Chapter 20: Atomic Mission

At a quarter of eleven on the morning of 6 August 1945, the White House solemnly announced: “Sixteen hours ago an American airplane dropped one bomb on Hiroshima, an important Japanese Army base.” More powerful than 20,000 tons of TNT, the bomb was an atomic bomb capable of wiping out whole cities.1 The statement produced a general sensation. A wave of exultation swept the United States: the war was practically over; the boys would soon be home. In London, where the story eclipsed all other news, a reporter noted: “The world has changed overnight.”2 Aboard the cruiser Augusta, on his way back from the Potsdam Conference, President Truman told a throng of cheering sailors: “This is the greatest thing in history.”3 Altering the course of civilization and opening a new era in the life of mankind, the release of atomic energy was a titanic task. Its achievement was a triumph for scientists, industrialists, and engineers.

As Hiroshima lay silent beneath a pall of smoke and dust and the world marveled at the scientific feat, the public learned about the Manhattan Engineer District: its hidden cities, secret plants, and secluded laboratories; its extraordinary size and scope; and its $2-billion expenditure. Early radio broadcasts told where the powerful new explosives originated—at the Clinton Engineer Works in Tennessee and the Hanford Engineer Works in the State of Washington.4 Newspaper tributes to the genius of the bomb’s developer, Dr. J. Robert Oppenheimer, appeared side by side with tributes to the driving force of the “atom general,” Maj. Gen. Leslie R. Groves of the Corps of Engineers. References to other prominent Engineer officers—Reybold, Styer, Robins, and Farrell—found their way into dispatches; and Nobel laureates in physics shared the limelight with hitherto obscure Engineer colonels.5 The castle emblem of the Corps was coupled inseparably to the armillary symbol of the atom. Yet many people at the time failed to understand fully why the castle was so prominently displayed. In the two decades that followed, many scholars also failed.

The bomb was the product of a remarkable set of circumstances. First, and basic, was the industrial power of the nation: the huge concentrations of capital goods and the great fund of

Brig. Gen. James C. Marshall (photograph taken in 1946)

technical and managerial skills capable of sustaining tremendous emergency burdens. A circumstance just as vital to the realization of the weapon was the presence in the United States of a group of brilliant scientists, a number of them refugees from Europe, working feverishly against time to beat the Germans in harnessing atomic energy. But fully as essential as any other factor was the existence of a Corps of Engineers, trained and tested in large-scale construction undertakings. It was this established, knowledgeable Engineer organization, ready and at hand as an integral part of the Army, which provided indispensable leadership and support. The devastation of Hiroshima, followed three days later by the dropping of a second atomic bomb on Nagasaki, proclaimed the success of a three-year project unique in engineering annals.

MED: Origins and Early Efforts

A summons from the Chief to Col. James C. Marshall, on 17 June 1942, set the project going. District engineer at Syracuse, New York, Marshall was an esteemed member of the Corps. A 1918 West Point graduate, he had had a well-rounded career: duty with troops in France and Panama; service with the New York, Puerto Rico, and Binghamton Districts; study at the Engineer School and the Command and General Staff College; four years as an instructor at the Military Academy; three years with the Engineer Board at Fort Belvoir; two years as head of the New York State Barge Canal Improvement; and a tour in the Civil Works Division, OCE. Over the years he had built a reputation as a good executive, sound engineer, and gifted organizer. A polished and gracious man known to subordinates as “Gentleman Jim,” an officer who coupled firmness with tact, he was a leader rather than a driver. His record at Syracuse spoke well for his methods. Responsible for a $250-million civil-military program; including a dozen major war construction projects, he could report virtually all jobs on or ahead of schedule in June 1942. Reybold’s message to him bore the stamp of urgency. Checking with key assistants and making several long-distance telephone calls, he got important matters squared away. By midnight he was en route to Washington.6

Twenty-four hours later, in a room at the Willard Hotel, Marshall sat, taut

and weary, puzzling over the contents of a folder labeled “S-1.” He had had a strenuous day: an all-night drive to New York City; an early morning conference with Colonel Dunn, the Division Engineer; an American Airlines flight to Washington; a serious talk with General Styer at the Munitions Building; and, finally, a grave session with Robins and Groves at the Chief’s office. The S-1 folder belonged to Styer, who had handed it over with the explanation that Marshall had a new job: to form an Engineer district and construct plants for atomic fission bombs. Abstruse and baffling, Styer’s papers mentioned several of the country’s leading scientists; revealed the enormous destructive potential of a rare uranium isotope, U-235, and of a recently discovered transuranic element, plutonium; outlined four possible methods of achieving quantity production of one or the other of these fissionable materials; and put the cost of the entire program at roughly $90,000,000. “I spent the night without sleep trying to figure out what this was all about,” Marshall afterward related. “I had never heard of atomic fission, but I did know that you could not build much of a plant, much less four of them, for $90,000,000. “7

The next day Marshall gained a clearer understanding of his mission. From talks with General Styer and Dr. Vannevar Bush, who headed the Office of Scientific Research and Development (OSRD), and from documents they showed him, he learned the outline of the story: the German discovery late in 1938 that the uranium atom could be split and the impact of this news on the world of physics; the eager activity at American universities—the spurt of theoretical speculation about chain reactions, atomic power, and atomic bombs and the unaided struggle for experimental proof; Albert Einstein’s letter to Roosevelt, which brought Uncle Sam into the enterprise in the fall of 1939; and the nuclear research or S-1 program carried forward under government auspices since that time. He learned, moreover, where the program stood. By the spring of 1942, the fact was plain: atomic bombs might be possible. S-1 scientists claimed to know in principle how to make the bomb stuff; in fact it seemed that they might be able to turn the trick several ways, separating U-235 from the far more abundant isotope U-238 by electromagnetic, gaseous diffusion, or centrifugal methods, and producing plutonium by bombarding natural uranium with neutrons. So far, however, none of these processes had advanced beyond preliminary laboratory stages; none had proved superior to the rest; and none had yielded as much as a microgram, though kilograms were needed to make bombs.8 Marshall’s task was unprecedented: from laboratory instruments to huge industrial

Colonel Nichols

plants, from invisible, barely weighable “bits of nothing” to bulk lots of material a billion times as large—no engineer in history had attempted such a scale-up. Back in 1918, when Marshall was a shavetail, the Corps had flaunted the breezy motto: “It can’t be done: but here it is!—U.S. Engineers.” This time, obviously, the “impossible” would take longer. But it must not take too long. What Americans could do, Germans could conceivably do also.

Sensing the urgency of the job, Marshall made every day count. During his first week as Engineer of the still nameless district, he conferred with more than a dozen people, traveled more than a thousand miles, blocked out a course of action, and started organizing. After going over Dr. Bush’s somewhat nebulous construction plans for a plutonium pilot plant and experiment station near Chicago, a heavy water production unit at Trail, British Columbia, and a giant industrial complex in the Tennessee Valley, he began exploring the priorities and power angles and laying the groundwork for bringing in Stone & Webster as overall AEM. On learning that OSRD was hard up for money, he arranged to tap the Corps construction funds. At the Chief’s suggestion, he opened temporary headquarters in the New War Building and commenced lining up personnel. Customarily, new districts drew their cadres from older elements of the Engineer Department; and, occasionally, a single well-established district served as sponsor for one just coming into being. Familiar with the able and experienced staff at Syracuse and knowing that the workload there soon would taper off, Marshall looked to his old bailiwick for recruits. On the 19th he chose as his deputy the area engineer at the Pennsylvania Ordnance Works, Lt. Col. Kenneth D. Nichols, a 34-year-old West Pointer whose background included several tours at the Waterways Experiment Station, canal survey work in Nicaragua, and four years as an instructor at the Military Academy. Described by associates as a scholarly type, Nichols had studied at the Technische Hochschule in Berlin and had earned two advanced degrees, an M.C.E. from Cornell and a Ph.D. from the State University of Iowa. On a weekend trip to Syracuse, Marshall also signed up Virginia J. Olsson, his attractive and efficient secretary, Charles Vanden Bulck, his resourceful administrative assistant, and Capt. Robert C. Blair, a capable civil engineer and one of the ninety-odd Syracuse Reservists on active duty with the Corps. Looking to the

future, Marshall made plans to “rob” the district systematically later on.9

Manhattan, he decided, would make an ideal headquarters. At first General Reybold was utterly opposed. “We will have it right here in Foggy Bottom,” he said. Determined not to place himself “under the gun” in OCE, Marshall stood his ground. The New War Building was already overcrowded, while at 270 Broadway Colonel Dunn had lots of room available. Stone & Webster’s main offices were in New York and Boston. You could get to Chicago or Tennessee just as easily from New York as from Washington. Besides, if you were looking for a place to hide, what better place was there than a big city. “We had quite an argument,” Marshall related; but at length, Reybold gave in.10 The issue was settled for the time being, although not for good.

At the Carnegie Institution in Washington on 25 June, Marshall and Nichols had their first get-together with Dr. Bush’s scientific colleagues, the S-l Executive Committee, OSRD. It was an eye-opening experience. Seated at the conference table in Bush’s office was a distinguished group: Dr. James B. Conant, President of Harvard, the committee chairman; Dr. Lyman J. Briggs, director of the National Bureau of Standards; Dr. Eger V. Murphree, vice president of the Standard Oil Development Company; and three of the country’s scientific greats, all Nobel laureates, Dr. Arthur H. Compton of Chicago University, Dr. Ernest O. Lawrence of California, and Dr. Harold C. Urey of Columbia. Getting down to business with these men, the Engineers discovered that nobody knew “just where we were.”11 Of the four bomb stuff processes, only electromagnetic separation, Professor Lawrence’s baby, was anywhere near ready even for preliminary engineering development. Supplies of uranium and other vital materials were inadequate even for research, much less for production. No one as yet had a clear concept of what Marshall was to build. Nevertheless, all the scientists save Lawrence, who wanted a location close to his Berkeley laboratory, were anxious to acquire a large tract west of Knoxville as the main manufacturing site. After two sessions with the committee, Marshall agreed to go ahead, signing up contractors, procuring supplies, acquiring land, and using every available means to move the project forward.12

He made a promising start. A conclave with the Chief and his principal advisers set the Corps machinery in motion. Reybold and Robins gave the signal for “all out support from the Engineer Department at Large.”13 Groves offered to assist in every way he could. Stratton made available site planner Leon Zach, power specialist Carl H. Giroux, and water supply expert Ray E. Lawrence as consultants. Colonel Gesler in the Fiscal Branch agreed to track down funds. Colonel O’Brien in Real Estate promised swift action on land

acquisition. Colonel Hall in Cincinnati and Colonel Worsham in Chicago alerted their division staffs to stand by for site directives. In Manhattan, Colonel Dunn rented space for the new district downstairs from North Atlantic Division headquarters and placed his organization at Marshall’s disposal. Talks with Dr. Compton and other scientists clarified plans for leasing a thousand-acre tract in the Argonne Forest southwest of Chicago and building a plutonium pilot plant there and for subletting part of the heavy water plant at Trail to E. B. Badger & Sons of Boston. An all-day negotiating session on 29 June produced a letter contract with Stone & Webster. A visit next morning to General Clay had encouraging results: a friend and classmate of Marshall, Clay agreed to help obtain a high priority rating and to use his good offices in breaking procurement bottlenecks. At this point, Marshall and Nichols confronted a major decision—choice of the main manufacturing site. On the afternoon of the 30th, after a last-minute chat with Groves, they took the 5 o’clock train for Knoxville.14

Early the next morning they checked in at the Hotel Andrew Johnson, where they met four Stone & Webster men and Captain Blair. After a briefing by officials of the Tennessee Valley Authority (TVA), the party spent the better part of two days exploring the foothills of the Cumberlands west of Knoxville, looking for a spot that met their requirements:– power, water, transportation, and special topography—“four isolated sites in one big isolated site,” as Marshall put it.15 Scouts for OSRD had been over the ground earlier and had sent back glowing reports. But, like all professional engineers, Marshall wished to be on the safe side. Jouncing over back country roads around Harriman, Dayton, and Athens, he ruled out several locales. One site was too rugged, another too remote, a third subject to flooding. Then, along the Clinch River southwest of the little town of Clinton and a few miles downstream from Norris Dam, he found it astride Roane and Anderson Counties—a hundred-square-mile rectangle of marginal farmland with a washboard terrain, an area of wooded ridges and lonely hollows. The population was sparse and real estate values were low. Watts Bar Reservoir was fairly close, and two railroads, the Louisville & Nashville and the Southern, ran nearby. There were some drawbacks, to be sure:– outcroppings of rock foretold costly excavations; and TVA could promise adequate power only if it could procure additional hard-to-get generators. Somewhere, no doubt, there was a better location, perhaps in the Columbia River Valley near the Corps’ own Bonneville Dam. Yet, on the whole, Clinton seemed a reasonably good choice.16 Marshall headed back East, full of plans and purpose.

Nichols and Blair continued on to the Metallurgical Laboratory, the cryptically named center for plutonium studies at the University of Chicago. In two days there, they covered a lot of ground. Conferring with Dr. Compton and his

colleagues, they learned what the “Met Lab” was up against. Organized early in 1942 under Compton’s direction, a team of eminent researchers was seeking a way to transmute uranium into plutonium on a large scale as quickly as humanly possible. Key to the success of this endeavor were the experiments of Enrico Fermi, the gifted Italian Nobel laureate who had fled Fascist tyranny in 1939. With uranium oxide and graphite, Fermi was struggling to build a chain reacting “pile.” Theoretically, the pile would go critical when it reached a certain size, that is, it would chain react and in the process produce plutonium within the parent uranium. Chemistry would do the rest. “Any fool can separate two elements,” Compton assured the Engineers.17 But the theory of the pile still lacked a demonstration. Shortages of pure materials hampered Fermi’s efforts. Moreover, he needed space; the University was crowded and, besides, the populous south side of Chicago was no place to be tinkering with chain reactions. Shouldering responsibility, Nichols marked out boundaries for the experiment station site in the Argonne Forest, arranged for Worsham to lease the land rent free from Cook County, and sketched preliminary construction plans for Stone & Webster.18 He also took on the duty of providing wanted supplies. Most important, he got off on the right foot with Met Lab leaders. Describing what proved to be a happy and fruitful relationship, Compton later portrayed Nichols as “straightforward and courageous,” “a man who really understood” the scientists’ problems.19

Rejoining Marshall in Washington, Nichols and Blair were caught up in a surge of activity: working with Stone & Webster to tie together myriad loose ends (a detailed survey of the Tennessee site stood high on the agenda); insuring vital supplies of uranium ore (on orders from the Chief, Engineers in northwestern Canada sent barges to the Eldorado mine, near the Arctic Circle on Great Bear Lake); negotiating contracts for purified uranium oxide and uranium metal (the producers were the Mallinckrodt Chemical Works, Metal Hydrides, and Westinghouse Electric); planning a village for the main industrial site (Stratton’s files yielded blueprints developed by the Corps for family housing at Ocala, Florida, and Passamaquoddy, Maine); furnishing the New York office and establishing a protective security system there (Vanden Bulck, with help from Colonel Dunn, quickly accomplished the job); pursuing a scheme to substitute silver for critically short copper in Professor Lawrence’s process (thousands of tons of conductive metal would go into the giant coils and busbars); trying to think of a suitable cover name for the project (Somervell’s suggestion, “DSM” for Development of Substitute Materials, satisfied virtually no one); and preparing a table of organization (Marshall expected to have 62 officers under his command by the end of the year).20 For a time at least, all went well.

Then, in mid-July, the project received a setback: assignment of an AA-3 priority. To Marshall and Nichols, the news seemed incredible; surely, the S-1 effort rated higher than the Pennsylvania Ordnance Plant. But a talk with Clay convinced them that there had been no mistake. The atomic bomb was a long shot. Gambling on it too heavily might risk losing the war. Extremely urgent programs—airplanes, naval vessels, cargo ships, landing craft, synthetic rubber, and high-octane gasoline—were in desperate conflict for materials. Only essential weapons slated for early production could claim AA-1 and AA-2 priorities. The special triple-A rating was reserved for breaking bottlenecks. Under ANMB rules, AA-3 was the highest possible classification for plant construction jobs. Clay saw no reason for making an exception of DSM; in fact, he discouraged any move to upgrade the project. Deeply disappointed, Nichols consulted Reybold, who gave him this advice: let the issue ride awhile, wait for trouble to appear, and, then, launch a determined drive for top priority.21

If Marshall was downcast, his mood soon changed. Visiting the Radiation Laboratory of Professor Lawrence in the third week of July, he felt his spirits rise. High on a hill overlooking the Berkeley campus and San Francisco Bay, in a newly built domed structure, a mighty “calutron,” a scaled-up adaptation of the California physicist’s original cyclotron, was taking form. Its magnet, the world’s largest, measured 184 inches in diameter and towered 20 feet above the floor. A C-shaped vacuum tank occupied the 72-inch pole gap. Enthusiastic and confident, Lawrence explained to Marshall how the apparatus would work: in the strong magnetic field, ions of uranium gas zipping through the vacuum at tremendous speeds would tend to separate according to mass, heavier particles describing longer arcs than lighter ones, and U-238 and U-235 ending up in different receptacles. Two smaller calutrons were already in operation. To be sure, their yield was minuscule and their product was highly impure; nevertheless, they were getting tangible results. A mass production plant patterned on this method would be extremely large and costly, but it would almost certainly succeed. When Lawrence spoke of trying to improve the process to effect economies, Marshall told him to “quit worrying about expense”—the Army would pay the tab. Summoning representatives of Stone & Webster, the colonel put them to work with the Berkeley scientists on preliminary plant designs. Encouraged, he noted in his diary: “Lawrence’s method is ahead of the other three methods and should be exploited to the fullest extent without delay.”22

Immediately upon his return to Washington, he asked for a gross appraisal of the Clinton site. O’Brien promised a rough estimate “about the middle of next week” and he was as good as his word. On 29 July he gave Marshall a cost breakdown. Eighty thousand acres at $30 per acre, plus improvements, crops, severance damages, and contingencies—the figures added up to approximately $4 million. Obtaining

right-of-entry would take about ten days. Colonel Hall’s real estate men were ready to start at once, but Marshall delayed giving them a green light until he could pin down the S-1 Executive Committee. Lawrence was insisting on a West Coast site for the big electromagnetic plant. Fermi’s crucial experiment at Chicago was still months away. Gaseous diffusion and centrifugal separation had only theoretical feasibility. Before he laid out millions in public funds and uprooted hundreds of families, Marshall intended to have a fixed purpose in view.23 The scientists wanted the Tennessee tract but could not say, specifically, what for. Recalling his ordeals with them, Marshall said: “When you get six or seven Ph.D.’s and three or four Nobel Prize winners around the table, you know, they are up in the clouds.” Impatient, he told them “that if they didn’t hurry up and make up their minds what they wanted to develop, we might not need a site; the war would be over.” His sarcasm had no discernible effect.24

A darkening cloud of uncertainty overhung the project. Striving for an early start at Trail, Badger & Sons ran into trouble as work on components for the heavy water process stalled, while shops completed longer standing orders with the same AA-3 priority. Badger’s case had disturbing implications, for, although Trail would be an auxiliary plant (its product was a possible substitute for graphite in the pile), its plight augured ill success for the whole atomic undertaking. Again and again, Marshall and Nichols tried and failed to wring a higher overall priority from General Clay and, through Bush and Conant, to enlist Donald Nelson’s aid. Without full top-level support, all the projected plants could not be built in time to be of value in the war; and no such support was immediately forthcoming. Sensing that they might have to focus on a single process, the Conant committee deliberated, refusing to go all-out on Lawrence’s method until Fermi’s experimental results were in.25 As planning bogged down in a morass of scientific indecision, Marshall endeavored to make headway in other areas.

Moving to Manhattan, he began shaping his command. By early August staffing was in full swing. A dozen officers in the Syracuse District were awaiting orders to join their former chief and various hand-picked civilians were preparing to take commissions in the Corps. A versatile group formed the nucleus of the new district. Among the men drawn from Syracuse were Lt. Col. John M. Harman, a Regular with 24 years’ service; Maj. Thomas T. Crenshaw and Capt. Joseph F. Sally, both successful area engineers on big emergency projects; Capt. James F. Grafton, a crack operations man who had overseen construction of the Whitney Point Dam near Binghamton, N.Y.; Capt. Benjamin K. Hough, Jr., a keen-minded soils engineer who had studied under Terzaghi at MIT; and 1st Lt. Harold A. Fidler, a young D.Sc. from MIT who had worked with Hough at

the Ithaca Soils Laboratory. The search for talent extended well beyond the Mohawk and Susquehanna watersheds. With assists from General Reybold and William H. Harrison, Marshall was able to recruit Wilbur E. Kelley, senior engineer for the Panama Canal, and Allan C. Johnson, a highly trained architect on loan to WPB from the American Telephone and Telegraph Company, and to make them both captains in the Corps. Another valuable find was Capt. John R. Ruhoff, the Mallinckrodt Company’s brilliant young director of inorganic research, recently called to duty with the Chemical Warfare Service and shortly to be transferred to the Engineers. As the ranks started to swell, Marshall moved to place the organization on a firm footing.

On 16 August 1942 General Reybold formally established the Manhattan Engineer District (MED).26 Selected by Groves and Marshall, the tag word “Manhattan” provided an effective cover, since ordinary Engineer districts took the names of their headquarters cities. Judged by Corps standards, the new super-secret setup was unusual. Unlike other districts, MED had no geographic boundaries and its areas were far apart: at Boston, Chicago, St. Louis, Berkeley, and Trail. Alone among district heads, Colonel Marshall had the authority of a division engineer and reported directly to the Chief. Another peculiar feature was the Washington Liaison Office, opened on the sixth floor of the New War Building to ensure concerted action with WPB, SOS, and other high-level agencies. Carefully matching men and duties, Marshall appointed Harman his administrative officer, put Kelley in charge of engineering, and gave Johnson the Washington assignment. In addition, he sent Crenshaw and Fidler to the Radiation Laboratory, Grafton to the Met Lab, Hough to Stone & Webster’s hometown, Boston, and Sally to British Columbia. As head of the St. Louis office, Ruhoff carried on his vital work at the Mallinckrodt plant.27 Still small but growing steadily, the Manhattan District was a going organization by late August.

After reading the first progress report from MED on 26 August, Reybold expressed his satisfaction with the project. Since mid-June the atomic program had come a long way. At Berkeley, Stone & Webster had completed blueprints for an electromagnetic pilot and construction was all set to go. At Chicago a Met Lab building was rising on the University campus and survey crews were busy at the Argonne Forest site. Although pinched for materials, the job at Trail was moving ahead. Even at Columbia, where Urey and his colleagues had still to work out kinks in the gaseous diffusion and centrifuge processes, construction plans were beginning to take form. Two major supply problems were clearing up: Marshall was about to close a deal with the Treasury for some 6,000 tons of silver; and Nichols was in touch with Edgar Sengier, a far-sighted Belgian mining magnate, who had 1,250 tons of Congo uranium ore cached in a warehouse on Staten Island. Marshall was prepared

to break remaining logjams. Fed up with academic shilly-shallying, he recommended immediate acquisition of at least part of the Tennessee tract. Tired of taking no for an answer on priorities, he proposed to go over Clay’s head.28

Achievements drew less notice from Dr. Bush than things left undone. Haunted by the fear that Hitler was winning the contest for the bomb, the OSRD chieftain was intolerant of delay. Apprehensive about the Tennessee site and the MED priority, he mistook deliberation for foot dragging and prudence for passivity. Feeling that the project needed more aggressive leadership and more effective status in the Army, he discussed with Generals Marshall and Somervell and others the formation of a policy committee that would command respect, a body composed of high-placed military men and eminent civilian scientists; and he spoke of appointing a prestigious officer, preferably Styer, as overall director. When Somervell mentioned Groves as the right man for this post, Bush coldshouldered the suggestion. So uncertain, so precarious, yet so fraught with awesome possibilities, the atomic effort undoubtedly needed a strong hand and a resolute will to lead and guide and push it through. Bush intended to take one step at a time: first, choose the committee and, then, name the general to carry out its will.29 But Somervell, adroit as ever, outmaneuvered him.

The week of 13 September was a decisive one for MED. Meeting at scenic Bohemian Grove near San Francisco, the S-l Executive Committee put an end to much of the uncertainty that had surrounded the project. Urged on by Nichols and Crenshaw, who attended as observers, the scientists voted to center production at the Tennessee site, make a prompt beginning there, and push plans to break ground for the big electromagnetic plant around the first of the year.30 In Washington, meanwhile, another major decision came to light. Emerging from a Thursday morning session with the House Military Affairs Committee, Groves bumped into Somervell, who told him: “The Secretary of War has selected you for a very important assignment. ... If you do the job right, it will win the war.” Groves, whose heart was set on going overseas, blazed with indignation, for he guessed correctly that the job involved “that thing,” the atomic bomb31—a “pipe dream,” as he saw it, with little chance of fulfillment. Reporting to Styer at the Pentagon later that morning, he received some rosy promises: a promotion, an easy task (merely to build a few plants), and virtual independence.32 Unmollified, he reproached Styer for “letting me get hooked into this.”33 Then, unheralded, he called on Bush, who froze as the burly colonel introduced himself. Groves’ stock soon rose. Good soldier that he was, he zealously obeyed his duty. Before the week was over, he had given the go-ahead on the

General Groves as Head of the Manhattan Project

Tennessee tract and inveigled Donald Nelson into granting him power to assign triple-A priorities.34

Groves waited until 23 September, when he received his brigadier’s star, before he assumed command. He understood rightly that a general could speak more convincingly than a colonel even to civilian scientists.35 But mere rank did not account for the change in administration which resulted from his appointment. Groves’ intrinsic qualities—his toughness, courage, and perspicacity—were far more significant. With exemplary self-discipline he gave every ounce of energy to a task which seemed as unrewarding as it was full of risk and all but impossible of accomplishment, and he expected no less of subordinates. He was often brusque and uncompromising, “ornery” by his own admission, a “brass hat” and a “stinker” in other people’s words.36 He little cared what was said about him. He was fighting to end a war, and he had a vivid appreciation of the personal consequences of failure. “The President has selected me to carry the ball, which is another way of saying that I am to be the Goat if it doesn’t work,” he told an MED colonel. “If our gadget proves to be a dud, I and all of the principal Army officers of the project ... will spend the rest of our lives so far back in a Fort Leavenworth dungeon that they’ll have to pipe sunlight in to us.”37

Just as MED was unique as an Engineer district without territorial limits, so General Groves was unique as an Army officer without clear-cut status in the chain of command. On the face of it, Somervell’s order to Reybold to release Groves for special duty with the DSM project seemed explicit: “He will report to the Commanding General, Services of Supply, for necessary instructions, but will operate in close conjunction with the Construction Division of your office and other facilities of the Corps of Engineers.”38 But Groves, who helped draft the order, dismissed this wording as “eyewash.” “Initially,” he commented, “General Somervell seemed to think that I would be under the SOS. This was never straightened out on paper. I never thought he wanted me

Mrs. O’Leary

to be under the Chief of Engineers. He wanted me to run the thing and he didn’t want anyone to interfere with me in any way.” No one challenged Groves’ interpretation. Among the high-ranking officers in the War Department, there was much fear that the project would absorb funds and materials in great amounts and then fail in its objective; and from this fear stemmed a growing desire not to be entangled. Somervell evidently looked upon the project as a hot potato more or less safely disposed of in Groves’ hands, that is, handed to a man of steady nerves not likely to drop it. Reybold greeted the new arrangement with undisguised relief. Frankly sympathetic, Robins told Groves: “I hate to see you get this assignment, because if you fail in it, it will destroy you. I would be sorry to see that. But it would be still worse if it destroyed the Corps of Engineers. That would really make me sad.”39 Groves, an officer never reluctant to assume responsibility, now had it in abundance.

He also had abundant counsel and support. On 23 September, the same day Groves officially assumed command, the President’s top atomic advisers created the Military Policy Committee, with Bush as chairman, Conant as his alternate, and two service members: Rear Adm. William R. Purnell, Assistant Chief of Naval Operations, and General Styer. This group formed a bond with the MED commander not unlike that of a corporation board with a chief executive officer. Some months later, recognizing the need for consultants who would demonstrate to the scientists that he had competent advice, Groves appointed Conant and Dr. Richard C. Tolman, graduate dean of the California Institute of Technology, to his immediate staff.40 Throughout the life of the project, cooperation and cordiality characterized the relations of top scientists and top military men; what misunderstanding there was, and at times there was considerable, developed in the middle and lower echelons. The resources of the whole defense establishment were available to MED, and Groves exploited them methodically. The Medical, Signal, and Transportation Corps, Army Intelligence, and Naval Ordnance, all contributed significantly to the realization of the bomb. But by

far the most massive contribution came from the Engineers. Construction was the central task, and the Corps’ construction capability had never been greater. Men, money, machinery, materials, wide-ranging technical and administrative services—“Everything we wanted, we got,” Groves related, “and we got it willingly.”41 A distinctive feature of MED was its “very limited organization,” a feature that evidenced the firm support provided by the Engineer Department.42

An admirer of General Sherman, Groves believed in traveling light, and he held with Sherman that “a small staff implies activity and concentration of purpose.” From a modest, sparsely furnished suite on the fifth floor of the New War Building, he steered the vast atomic endeavor almost single-handed. His principal assistant was his girl Friday, Mrs. Jean M. O’Leary. Saluted good-humoredly as Major O’Leary by MED wags, the pretty, spunky widow was his de facto executive officer. Not until early 1945, when General Farrell returned from CBI, did Groves have a deputy. Aided mainly by Mrs. O’Leary and a few picked men drawn from the Construction Division, he played what he described as the impresario’s role in “a two-billion-dollar grand opera with thousands of temperamental stars in all walks of life.” The story was epic and the stage was worldwide. Limited at first to plant construction and engineering, Groves’ responsibilities rapidly ballooned to take in security and press censorship, intelligence and counterintelligence, all scientific research, and design of the weapon itself, and eventually encompassed matters of international relations, high-level policy, and atomic strategy. Much of his time was taken up by “numerous, all-important decisions, seemingly insuperable problems and fantastic controversies.”43 His account of MED, Now It Can Be Told, focused largely on these. “The bulk of the project,” he wrote, “moved ahead by dint of the hard work and the feeling of urgency of everyone concerned and without requiring any personal supervision on my part.”44 Construction, which accounted for roughly 90 cents of every dollar spent, received comparatively little space in his book.

The fall of 1942 witnessed lively activity in the Clinch River Valley of Tennessee. On 24 September, the day after Groves formally assumed command, he and Marshall made a thorough, final reconnaissance of the site. Four days later an attorney from the Ohio River Division opened an office in Harriman and began mapping the area. On 6 October he filed a declaration of taking with the Federal Court at Knoxville and obtained immediate possession. Like virtually all mass condemnations, this one caused a furor—protest meetings, appeals to Washington, and congressional inquiries. Acquisition proceeded all the same. “Really child’s play,” Marshall termed it.45 By mid-November U.S. marshals were tacking notices to vacate on farmhouse doors, and within a week

or two residents were leaving.46 Construction crews came in right behind them. On the scene since October the area engineer, Maj. Warren George, and Stone & Webster’s project manager, T. Cortlandt Williams, were set for a fast start. Key men were arriving daily. Materials were on order. An employment office in downtown Knoxville was open for business. From the contractor’s Boston headquarters plans and blueprints were flowing to the project. At the Chiefs office in Washington Colonel Barker was pressing for prompt wage determinations and General Robins was circularizing the Corps for surplus equipment, supplies, and personnel. Late in November dirt began to move. Before long construction forces were spreading out to provide temporary utilities, improve primitive roads, run a rail connection to the Louisville & Nashville at Elza, and erect the project’s first big structure, the main administration building.47

Even before a spade was turned at Clinton, the Engineers were moving toward their ultimate objective, the weapon itself. Late in October 1942, a Regular with the Syracuse District, Maj. John H. Dudley, received a special assignment, “to make a survey for an installation of unnamed purpose.”48 His orders, signed by Marshall, specified a partly developed site surrounded by hills in a thinly settled area of the southwest, where a community of 250-450 persons could live in isolation. His mission was the outgrowth of conversations between Groves and Dr. J. Robert Oppenheimer, the young Berkeley professor who spearheaded studies of the physics of the bomb. “The first job was to make the stuff,” Oppenheimer related. “But in hope that would come out all right, we had to have a place where we could learn what to do with it.”49 After traveling thousands of miles, part of the way on horseback, consulting district engineers along his route, Dudley narrowed the search to the Santa Fe area. On 16 November he showed Groves and Oppenheimer a spot that fitted their stated criteria: Jemez Springs, a village of 500 on the floor of a canyon in the Jemez Mountains. Oppenheimer promptly objected that the tall surrounding cliffs “would give his people claustrophobia,” and the houses, simple Indian and Mexican dwellings, would be too humble for them; while Groves noted that the site might be subject to flooding. The party then drove east and on up a steep, narrow dirt road to the exclusive Los Alamos Ranch School. On a mesa jutting out from the Jemez Mountains and overlooking the upper Rio Grande Valley, the 790-acre site was impressive in its solitude and scenic grandeur. The attractive campus, with its log and stone buildings and well-kept grounds, offered comforts and amenities taken for granted by the well-to-do. Oppenheimer

indicated that this was it. Groves and Dudley put their heads together. Except for the road, the setup seemed ideal: the owners were anxious to sell; the water supply was adequate for 500 people; and there was plenty of room for expansion. They made their selection then and there.50

Speed was the byword at Los Alamos. Responding to a signal from the Chief’s office, the Albuquerque District snapped into action. Zia Project, named, fittingly enough, for the Sun God of the Pueblo Indians, promptly claimed the services of engineers, appraisers, and attorneys. By 21 November early reports were in. On the 23rd the district engineer, Col. Lyle Rosenberg, obtained right-of-entry. Hand carried from Robins to Somervell to Patterson on the 25th, the formal site directive gave Colonel Neyland of the Southwestern Division authority to acquire the ranch school and environing forest and grazing lands—54,000 acres in all. Signed by Groves as Robins’ deputy, a title he continued to use until mid-1943, the work directive came out on the 30th. Five days later Rosenberg awarded a secret contract to the M. M. Sundt Construction Company of Tucson. Sundt’s deadline was short: a scientists’ enclave, complete with dwellings and laboratories, fenced and tenanted by mid-May.51 This schedule reflected the urgency that surrounded the project, the pressure, which Oppenheimer noted, “started at the beginning and never let up.”52 The need for haste was keenly felt by General Groves. Although leading scientists thought of putting a bomb together as a few months’ work, Groves, thinking as an engineer, took nothing for granted: the widest possible margin of safety might not be wide enough.53

For all their brilliance, the academic scientists often seemed naive and impractical to hardheaded military engineers. As theorists “they were wonderful,” Colonel Marshall said; but as doers he rated them low.54 Nichols, who agreed with Marshall, chuckled over the scientists’ self-esteem. One day, on a visit to Chicago, he found Fermi’s group speculating how to design concrete, how to keep the water content in. “This was typical,” he commented. “It’s true of most scientists. They’re outstanding and they are geniuses in one aspect, so they think that in every other aspect, in every other trade or profession, they can be equally proficient if they only try.”55 Groves, on entering the project, was appalled—“horrified” was his word—by the visionary nature of the enterprise. An all-round lack of concrete results, postulates taken as truths, key calculations accurate to a factor of 10, mistakes in simple mathematics—impressions gained on a tour of the laboratories spurred him to action.56 Deciding to “wash out” the centrifuge (“We didn’t know whether that would ever work,”

Marshall related), Groves favored bold assaults on the other processes. “We just can’t wait for these people to perfect things,” he and Marshall told Bush. “We have got to go ahead and build something and work out the details as we build it.” The Engineers turned instinctively to industry for help.57

Groves knew which firms he wanted and he got them. To design, build, and operate the plutonium works, he picked DuPont, a company with a flawless record on Army munitions projects. As design consultant to Stone & Webster and operator of the electromagnetic plant, he chose Tennessee Eastman, the Kodak subsidiary which had masterminded the Holston Ordnance Works. For the gaseous diffusion process, he selected two highly reputable concerns, the M. W. Kellogg Company as architect-engineer and the Union Carbide and Carbon Corporation as operator. None of the manufacturing firms welcomed the assignment. “Why pick on us?” three vice presidents of Union Carbide asked Groves and Marshall.58 DuPont officials were especially reluctant. Their forte was chemistry, not physics. Besides, they had their corporate image to consider. Association with a horror weapon would do their reputation no good. What’s more, the odds were long, and they wanted no part of a fiasco. Equating consent with patriotic duty, Groves refused to take no for an answer. Primarily to reassure DuPont executives, who felt that the pile process was the least likely to succeed, Groves appointed a committee, headed by Dr. Warren K. Lewis, distinguished professor of chemical engineering at MIT, to evaluate the prospects of the various methods. As luck had it, the committee visited Chicago on 2 December 1942, the day Fermi gave his clinching demonstration—the first self-sustained nuclear chain reaction.59

Selling DuPont to the project was as difficult as selling the project to DuPont. Word that the company was taking over roused the Met Lab to near-mutiny. With a strong parental feeling toward their brainchild and an almost total blindness to engineering problems, the scientists wished to take the pile all the way themselves.60 On visits to Chicago, Groves heard pleas to keep industrialists out.61 Recalling a Met Lab roundtable, Nichols told a revealing story:–

I can remember Enrico Fermi protesting:– “We don’t need this great organization; they are too conservative. If you people will just hire for me the laborers and supply them with brick, I’ll tell them where to lay it.” Enrico Fermi was one of the greatest brains in the history of the world and that was a statement he made. I remember later going over to Arthur Compton, and Arthur said: “Sometimes, you know, I’m inclined to agree with Fermi. If we just had somebody to design the waterworks and roads, I think I’d almost be willing to back him.” I said: “Well, Arthur, I’m a hydraulics expert and I have built a lot of roads and runways. I can design the waterworks and the roads. Let’s do it.” Then he started to laugh. He kept his feet on the ground. He was a great man, but he wanted us to listen to him.62

Perturbed by DuPont’s lack of enthusiasm, Compton suggested that a combination of General Electric and Westinghouse might be a better choice.63 But Groves’ decision was firm. “I wasn’t interested in somebody who was enthusiastic,” he explained, “I was interested in somebody who could do the job.”64

A hunt for a second manufacturing site followed the hiring of DuPont. A talk with company president Walter S. Carpenter, Jr., confirmed Groves’ own misgivings about putting the big plutonium works at Clinton. The chance that a nuclear reactor might explode, wreck the separation plants, and poison the air of Knoxville, thus destroying all security and forestalling further work on atomic energy—these thoughts impelled him to look elsewhere. Meeting at Wilmington on Monday, 14 December, DuPont officials, Met Lab scientists, and Corps representatives defined the site criteria: a 700-square-mile tract in a sparsely settled area with abundant power and water and year-round construction weather. Named by Groves to head the survey team was Maj. Franklin T. Matthias, a 34-year-old Engineer Reservist whose good work in the construction program had attracted the general’s attention. Moving on the double, Matthias spent Tuesday arranging for DuPont men Gilbert P. Church and Albert E. S. Hall to join in the search and conferring with site and power specialists, principally General Robins and Mr. Giroux. All signposts pointed west toward the great hydroelectric dams, Boulder, Shasta, Grand Coulee, and Bonneville. After a day of preparation, the party left on Wednesday evening for Spokane.65 Messages from OCE had paved the way. Impressed by the ready response, Matthias commented:–

A few telephone calls, a description of what we were looking for and every District and Division office in areas where a favorable site ... seemed possible went to work. ... They knew not why the site was needed, but they were told what was needed, and with their detailed knowledge of their District or Division were able to save us endless hours of investigation when any wasted time could result in a longer war or more lost lives.

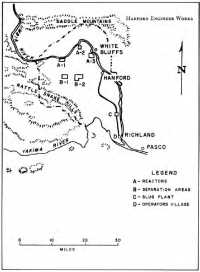

On 31 December the three men turned in their report: near the village of Hanford, Washington, not far from Bonneville and Grand Coulee, they had found an almost perfect site.66

Bigger and bolder than scientific dreams, the atomic program crystallized in late 1942. Full-scale electromagnetic and gaseous diffusion plants plus a plutonium semiworks at Clinton; a complex of nuclear reactors and chemical separation plants at Hanford; camps for construction workers and towns for operating personnel at both main production sites; three heavy water plants in addition to the one at Trail; and Los Alamos, the wizards’ workshop in the mountains of New Mexico: these were its major facets. The estimated cost was half a billion dollars. The target date for turning out the first bomb was sometime

in late 1944 or early 1945.67 It was a desperate undertaking, fraught with perils and uncertainties. Contrary to all industrial experience, the plan made no provision for pilot plants. “With everything else the Corps built in the way of munitions plants,” Marshall emphasized, “you would have a pilot plant until you perfected the process. But not in the Manhattan District.”68 So raw was the concept of gaseous diffusion that no one as yet knew how to make the barriers or porous membranes that were the very heart of the process. “Nothing like this had ever been attempted before,” Groves reflected, “but with time as the controlling factor we could not afford to wait to be sure of anything. The great risks ... simply had to be accepted.”69

The chance that Hitler’s Germany might gain the nuclear prize prompted the attempt and justified the risks. Mindful that the fate of mankind hung in the balance, President Roosevelt at the turn of the year committed the nation unreservedly to a concentrated drive for the bomb.70

Clinton and Hanford

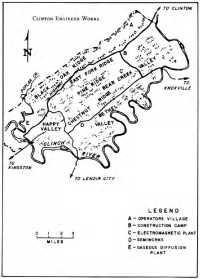

To design and build the great manufacturing complexes in the States of Tennessee and Washington was, as Groves styled it, “the most exacting construction job of the entire war.”71 Vast, complicated, and supremely urgent, the task called for exceptional feats of engineering, organization, and management. To create a new industry normally took many years. From test tube to mass production, the development of nylon had spanned a decade; yet the nylon process was simple compared with any for fissionable materials. According to informed estimates, the electromagnetic plant at Clinton “in peacetime would easily require 10 to 15 years”;72 yet this was but one of three major plants undertaken by the Manhattan District. Together, the Clinton and Hanford Engineer Works comprised the largest crash construction job in history. Under the compelling stimulus of war, a generation of effort was compressed into a period of little more than two years.73 With remarkable swiftness, the peaceful, rural Clinch River Valley of Tennessee was transformed into a mammoth construction project, dusty, noisy, and pulsing with activity. Early in 1943 bulldozers swept through the area, clearing trees, demolishing sheds and shanties, and cutting broad roadways where narrow country lanes had served. In the northeast corner of the reservation, on the slopes of Black Oak Ridge, laborers battered subsurface rock to trench sewer and water lines for a residential community. To the south in East Fork Valley, alongside a new four-lane turnpike, carpenters erected plywood huts to house construction workers. Still farther south, beyond the crest of Pine Ridge, in the meadowlands of Bear Creek Valley,

surveyors staked out base lines for the great electromagnetic plant. Some six miles to the southwest, on the Bethel Valley Road, work gangs prepared the site for the plutonium semiworks. On the low ground of neighboring Happy Valley, near the spot where Poplar Creek flowed into the Clinch, engineers scanned a 5,000-acre tract with a view to building the gaseous diffusion plant there. (Map 4) Although no earth would move in Happy Valley for several months, mid-winter groundbreakings at other points in the Clinton site marked the opening of what would be one of the stiffest battles of the war.

Directing field operations were four organizations, each with an arduous mission to perform. Having general oversight of the entire project was MED’s Tennessee Area, headed by Lieutenant Colonel George. Trained in two professions, engineering and law, George relied initially on a small, close-knit staff: Maj. Paul F. Rossell (Engineering); Capt. Samuel S. Baxter (Town Planning); Capt. Thomas J. Rentenbach (Procurement); and several others. Except Baxter, an official of the Philadelphia Public Works Department until the war, all were former Corps employees. Carrying major managerial responsibility was Stone & Webster’s project force under Cortlandt Williams. An able, dedicated construction man, associated with the firm since 1923, Williams pulled in seasoned experts from other company jobs. Headquartered briefly at the Hotel Andrew Johnson, George and Williams soon took over a large converted garage in downtown Knoxville. Two smaller groups, arriving later, set up shop at the site. DuPont’s James D. Wilson, in charge of building the semiworks, had his office in an abandoned school; and John O. Merrill, whose architectural firm, Skidmore, Owings & Merrill, had been selected in February to design the community, had his in a deserted farmhouse. The other teams continued working out of Knoxville until 15 March, when the project’s main administration building, dubbed “The Castle,” was ready for occupancy. By then, construction was well under way.74

From the window of his office in the Castle, Colonel George could view a fair-sized city in embryo. Red brick chimneys brightened the woods on Black Oak Ridge; and freshly dug foundations in East Fork Valley marked the sites of apartment houses, dormitories, eating places, commercial buildings, schools, a hospital, a theater, a post office, a firehouse, and a police station. Begun by Stone & Webster and carried forward by Skidmore, Owings & Merrill, the master plan for town development showed originality and skill. Roads and streets followed winding routes along natural grades, reducing cuts and fills and adding charm and grace. Clusters of stores and supermarkets with large adjoining parking lots were prototypes of the shopping centers that would dot postwar America. Cafeterias outfitted with Automat equipment would feed 2,000 diners per hour. Structural designs were streamlined and distinctive. Believing that high-class quarters were essential to attract high-caliber people, Colonel Marshall insisted that every

Map 4: Clinton Engineer Works

Cemesto houses on Black Oak Ridge, Clinton Engineer Works, Tennessee

house have a fireplace and a porch. Since time was short, manpower scarce, and many materials were critical, a family unit developed by the John B. Pierce Foundation seemed just right for the purpose. Featuring prefabricated “cemesto” panels, consisting of fiber board with asbestos-cement bonded to both sides, and slotted wooden posts, the unit made use of available materials and permitted assembly-line construction. Cemesto, combined with brick instead of wood, also figured in Merrill’s plans for attractive, modern, low cost schools. While Stone & Webster pushed work in the town center and provided utilities for a population of 12,000, O’Driscoll & Grove of New York City built the first thousand houses on the ridge.75

Over behind the hills, in Bear Creek Valley, men strained to meet a sterner challenge: construction of Y-12, the huge electromagnetic plant. Scientifically, industrially, in every way, the

plant represented a daring leap from laboratory scale and methods. Research was still in progress and equipment only partially designed when excavation began on 18 February 1943. Bundles of drawings received from Boston gave project manager Williams a rough idea of what he was to build: three, and possibly four, huge concrete and masonry structures to house the separation process; two chemistry buildings for preparing feed material and recovering the final product; a development plant, complete with experimental calutrons; plus utilities, roads, spur tracks, storehouses, shops, a foundry, and numerous other supporting facilities. The plans showed the general layout, size, and profile of the process machinery: fantastic “race tracks”—enormous ovals formed by many jumbo magnets; vacuum systems larger and more powerful than any heretofore dreamed of; and rube goldberg phantasmagorias of pipes and valves. But many particulars were lacking, among them designs for vacuum pumps, ion sources, and receptacles. And troublesome questions were unanswered; for instance, would two stages of separation, Alpha and Beta, be required or would Alpha alone do the job. Although details were fuzzy, Williams pushed construction with all possible speed, for if the project was big and complicated, it was, above all, urgent. Groves wanted one racetrack in operation by July.76

Far smaller than Y-12 but scarcely less critical was the semiworks or X-10 plant in Bethel Valley. Explaining his decision to undertake this project, Groves dwelt upon the desperate need for uranium that had undergone irradiation in a pile and thus contained plutonium; until this need was met, planning for the chemical separation plants at Hanford would be handicapped. X-10 would meet other needs as well; although not a true pilot, it would nevertheless provide a practical demonstration of the basic production process and offer a means for training operating personnel. As blueprints emerged from DuPont’s Wilmington drafting rooms, the construction task assumed fixed dimensions. Comprising the heart of the semiworks would be an experimental air-cooled pile, underwater storage, an underground canal, and a series of cells for chemical separation—all shielded by thick concrete walls and all operated by remote control. Other major structures would include laboratories, shops, a training school, and subterranean tanks for radioactive waste. When construction forces started work in February 1943, two veteran field engineers were on the scene: DuPont project manager Wilson and Captain Grafton, recently transferred to Clinton from Chicago. Both had tackled tall jobs before, but never a job like this. Key scientific decisions were still up in the air and the deadline for completion was “next fall.”77

The buildup at Clinton was remarkably swift. Suddenly, in the early months of 1943, the hidden project in Tennessee became a loadstone for war-scarce manpower and supplies. Talks with regional labor leaders paved the way for a vigorous recruiting drive. Assists from the

War Manpower Commission, the U.S. Employment Service, and Colonel Barker’s staff in OCE helped to assure success. Construction forces mushroomed despite the need for at least a limited security check on every applicant. The largest payroll, Stone & Webster’s, jumped from 1,000 men in January to 7,300 in April. Intensive courses in welding and other trades eased shortages of skilled workers; and women draftsmen, rodmen, and chauffeurs gave the job a boost. While early recruitment was largely local, procurement was countrywide. From towns and cities in nearly every state, shipments converged on the whistle-stops of Elza and Oliver

Springs. Freight cars jammed sidings for miles around and traffic clogged highways, as thousands of tons of materials and hundreds of machines and vehicles flowed into the area. Materials bought by the contractors, purchases made centrally by Colonel Sherrill, and surplus transferred by Captain Rentenbach from other Corps jobs nearly swamped the project. Receiving and checking and distribution were major operations. Labor gangs, some composed entirely of Negro women, worked around-the-clock unloading, and carpenters put up the first of fifty big warehouses.78 Spring found construction moving forward amid rain and mud. Subcontractors’ name boards dotted the site—Clinton Home Builders of Charlotte, Foster & Creighton Company of Nashville, Harrison Construction Company of Pittsburgh, Transit-Mix Concrete Corporation of New York City, and D. W. Winckelman of Syracuse. Long lines of automobiles passed through the heavily guarded gates each morning and evening. Working conditions were still primitive (tank wagons hauled drinking water from the town of Clinton seven miles away and circus tents housed canteens), yet evidence of progress was all around. The main line connection with the Louisville & Nashville, completed and in use; a rambling frame laboratory, occupied by Met Lab scientists; deep excavations in the plutonium separation area; foundations under way for two Y-12 process buildings; a pump house and a filter plant rising near the Clinch River—these were among the highpoints. To Colonel Marshall, a frequent visitor, the job appeared to be going fairly well. To Groves, who showed up every other week or so for a predawn parley and a rigid inspection, the pace seemed fast but not nearly fast enough; he maintained a steady drumbeat for greater speed.

Meanwhile, two thousand miles northwest of Clinton, near the big bend of the Columbia River, a second production complex—the Hanford Engineer Works—was coming under development. Groves’ mid-January decision to acquire 670 square miles of semiarid land in south central Washington had prompted brisk activity: subsurface explorations by the Seattle District; a power survey by Giroux and a site reconnaissance by Zach; establishment by the Portland District of a real estate office at Prosser; large-scale purchases of materials and equipment by Colonel Sherrill and DuPont; calls from the Chief’s office to the field for surplus steel, relay rail, electric wire, trucks, tractors,

locomotives, and myriad other items; and countless meetings in Washington, Wilmington, Chicago, and New York. By mid-March preliminaries were well advanced. Temporary offices at the Gray Building in Pasco buzzed with new arrivals: Colonel Matthias, who had volunteered for the post of area engineer; Lt. Col. Harry R. Kadlec, his highly regarded deputy; Gilbert P. Church, DuPont’s project manager; Leslie S. Grogan, his field superintendent; and large supporting staffs. A petition in condemnation had sailed through the Federal Court at Spokane; a hook-up with the Bonneville-Coulee power grid was in the works; arrangements were firming up to restrict flights over the area; the architect-engineer for the operators village, G. A. Pehrson of Spokane, was ready to start work; and the general layout for the entire project was falling into place.79

Late in March Groves and O’Brien spent two days at the job, going over the ground and settling details. With Church and Matthias, they covered many miles; northwest from Pasco to Richland, a hamlet nestled in the Y formed by the conflux of the Yakima and the Columbia; then on over parched dirt roads, through wide stretches of sand and sagebrush, to the villages of White Bluffs and Hanford. From a butte opposite White Bluffs, above the blue Columbia, they commanded a good view of the roughly circular site: the steep-faced Saddle Mountains on the northern rim; the narrow zone of irrigated orchards and croplands along the winding river; and the gray expanse of undulating tableland bounded on the south by the Rattlesnake Hills. At evening sessions in Pasco, Groves reviewed the layout: three huge reactors spaced miles apart on the right bank of the river; two chemical separation areas some distance to the south; a big construction camp at Hanford; a plant for making uranium slugs and testing pile materials midway on the Richland-Hanford road; and a town for operating personnel at Richland. (Map 5) Meantime, at after-dinner meetings with the real estate group at Prosser, O’Brien went over acquisition plans. At Groves’ suggestion, he kept two secondary requirements in mind, minimum publicity for the project and maximum cooperation with the President’s “Food for Victory” program. With construction planning barely begun, there was no need to bear down. Partly to soften owners’ protests and partly to salvage growing crops, O’Brien told his men to rely mainly on negotiation, hold off eviction notices as long as possible, and let farmers and orchard-men bring in their harvests. Later, when bumper crops raised asking prices and sellers’ resistance stiffened, Groves regretted this leniency, for the Hanford acquisition proved to be long and litigious.80

As the magnitude of the construction job became apparent, pressure began to mount. Planned on the same basic principles as the Clinton semiworks, the Hanford project was nonetheless formidably dissimilar; the 112-acre site in

Map 5 Hanford Engineer Works

Bethel Valley was tiny compared with the vast sweep of prairie north of Pasco, and the Clinton pile’s expected power output of 1,000 kilowatts shrank to insignificance beside the 250,000 kilowatts of each Hanford pile. There were other marked differences also. Unlike the Clinton midget, the giant reactors at Hanford would be water-cooled, a circumstance that raised such varied problems as rust prevention and stream-life preservation. The remoteness of the Hanford tract was another exceptional feature; since the nearest city of any size, Yakima, was 40 miles away, recruiting, transporting, housing, and feeding the workforce would take a lot of doing and so would keeping up morale. Massive industrial structures, heavily shielded to confine radiation and designed for operation by remote control, a permanent town for 17,000, a construction camp for 40,000, plus administration buildings, depots, shops, laboratories, test facilities, pumping stations, filtration plants, and hundreds of miles of roads, railroads, and transmission lines—the scope of the undertaking was impressive. The best way to meet the challenge was to tackle it head-on. Bringing machinery and materials from other Corps projects, recruiting labor throughout the northwest, opening gravel pits and obtaining concrete batch plants, establishing bus connections with nearby towns, erecting barracks and tents at Hanford, inaugurating food service, letting contracts for Richland Village, studying how to safeguard the Columbia River salmon, and pushing “hard and fast” on roads and railroads—all these activities proceeded during the spring of 1943. By May, 1,300 men were at work. With luck, the main task of plant construction would start in the summer.81

Although dwarfed by Clinton and Hanford, other industrial construction jobs were pressing and important. On Colonel Marshall’s crowded itinerary were Milwaukee, Wisconsin, where the Allis-Chalmers Company was expanding to manufacture pumps; Niagara Falls, New York, where the Electro Metallurgical Company was erecting facilities to cast uranium ingots; and spots in Alabama, Colorado, Indiana, Iowa, Michigan, New Jersey, and West Virginia. Of the various auxiliary plants, those for heavy water were perhaps most noteworthy. The possibility of failure with graphite piles dictated Groves’ decision in November 1942 to augment supplies of heavy water. At his request, DuPont engineers took the matter in hand. After weighing possible production methods, including the electrolytic process used at Trail, they backed distillation as the surest and quickest, though not the most economical. Soon plans were afoot for distillation units at three Ordnance works having excess steam capacity, Morgantown, Alabama, and Wabash River, plus an electrolytic finishing plant at Morgantown. A “horseback guess” put the cost at about $28 million. Started by DuPont in January and February 1943, the projects raced to meet close deadlines—partial operation by mid-summer and final completion by the end of the year.82 With many

such undertakings at scattered locations, the MED building effort was a miniature war construction program in itself.

Undergirding endeavors in the field was powerful support from contractors’ home offices. At Boston, Stone & Webster had a special force of 800 employees, occupying 13 floors in 4 heavily guarded buildings, at work on the atomic program. Headed by the firm’s chief mechanical engineer, dynamic, genial August C. Klein, this group discharged heavy duties: translating scientific data into construction plans and blueprints; procuring process equipment from Allis-Chalmers, General Electric, Westinghouse, and other manufacturers; expediting orders of basic raw materials, including uranium; and overseeing operations at Clinton and Trail. At Wilmington, DuPont had a comparable organization under the direction of chief engineer Everett G. Ackart and his hard-driving principal assistant, Granville M. Read. Early in the game, a 400-man design team toiled over information submitted by the Met Lab; in time, the pile project soaked up 90 percent of the company’s engineering and construction talent. From the Woolworth Building in downtown Manhattan, a newly created Kellogg subsidiary, the Kellex Corporation, pioneered development of the gaseous diffusion process. The staff, which grew eventually to about 3,000, included many luminaries of the engineering profession, but none more brilliant than the president, Percival C. Keith.83 With researchers at Columbia and associated universities, Keith and his group had baffling obstacles to overcome. Bracketing Kellex and the other contractors, Nichols related, “In every case, they really worked their hearts out to get the thing done.”84

Tying all these vital cords together was the Manhattan District centered in New York. Grown too large for its Broadway headquarters, Colonel Marshall’s staff had taken over floor after floor of a garment industry building at 261 Fifth Avenue. Aiming for “the same kind of District that we had at Syracuse,” Marshall relied on the same sort of personnel and the same type of setup. The majority of his officers were Corps employees in uniform and many of his civilian aides wore Corps service pins in their lapels. But for a few exceptional features—a scientific adviser (Dr. Henry T. Wensel), a chief medical officer (Col. Stafford L. Warren), and four unit chiefs or process coordinators (Kelley for electromagnetic, Matthias for the plutonium piles, Lt. Col. James C. Stowers for gaseous diffusion, and Capt. Harry S. Traynor for heavy water)—the MED organization chart could have served most Engineer districts. (Chart 27) “We had a good organization,” said Nichols, “and a group of people that could work together.” The only rub was Groves. Dealing with him was “an interesting and difficult problem,” according to Nichols: “There was no question as to his ability, but his methods of working were to violate all channels.” Marshall, who outranked Groves on the permanent promotion list, did not take kindly to this mode of operation. “Who is the District Engineer?” he demanded. “You

Chart 27: Organization of Manhattan Engineer District, April 1943

Source: Orgn. Chart, MED, 1 Apr 43, EHD Files.

are,” Groves replied. “Who gives the orders?” “You do.” Nevertheless, as time went on, the general exerted more and more authority. At one point, Marshall told him, “There is no need for both of us here; I want out.” Groves demurred, but finally agreed: “O.K., at the first opportunity.” Absorbed in his work, Marshall soon forgot the conversation; and, apparently, so did Groves. The two men pegged along, disagreeing occasionally, but never reaching an impasse. Too big to harbor grudges, they pushed toward their common goal.85

Both kept an anxious eye on Clinton, a healthy project on the whole, but not immune to trouble. By May 1943 the job was bounding ahead. The atmosphere was one of challenge and excitement, and the spirit was enthusiastic. The construction camp was filling up, as recruiting centers throughout the South funneled workers to the site. A ten-hour shift and a partial second shift kept equipment running from dawn to dusk, and unloading crews grappled with hundreds of incoming freight cars. Three thousand houses were under construction on Black Oak Ridge, and water and sewer lines were advancing at the rate of one mile per day. In the Y-12 area, dozens of structures, among them a recently authorized Beta process building, were going up, and the development plant, started in mid-April, was already roofed. The plutonium semiworks was right on schedule. Good progress notwithstanding, the job produced its share of headaches. Two were political: a strained relationship with the Governor of Tennessee and an impending congressional probe into land acquisition. Another was administrative: a personality clash between George and Williams, in part smoothed over after Blair took command of Clinton on 15 May and George became his construction officer.86 But these problems, however vexing, were relatively minor. The really big ones flowed from the complexities of the engineering task.

Foundations for the Y-12 process buildings proved to be a rugged undertaking. From the beginning, some difficulty seemed inevitable. “Everybody knew the place was faulted,” Williams pointed out; and because of the many heavy magnets, load concentrations would be quite high and permissible settlement, practically zero. With due precaution, Stone & Webster mobilized a crack team of foundation engineers, captained by Lynnwood Kerr, one of the best men in the business.87 Early in 1943 Kerr sent William F. Swiger, a young Harvard-trained soils technologist, down from Boston to take core-borings and dig test pits. On the north side of Bear Creek Valley, Swiger found underground formations of Conosauga shale, an excellent support for heavy structures. On the south side, where the main process buildings were to go, he came upon less favorable conditions: uptilted beds of deeply weathered limestone. After rejecting several alternatives, Kerr adopted a procedure which

worked nicely for the first two Alpha buildings: stripping the surface, grouting seams and joints, and founding footings on this “dental work.” When excavating crews removed the overburden at the site of Alpha III, he faced crueler obstacles: irregular boulders up to 30 feet in diameter, lodged closely together and imbedded in soft clay. “Here,” he wrote, “was real trouble, so serious that time and labor expended in attempting to excavate to suitable foundations only made conditions appear more hopeless.” Eventually, he opted for an unorthodox method, a military engineer’s expedient proposed by Groves. Leaving the rock where it was, he flushed out the muck with firehoses and then poured a heavy concrete mat, two to three feet deep in some spots, eight feet in others, which amalgamated the whole mass into one firm solid base. Conventional engineering or not, the trick succeeded. The job was well and swiftly done.88

When earthmovers started work in Happy Valley on June 2nd, the atomic project passed another milestone. Picked by the Lewis Committee as the method most likely to succeed, gaseous diffusion—K-25 in code—was also the most disheartening. Based on Graham’s Law, the process was beautifully simple in theory—when uranium hexafluoride gas was pumped against porous membranes, the lighter U-235 molecules would tend to pass through more easily than the heavier U-238—but making it work industrially was a herculean labor. Thousands of separation stages, millions of kilowatts of electricity, unique metallic barriers or membranes with countless submicroscopic holes, pumps and seals of revolutionary design, new coolants and lubricants, corrosion-proof materials, vacuum tightness, surgical cleanliness, and watchmakers’ tolerances were items in the engineer conspectus. Moreover, the Columbia scientists, at odds with one another, inspired Groves with far less confidence than the ebullient Lawrence team or the coolly competent Met Lab group. Bright spots in the picture were “Dobie” Keith and his “can-do” associates, whose initial progress was reassuring, and the Union Carbide engineers, who were moving into operational planning. As development of component parts went forward (soon the barrier remained the chief unsolved riddle) and as construction drawings multiplied (the total would eventually reach 12,000), Groves made a bold commitment. In mid-May Marshall signed a letter contract with the J. A. Jones Construction Company for the largest steam-electric power plant ever built. Within a fortnight, Jones’ men were on the scene.

High-geared and high-priced, the power plant project exemplified the don’t-spare-the-horses spirit of MED. Scheduled for completion in 10 months, the $185-million generating station was an added safeguard, another hedge against misfortune. The decision to build it rested on the scientists’ belief, later proved unfounded, that a momentary outage would shut down K-25 production for many weeks and also on the reasoning that since TVA current, coming by wire, was subject to interruption by storms and sabotage, locally generated current was a necessity. A difficult undertaking at best, construction of the plant

was rendered more difficult by unfavorable site conditions and wartime shortages. By bringing in top-notch subcontractors, among them the A. S. Shulman Electric Company of Chicago and The Foundation Company of New York; by commandeering boilers and turbines intended for Commonwealth Edison’s new Fiske Street Station in Chicago; and by vigorous expediting, MED leaders helped the cause along. Within a short time, the job was booming.89 Assigned to Clinton in late July as K-25 construction officer, Maj. William P. Cornelius found the powerhouse “fairly well established.”90