Chapter 7: Artillery Ammunition: Production

By the summer of 1942 the period of plant expansion for artillery ammunition had to come to an end, and the period of intensive production was beginning. In the history of the ammunition program the transition from expansion to production is conveniently marked by the creation on 5 August 1942 of the Office of the Field Director of Ammunition Plants (FDAP) in St. Louis.1 Headed by Col. Theodore C. Gerber, an Ordnance officer with experience as commander of a government - owned, contractor - operated (GOCO) plant, this office administered all the ammunition plants, most of which were within an overnight train ride from St. Louis. The new headquarters was staffed by transferring from Washington the lawyers, contract negotiators, and administrators who had piloted the plants through the expansion period.

Operations of FDAP

At the outset it was assumed that FDAP would be primarily an administrative and legal office and that most technical problems would be referred to Washington or to Picatinny Arsenal. General Campbell, who had launched the GOCO plants while assistant chief for new facilities, knew that legal and administrative problems were inevitable because of the novelty of the GOCO arrangement whereby private concerns produced war materials on government property, using government-owned machinery, and received payment under a cost-plus-fixed-fee formula. In the beginning FDAP had no authority over inspection, packaging, renovation, or scheduling, but as time went on these responsibilities were delegated to it. By 1945 FDAP had, in the words of the official memorandum, “complete control, administration, coordination, and direction” of the GOCO plants under the Ammunition Division.2 But it never had as full control of the ammunition program as OCO Detroit had of tank-automotive procurement. Broad control of scheduling of production remained in Washington, as did authority to approve engineering changes. St. Louis was not granted as much authority as was Detroit, primarily because of the marked procurement differences between ammunition and vehicles. Ordnance did not contract for a complete round of ammunition as it contracted for a complete truck or tank. The division into

three distinct operations—procurement of metal components from industry, production of powder and explosives at GOCO plants, and assembly and loading at GOCO plants—made wholesale decentralization to St. Louis far more difficult than was decentralization of tank-automobile procurement to Detroit.

The administrative problems handled by FDAP covered a wide range. Most of them centered around the interpretation of contracts, auditing expenses, and applying specifications. There were questions, for example, about the propriety of charging to government expense the cost of certain activities such as plant newspapers and charitable contributions that were normal business practice for the contracting firms. There were more important problems in recruiting personnel and obtaining draft deferments for essential workers. Difficulties in production, or in satisfying inspection demands, were also brought to the attention of FDAP, which served as a “home office” for all the plants.3

There were many obvious advantages in the GOCO arrangement, but the dual control required by the government-industry partnership in the ammunition plants caused certain difficulties. There was inevitably some duplication of function between contractor and government and many opportunities for friction developed. When emergency production first began, all available talent had to be used in the process of training new personnel. Contractors who knew little or nothing about handling ammunition had to depend upon Ordnance officers and civilian technicians. During the construction period, government representatives at each plant site handled payrolls, timekeeping, and inspection of all incoming material. After the plants reached the operating stage the contracting firms took over most of these duties, with government auditors checking the accounts only on a selective basis. As all the sites on which Ordnance facilities were located were designated as military reservations, a commanding officer was assigned to each with responsibility for the activities of the government auditors and inspectors, and for protecting government property. This system of dual control was not only wasteful of personnel but annoying to both sides and administratively unsound because it tended to divide responsibility for performance. Frequent changes in the Ordnance commanders at the plants caused further difficulty. One plant, for example, had seven different commanding officers during three years, each new commander “coming in to get the plant running right.”4 Most of the contracting firms directed their representatives at the plant sites to work in cooperation with the government representatives and to reach practical solutions on the spot rather than to refer every problem to the home office. With some firms, particularly those with no experience in munitions making, there was criticism that the safety provisions required by Ordnance were too elaborate, that labor-saving machinery was not used enough, and that “many decisions forced upon the contractor by directive were uneconomical and unsound. ...”5

On 3 October 1942 the Chief of Ordnance issued a directive to clarify the situation at the GOCO plants. His purpose was to put a stop to duplication of effort between contractors and Ordnance field staffs, to reduce the Ordnance payroll by transferring to the contractor responsibility for property records, production planning, motor pools, and in-process inspection.6 As a result of this directive, the number of Ordnance officers and civilian employees at the plants dropped sharply. At the Arkansas Ordnance Plant, for example, there were 424 civilians on the government payroll in September 1942 but only 255 at the end of December, and during the same period the number of officers dropped from 15 to 9.7 Nevertheless, a study of loading plants completed in January 1944 showed that some Ordnance employees were duplicating work done by contractor employees.8 Between January 1943 and June 1944 the number of civilian employees at all GOCO ammunition facilities was cut in half.9 The October 1942 directive not only conserved manpower and reduced duplication but it also promoted greater understanding and confidence between the contractor and the government.10

Competition among Plants

Perhaps the most noteworthy achievement of FDAP was the use of standard methods to measure the efficiency and economy of plant operations. The need for such methods was obvious. The CPFF contracts under which the plants operated provided an incentive for quantity production but not for efficiency and economy. As the contracting firms received a certain fee per unit of production their prime objective was speed of production, not economy or efficiency. Colonel Gerber and his superiors in Washington decided to attack this problem by recording and analyzing the cost of operation for each plant. They believed that once this was done—and the results distributed—a spirit of competition would develop, with every plant manager eager to make a good showing in the eyes of his home office and in view of the other plant managers. Pride was to take the place of profit as an incentive to efficient low-cost production.11

The success of this plan cannot be measured accurately, but there is some indication that it worked well. A record of improved efficiency under the system does not of itself prove the point, for efficiency

would probably have risen steadily under any circumstances as both management and worker gained experience and as new machines or techniques were introduced on the production lines.12 But the record of the GOCO plants was so good that the FDAP administration must be credited with having inspired performance far above normal. The record was one of steadily increasing production, lowering costs, rising labor productivity, and substantial savings in the use of raw materials. The cost of TNT, for example, was cut in half while the rate of production was doubled. The amount of alcohol required per too pounds of smokeless powder was cut from 7 gallons to 2 gallons, a saving of over 4,000,000 gallons per month. It cost over 27 dollars and took nearly to man-hours to load a 1000-pound bomb in January 1943; the same bomb was loaded a year later at a cost of about 16 dollars and in less than 5 man-hours.13

In the spring of 1944, Representative Albert J. Engel, a member of the War Department Subcommittee of the House Appropriations Committee, personally inspected twenty-two ammunition plants and summarized his findings in a report printed in The Congressional Record, 21 June 1944. After citing many specific examples of the remarkable savings achieved by Ordnance and its ammunition contractors, Representative Engel offered the following comments, which still stand as the best brief explanation of the factors behind the FDAP accomplishment:

Reduction of cost and conservation of manpower has been outstanding. It has been due, in my judgment, in a large measure to: (1) The excellent quality of the responsible and experienced contractors selected. (2) The creation of integrating committees and the meeting of those committees periodically to exchange information between plants. (3) Continuous analysis and comparison of unit costs and cost of operation of respective plants by the Field Director of Ammunition Plants. This policy created a competitive spirit, each plant trying not only to increase efficiency but also to reduce their costs to the level of the plant which had the lowest unit-cost level. (4) The high quality of the technical knowledge available in loading units of the Field Director of Ammunition Plants. (5) The establishment of manpower standards by skilled industrial engineers working through administrative units aided by industrial representatives. (6) Last, and certainly of great importance, was the close and effective cooperation between industry and the War Department in the operation of these plants, making available, without reservation, information of every kind and quality which industry possessed.14

Shortcomings

There was also much that was not accomplished by FDAP and industry before the war ended. No fully satisfactory method of comparing the operating efficiency of plants was devised. Cost statements alone were not adequate, for there were many uncontrollable factors in the

total cost. The labor rate at each plant was geared to the prevailing rates in the locality, and costs of raw materials varied from month to month and plant to plant. In January 1945 a proposed plan for evaluating the performance of TNT works was prepared, assigning a percentage value to each basic cost factor and expressing overall ratings by a single index number. But the proposal did not proceed beyond the discussion stage before the end of the war was in sight.15

Few of the plants under FDAP supervision ever had a chance to achieve peak efficiency by operating at capacity over a long period. In most cases, as soon as a plant came into production and completed a few months of shakedown operations, it received notice to curtail production. By the fall of 1943 the tendency throughout the War Department was to feel that adequate supplies were on hand and that Ordnance was producing too much ammunition.16 In January 1944 Ordnance was forced to practice extremely short-range scheduling of plant operations, few schedules running for more than one month ahead. Changes in types of ammunition also had an effect on plant efficiency, for it required the plants to shut down a line for loading bombs, for example, and convert to a shell-loading line, or switch from small to large calibers. Changes often had to be made suddenly, without advance preparation for management or workers, and the effect on morale was, to say the least, disconcerting. Because of the lack of firm, long-range forecasts of requirements, it was not possible to concentrate production in the most efficient plants and operate them full time. Instead, particularly in late 1943, the production load was spread out among many plants in order to keep them in operation as a reserve against unexpected demands in the future. But during the winter of 1943-44 many plants were closed as the War Department emphasized the curtailment of production.17

As noted in the preceding chapter, the Ordnance Department’s management of the ammunition program was subject to criticism on one score—the terms of its contracts with the plant operators. No generalization applies with equal force to all the contracts, but it may be said that in many cases the contractors received fees that were generous if not excessive. The contractors were as free of business risk as any businessman could hope to be. They had no capital invested in the plants; they contributed no operating funds; they oftentimes utilized government free-issue materials; they had an assured market for their products; and they were reimbursed for all costs. Officers of The Inspector General’s Department who made a special inspection of FDAP in March 1945 expressed the view that the terms of contracts with the operating firms were “extremely liberal.”18 Though in many cases

the fees originally agreed upon had been substantially reduced during the preceding two years, the inspecting officers felt that further reductions were in order. They pointed out that one company, operator of a loading plant, had contributed very little “know-how”; it had not contributed trained employees from its own staff but had trained all its workers for the plant at government expense. Yet, in spite of its modest contribution the company had received to date over $470,000 in fees. Neither the Chief of Ordnance nor the director of FDAP agreed with these conclusions. They insisted that, all things considered, the fees were not excessive and pointed to the fact that FDAP was constantly reviewing contracts to keep fees down to the proper level.

Cost-plus-fixed-fee supply contracts differed from CPFF construction contracts in one important respect: the fixed fee was not really fixed. It was not a single lump-sum payment for the whole operation but a fee for each unit produced, such as a pound of TNT or round of small arms ammunition. The fees were originally set without full knowledge of production costs or of economies that might be achieved. Volume production usually resulted in high fees. One small arms producer, for example, received a total of $12,801,620.16 in fees during thirty-two months of operations. In 1943, when output was at its peak, the firm averaged over $600,000 per month in fees. Though the fixed fees had been reduced three times, an inspecting officer in October 1944 still considered them to be out of line.19

Safety

No account of ammunition production would be complete without a word about safety. The operations at ammunition plants, where huge quantities of TNT, RDX, and smokeless powder were handled by relatively inexperienced workers, were potentially the most hazardous in the world. But Ordnance and its industrial contractors took such effective safety precautions that the ammunition industry proved to be one of the safest in wartime America. These safety measures have a particular relevance to the preceding paragraphs on efficiency and cost of production, for, in the minds of Ordnance officers, safety was more important than either efficiency or economy. Speaking at a meeting of plant managers in the summer of 1944 Colonel Gerber declared: “I cannot overemphasize safety. ... Safety comes first, quality comes second, and efficiency comes later.” At the same meeting Brig. Gen. Roswell E. Hardy, Chief of the Ammunition Division, said: “I don’t care how much it costs or how much time it takes, I want safety and quality.”20 This attitude was supported by many coldly practical considerations as well as by the ever present desire to safeguard the lives of employees. Fires and explosions were to be avoided because they destroyed badly needed facilities, stopped production, and cost a great deal of money. Older Ordnance officers remembered the disastrous explosion at the T. A. Gillespie Company plant at Perth Amboy in World War I that took the lives of scores of workmen and destroyed over three hundred buildings. Furthermore, in a tight labor market the danger of explosions was a serious

handicap to the recruitment of needed workers.21

From the very beginning, safety was built into the ammunition plants. The explosion in the late summer of 1940 at the privately owned Hercules Powder Company plant at Kenvil, New Jersey, served as a dramatic and timely warning to the whole industry. It revealed the hitherto unknown fact that small-grain smokeless powder would explode if the depth of the mixture exceeded a certain critical point. The layouts of the Radford and Indiana plants then under construction were immediately revised to incorporate additional safety features. Operations were thereafter more widely separated so that a blast in one unit would not set off another unit. Workers were trained to be safety conscious and were required to observe rigid safety rules. Elemental good housekeeping, including sweeping and scrubbing, was stressed constantly. Ordnance sought the aid of the Surgeon General’s Office and the U.S. Public Health Service to protect the health of workers. As a safeguard against the toxic effects of TNT a special soap was developed that turned violet until a worker had washed all traces of TNT from his body. Whenever an explosion occurred, its cause and prevention were studied by a flying team of experts and warnings were immediately sent to all other plants.

During the early months of the war the safety record left much to be desired. Between December 1941 and June 1942 there were three explosions that killed a total of 83 persons and caused property damage of more than one million dollars. Two of these three incidents occurred at the Iowa Ordnance Plant where an explosion in December 1941 caused 13 deaths, and another in March 1942 took 22 lives. The worst disaster in an Ordnance plant during World War II occurred at the Elwood Plant on 5 June 1942 when an explosion occurred in a building where antitank mines were being loaded. Forty-eight persons were killed, and property damage amounted to $489,000. To see these explosions in perspective we need to view them in relation to other wartime disasters. Each of the worst Ordnance explosions was comparable, in terms of lives lost and property damaged, to the crash of a single commercial airliner. When compared to the Navy’s Port Chicago explosion in July 1944, when 250 persons were killed, and over 1,000 injured, or to the disasters of World War I, the accidents at Ordnance plants appear small.

To strengthen the Ordnance safety organization, General Campbell established an Explosives Safety Branch (later renamed the Safety and Security Branch) in Chicago in July 1942. The new office was headed at first by Col. Francis H. Miles, Jr., and later by Colonel Gerber who was at the same time head of FDAP.22 This office reviewed the design of new plants before their construction, prepared safety manuals and bulletins, investigated fires and explosions, and kept the Chief of Ordnance informed on matters of safety. It launched an intensive program for training “safety auditors” who inspected plants, and it outlined plans for training foremen and workers in safety

Box of bulk TNT being processed in the melt unit is handled by a workman wearing nonsparking safety shoes made without nails.

methods. This latter type of training was considered the one most important means of preventing accidents. In its early days the branch received helpful advice and assistance from civilian agencies such as the National Safety Council, Underwriters’ Laboratories, Illinois Institute of Technology, and metropolitan fire and police departments.23

In the twelve months following establishment of the safety office in Chicago the accident frequency rate at GOCO plants was cut by more than half. It declined further in 1944, and in 1945 the ammunition industry had the best safety record of all manufacturing industries in the United States, surpassing even the traditional leader, the ladies’ garment industry. Congressman Engel termed the Ordnance safety achievement “one of the most amazing records made in the history of any industry.”24 The Morgantown Ordnance Works, to cite one outstanding example, operated for nearly four years, accumulating approximately nine million man-hours, without a single lost-time injury. A note-

Inspector at volunteer ordnance works taking a sample of TNT for testing at an ordnance laboratory.

worthy feature of the World War II record is that more than 95 percent of all disabling injuries at ammunition plants were not due to explosives but to run-of-the-mill accidents such as falling off a ladder or being hit by a truck.25

Technological Advances

Some of the most remarkable technological advances of World War II occurred in the ammunition industry. The field was wide open for the development of new processes and new machinery, for there had been virtually no mass production of military ammunition in the United States for over two decades. Small-scale production of powder and explosives by Pica- tinny Arsenal and by several commercial firms had served to keep alive some knowledge of production methods and to make important advances in certain areas. Pilot production lines at Frankford Arsenal served a similar purpose for metal components. But small-scale production does not justify construction of the costly and intricate machines suitable for mass

production, nor does it always clearly reveal the problems of the high-speed production line. Ordnance officers were well aware of these limitations during the peace years but were unable to do much about them until 1938-40. Long before the beginning of the emergency period Ordnance experts had seen the need for automatic machines to road detonators, for example, but the problems involved in designing them were so baffling, and the prospects of profit so dim, that few machine designers could be persuaded to take any interest in the matter. The whole list of World War II technological advances made under pressure of war would fill a volume; only a few may be mentioned here. Reverse nitration of TNT, toluene from petroleum, mechanization of loading, and the development and use of wood pulp, RDX, and rocket powder—these have been selected because of their intrinsic importance and illustrative value.26

Reverse Nitration of TNT

During the 1941-42 period the inadequate supply of TNT for high-explosive bombs and shells was a major problem for Ordnance. Because the shortage had been foreseen, plans were made to use a substitute explosive known as amatol (a mixture of TNT and ammonium nitrate) for shell or bomb loading until new TNT plants came into full production.27 Quantities of ammonium nitrate were imported from Canada and maximum use was made of commercial ammonium nitrate facilities in the United States to stretch available supplies of TNT as far as possible. Admiral Blandy reported that the TNT shortage was so acute he had to dole TNT out to the Navy “with a teaspoon.”28 But the shortage suddenly disappeared when a new process appeared on the scene almost by accident. For many years before the emergency, the method used by TNT makers, and the only method considered safe, had been to add the nitric acid to the toluene. But in 1941 Lt. Col. John P. Harris visited a small Canadian TNT plant at Beloeil, near Montreal. His visit to this plant had not been planned in advance but was added at the end of his itinerary to fill in the time before his train left. To his surprise, he found the plant was “doing things backward” by putting toluene into the acid instead of putting acid into the toluene; thereby making TNT much faster. When Colonel Harris reported what he had seen at the Canadian plant, American TNT makers were skeptical. They were reluctant to change tried and proven methods, but a successful trial run of the new process at the partly built Keystone Plant at Meadville, Pennsylvania, convinced them. Soon the reverse nitration process was adopted for all TNT production in the United States. The result was a trebling of TNT output. Lines designed

to turn out 33,000 pounds a day produced more than 100,000 pounds a day. The need for TNT substitutes vanished and the price dropped from twelve cents a pound to six cents.29

Toluene from Petroleum

Development of a new means of producing toluene,30 the basic raw material from which TNT is made, was another highly significant technological advance of World War II. The importance of this chemical stems from the fact that nearly half of every pound of TNT—trinitrotoluene—must come from toluene. In World War I toluene was derived from coal as a byproduct of coke ovens, and some was extracted from illuminating gas. But the supply was so limited that the Assistant Secretary of War, Benedict Crowell, later called it “the greatest and most pressing of all the problems in regard to the existing raw materials.”31 In contrast, during World War II, high-explosives production was never seriously hampered by lack of toluene. Production of toluene by Ordnance-sponsored facilities reached such a high level in 1943 that large quantities were diverted from ammunition to aviation gasoline.32

The groundwork for this achievement was laid during the 1930s by Picatinny Arsenal, Maj. John P. Harris, and the Standard Oil Company of New Jersey. As early as 1927 Standard had obtained patent rights from a German firm to use a process for producing toluene from petroleum. Tests were made on small samples at Picatinny during the 1930s, and in 1939 Major Harris began negotiations with Standard to prepare for the day when the striking power of the nation’s military forces would depend on abundant supplies of TNT. In June 1940 Ordnance placed a contract with Standard for two tank cars of toluene to be produced in the several refineries owned by the company and its affiliates. The raw material had to travel to three widely separated plants in Texas, Louisiana, and New Jersey before the process was completed and the first tank car of synthetic toluene ever made was delivered to Ordnance. After test at DuPont’s TNT plant in Wisconsin, Ordnance signed a contract with the Humble Oil and Refining Company, Standard’s affiliate in Texas, for the specific purpose of building a toluene plant, the Baytown Ordnance Works, on a site adjacent to its Baytown refinery in Texas. By October 1942 this plant was producing toluene at the rate of 65 million gallons per year—compared with less than 9 million gallons total toluene production in the United States in 1918.33

RDX

The superexplosive known as RDX (Research Department Explosive) or cyclonite, with 30 percent more power than TNT, was not new at the outbreak of World War II.34 It had been known for many years but had never been produced commercially in this country. It was considered too sensitive for use as a bursting charge and no more effective than tetryl as a booster. Ordnance was reluctant to embark upon large-scale production of RDX, a new and untried endeavor, in view of the existing capacity for production of TNT.35 But in May 1941, when the British Purchasing Commission requested the United States to produce 6,500 tons and the U.S. Navy expressed a desire for 20 tons per day, Ordnance constructed a completely new RDX plant, the Wabash Ordnance Works, at a cost of $70 million. Starting production in November 1942, Wabash attained a monthly capacity of over five million pounds of RDX which was converted into various compositions.36

As demands for RDX skyrocketed after Pearl Harbor, Ordnance built another facility, Holston Ordnance Works, to use a more economical process than the British nitration method used at Wabash. This new process, developed by Canadian and American investigators through the National Defense Research Committee (NDRC), enabled Holston by May 1945 to reach a monthly capacity of 27 million pounds and cut the estimated cost in half. Holston was operated by the Tennessee Eastman Corporation, which had taken a leading part in the development work. The support auxiliary facilities that provided raw material for Holston were the Morgantown Ordnance Works that produced ammonia, methanol, formaldehyde, and hex- amine, and the Cherokee Ordnance Works that made formaldehyde and hexamine.37

Wood Pulp and Cotton Linters

Before the war the standard practice for making smokeless powder called for the treatment of bleached cotton linters38 with a mixture of nitric and sulfuric acid.

In the summer of 1941 it became apparent to Ordnance that, even with a good cotton linters crop and capacity operation of bleacheries, the supply of linters for powder would fall short of requirements. Ordnance therefore turned to the use of a special type of wood pulp that was available in quantity, was suitable for most kinds of powder, and was cheaper than cotton linters. The Hercules Powder Company had made smokeless powder from wood pulp for a number of years, and Ordnance had found the product fully acceptable. Use of wood pulp as a supplement to, but not a replacement for, cotton linters was approved promptly except for rifle powder, Navy rocket powder, and certain other uses. New machinery was installed first at Indiana and Radford, and then at other plants. Soon most plants had one or two lines for nitrating cotton, an equal number for nitrating wood pulp, and several “swing lines” adaptable to the use of either material.

From January 1942 to the end of the war, Ordnance plants used roughly equal quantities of cotton linters and wood pulp. There was never a concurrent shortage of both materials, although there were times when the supply of one ran low or was expected to run low. At such times Ordnance drew upon its inventories while it converted the “swing lines” to meet the situation. The use of wood pulp doubled the existing supply of cellulose for powder and eliminated a serious potential bottleneck in ammunition production.

Rocket Powder

When development of military rockets was undertaken in the United States in 1940-41, one of the most troublesome problems was the manufacture of suitable propellants. Double-base smokeless powder39 was a satisfactory rocket propellant but its production in the large, long-burning, thick-web sticks or “grains” needed for rockets was a difficult undertaking. The accepted method of producing smokeless powder in this country in 1940 was by the solvent-extrusion process in which the nitrocellulose and nitroglycerine were mixed with a volatile solvent (alcohol or acetone) to form a doughlike substance that could be pressed into grains of the desired shape. The solvent was then removed by evaporation. As solvent powder was used for the 2.36-inch bazooka rocket and for the 4.5-inch rocket, lines for its production were built at the Radford and Sunflower Works. For the small, thin-web powder this production method proved satisfactory, but when it was employed for large, thick-web grains two difficulties arose—the long time required for the sticks to dry out, and the distortions in the sticks that occurred during the drying period. The obvious answer was to turn from solvent powder to solventless or dry-extruded powder, but American producers lacked both the experience and the heavy equipment needed for producing solvent-less rocket powder. British firms made large thick-web grains of cordite, the standard British smokeless powder, by rolling the powder into a sheet, winding the sheet into a roll, and then placing the roll, still dry, into a press that extruded it at moderate temperature and high pressure.

In 1941 the National Defense Research Committee undertook study of dry-extrusion processes, as did the Hercules Powder Company under contract with Ordnance. By December 1941 the dry-extrusion press set up by NDRC representatives at the California Institute of Technology produced sticks nearly an inch in diameter, and by the early months of 1942 a larger press was extruding sticks up to three inches in diameter. In February 1942, Hercules was authorized to establish a pilot plant with a capacity of twelve hundred pounds per day at the Radford Works. Soon the Soviet Union requested thirty-six thousand long tons of solvent-less rocket powder to augment its own production, and authority was granted Ordnance to build an addition to the Sunflower Ordnance Works in Kansas to fill the Russian request. By the middle of 1943 the U.S. rocket program had reached the point where large new requirements -for solventless powder were placed on Ordnance, and thereafter the requirements steadily increased. In January 1945 the over-all requirements reached a peak of more than eighteen million pounds per month, and plans were made to expand facilities at the Sunflower, Badger, and Indiana Works. Without the dry-extrusion process developed for making solventless rocket powder the extensive employment of rockets by U.S. military forces in 1944-45 would not have been possible.40

Mechanization of Loading Operations

In the tedious process of loading and assembling complete rounds of ammunition, industry and Ordnance made countless improvements. The simple hand fixtures and machines in use at Picatinny Arsenal in 1939 gave way to high-speed mechanisms that operated as nearly automatically as possible. One striking example was the detonator-loading machine developed under contract with Picatinny by R. A. Jones and Company, an Ohio manufacturer of automatic machines. As several detonators, each containing a sensitive explosive, were needed in a single fuse, and fuses were needed by the millions, the demand for speedy production was great. After many failures, R. A. Jones and Company finally developed a detonator-loading machine with which 6 operators could load 8,000 detonators in one 8-hour shift, as compared with 7,500 formerly loaded in the same time by from seventeen to twenty operators.41

Ordnance introduced a new method of loading TNT that was considered to be one of the greatest developments in the shell-loading industry, resulting in great savings in time, money, and manpower. In the older process, molten I N F was poured into the shell where it cooled and solidified. Because the TNT contracted as it cooled, and left a hollow in the center, the pouring was done in layers, the hollow in each layer being opened up by hand to permit molten TNT to flow into it when the next layer was poured. Each shell was thus practically tailor-made as each was loaded individually and by hand. In the new

Workmen pouring molten TNT into 155-mm. shells at Charleston Ordnance Depot, October 1941

method the shells were loaded in groups by a multiple volumetric loading machine and were then transferred to another machine, a multiple core melter, which forced a heated probe into the center of each shell to melt out all porosity and crystals. As these probes were withdrawn, molten TNT was quickly poured into the cavity. The Chief of Ordnance reported late in 1944 that this new procedure would save nearly five million man-hours during the year ahead.42

In making ammunition, minute quantities of sensitive explosives, such as tetryl, must be placed in small cups or cavities in primers, detonators, boosters, and other components. To permit their speedy handling, the explosives are pressed into pellets by using the same type of machinery employed in making pills or candy. In cooperation with Picatinny Arsenal, the F. J. Stokes Machine Company of Pennsylvania developed rotary presses that poured out pellets in any size or shape in a continuous stream. After the pellets were made they had to be placed in small booster cups by hand. Not only was it slow and tedious work, but handling the pellets presented a health hazard. This phase of the problem was finally solved when the Stokes Company produced a rotary pelleting press that automatically inserted pellets into booster cups at a speed of 75 units per minute. When machines of this type were put to use throughout the ammunition industry the dividends in terms of increased output, reduced costs, saving in floor space, and

reduction of personnel requirements were tremendous.43

At the bag loading plants, where powder for large-caliber separate loading ammunition was put into cloth bags, there were equally important improvements in machines and equipment. Instead of wrapping the powder charges by hand, as was the standard practice, machines that were almost entirely automatic were introduced, with resultant saving of manpower and increase of production by over 50 percent. Changes in design of propelling charges were introduced to permit application of mass production principles in cutting the cloth and assembling the powder bags.44

There was no end to the improvements that could be made in the loading of ammunition, nor was there any lack of engineering skill and imagination among the World War II producers. The ceiling on technological advances was set by the demand for production, the funds available, and requirements of other programs for machines and materials. The end of the war in 1945 momentarily stopped the intense drive for increased mechanization of bomb and shell loading, but the process continued on into the postwar years.45

Speeding production and conserving manpower were highly important considerations throughout World War II, but they were not the only considerations in the minds of Ordnance ammunition officers. In commenting on the trend toward more and more mechanization of operations at the loading plants, Brig. Gen. Merle H. Davis, postwar chief of the Ammunition Division, observed that the most important result was not increased output nor reduction in the number of employees, great as those considerations were. “The most important dividend,” he wrote, “is a better and more uniform product, with a reduction in the errors that can be made by human beings.”46

With reduction of errors and elimination of imperfections its constant goals, the Ammunition Division set up elaborate inspection procedures for metal components, powder, and explosives, and stood firm against manufacturers’ requests for waivers of inspection standards. Inspection of ammunition was rigid but was not intended to be arbitrary. Throughout the production phase, efforts were made to keep quality high even if it meant holding up production. The Ordnance philosophy was well expressed by General Hardy when he advised the district chiefs that, “We don’t save anybody any expense and we cause plenty of trouble when we let anything of an inferior nature get into the hands of troops.”47

Balancing Production, 1941-43

In theory, the procurement of all chemicals and metal components should have

been kept in balance so that the number or quantity of each exactly matched the needs of the loading plants. But such theoretical exactness was impossible to attain in practice. As some components were easier for industry to produce than were others, production of the easy-to-manufacture items surged ahead and got out of line. Shells, bomb bodies, and cartridge cases, for example, came into quantity production during 1941 well ahead of powder, explosives, and fuses. After Pearl Harbor the unbalance grew worse because of the public statements by high-ranking government officials urging every war plant to speed production to the maximum. To arrest the trend toward unbalance, the Industrial Service issued in December 1941 a directive to the districts and other field installations to expedite only those items appearing on a “Short List” to be issued weekly.48

The “Short List” helped, but it did not work miracles. It was not possible to achieve exact mathematical balance of all components by curtailing or stopping completely the production of fast items, for that would have resulted in complete loss of facilities through their conversion to other work, loss of labor force, or, in the case of smaller plants, bankruptcy. There were also many other factors that entered the picture—changing requirements, slow deliveries on machine tools, lack of raw materials, technical difficulties in production of certain components, and occasional plant shutdowns due to strikes, fires, or explosions. Use of the “Short List” brought criticism on Ordnance because some of its contractors were working only half their maximum capacity at a time when the whole nation was being mobilized for war. These were contractors producing fast items and they had to be held back until plants making slow items caught up with them. Ordnance reported that about io percent of its contractors were responsible for items on the “Short List” and that half of these were still tooling-up and were not yet in production. Other plants had unbalanced production lines because the tools needed for some items had not been delivered; others reported interruptions in their raw materials supply as the source of their troubles.49

During the 1941-42 period the Ammunition Division was not at all satisfied with the means at its disposal for balancing production. One of the chief difficulties lay in the lack of flexibility in dealing with industry. The Division could institute procurement only on programs for which funds were available, and these programs often bore no relation to the needs of industry or to production potential. With ammunition, as with other types of matériel, Ordnance could not forecast its requirements long in advance and take the steps necessary to prepare industry for production, to eliminate bottlenecks, or smooth out uneven spots in the schedule. Contractors already engaged in production were sometimes faced with interruption in production, and potential contractors requiring some preparation or additional equipment were often unable to proceed until an order was available under a specific program. Savings on one fund

could be applied to another fund only by going through the cumbersome process of getting approval from higher authority. The result was a long lag in getting new production started. Deliveries against new requirements were always behind schedule. In 1941 the chief of the Ammunition Division summarized the situation as follows:

A proper description of our present situation is that we are trying to run an arsenal the size of the United States without the flexibility of existing government arsenal procedure. We are trying to operate a mass production job involving numerous production changes without any anticipatory action regarding procurement until the funds are available and the requirements are announced in the form of an official program specifying delivery schedules. To put it another way, we are in the position of an automobile company which takes no action as regards the procurement and production of new equipment, raw materials, and parts in planning the corning year’s production, when the standard practice in that industry is to start such activity 18 to 24 months before the model is announced.50

With adoption of the Army Supply Program early in 1942 an effort was made by ASF to provide long-range procurement forecasts for all types of ordnance. The emphasis shifted from monthly capacity objectives to yearly quantity objectives. At the same time, fiscal regulations were relaxed so that the necessity for earmarking each increase for a specific production order was no longer necessary. In the summer of 1942 the Ammunition Division under General Hardy set machinery in motion to improve procedures for keeping ammunition production in balance. The former practice of forecasting production by adding together all theoretical maximum monthly capacities, and multiplying the total by the number of months in the period, was abandoned. Production forecasts for each component were made in terms of realistic capacity figures, not theoretical maximums, and in terms of orders actually placed. Production of complete rounds was then scheduled in terms of planned delivery of components to the loading plants, with the components in shortest supply setting the pace for all the others.

The new procedure centered around use of “preliminary work plan sheets” issued each month by the Ammunition Division. These planning sheets showed the status of all metal components in terms of realistic production forecasts and were used to determine feasible loading schedules. They placed on one sheet of paper all procurement data concerning a single component by district, by manufacturer, and by quantities expected in the months ahead. Although used at first only for analyzing and planning procurement the sheets were soon given the status of legal documents authorizing the districts to procure.51 The value of the PWP sheets is attested to by the fact that they were not only used during the rest of the war but were continued into the postwar years. At the same time that the new scheduling procedures were being put into effect in the latter half of 1942, Industry Integration Committees

were formed to help balance production by raising the output of plants working on problem items.

Along with the PWP sheets for components the Ammunition Division drew up forecast sheets for end items showing the quantity of complete rounds of ammunition expected to be available each month for distribution to troops. They were based on known production capacity and were kept within the requirements set by the Army Supply Program. They constituted the basic control documents for the FDAP in regulating activities at the loading plants and were used by the military high command to plan the allocation of ammunition to the Ground Forces, Air Forces, Navy, Marines, and lend-lease recipients. Even before the new system was put in operation the emphasis switched from maximum production at any cost to curtailment and leveling off of production in terms of combat experience and existing stock levels. Downward revision of the Army Supply Program was so substantial in the latter half of 1942 that the Chief of Ordnance appointed a special board of officers to review all matters relating to the readjustment of production schedules.52

A drastic reduction of bomb requirements was made early in 1943 with consequent reduction in the demand for TNT, ammonium nitrate, metal components, and loading capacity. Some plants that were still under construction were dropped from the program, and in many other plants individual lines not needed to meet the new requirements were eliminated.53 Several factors other than requirements were taken into account in deciding which plants were to close and which were to stay open. Cost of production, flexibility, labor supply, location with respect to other plants, and the variety of items produced—all these were considered.54 Cutbacks in certain items made it impossible to keep metal components in balance. Ordnance reported in September 1942 that its powder and explosives production was in balance with the loading schedule but that for some metal components there was no stock on hand and with others there was a 2-year supply in stock. The former were new items that were in great demand but were not yet in full production. The latter were supplies made surplus by sudden and drastic cuts in requirements.55

The cutback policy was reinforced in the fall of 1943 when the War Department Procurement Review Board, headed by Maj. Gen. Frank R. McCoy, urged curtailment of production on the ground that excessive stocks of many kinds had been built up both in the ZI and in overseas theaters.56 Ordnance contended that ammunition stocks were not excessive, and

declared that expenditure rates for the North African campaign, a war of movement allowing for little artillery fire, should not be accepted as a guide to expenditure rates during an invasion of western Europe.

In spite of Ordnance objections, the ASF policy announced in January 1944 was directed toward continued retrenchment and avoidance of overproduction in the year ahead. All down the line the technical services were told to procure during the calendar year 5944 only the matériel specifically required by the Army Supply Program. Production of any items in excess of requirements for the purpose of retaining labor or facilities was expressly forbidden.57 In conformity with this policy, work at some Ordnance facilities was stopped altogether in January 5944. In other cases, facilities not currently needed for Ordnance production were diverted to other programs, notably fertilizers, synthetic rubber, and aviation gasoline.

The Crisis of 1944–45

The year 1944 was a year of trial and tribulation for the Ammunition Division. At the start the emphasis was on slowing down the mounting tide of production as the defeat of Germany appeared more and more imminent, but at the end there was an almost frantic drive for more production at any cost. As late as the last week in March 1944 Ordnance, in line with recent ASF directives, was reviewing the need for existing plants and recommending that three bomb- and shell-loading plants—Illinois, Pantex, and Gulf—be closed within the next sixty to ninety days and put in stand-by condition. Illinois had always been a high-cost plant while Pantex and Gulf were both small plants with only three or four lines. But by the time the Ordnance recommendation reached ASF it encountered a reversal of the cutback policy and was not approved.58

Early in 1944 Ordnance officers were convinced that the Army’s neglect of heavy artillery and its ammunition was a mistake, but they felt they had nearly exhausted their powers of persuasion in presenting the argument to higher authorities. At the end of February, and again in mid-March, Ordnance called to the attention of ASF the low stocks of 240-mm. ammunition and the high expenditure rates reported from overseas theaters. “This type ammunition is so large,” wrote General Hardy, “that facilities for its manufacture are very limited in extent, and the time required to reach production amounts to about eight months.” He warned that, if authority were not granted him to expand facilities immediately, it would be impossible to meet increased requirements during 1944 or early 1945.59 This appeal broke the log jam. Ordnance was authorized on 27 March to expedite production with a view to attaining as soon as possible a monthly production rate of forty thousand rounds of 240-mm.

ammunition. Similar increases in ammunition for the 8-inch gun and howitzer, the 155-mm. gun and howitzer, and the 4.5-inch gun were authorized on 2 April. By far the largest quantity in this directive was for the 155-mm. howitzer—1,303,000 rounds per month.60

The next step was taken in mid-May when G-4 and ASF, concluding that the cutback policy had been a mistake, ordered a major increase in production of medium artillery and ammunition, and added to the heavy artillery program. The campaign in Italy, where artillery ammunition and bombs were used in huge quantities against strongly fortified mountain positions, had forced a change in Army plans. The new directives required Ordnance to double its monthly rate of heavy artillery ammunition production in seven months and triple it in thirteen months. In June and July substantial increases in bomb requirements were added. Here, at last, was the procurement authority Ordnance had repeatedly requested earlier, but it came so late in the war that it had to be handled on a “blitz” basis.61

Creation of additional production capacity for heavy artillery ammunition was a big job comparable to the expansion undertaken by Ordnance after Pearl Harbor. Some of the government-owned plants, such as Gopher, Keystone, and Weldon Springs, that had been shut down a few weeks or months before, had to be speedily reopened and re-equipped, and new contracts for metal components had to be placed with industry under very unfavorable conditions. Enormous forging presses had to be built and countless gages, jigs, fixtures, and machine tools assembled; production of explosives and smokeless powder had to be increased; new lines had to be set up at the loading plants; and increased capacity had to be’ found for forging and machining shells, machining cartridge cases, and producing fuses. General Campbell reported that the facilities for production of shells for the 240-mm. howitzer and the 8-inch gun and 8-inch howitzer called for one thousand heavy-duty lathes, nineteen 1,000-ton piercing presses, seventeen Soo-ton draw presses, twelve 600-ton billet-breaking presses, and twenty-seven 500-ton nosing presses. All this equipment required motors, hydraulic pumps, and other accessories. The expansion program for heavy artillery ammunition as of April and May 1944 required the building of new facilities costing $203 million, divided in roughly equal parts between production of metal components and the manufacture and loading of explosives and propellants. A heartbreaking feature of the situation for Ordnance was that production capacity for part of this load had been laboriously built up in

1941-1942, only to be lost during the 1943 cutback era.62

Every facility of the Ordnance Department was placed at the disposal of the heavy ammunition contractors to expedite delivery of equipment and help with technical problems of manufacture. Industry integration committees’ disseminated information among contractors and provided a common pool of knowledge and experience. Col. Simpson R. Stribling was sent on a mission to England, France, and Italy to survey production facilities in those countries and to arrange for shipment of available machine tools to the United States. In August 1944 Ordnance reported to the Secretary of War that manpower was “the greatest single problem facing the expanding heavy artillery ammunition program.”63 Labor recruiting caravans toured the country to help overcome the shortage, and women were employed for many positions formerly held by men.64 When requirements were further increased at the end of the year provision was made for furloughing enlisted men having skills as machinists, toolmakers, or machine operators to work in ammunition plants. The furlough program reached its peak in March 1945 when 3,066 enlisted men were at work in plants and several thousand requisitions for additional men were on file with ASF.65

On 1 December 1944 Ordnance was directed to step up its production of light and medium artillery ammunition. The monthly rate of production for ammunition for the 155-mm. gun was to be increased by 50 percent, from four hundred thousand per month to six hundred thousand; similar increases for the 57-mm. and 90-mm. guns, 1 05-mm. howitzer, and the 60-mm. and 81-mm. mortars were included,66 Knowing in advance that these increases were coming, the Ammunition Division worked night and day to prepare its plans. General Campbell then called a conference attended by Robert P. Patterson, Bernard Baruch, General Clay of ASF, and representatives of the War Production Board, War Manpower Commission, and other government agencies, at which the chief of the Ammunition Division outlined a program of expansion that called for expenditure of about $300 million for producing mortar and medium artillery ammunition, in addition to the $329 million earlier allotted for heavy ammunition expansion. He provided the conferees with a complete set of planning sheets showing all the facilities selected for increased capacity and detailed information about each plant’s management, previous work on ammunition, available machine tools,

floor space, and requirements for manpower, fuel, and electricity. In the course of one day it was possible for Ordnance to obtain coordinated approval for the greater part of its planned expansion, and by the end of the month contracts for the entire program had been placed.67 In January 1945 came new directives for increased production of ammunition for the 75-mm. howitzer, the 75-mm. field gun, and the 37-mm. antitank gun, followed by a demand for 355,300 rounds of armor-piercing ammunition with tungsten carbide cores for guns ranging from the 75-mm. to the 155-mm. When these comparatively small January 1945 additions were made, the total program called for the expenditure of $682 million on facilities alone, divided on roughly even proportions between metal components, on the one hand and powder, explosives and loading, on the other.68

Production of 105-mm. high explosive (HE) howitzer ammunition in December 1944 reached a record high of 3,600,000 rounds and put this item at the top of the Ordnance list in terms of dollar value of procurement, just ahead of the medium tank. By the end of January 1945 Ordnance reported that it had procured a little over fifty million rounds of this type since 1940. Deliveries on some other rounds, mostly the heavy types, did not come up to expectations in December 1944. One of the chief causes of failure to meet production forecasts was the high rate of absenteeism at loading plants because of unusually heavy snowstorms during the month. Labor and machine-tool shortages retarded production of smoke shells for the 155-mm. gun early in 1945, but by April rates of production for nearly all types were so high that cutbacks were being talked about.69

During the first four months of 1945 expenditures for heavy artillery ammunition reached record level—more than four times those of the first four months of 1944—and then declined sharply after Germany’s surrender in May. (Table 11) At the end of June the chief of the Ammunition Division reported that his office had supervised the procurement of more than $5 billion worth of ammunition weighing over seven million tons during the fiscal year 1945. Procurement was roughly 50 percent greater, in both dollar value and weight, than in fiscal year 1944. Over two hundred new items, representing more than one-third of the average number of ammunition items under procurement, were brought into production. The new items included various calibers of recoilless ammunition, and the “Tall Boy” and “Grand Slam” bombs for the British. A new rocket propellant went into production at Longhorn, a new RDX composition at Wabash, and a new explosive, tritonal, was used to load British bombs. TNT production increased so much that a shortage of nitric acid developed, necessitating expansion of acid-making capacity.70

These events naturally raise the question, “Were the frantic efforts to boost production necessary?” The answer seems to be “yes” if we base our analysis on the situation as it existed in the winter of 1944-45.

Table 11: Expenditures for Heavy Field Artillery Ammunition, January 1944–August 1945

| Period | Amount |

| 1944 | |

| January | $10,312,000 |

| February | 12,327,000 |

| March | 17,888,000 |

| April | 24,708,000 |

| May | 26,643,000 |

| June | 32,999,000 |

| July | 32,938,000 |

| August | 36,515,000 |

| September | 40,534,000 |

| October | 43,006,000 |

| November | 53,120,000 |

| December | 53,931,000 |

| 1945 | |

| January | 65,289,000 |

| February | 67,939,000 |

| March | 77,038,000 |

| April | 82,573,000 |

| May | 78,073,000 |

| June | 53,065,000 |

| July | 37,189,000 |

| August | 16,535,000 |

Source: Stat Review World War II, app. A, p. 75, by ASF Contl Div, OHF.

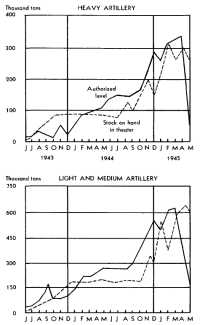

Chart 1 shows that stocks of artillery ammunition on hand in the European Theater of Operations ran well below the authorized level from the summer of 1944 to early 1945. An urgent cable from the ETO to the War Department on 23 September 1944 declared bluntly, “There is a serious shortage of heavy artillery ammunition for current operations.”71 As Table 12 reveals, ammunition was shipped in increasingly large quantities during these months, but did not catch up with the rise in authorized levels resulting from deployment of additional weapons. Vigorous efforts were made to speed the flow of ammunition from England and from the European beaches and ports to the front lines. Ammunition was rationed, and the armies were unable to fire at the desired rate. The fact that the campaign was a success does not prove that the ammunition supply was adequate, for the fighting

Chart 1: ETO Authorized Levels and Theater Stocks—Ground Ammunition

Source: Ammunition Supply for European and Mediterranean Theaters Control Division, Hdqrs, ASF, War Department—15 August 1945—p. 3.

Table 12: Shipments of Selected Types of Artillery Ammunition to the European Theater, December 1944–March 1945

[In rounds]

| Quantity | ||||

| Type | December | January | February | March |

| Total | 1,239,356 | 2,268,486 | 3,087,372 | 4,227,884 |

| 155-mm. howitzer | 937,881 | 1,531,414 | 2,052,000 | 2,672,571 |

| 155-mm. gun | 220,217 | 438,826 | 555,043 | 786,073 |

| 8-inch gun | 8,432 | 27,522 | 42,185 | 54,180 |

| 8-inch howitzer | 58,131 | 238,196 | 382,181 | 629,752 |

| 240-mm. howitzer | 9,695 | 32,528 | 55,963 | 85,308 |

Source: Ammo Supply for European and Mediterranean Theaters, ASF Conti Div, 15 Aug 45, p. 13.,

might have ended sooner and with fewer casualties had more ammunition been fired. The conclusion seems to be inescapable that strenuous efforts to increase production and to speed distribution were called for in the critical months following 6 June 1944. The statistics showing that output more than doubled between June 1944 and June 1945 suggest that the production part of the program achieved a fair degree of success.

After Germany surrendered there were, of course, large quantities of all types of ammunition on hand, surplus to the needs of a campaign that was ended. How great was the surplus? It was large in all calibers and in some calibers it was unreasonably large. Table 13 shows that the 3.8 million rounds on hand at the end of May 1945 constituted a 3-month supply for the 155-mm. gun, based on the experience of the preceding three months (February, March, April). For the 155-mm. howitzer the supply was nearly four months, and for the other calibers it was roughly six months.

In June and July 1945 procurement was scaled down to the level of the one- front war against Japan, and requirements were far less than during the early months of the year. Then in mid-August the surrender of Japan put a stop to further production. On 14 August the FDAP sent telegrams to all its ammunition plants to halt production on all except a few types of matériel, and the district offices took similar action with respect to their contractors. These events suddenly ushered in a new era for which Ordnance had been making plans for many months, an era of demobilization and postwar planning.

In Conclusion: Quality and Quantity

Ammunition has been called the unsung hero of wars. When a gun fires straight and true the user is likely to remark that it is a fine weapon. When the gun fails to function properly the comment is likely to be, “There’s something wrong with the ammunition.” Realizing that ammunition which failed to function properly might have disastrous consequences, Ordnance went to extreme lengths to maintain quality at the highest possible level. Every

Table 13: Heavy Artillery Ammunition Stocks on Hand in ETO, 31 May 1945

[In rounds]

| Type | Quantity |

| Total | 3,834,492 |

| 240-mm. Howitzer | 65,428 |

| 8-inch Gun | 46,832 |

| 8-inch Howitzer | 435,509 |

| 155-mm. Gun | 574,284 |

| 155-mm. Howitzer | 2,712,439 |

Source: Prepared from data found in Ammo Supply for European and Mediterranean Theaters, ASF Conti. Div, 15 Aug 45, OHF.

newly designed shell, fuse, or cartridge case was subjected to the most severe tests before it was standardized for issue to troops. In the manufacturing process an unbelievable number of inspections were made to screen out defective elements. And in the overseas theaters Ordnance officers followed up on every reported instance of malfunction to determine its cause and root out the source of the trouble. General Merle H. Davis, who had wide experience in ammunition procurement and as a theater Ordnance officer, estimated that during World War II the Chief of Ordnance received information on 95 percent of the serious malfunctions that occurred in combat.72 Early in the war, reports of premature explosions of shells came in from time to time, but by mid-1944 the rate of such malfunctions dropped to something less than one in 100,000 rounds fired. For certain rounds it was less than one per million.73 “Based on performance,” wrote Maj. Gen. Henry B. Sayler, chief Ordnance officer in ETOUSA, “American artillery ammunition was far superior [to German]. Whether because of sabotage or poor workmanship, the percentage of German duds was exceedingly high as compared with that of American performance.”74

If combat troops seldom had cause to complain of the quality of their ammunition, they sometimes cursed its inadequate supply. This is not the time or place to analyze the intricacies of overseas ammunition supply, but the observation may be made here that lack of ammunition has been a perennial complaint of combat troops since the invention of gunpowder. In American history, from the defeat of the colonial forces on Bunker Hill to the war in Korea, field forces have occasionally run short of ammunition, sometimes at critical moments in the tide of battle. Ammunition is one of the most unpredictable items in the military supply catalog. Food, clothing, guns, tanks—the need for all these can be predicted with fair accuracy, but the supply of ammunition depends upon such incalculables as the success of an attack or the stubbornness of enemy resistance. It is not enough to have at overseas bases a large supply of ammunition in general. What the fighting forces need and demand are the particular types

Table 14: Major Types of Ammunition Procured, 1 July 1940–31 August 1945

[In rounds]

| Type | Rounds |

| Total for types listed | 1,087,083,000 |

| Total rounds for guns, howitzers, and mortars a | 942,037,000 |

| 20-mm. gun (aircraft) | 411,302,000 |

| 37-mm. gun (aircraft) | 11,451,000 |

| 37-mm. gun (antiaircraft) | 12,152,000 |

| 37-mm. gun (tank, antitank, and canister)_ | 78,093,000 |

| 40-mm. gun (antiaircraft) | 60,747,000 |

| 57-mm. gun | 12,321,000 |

| 57-mm. recoilless rifle | 203,000 |

| 75-mm. gun (aircraft) | 656,000 |

| 75-mm. gun (tank and antitank) | 48,405,000 |

| 75-mm. howitzer | 26,872,000 |

| 75-mm. recoilless rifle | 398,000 |

| 76-mm. gun | 13,083,000 |

| 3-inch gun (tank and antitank) | 13,795,000 |

| 3-inch gun (antiaircraft) | 2,266,000 |

| 90-mm. gun (antiaircraft) | 8,719,000 |

| 90-mm. gun (tank and antitank) | 7,981,000 |

| 105-mm. howitzer | 93,434,000 |

| 4.5-inch gun | 1,969,000 |

| 155-mm. gun | 7,168,000 |

| 155-mm. howitzer | 20,800,000 |

| 8-inch gun | 187,000 |

| 8-inch howitzer | 2,531,000 |

| 240-mm. howitzer | 409,000 |

| 60-mm. mortar | 51,756,000 |

| 81-mm. mortar | 37,043,000 |

| Rockets, 2.36-inch (bazooka) | 15,603,000 |

| Rockets, 4.5-inch | 2,537,000 |

| Rockets, 7.2-inch | 156,000 |

| Total bombs, mines, and grenades | 145,001,000 |

| Bombs b | 33,279,000 |

| Mines | 24,402,000 |

| Grenades | 87,320,000 |

a Not including a few minor types such as the 7.2-inch, 6-inch, 5.5-inch, and 120-mm.

b Excludes chemical bombs procured empty by Ordnance Department to be filled by Chemical Warfare arsenals. The total exceeds 100,000,000 if the individual bombs in bomb clusters are counted separately. See Bomb—Research, Development, Production, and Performance by Maj. Berkeley R. Lewis, pp. 58-59.

Source: Whiting, Statistics, Procurement sec., 9 Apr 52, Table PR-8.

and sizes of shell to fit the weapons being used to achieve the specific objective of the moment. With literally hundreds of different sizes and types of shell in common use, this problem was enormously difficult from both the procurement and the

distribution angles. But at the end of the war the Ammunition Division was prepared to stand on its record of procurement and to maintain that, except for heavy artillery, lack of production was not the cause of shortages in overseas supply.75 (Table 14) The Mead Committee of the U.S. Senate supported this stand in a report issued in July 1945.76 Perhaps the most thorough analysis of the problem was made by the General Board, U.S. Forces, European Theater. It concluded that no one factor caused the shortage but that three elements entered the picture at different times: (a) insufficient discharge over the beaches or through the ports, June through October 1944; (b) inability to move ammunition from ports and beaches to the armies, August through October 1944; and (c) inability of the Zone of Interior to meet requirements, November 1944 through March 1945.77