of thing.”7 While disclaiming any intention of providing runways that were “not entirely satisfactory” to the Air Corps, Colonel Hardin argued that ground conditions at each site ought to determine the type of construction. Moreover, he pointed out, competition between asphalt and cement would serve the public interest. In an appeal to G-4 on 25 July, he asked that engineering decisions be left to the Engineers. Stating that asphalt pavements could be designed to carry even the heaviest planes, he insisted that surface textures could be altered to increase frictional resistance and surface colors, lightened to enhance visibility. And, he contended, high-type asphalt runways could be maintained almost as cheaply as concrete.8 Deciding in favor of the constructing agency, the G-4, General Reybold, handed down the ruling: airmen would state their functional requirements and Engineers would take it from there.9

As outlined by General Brett on 8 August 1941, the functional requirements were rigorous indeed. Runways were to have the following characteristics:– inherent strength to carry wheel loads up to 100,000 pounds; a stress load value of 500 pounds per square inch under impact; safeguards against “any weakness caused by infiltration of water into the subgrade”; high skid resistance in wet weather and high visibility at night; low crown, to reduce the hazard of ground looping, and low rolling friction; freedom from loose particles; durability; and no maintenance except repairs of bomb damage. In short, airstrips were to be safe for all-weather operations, 24 hours a day, by B-19s.10 General Schley proposed to meet the Air Corps requirements, but to do so in accordance with principles of sound engineering and scrupulous economy.

When Schley retired as Chief of Engineers on 1 October 1941, a broadly conceived investigative effort was under way. Formulated by the Engineering Section, OCE, under William H. McAlpine, this effort had a five-fold purpose: insure adequately designed airports; eliminate wide variation in designs; limit the use of unproved theories; maintain competition between materials; and lay the basis for further development of pavement criteria through behavioral studies. The overall objective was to write a new chapter in civil engineering. Assigned to this mission was a sizable team of investigators. The Corps’ civil works experience came into play, as experts in hydraulics, hydrometeorology, earthworks, and foundations attacked airfield problems. Assisting Kemp and McFadden in Washington were two of the Corps’ foremost technologists, hydraulic engineer Gail A. Hathaway and soils engineer Thomas A. Middlebrooks. Undertaking a series of special studies was the research staff of the Waterways Experiment Station (WES) at Vicksburg, Mississippi, headed by Gerard H. Matthes. Conducting tests and experiments were district offices throughout the country. Because the civil organization could not provide all the needed skills, McAlpine brought in specialists from outside; among these

recruits were James L. Land, a mainstay of the Alabama State Highways Department since 1910, and Walter C. Ricketts, a chemical engineer who had worked for the Asphalt Institute. A number of prominent consultants also joined in the endeavor. Continuing his predecessor’s policy, the new Chief, General Reybold, gave the program vigorous support.

During the autumn of 1941, research went forward on many fronts. Aware that drainage was critically important and that broad pavements and nearly level grades would complicate this aspect of airport engineering, McAlpine told Hathaway to develop criteria for handling surface runoff and asked WES researcher Audley A. Maxwell to push investigations of subsurface pipe. Knowing that thousands of acres would have to be carpeted with grass, he consulted experts in turf culture and set out to mechanize planting. At his request, Dr. John Monteith, Jr., agronomist for the U.S. Golf Association, furnished advice on seeding, sodding, and fertilizing, and farm equipment manufacturers developed a special grass planting machine for use at airports. Seizing the earliest opportunity for tests with a very heavy plane, McAlpine asked Colonel Kelton for detailed reports on pavement performance under the XB-19. The Chief provided money for analyzing subgrades and base courses and for evaluating runway strengths at every field visited by the experimental bomber. Meantime, placing greatest emphasis on problems of greatest difficulty, McAlpine stepped up efforts to formulate criteria for adequately designed pavements.11

Highway practice was the starting point. A science of great antiquity, road-building had made rapid strides since 1900. With the advent of the motor car in the first years of the century, gravel and macadam surfaces designed for horse-drawn vehicles and for the myriad bicycles of the Nineties proved inadequate. The decade 1904–1914 witnessed construction of more than 10,000 miles of bituminous roads. As trucks began to claim a share of the nation’s transport, demands arose for rigid pavements. Between 1909 and 1925, the total mileage of concrete highways in the United States increased from 5 to more than 30,000. These developments spurred research. State highway departments and leading universities cooperated in studies of pavement design.12 The federal government took a hand, promoting investigative programs through the Bureau of Public Roads, established in 1916, and the Highway Research Board, set up under the National Academy of Sciences in 1920. The Portland Cement Association, organized in 1916, and the Asphalt Institute, founded three years later, sponsored systematic inquiries into techniques of highway engineering. Because their problems were similar—a single-engine trainer had about the same wheel load as a heavy commercial truck—early airport designers employed the methods of highway engineers. But with the coming of very heavy bombers, military engineers had to re-examine these methods and to pioneer a new technology.

In line with Brett’s strong preference for concrete, the Engineers gave close attention to rigid pavements. After

talking matters over with his staff, chief engineer McAlpine outlined the problem. Would principles used in building concrete roads hold good for concrete runways, taxiways, and aprons? Would conventional methods of slab design and standard formulas for pavement thicknesses be applicable? More specifically and most important, would the classic analysis of Harald M. Westergaard, Harvard’s Dean of Graduate Engineering, provide a rationale, a theoretical “handle,” for designing heavy duty airfield pavements? A set of formulas for determining stresses produced in slabs by rolling loads, the Westergaard analysis took into account subgrade reactions, concrete strengths, and tire contact areas. Publishing his theory first in 1926, when trucks were the yardstick, Westergaard had extended it in 1939 to cover the heavier wheel loads and larger tire imprints of big commercial planes.13 Essentially a theorist, a man who did his work sitting at his desk, Dean Westergaard was concerned more with the validity of his analysis than with its application. Explaining his attitude, he told one engineer: “I have developed a theory and it is mathematically sound, but whether it fits the facts of nature is up to you to prove.”14 To verify Westergaard’s theory by experiment was McAlpine’s primary goal.

Quite logically, he decided to center the investigation in Colonel Hall’s Ohio River Division, where an extensive program of flood control begun in the 1930s had developed unique technical capabilities. Organized in 1934 as part of the Muskingum River project were two laboratories whose contributions gained quick recognition. Pioneer work in the use of air entraining agents, curing membranes, and portland cement substitutes was done by the Concrete Laboratory under Bartlett G. Long. A versatile construction man, trained in architecture and experienced in hydraulics and hydrology, Long had a small but highly competent staff of chemists and civil engineers. Important advances in foundation engineering were scored by the Soil Mechanics Laboratory. The first of its kind in the United States, this laboratory was headed by Robert R. Philippe, an alumnus of MIT, who had studied under Karl Terzaghi, the father of soil mechanics. Philippe’s talented young deputy, Frank M. Mellinger, held engineering degrees from Princeton and Carnegie Tech. Nearing completion in the Cincinnati suburb of Mariemont was a large modern structure designed to house both laboratories. Only a few miles away, at the division’s downtown headquarters, Evan P. Bone, a specialist in Westergaard’s analysis, stood ready to aid in research on airfield pavements. Moreover, the big air force installation at Wright Field, with its own scientific staff and its own Engineer district, seemed an ideal place to conduct experiments. Prepared in collaboration with Philippe and Long, McAlpine’s investigative plan called for large-scale tests at Wright and for control tests at Langley Field, Virginia.15

In September 1941 teams of investigators and truckloads of instruments converged on the test sites. The Waterways Experiment Station sent crews of skilled technicians. The Portland Cement Association sent observers. A trio of consultants came from leading universities:– Professor Kenneth B. Woods, a distinguished authority on highway engineering, from Purdue; Dr. Nathan M. Newmark, a structural engineer and researcher in applied mechanics, from Illinois; and Dr. Frank Baron, a disciple of Dean Westergaard, from Yale. An impressive array of equipment was on hand: accelerometers, geophones, strain gages, and specially built pressure cells had come from Vicksburg; thermohms, extensometers, bearing plates, hydraulic jacks, cranes, trucks, and miscellaneous tools, from various other elements of the Corps; a phototheodolite, from the Civil Aeronautics Authority; and a drop test rig and a late model bomber, from the Air Corps. Plans received a final check. Early in October, tests began.16

“To measure the reactions of a pavement under a set of idealized conditions as assumed by Westergaard’s theory” was the first order of business.17 At Wright Field the district engineer, Lt. Col. James B. Newman, Jr., directed a series of experiments on a 7-inch reinforced concrete apron, constructed 12 years earlier on a clay subgrade. Newman’s men first loaded a frame of steel I-beams with 60 one-ton concrete blocks. Then, using a hydraulic jack and a bearing plate, they applied this load in successive increments until the pavement failed. They tested centers, edges, and corners of slabs in this way and measured vertical deflections at various distances from the loads. Lt. Col. Robert R. Neyland, Jr., the Norfolk District Engineer, followed a similar procedure at Langley Field, where a 6-inch concrete apron had been laid on a sandy silt subgrade some years before. Samples taken from the pavements went to the Concrete Laboratory for analysis. Meanwhile, drop tests and experiments with planes landing on lime-coated runways were yielding more accurate information about tire imprints.18 As they correlated results from field and laboratory tests, researchers saw that they had hold of a “very, very wonderful handle.”19 Theoretical values obtained by the Westergaard method were virtually the same as values obtained from actual tests.

By late 1941 a convenient tool was in the hands of project engineers at work on the new Lockbourne Army Air Base, near Columbus, Ohio. Early in October, before field experiments were fully under way, Evan Bone began a series of intricate calculations. Using Westergaard’s equations, he developed a family of curves, entirely theoretical in origin. Then, as data became available from the tests at Wright and Langley, he proceeded to refine these curves. “Theoretical analysis adjusted by experience” was Philippe’s description of the finished product. After finding the modulus of

soil reaction, k (the technical term for the rigidity of the subgrade), an engineer could readily determine from Bone’s curves the required pavement thickness for any wheel load up to 60,000 pounds. The curves were soon in use throughout the Corps. But official blessing awaited fuller proof. Only after further tests with different sets of variables would the curves find a place in the Engineering Manual.20

Perhaps the most remarkable discovery made in this early period had to do with the landing impact of aircraft. In the past engineers had designed commercial runways to withstand heavy jolts when planes touched down. “Wheel load times an impact factor of 1.25 or 1.50” had been the general rule. But early observations of the XB-19 brought this method into question. Landing at March Field in June 1941, the super-bomber caused no damage to the pavement. Only when the ship slowed down did cracks appear. At other airfields in the Los Angeles area the story was the same. Reasoning that net forces were at work, engineers theorized that the buoyancy or wing lift of rapidly moving planes markedly reduced the stress on runways. Colonel Hall’s soils engineers tested this theory at Dayton Municipal Airport on 8 October 1941 using a B-26 Martin Marauder. With Philippe in the bombardier’s seat, the pilot made repeated near-crash landings on a concrete strip. Accelerometer readings, photographs by high-speed cameras, and measurements of tire imprints furnished ample proof: the greater the speed, the lighter the load on paved surfaces.21 The evidence left little room for doubt. Yet airmen and plane designers were slow to embrace the concept.

Concurrent with tests on rigid pavements were tests on flexibles. A pliable material with virtually no tensile strength, asphalt offered far greater difficulties than concrete. Bituminous surfaces do not support superimposed loads but simply transmit the loads to the subgrade. On unstable foundations, these surfaces deteriorate rapidly, rutting, bulging, and weaving under traffic. Hence, with asphalt pavements, the bearing capacity of the soil, its deflection tolerance or resistance to deformation, is a make-or-break proposition. Among highway engineers, there was little agreement as to how flexible pavements ought to be designed. Various methods were in vogue, all of them empirical and none of them proved for wheel loads beyond 12,000 pounds.22 Because the problem was primarily one of soils, McAlpine turned it over to his soils experts, Thomas A. Middlebrooks and George E. Bertram. Both veteran flood control engineers, these men possessed a wealth of practical experience with earthworks and foundations. Moreover, both were solidly grounded in the theory of soil mechanics. Middlebrooks had done graduate work in the new science under Terzaghi at MIT; Bertram, under Dr. Arthur Casagrande at Harvard.

Their early efforts were exploratory.

After a precursive look at the methods of state roads departments, their first surmise was that load bearing tests might be the answer. Widely used in highway work, these tests were also applied by designers of earth dams and embankments. Going out into the field, Middlebrooks and Bertram launched a series of experiments with bearing plates. Initial trials were at Williamsburg, Virginia, on flexible sections in the State Highway system. The two researchers tried out plates of different sizes, different rates of loading, and different ways of interpreting results. Then, learning that heavy commercial planes were breaking up asphalt pavements at Tri-Cities Airport near Bristol, Tennessee, Bertram went there to find out why. Within a short time, he and Middlebrooks knew what they were up against. The problem was much tougher than they had anticipated.23

In a paper presented to the Highway Research Board in December 1941, summarizing their findings, they reported two important discoveries. First, allowable deflection for asphalt bomber strips would be far smaller than for asphalt roads. Their experiments had shown this deflection to be not 0.5 inch, as specified by the Asphalt Institute, but a mere 0.2 inch. And this figure applied only to static loads. “It must be recognized,” the writers pointed out, “that for a large number of repetitions the allowable deflection will approach 0.1 inch.” Second, load bearing tests had proved unsatisfactory. So far they had failed to give a realistic picture of a soil’s capacity to resist displacement. They would not measure the effects of repetitive loads and they would not measure shear. Nor would they show what would happen when the soil beneath a pavement became saturated.24 In time perhaps they could be made to work, but there was no time. With Land, Middlebrooks and Bertram were investigating other methods favored by various states—California, North Dakota, Kansas, and several others. But their “ideas were not formulated sufficiently to fix on a method of design.” Recalling where they stood on the eve of Pearl Harbor, Bertram said, “We were rather groping at the time.”25

By early December 1941 further, more sophisticated tests were in preparation. At Langley Field, Colonel Neyland was readying fourteen experimental asphalt sections of varying thicknesses on various types of base courses. At Wright Field, the new district engineer, Lt. Col. Henry F. Hannis, was pouring nine specially designed concrete slabs, some on natural subgrades and some on gravel. Several eminent professors were collaborating on theoretical phases of the work. Top civilian engineers of the Louisville and Pittsburgh Districts were standing by to help conduct the tests. A large rubber-tired Tournapull was on the way to Langley, where it would simulate rolling pressures of heavy bombers; and the XB-19 was soon to fly from the West Coast to take part in the Wright Field experiments.26

Shortly after Pearl Harbor, Colonel

Kennedy proposed that this program be suspended. On 19 December he told Hardin that the war would not wait for the Engineers to conclude exhaustive investigations. Sufficient information for designing concrete pavements—the only type the airmen wanted—could be had from the National Advisory Committee for Aeronautics, the Public Roads Administration, and the Portland Cement Association, Kennedy maintained; what Hardin ought to do was assemble this material, digest it, and put it in usable form. Questioning the value of the recent impact study, Kennedy pointed out that XB-19 landing gears were designed to withstand loads equivalent to four and one-half times the gravitational constant. Runways, he asserted, would have to withstand similar impact loads. Calculations could be made by simple arithmetic:– a 60,000-pound wheel load would land with the force of 270,000 pounds. An impact factor of 1.25 or 1.50 was not too large, as the Engineers contended, but far too small.27 Asked about Kennedy’s theories some years later, Philippe gestured toward a 9-foot ceiling and laughed: “Why, for the heaviest planes of World War II, you’d need a slab as thick as this room.”28

The reply to Kennedy came not from the Engineers but from the Air Forces. Early in January 1942 General Arnold’s A-4 reminded the Chief of the Air Corps that the Chief of Engineers was responsible for designing military airfields. The G-4 of the Army had so ruled, and the ruling would not be questioned. Hardin and his associates had already pulled together all available information on concrete pavements. A review of this material clearly showed the need for further tests. Moreover, the A-4 continued, landing gears and airfield pavements were entirely different matters; there could be “no direct parallel” between them.29 At this point, the two services called a truce: Col. Walter J. Reed succeeded Kennedy as Chief of the Buildings and Grounds Division; Lt. Col. James B. Newman, Jr., the former Wright Field District Engineer, became Reed’s deputy; and General Robins sat down with senior air officers to hammer out a working agreement.

Announced on 18 January 1942, the agreement envisioned fleets of super-bombers in the skies by 1944. Because the B-19 had proved a disappointment (its engines were unequal to its great weight), General Arnold was pinning his hopes on a plane which had yet to be tested, the B-29. Under development by the Boeing Aircraft Company, this ship was more streamlined and more powerful than the Douglas model. With the B-29 in mind, Arnold and Robins reached an understanding that wheel loads of 60,000 pounds would govern airfield construction until 1944, when a much heavier bomber, the B-36, might go into production. Pending completion of comprehensive studies, the Engineers would continue to allow 25 percent for landing impact on all runways.30 As equitable as it was authoritative, this agreement signaled an end to dissension and confusion.

Harmonious relationships with the Air Forces were all to the good, but the

big problems were scientific, not administrative. There was no way to ease the strain on researchers striving desperately to score a technological breakthrough.

Breakthrough and Advance, 1942–1944

In the weeks following Pearl Harbor, as efforts to reinforce Hawaii and to develop a life line to Australia threw a crushing load on West Coast airfields, the urgent character of the research task was emphatically affirmed. On General Arnold’s orders every available B-17 was to move to the Pacific war zone as soon as possible. Before long, dozens of the big Flying Fortresses, most of them straight from the factory, were converging on the Sacramento Air Depot to be readied for combat. Airstrips in the area took a pounding. At Mather and McClellan Fields, near Sacramento, construction crews worked around the clock, patching damaged pavements with blacktop by night and putting in new concrete runways by day. At Hamilton Field, near San Francisco, the staging point for planes en route to the Pacific, concrete slabs laid some years earlier on a fill of bay mud started to disintegrate.31 These difficulties warned of large-scale trouble ahead, for the B-17s weighed only half as much as the very heavy Superforts of the future.

Plans for strategic air offensives underscored the gravity of the Engineers’ assignment. Convinced that bombardment was the “main job” of the air force, General Arnold resolved to carry the war to the enemy by attacking key targets deep in hostile territory. Large formations, daylight raids, and precision bombing were important features of his program. High-altitude, long-range aircraft were essential weapons.32 By early 1942 assaults on Germany by British- and Egyptian-based B-29s were part of the Allied design for victory in Europe. Superfortress strikes against Japan were left to the more distant future, when the defeat of Hitler was assured and a foothold in the western Pacific was regained. Earmarked for quantity production before it was airborne, the B-29 came to be known as “the three-billion-dollar gamble.”33 In opting for the untested model, Arnold wagered heavily on Boeing’s ability to deliver an airworthy ship. He also counted on the Engineers to provide serviceable training fields and operational bases.

When Lt. Col. James H. Stratton reported for duty in December 1941, the Chief’s office was in a bind. Beginning his new assignment as head of the Engineering Branch, Stratton found only fragmentary data on airport design. Hathaway had outlined a scientific method for predicting maximum rainfall and computing peak runoff for any area, and a preliminary bulletin on the required hydraulics capacity of storm drains had gone to the field. The Waterways Experiment Station had tested subsurface pipes of various types and a table prescribing minimum required

earth cover for sizes up to 24 inches in diameter was in the hands of division and district engineers. A digest of facts on turfing, prepared by Dr. Monteith, was ready for publication. Results of the early Wright Field experiments were making the rounds.34 But general solutions to fundamental problems were not yet in sight. Deeply concerned, Stratton gave close attention to the investigative effort.

A product of the career development program adopted by the Corps in the 1920s, the 43-year-old West Pointer was grounded in both military leadership and engineering science. After completing his formal education at the Engineer School and at Rensselaer Poly, he had served for a decade with troops in the United States and Panama. Assigned to civil duty in 1933, he played an important part in two of the great dam and reservoir projects launched under the New Deal. At Conchas Dam in northeastern New Mexico—a huge gravity concrete structure extended by earth dikes to a width of several miles—he headed the technical force. At John Martin Dam in southeastern Colorado—a large concrete and earth-fill barrier across the Arkansas River—he headed the project as district engineer. A paper presented to the Boston Society of Civil Engineers in the fall of 1938 displayed his familiarity with soils engineering, concrete construction, and hydrometeorology—all subjects of concern to airfield designers. At Lubbock Field, Texas, in 1941, he confounded skeptical airmen by developing a structurally adequate bomber runway of asphaltic concrete on a compacted caliche base.35 An experienced commander and a trained engineer, respected alike by brother officers and fellow civil engineers, he seemed ideally suited for the super-airport mission.

Immersing himself in the details of flexible pavement research, he quickly learned where matters stood. Kemp gave him a rundown on the Langley Field endeavor: experimental sections, designed with the help of the Asphalt Institute, were nearing completion; tests would soon commence. But Kemp was pessimistic about the outcome, for he questioned the institute’s claim that thick bituminous surfaces provided measurable beam strength. In briefing their new chief, Middlebrooks and Bertram pointed to a possible solution. Their study of state highway practices had led them to conclude that the California method, strongly backed by Land, held considerable promise. Middlebrooks was in correspondence with Thomas E. Stanton, Materials and Research Engineer of the California Division of Highways; and Bertram had been to Sacramento to confer with the originator of the method, O. James Porter, Stanton’s assistant. There was still some hope of finding a theoretical handle, but, the two men warned Stratton, that hope was dim.36

The Langley tests were decisive. On Washington’s Birthday the Virginia airbase was bustling with activity. Robert F. Jackson was there from the Louisville District to direct the experiments. Frederick C. Field was there as an observer for the Asphalt Institute; and Bertram was there from Washington as Stratton’s representative. Men of the 21st Engineers filled a 12-cubic-foot scraper to struck capacity with tamped earth. Unequally distributed, the load exerted weights of 13,000 pounds on the front wheels and 20,000 on the rear. Coupling the scraper to a six-ton truck, the troops pulled it to the test site and began making passes over the asphalt surfaces. That day and the next the trials continued. After 25 passes, 6 of the 14 test sections had begun to rut; after 50 passes, 10 of the sections had failed and the rest had developed a definite weave. Designed supposedly for wheel loads of 60,000 pounds, the Langley pavements rapidly deteriorated under loads of 20,000 pounds.37 On reading Bertram’s report of the experiment, Stratton decided to stop theorizing and to send for Jim Porter at once.

On his way east, Porter thought the problem through. He had known for some time what the Army was up against. For almost a year he had been working informally with Col. Robert C. Hunter of the Sacramento District and Lt. Col. John O. Colonna, the Fourth Air Force engineer, on plans for California flight strips. Since Bertram’s recent visit, he had had the broad picture in mind. The news from Langley came as no surprise to him. An independent and creative thinker, a man whose policy it was always to question other people’s theories and to try to see what others might have missed, he thought he knew the secret of flexible design. As a junior engineer for the California Division of Highways in the late 1920s, he had investigated pavement failures throughout the state. Most of the trouble stemmed from porous, loosely compacted soil, which took up moisture, became plastic, and remolded as wheels rolled over the pavement. Porter thought of the untouched lodes of disintegrated granite in the mountains of California and the large deposits of gravel in the river valleys. Compacted fills of these materials topped by thin wearing courses seemed to him the common-sense prescription for inexpensive, durable roads. He devised a simple procedure, the California Bearing Ratio (CBR) test, for measuring the shear resistance of base and subbase materials. Experience proved his test could be relied upon. He also helped to originate a superior method of compaction control, the modified density test associated with the name of Ralph R. Proctor. In time Porter was able to develop curves showing the relationship between bearing ratios and pavement thicknesses for wheel loads up to 12,000 pounds and to correlate these curves with field performance.38 During the trip to Washington, he decided to offer Stratton a “package” plan—compaction method, CBR test, and curves for heavy wheel loads derived from traffic tests.

Within an hour or two after his arrival, Porter was deep in conversation with Middlebrooks and Bertram. They found that their ideas were far apart. When the discussion stretched on fruitlessly for several days, Stratton sent for Dr. Casagrande. A world renowned figure in the field of soil mechanics and foundation engineering, the Harvard professor modestly described his role as that of “a catalyst.” Stratton, more accurately, called him “the heart and soul of our inquiry into the use of CBR.” After lengthy talks with Middlebrooks and Porter, Casagrande suggested a procedure. Extrapolating Porter’s curves was the first order of business. Each man went off to work alone. Using different methods, they plotted tentative curves for wheel loads up to 70,000 pounds. Comparing notes the next morning, they found that their results were close. But as Porter later put it, they were not yet ready “to spread the curves around.” That afternoon, they began blocking out a series of tests for checking their extrapolations. Details were soon complete. Before the week was out, Stratton had agreed to the plan. Porter was soon back in Sacramento, but not for long. According to his wife’s count, he was away from home on missions for the Corps for 300 days out of the next 365.39

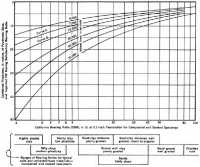

In adopting CBR, Colonel Stratton assumed a calculated risk. Extrapolation is always something of a gamble, and in this instance the odds were long and the stakes were high. Likened by one humorist to lines drawn “in a dark room”40 the tentative design curves were little better than educated guesses. The interval they bridged was vast and the concept they embodied was crude. (Chart 24) Used successfully on California highways for more than a decade, CBR had never been tested on airports. Still, there appeared to be no safer course. Professor Casagrande “would not endorse a notion unless he was reasonably sure of his grounds.” Of that Stratton was certain. Moreover, his own experience with airfields in the Southwest gave him confidence “that we were on the right track.”41 With several hundred new air stations already on order and directives for hundreds more in prospect, he could not afford to shilly-shally. Deciding for the California method, he plunged resolutely ahead.

The test program was labeled “crash.” Early in March 1942, Stratton issued rush orders to five division engineers. Four were to investigate prewar commercial runways which had been down long enough for subsoil moisture to equalize. Colonel Bragdon in the South Atlantic was to choose an airstrip built on sandy clay, a fairly good subsoil; Colonel Scott in the Southwestern, one on lean black clay, a rather poor foundation; Colonel Elliott in the Upper Mississippi Valley, one on Fargo clay, a highly plastic material; and Colonel Besson in the Missouri River, one on a porous subgrade subject to frost action. Tournapulls with wheel loads of 12,500 to 50,000 pounds would be towed over the pavements until failure occurred or 10,000 runs had been made. Each experiment would test one point on the

Chart 24: Tentative design Curves for Flexible Airfield Pavements

Source: T. A. Middlebrooke and G. E. Bertram, “Adaptation to the Design of Airfield Pavements,” ASCE, Vol 115, (1950), p. 470.

extrapolated curves. Broader in scope and critically important was the task given Colonel Hannum in the South Pacific Division. At Stockton air base, near Sacramento, Porter would conduct a crucial test. Stockton’s original runway, built by the city in 1936, had failed during the winter of 1940–41 under the weight of light Army trainers. An abandoned taxiway nearby, constructed at the same time and along the same lines—the subgrade was adobe, the base course was six inches of compacted sandy loam, and the surface was a seal coat of emulsified asphalt—remained intact. The plan was to make tests on the taxiway and on a special, Porter-designed section to be built atop it. The purpose was to validate a wide range of points on the tentative curves and to verify premises on allowable deflection and effects of repetitive loads. Hannum was to see to it that Porter lacked nothing in the way of support. Stratton’s appeals to the five divisions for “expeditious action” were couched in terms of urgency.42

Strenuous endeavors produced quick results. In almost no time, Stratton had telegrams reporting the progress of tests on commercial runways at Dothan, Alabama; Corpus Christi, Texas; Fargo, North Dakota; and Lewistown, Montana. Soon communiques were coming in from Middlebrooks, who functioned as traveling coordinator for this phase of the program.43 Meantime, at Stockton, Porter and company set a blazing pace. On 10 March Bertram arrived in Sacramento and gave the signal to begin. Next morning, bright and early, a crew was out taking borings at the site. By the 13th deflection gages were in place and Porter was taking readings as a light training plane idled its engine, revved up, and taxied over the pavement. By the 20th the surface had developed hairline cracks and Porter had seen enough to know that the pavement was incapable of withstanding deflections of 0.1 inch or even of 0.05. Construction of the test track started the following day. Built to Porter’s specifications (a thoroughly compacted base course of sand and gravel, increasing gradually in thickness from 6 inches to 4 feet, was topped by 3 inches of asphaltic concrete), the section was complete on the 24th. Tests proceeded rapidly, first with Tournapulls exerting wheel loads of 5,000, 10,000, 25,000, and 40,000 pounds and then with a B-24 Liberator bomber, provided by Colonel Colonna. By early April the experiment had shown that the extrapolated curves were fairly accurate and that allowable deflection was in hundredths rather than in tenths of an inch. Further confirmation came from Dothan, Corpus Christi, Fargo, and Lewistown.44 Asked later if Stockton and the other tests produced any surprises, Porter smiled and said, “Not for me they didn’t, but for thousands of engineers they did.”45

On a Monday morning early in April, Porter faced a skeptical group, the senior

soils men of the engineer divisions who had come to Sacramento for a 5-day course in the California method. After giving them an illustrated talk on highway failures, he showed them through his laboratory. That afternoon the class looked on as he demonstrated the CBR test. He wet a sample of soil, compacted it in a cylindrical mold, forced a piston into the soil, and measured the load required. Expressed as a percentage of the load required to penetrate crushed stone, this measurement was the CBR value of the compacted sample. Next, he placed the specimen in a tank of water to soak for four days, explaining that the saturated sample would simulate the worst condition that could develop under a pavement. A second penetration test would give its bearing value. Practice sessions in the laboratory, lectures on soil sampling and boring techniques, a tour of the Stockton test site, and a buffet supper at Porter’s ranch were packed into the next three days. At a meeting Thursday evening, the students challenged the professor. The discussion went on far into the night and continued the following day. Styling himself the “principal objector,” Philippe afterward explained his stand. “Engineering starts with theory,” he declared, and the California method had no foundation whatever in theory. “You stuck a plunger in a hunk of soil,” he said of the bearing test. In reply to his critics Porter pointed out, “We are not contending that this tentative design is accurate, but that it is the simplest and most practical method now available.” Middlebrooks, who had flown out from Washington to help wind up the course, took the same line as Porter. Relaying Stratton’s orders, he told the men to return to their divisions and teach their district soils groups the California method.46

The news from Sacramento created quite a stir in professional circles. Passed by word of mouth, reports of the meeting produced raised eyebrows and sharp demurrers. Professors, researchers, and state highway officials were frankly dubious. Most foundations experts took a “wait-and-see” attitude. The Air Corps’ Buildings and Grounds Division was “inclined to be skeptical,”47 and the Navy’s Bureau of Yards and Docks was openly opposed.48 Critical remarks were aimed at Porter, who heard himself described as “that guy who wants a base course halfway up the door.”49 Some engineers likened his method to the technique of the ancients, who determined the weight a bridge could bear by loading it to failure. Probably the most strenuous objections came from the Asphalt Institute. At several conferences with Middlebrooks and Bertram, institute representatives argued unsuccessfully for thicker asphalt pavements and thinner base courses than Porter prescribed.50 All those who challenged the Corps’ approach received the assurance: “It has never been the policy of the Engineer Department to standardize to the extent that research and development would be stifled and

Conference at Stockton test track, California

Front row (left to right): Col. Henry C. Wolfe, Harald M. Westergaard, Philip C. Rutledge. Back row (left to right): Arthur Casagrande, Thomas A. Middlebrooks, James L. Land, 0. James Porter.

we don’t want to do that now.”51 Research contracts with Harvard and MIT testified to the Corps’ interest in developing a rationale.52 But to evolve a theory might take years. CBR was available and workable, and Stratton intended to use it. Tests at Stockton would continue, and a chapter on flexible design soon to appear in the Engineering Manual would set the Corps’ seal of approval on the California method.

While he pushed research on flexible pavements, Stratton tried to invigorate the whole investigative effort. During the spring of 1942, he reshuffled his organization, reinforced his staff, and called in distinguished advisers. McFadden replaced Kemp, who was anxious to return to his post with the D.C. government. Lines of responsibility, heretofore vague, were sharply defined. All paving, drainage, and turfing problems were assigned to a runways unit under Land; and all foundations engineering, to a soil mechanics unit under Middlebrooks, who along with Bertram formally transferred from civil works to

military construction. More experts were recruited. Thomas B. Pringle, a graduate of Virginia Polytechnic Institute who had recently formulized a 20-year highway development program for the state of West Virginia, became McFadden’s right-hand man. Dr. Monteith and another skilled agronomist, Dr. Frederick V. Grau, also accepted full-time positions with the Corps. Taking advantage of the decline in civil projects, Stratton brought two experienced soils men, Reuben M. Haines and D. Dana Leslie, from the New England Division to help lighten the load on Middlebrooks and Bertram. Appeals for top-flight consultants were answered by Dean Westergaard and Dr. Casagrande, who, with Mr. Porter, agreed to serve as McFadden’s advisory council. A high level of technical proficiency seemed assured. Colonel Stratton, as one of his brother officers remarked, had “assembled a bunch of damn good engineers.”53

Mindful of the stern necessity for speed, Stratton tried to vault technical hurdles several at a time. During the first half of 1942, he expanded the scope of his inquiries and stepped up the pace. Pressing the attack on runway problems, he ordered fresh investigations: deflection tests on an asphalt pavement at Bradley Field, Connecticut; accelerated traffic tests on a concrete apron at Godman Field, Kentucky, and on a concrete turnaround button at Northern Field, Camp Forrest, Tennessee; and elaborate experiments on specially designed sections to be built in Virginia and Louisiana.54 Making use of his new consultants, he sent Westergaard to Cincinnati to collaborate with Philippe and Bone and set Casagrande to work on a soils classification system for the Corps. Casagrande also took on a most important pedagogical mission, establishing a special school at Harvard for teaching soil mechanics to Engineer officers.55 Hailing the completion of Maxwell’s WES investigation, “the most comprehensive ever made on the load carrying capacity of drain pipe,” Stratton arranged for further tests on pipe at fields under construction.56 At the suggestion of highway engineers in the Southwest, he asked the Tulsa District to evaluate rock asphalt as a surfacing material.57 Meanwhile, he reminded all researchers of the primary goal—to get reliable criteria in the hands of project engineers and Engineer troop commanders at the earliest possible moment.

Week after work-crammed week, the hard-won facts accumulated. From bearing tests at Bradley and Wright Fields (the static loads applied ranged from 20 to 112.5 tons) and from traffic tests at Godman, Forrest, and Stockton (Tournapulls with wheel loads up to 53,000 pounds made a total of 33,000 passes at these three sites) came an impressive mass of data. From the Tulsa District, where Lt. Col. Bruce D. Rindlaub was coordinating experiments in eight states; from Harvard, where Professor Casagrande was reviewing the physical properties of soils; and from other sources throughout the country—federal

agencies, industrial research laboratories, state highway departments, and individual experts—came a wealth of useful information. Further confirmation of Westergaard’s basic analysis and a revised set of concrete thickness curves were major results of rigid pavement investigations. A new concept of pavement section design was another: because troughing disturbed subgrades and bases, the thickened edges favored by highway engineers were limited to longitudinal expansion joints and free sides; and because keyed joints were seldom properly installed, they were ruled out almost entirely. Fresh light on the problem of critical deflection and a clearer understanding of the effects of repetitive loads were significant gains in the flexible area. The question of landing impact was settled once and for all, when observations of the XB-19 verified the winglift theory. Meteorological studies, analyses of materials strengths, appraisals of compaction methods, reports on curing techniques, guidelines for classifying soils, and pointers on establishing and maintaining turf—contributions in many fields increased the fund of knowledge. A flurry of preliminary bulletins and circulars issued in the spring of 1942 quickened the already brisk demand for comprehensive manuals.58

A heavy task, the manual writing moved ahead with impressive speed. Under great pressure, three teams of experts toiled to digest a mountain of information and put it into usable form. One group, composed of Middlebrooks, Haines, Pringle, and Ricketts, tackled the complexities of pavement design; a second, consisting of Albert L. Cochran and Howard M. Williams, Hathaway’s chief assistants, focused on drainage; and a third, made up of Monteith and Grau, dealt with turf and other vegetation. The writers sweated over their assignments. “It was a big job,” Hathaway recalled.59 Pringle, a driving force in the whole endeavor, put in sixty hours a week or more at his desk and worked at home nights and Sundays. Colonel Stratton and his executive, Major Hill, also did a lot of homework, reviewing and editing draft manuscripts in their quarters after hours. These efforts were highly productive. Under ordinary circumstances, preparing a technical manual is a slow, deliberate process. Spurred by the war emergency, Stratton and his associates turned out ten publications in as many months. Together with special pamphlets on wearing courses, bituminous mixes, and concrete paving, they issued four basic texts—three new chapters in the Engineering Manual and a comprehensive handbook for Aviation Engineer Battalions.60

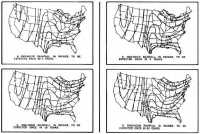

Of the supplements to the Engineering Manual, the chapter on airfield drainage was the most nearly definitive. Hailed as “a major contribution from the

science of hydrology to the advancement of both civil and military aviation,” it adapted a sizable body of specialized knowledge to a new purpose.61 Drawing on an extensive technical literature, including the notable works of Robert E. Horton, Wesley W. Horner, and David L. Yarnell, utilizing a mass of observational data collected by the Weather Bureau and by Hathaway himself, and applying the Corps’ long experience with flood control and river basin planning, the chapter introduced airport engineers to isohyetal maps, rainfall intensity-duration curves, design storm criteria, overland flow formulas, and infiltration theories. Ponding basins, small temporary reservoirs which would modulate surface runoff during torrential showers, were a striking innovation. Following Cochran and Williams’ instructions, an engineer would first select a design storm—a 2-year storm for an emergency landing strip or a l0-year storm for a major bomber base. (Chart 25) He would next compute infiltration losses, peak runoff, capacities of ponding basins, and capacities of drains. Only then would he design his storm drain system. Unless the site was boggy or the ground water table reached above the frost line, he would probably dispense with costly subsurface drains.62 So complete was the manual and so clear the text that even a novice could proceed with confidence. So reliable was the information and so solid the work that the chapter stood, unchanged, for the duration of the war and for many years thereafter.

The new chapter on airfield pavements was less authoritative. A signal achievement, the first important treatise of its kind, it nevertheless displayed certain weaknesses. Frost action, still largely unexplored, received only one page. The discussion of paving materials, based partly on studies in progress, was somewhat rudimentary. The section on rigid pavements, although it represented a major contribution to engineering science, left a number of problems unsolved, among them stress transfer and base course design. The section on flexible pavements bore the marks of expedience:– the paragraphs on test procedures and equipment were extracts from Porter’s writings; the prescribed method of compaction control was a hastily modified version of standard highway practice (plans for adopting the Proctor method had foundered because most Corps laboratories lacked necessary equipment); and the design curves for base and pavement thicknesses were labeled tentative.63 As the chapter came into use, an unexpected hitch developed. In Colonel Hill’s descriptive phrase, the CBR test “developed bugs, if not disease.”64

McFadden’s telephone rang repeatedly, as project engineers called in questions and complaints about the Manual. One man reported fantastic results from his running of the CBR test; another claimed he could get no results at all; a third discovered that instruments furnished by the Chief’s office were calibrated improperly. Many field men experienced maddening frustrations as they did their “damndest” to make CBR work

Chart 25: Design Storm Index

Source: Reproduced from Miscl. Pub. No. 204, U.S. Department of Agriculture, “Rainfall Intensity—Frequency data,” by David L. Yarrell, pages 41, 42 and 43.

on sandy or gravelly soils. A few questioned the curves for concrete thicknesses and called for fuller information on base course design. A request from one project or another for a visit by “Dad” Middlebrooks was an almost daily occurrence.65 Stemming from confusion, from the bewilderment caused by sudden innovations, most of these troubles soon cleared up. But some, which flowed from fundamental problems, were not easy to overcome.

To improve the method for designing flexible pavements was Stratton’s cardinal goal. Even before Porter ran his quick, rough tests at Stockton, plans were under way for more elaborate studies. In March 1942 Stratton picked two airfields, Langley in Virginia and Barksdale in Louisiana, as sites for traffic tests on specially built sections. Within six months he hoped to have the answers to several key questions. Were the tentative CBR curves right for black plastic clays, characteristic of the southern states? Would the California method work on hard-to-drain sandy silts, which were apt to become quick under stress? And, highly important, what standards should govern compaction?66 When completion of the test tracks lagged as war construction took priority over experimentation, Stratton asked Engineer districts to investigate all failures and furnish empirical data which would serve as a check on the extrapolated curves.67 When defects showed up in the CBR test, he directed the Waterways Experiment Station to make a step-by-step analysis of the procedure, a job WES director Matthes turned over to his Soils Division chief, Willard J. Turnbull.68 When Stratton heard that the flexible curves were conservative for pavements on sand, he launched investigations at Eglin Field, not far from Pensacola, Florida, and at Grenier Field in the Merrimack River Valley of New Hampshire.69 Meanwhile, mindful that cement was scarce in some localities and steel was short the nation over, he limited research on rigid pavements. Although he approved inclusion of two slabs in the Barksdale track, he postponed further large-scale tests on concrete.70

Flexible, not rigid, pavements were the agonizing problem. Criticism of CBR, harsh to begin with, grew more vehement as time went on. The strength of the opposition became apparent at a meeting of the Highway Research Board at St. Louis in December 1942. The reading of papers by Middlebrooks and Porter touched off a lively discussion, as commentators challenged concepts contained in the Engineering Manual. One man termed CBR half-baked and misleading; another called the thickness curves unrealistic; while a third warned that construction costs would be prohibitive. A group from the Asphalt Institute reportedly held an all-night strategy session at which they debated, and finally agreed to table, a motion to condemn the Corps procedure. Much of

the opposition to Porter’s ideas stemmed from misunderstanding: some engineers seemed to think that he was recommending a five-foot-thick base of crushed stone.71 And much of it was highly subjective:– after all, the Asphalt Institute was interested in selling asphalt, and here came a man who said: “Put a thin coat of asphalt on top of this ‘stuff’ and you’ve got it made.”72 Still there was a good chance that Porter could be wrong. Until the question was finally settled, flexible pavements would be Stratton’s chief concern.

To many a hard-pressed project engineer, the deliberations of the Highway Research Board were academic. Demands by air commanders for utmost speed, exerted with ever greater urgency as long-delayed expansion plans matured, created an unhappy situation. In the fall of 1942, near the end of the construction season, directives appeared for more than a hundred major air projects to be operational as soon as possible. Largest and most challenging of the new undertakings were several dozen bases for heavy bombardment training. Concentrated in the region of the Second Air Force, the northern Great Plains and the Pacific northwest, these bases ranged in size from a $1.7-million unit training center at Redmond, Oregon, to the huge $15-million airdrome at Mountain Home, Idaho. Protests greeted the decision to carry on construction through the harsh northern winter. Some officers suggested relocating the fields farther south, and some urged postponement until spring; but to no avail. At the Air Forces’ insistence, grading and paving operations went forward in the face of snow, sleet, heavy gales, and subzero temperatures.73 To men at the job sites, exhortations from the Chief’s office to employ “sound engineering practices” often seemed unrealistic.74 Most tried gamely to go by the Manual, but a number gave it up as a hopeless task. “In many cases,” an observer noted, “caution was thrown to the wind.”75

In the hope of averting gross mistakes, McFadden kept a troupe of troubleshooters on the road. So ceaseless were Porter’s travels that General Hannum proposed commissioning him a colonel in the Corps, a proposal vetoed by Reybold and Stratton on the grounds that under the Army system he could be transferred “God-knows-where.” The discomforts of transcontinental train trips were among Pringle’s vivid memories of this period. Middlebrooks, Haines, Leslie, and Ricketts also spent considerable time trekking back and forth across the country. At many projects, all was going well. At many others, a bit of sound advice was enough to set matters right. But occasionally the travelers uncovered egregious blunders. At three satellite fields in Montana—Cut Bank, Glasgow, and Lewistown—Porter learned that frozen materials had gone into the base course fill: spring thaws would surely take these airfields out. At a job in eastern Nebraska, Pringle watched, amazed, as

a gopher emerged from the freshly poured concrete, shook itself, and walked away: clearly, base compaction left something to be desired.76 Determined vigilance retrieved many errors but could not prevent all.

Not until 1943 did Stratton’s renewed assault on problems of flexible design begin to show results. Months of careful effort went into planning the experiments. The test track at Barksdale Field, the most elaborate to date, took nearly six months to design. More months were consumed in building the sections, procuring giant Tournapulls, and putting together teams of researchers. Precise and methodical, testing proceeded at a measured pace, as the big earthmovers crawled along, making thousands of passes over the pavements at speeds of 2 to 4 miles an hour. Halts were frequent. Couplings broke repeatedly. Bad weather intervened. From time to time traffic stopped, while measurements were taken and test tracks were repaired.77 By March 1943 test directors at Langley, Barksdale, and Eglin were coming through with their preliminary findings. Reports from minor traffic tests—at Beltsville, Maryland; Natchitoches, Louisiana; Richmond, Virginia; Santa Maria, California; and Manchester, New Hampshire—helped clarify the picture. The extrapolated curves were sufficiently close for all practical purposes. True, a few changes seemed in order—somewhat thicker bases on sandy silt and black clay and somewhat thinner ones on clean well-drained sand. But, by and large, assumptions were proving out. Moreover, the Proctor compaction method or something very like it, appeared to be essential.78 As new facts came to light, McFadden and Pringle brought the Engineering Manual up to date, and then sent the mass of investigative data to Vicksburg for further study.

By spring 1943, the Waterways Experiment Station was emerging as the leading center of flexible pavement research. Since the previous fall, when military airfields had replaced earth dams and embankments as his major mission, Soils Division chief Turnbull had struggled to keep abreast of a rapidly growing work load. Going over test reports, visiting project sites, programing future investigations, and hosting several large conferences on CBR, Turnbull put in 12 to 18 hours a day. When fresh assignments loomed ahead of him, he launched a vigorous recruitment drive. Raids on the district offices at Little Rock and Vicksburg netted two foundations experts, Charles R. Foster and William H. Jervis. An experienced highway engineer, John F. Redus, Jr., answered an appeal to the Mississippi state roads department. Journeying to North Dakota, Turnbull brought back W. Keith Boyd, a pioneer in flexible pavement design, to head the research effort. Working independently,

Boyd had recently completed hundreds of tests on soils under bituminous surfaces, using his own cone penetrometer to measure bearing strength. The results of his work, including extrapolated curves for single wheel loads up to 100,000 pounds, closely matched the CBR curves in the Engineering Manual. As his staff expanded, Turnbull asked the Chief to provide $100,000 for a building and more equipment. Granting the request in April 1943, Reybold named the new facility the Flexible Pavement Laboratory.79

Comfortably housed in its new brick building, the laboratory was a going concern by the late summer of 1943. With Turnbull’s help, Boyd quickly filled the spaces on his organization chart. Foster became his deputy. Dr. Philip C. Rutledge, a leading authority on soil mechanics and head of the department of civil engineering at Northwestern University, became his principal consultant. Bruce G. Marshall, whose recently invented machine for measuring asphalt stability was attracting wide interest, was a valuable addition to the staff. Before long the team numbered 25 persons and one working cat, a dedicated mouser who served as mascot. During the latter part of 1943, Boyd and his colleagues launched a long-range research program, which included laboratory and field investigations of base course design, compaction methods, moisture conditions under pavements, and many varieties of asphaltic surfaces.

In mid-1943, as the flexible pavement group at Vicksburg settled down to work, rigid pavements were, belatedly, receiving close attention. In recent months, failures had occurred at 20-odd newly completed airfields. As General Robins pointedly apprised Colonel Pick, the sorriest record belonged to the Missouri River Division, which muffed eleven important jobs.80 The runways at Cut Bank, Glasgow, and Lewistown failed so utterly when frost left the ground that the Air Forces abandoned the three bases, constructed at a total cost of $11 million. Five or six other fields in Pick’s division required extensive repairs. Runner-up for Robins’ booby prize was Colonel Neyland of the Southwestern Division, who had as many failures as Pick though none so serious. Most of the trouble, countrywide, was with flexible pavements; and much of it was traceable to hasty construction in wet or freezing weather.81 Given the size of the program, the necessity for speed, and the novelty of CBR, mistakes were bound to happen. Stratton took the flexible failures more or less in stride. But half a dozen rigid failures gave him pause. Virtually no one except Philippe and his associates at Mariemont had foreseen serious trouble with concrete.

Since the summer of 1942, Philippe had been calling for a comprehensive investigation into rigid design. As he studied reports of the Wright Field tests, he grew apprehensive. Starting from the

popular highway theory that no slab should be thicker than 8 inches (honeycombing and temperature warping would ruin slabs of greater thickness, this thinking ran), the Corps was relying on thin base courses to undergird rigid pavements.82 Philippe’s results indicated that such bases under concrete paid little benefit for the magnitude of loading involved. Twice he submitted research proposals to Washington, and twice he was turned down. Reflecting the position of most paving engineers, McFadden and Land dismissed Philippe’s concept as a “pet idea.”83 Stratton, also skeptical, challenged the concept on technical grounds. Even to Colonel Hall’s sympathetic eye, Philippe’s request for $47,000 appeared inopportune. Discussing the matter with Reybold in March 1943, Hall took an equivocal stand.

Beyond any question [he advised the Chief], the additional information secured will be worth $47,000 to the engineering profession and the aeronautical industry. Whether, in the present state of the Army’s construction program, it will be worth $47,000 to the war effort is a matter which the Division Engineer does not feel justified in attempting to settle.84

Not until a few rigid pavements failed did the picture alter. Then, Middlebrooks, who had Robins’ ear, intervened decisively. By summer Philippe had $150,000 to spend for research.85

As Philippe made plans for an elaborate test track at Lockbourne Field, the Engineers were winding up major air force construction in the United States. By the spring of 1943, General Robins could point to more than 1,100 military and civil airports completed under his direction. In a commendatory letter to the Chief of Engineers, General Arnold expressed his “keen appreciation” for the “fine support” given the Army Air Forces. Commenting on the vast size and complexity of the undertaking, Arnold noted that the program had “been prosecuted with outstanding efficiency and dispatch.”86 Equally gratifying to the Engineers was the boast of Maj. Gen. Davenport Johnson: “The Second Air Force has some of the finest airfields in the world.”87 From his headquarters at Spokane, Washington, Johnson would oversee the training of combat crews for very heavy bombers. After a series of reverses, the XB-29 passed its final flight tests in June 1943, and in July Boeing delivered 7 planes, the first of more than 3,700 Superforts to be produced before V-J Day. Commenced in the fall of 1943 at 4 fields near Salina, Kansas, the training of very heavy bombardment groups expanded to take in operations at 40 major airbases by the late spring of 1945.88 The advent of the B-29, the biggest bomber employed by the United States in World War II, ushered in a new phase of air force-engineer collaboration.

Danger signals flashed by air commanders in the summer of 1943 launched the Corps on a large undertaking. Early in June, Maj. Gen. Barton K. Yount of

the Air Training Command complained to Arnold that fields in his command did not perform as advertised; some did better and some, worse; which could take B-29s was any man’s guess.89 Other air force generals voiced similar complaints:– runways designed for Superfortresses were going to pieces under lighter planes, and pavements intended for medium bombers were standing the test of heavies. The explanation was not hard to find. As McFadden pointed out, war construction was a “hurry-up job,” and “in many cases the progress chart took precedence over engineering judgment.” Hence, design strength and actual strength were seldom equivalent.90 The question was not whom to blame but how to get out of the predicament. Concerned about the Corps’ good name, General Hannum gave the matter careful thought. Fully loaded, the new B-29s weighed 140,000 pounds, 20,000 more than originally anticipated. No airfield in the country was designed to withstand a gross load of more than 120,000 pounds. Moreover, inexperienced pilots were landing heavy planes on any blacktop surface that looked to be safe. Visualizing fatal crack-ups and damaged runways, Hannum urged the Chief to determine the actual load-carrying capacity of all military airfields, and, when necessary, to reinforce them.91

Having seen the crisis coming, Stratton’s advisers were prepared to meet it. Ready with a plan for gaging actual strength of paved surfaces, Pringle quickly drafted a directive. Issued on 5 August 1943, this order set forth procedures and priorities. Using CBR for flexible and plate bearing tests for rigid pavements, each division engineer would evaluate the load-carrying capacity of pavements within his jurisdiction. How much punishment could a given airstrip take? Where could the training of B-29 groups continue year in and year out? Where could very heavy bombers land occasionally? Although fields intended for Superfortresses would come first, every military airport would eventually receive a rating based on the strength of its principal runway. Knowing that many pavements would require “beefing up,” McFadden took a cue from highway engineers, who frequently used overlays (asphalt “retreads” and “second-story” slabs) to strengthen roads. Prescribing the same treatment for runways, taxiways, and aprons, he nevertheless reminded Stratton that highway experience was no sure criterion for airfield design: only through research could the Corps develop sound techniques. While McFadden blocked out an investigative program, Pringle took charge of the evaluation project. By mid-1944 the Air Forces Installations Directory listed the strength of runways at more than 600 airports, and scientists from the University of California, under contract to the Corps, were experimenting with overlays at Hamilton Field.92

As Superfortress groups began training

near Salina in the fall of 1943, the course of the war was shaping their strategic mission and future logistical needs. Long-awaited and eagerly sought by air commanders in all theaters, the B-29 appeared after the tide in Europe had turned. Enemy forces in North Africa had met defeat. Italy had capitulated. Hitler’s invasion of Russia was ending in disaster. And Allied plans were firming up for the big cross-Channel operation in mid-1944. Meantime, the British-American bomber offensive against Festung Europa was gathering momentum. Bremen, Hamburg, Hannover, Frankfurt—one by one the great German cities were undergoing devastating raids. After a mass attack by B-17s on Polish and East Prussian targets in October 1943, Prime Minister Churchill confidently declared: “We shall, together, inexorably beat the life out of industrial Germany and thus hasten the day of final victory.”93 On the other side of the globe, in the far Pacific, industrial Nippon was virtually unscathed and the day of Allied victory seemed far distant. The roads to Tokyo stretched thousands of miles, through hostile seas and past concentric barriers of island strongholds or through the difficult terrain and enemy-occupied areas of the Asiatic mainland. Offensives under way in the Southwest and Central Pacific were little more than preliminary thrusts, aimed at attaining a position of readiness for the eventual full-scale assault on Japan. And much of the activity in the China-Burma-India Theater was directed toward keeping the Chinese in the war. By bringing the Japanese home islands within bombing range, the Superfortress made possible a more aggressive strategy. Committing the new weapon to the Pacific war, President Roosevelt decreed that missions would be flown first from China and later, when footholds were secured in the Western Pacific, from island bases nearer Japan.94 In these remote and backward areas, engineers would have to provide airdromes for the giant planes.

On a sultry evening in August 1943, six men gathered at the Washington-Youree Hotel in Shreveport, Louisiana, to consider how to accomplish the task. Five of the perspiring conferees were civilians: McFadden, Middlebrooks, and Haines had come from Washington, Philippe from Mariemont, and Turnbull from Vicksburg. The sixth man was Capt. George E. Bertram, since September 1942 an officer on the staff of the Air Engineer, Brig. Gen. Stuart C. Godfrey. Disclosing plans for stationing B-29s in India and staging them from advance fields in China, Bertram previewed the tough construction job ahead. He traced the thin supply line halfway around the world and beyond the peaks of the Himalayas, and he pictured the slim local resources—coolie labor, primitive tools, and low-grade materials. At Godfrey’s request, Stratton had promised to help find ways of cutting through these obstacles. A revolutionary feature of the new bomber—its dual wheel landing gear—might offer a partial solution. Adopted by Boeing at the Corps’ suggestion, this wheel design would, in theory, distribute the weight more widely and thus reduce the load on airfield surfaces. Growing out of the Shreveport

meeting was a fresh investigative program launched at Marietta, Georgia, in the fall of 1943. Near the big B-29 assembly plant recently completed by the Corps, Turnbull and Boyd laid out a test section composed of types of pavement never before considered for very heavy bombers—old fashioned, handset telford stone, water bound macadam, and sand-clay and sand-asphalt bases, surfaced with bitumen or pierced steel planking; and they made plans for experiments with single-wheel B-24s and dual-wheel B-29s. As construction crews finished work, test director John M. Griffith tackled what proved to be an ulcer-producing task: providing blueprints for the fields overseas and plotting design curves for dual wheels.95

Marietta exemplified the Engineer Department’s deepening involvement with airdrome construction overseas. At the Waterways Experiment Station, Turnbull and his colleagues enlarged the scope of their investigations to include problems of theater engineers. Across the Mississippi River at WES’s Mound (Louisiana) test site, field men conducted studies of base course requirements under landing mat and experimented with a new type of temporary surfacing—burlap, duck, or osnaburg fabric impregnated with bitumen and laid down by a novel machine called a “stamplicker.” At the Flexible Pavement Laboratory, inventor Bruce G. Marshall remodeled his asphalt stability machine for use by troops in designing paving mixtures. In the Chief’s office, Hathaway’s group assembled data on rainfall rates in prospective battle zones, while McFadden’s staff updated the manual for Aviation Engineers and prepared reports for the Joint Chiefs of Staff on the bomber base potentialities of various Pacific islands.96 Meantime, demands from the theaters for expert soils men were answered by longtime Corps civilians, of whom perhaps the most outstanding were Spencer J. Buchanan of the Mississippi River Commission and Waldo I. Kenerson of the South Atlantic Division. Both Buchanan and Kenerson achieved distinguished records, the former in the Southwest Pacific, and the latter in China.

An important contributor to the winning of the air war was the Army Soils Control School at Harvard University. Sponsored by the Corps, the school was the brainchild of Professor Casagrande. As a consultant on airfield design during the spring of 1942, Casagrande realized that the Army needed men trained in soils engineering. His offer to establish a 6-week course for officers was snapped up by the Chief. The first class of 24 newly commissioned lieutenants reported at Harvard’s Pierce Hall on Friday, 3 July. Monday morning they began a rapid but intensive survey of soil mechanics and related subjects. The faculty included the top men in the field, Casagrande and Terzaghi. The students were enthusiastic. The schedule was well planned; laboratory sessions, field trips, and lectures by outside experts supplemented classroom work. Rated a

success by all concerned, the course was given repeatedly until mid-1944. As Aviation Engineers, the 400 graduates made good use of their knowledge at airfield projects around the world.97